Valve flow distribution ultrahigh-pressure axial plunger pump

An axial piston pump and ultra-high pressure technology, which is applied to the components of the pumping device for elastic fluids, pump components, variable displacement pump components, etc. and other problems, to achieve the effect of expanding the selection range, reducing the manufacturing cost and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

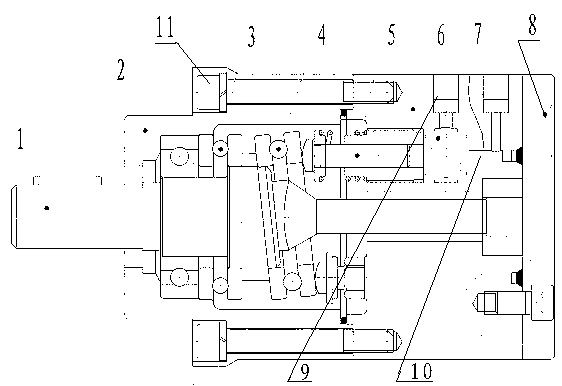

[0013] Refer to figure 1 , Make an integrated drive shaft 1, connect the pump body 2 in which the left rotation bearing 3 and the right rotation bearing 4 are installed in order from one end thereof, and are designed with a communicating oil passage 10 and an oil discharge port communicating with the communicating oil passage 10 The pump body 6 of 9 is designed with a communicating oil passage 10 and an oil discharge port 9 communicating with the communicating oil passage 10, and the plunger cylinder assembly 5 and the integrated oil suction and discharge valve 7 are connected and installed in the pump body 6 from the direction of the pump body 2. The pump body 6 and the pump body 2 are connected together by connecting bolts 11, and finally an outer cover 8 is connected to the outer end of the pump body 6 to form a structure. When in use, the present invention is transported to the site of use, connected to the power, and can be operated reliably after starting.

[0014] The ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com