Device for imparting ultrasonic vibration to resin material, method of melt-molding resin material using the device, and resin composition

A technology of resin composition and resin material, applied in the field of ultrasonic vibration application device, can solve the problems such as difficulty in showing the improvement effect of mechanical properties, limited effect, etc., and achieve excellent mechanical properties, easy resin modification, and improved impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

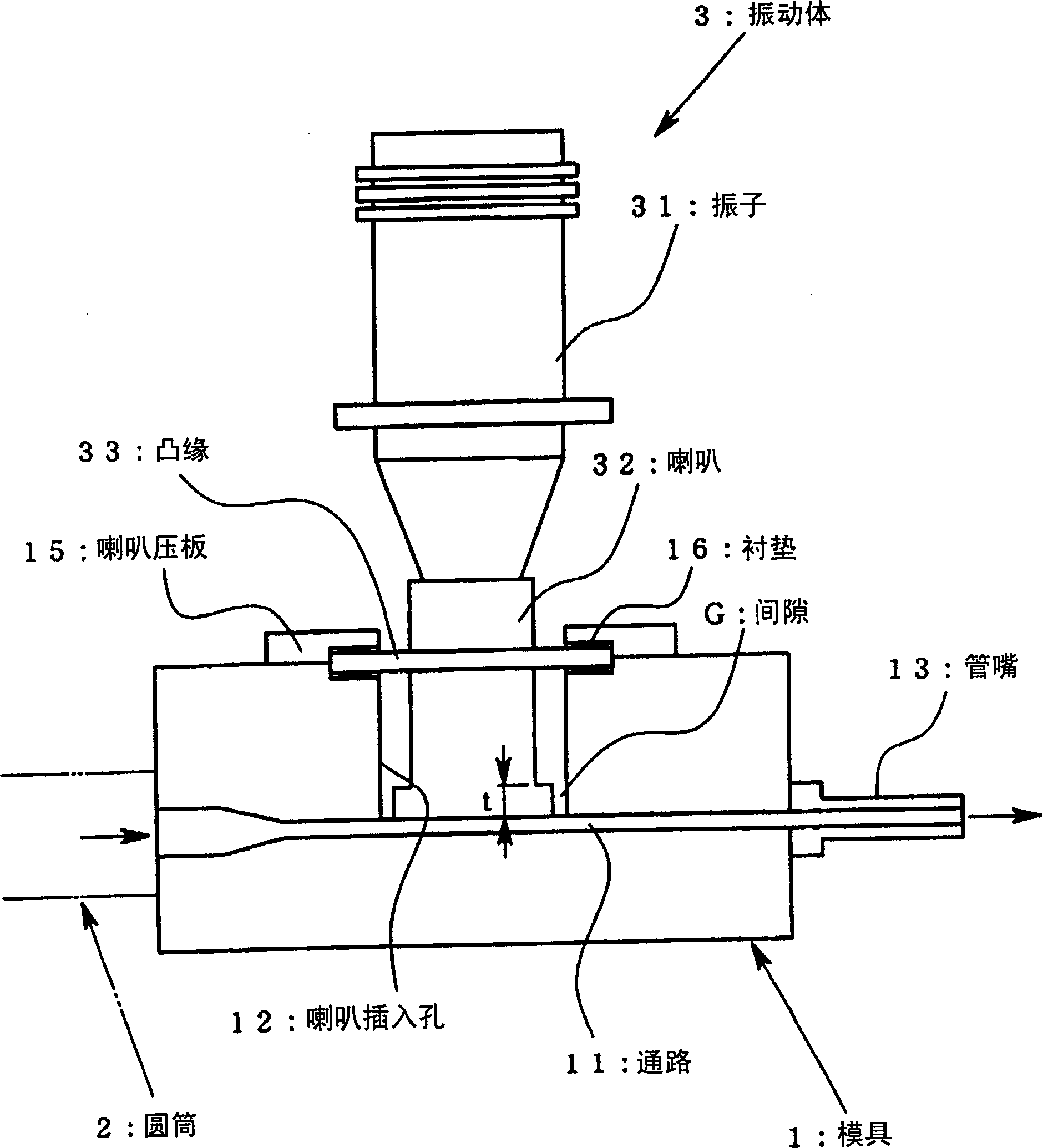

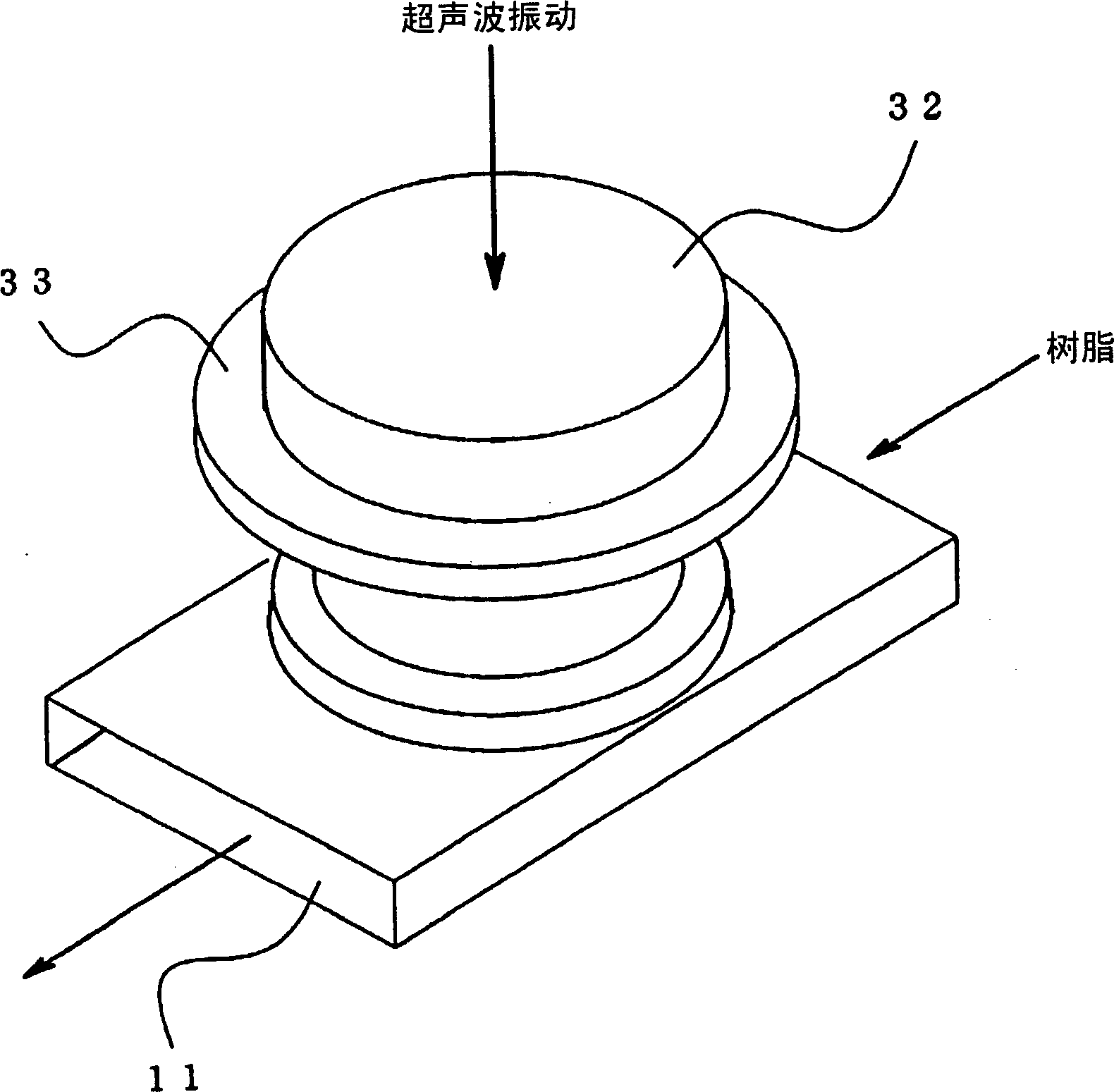

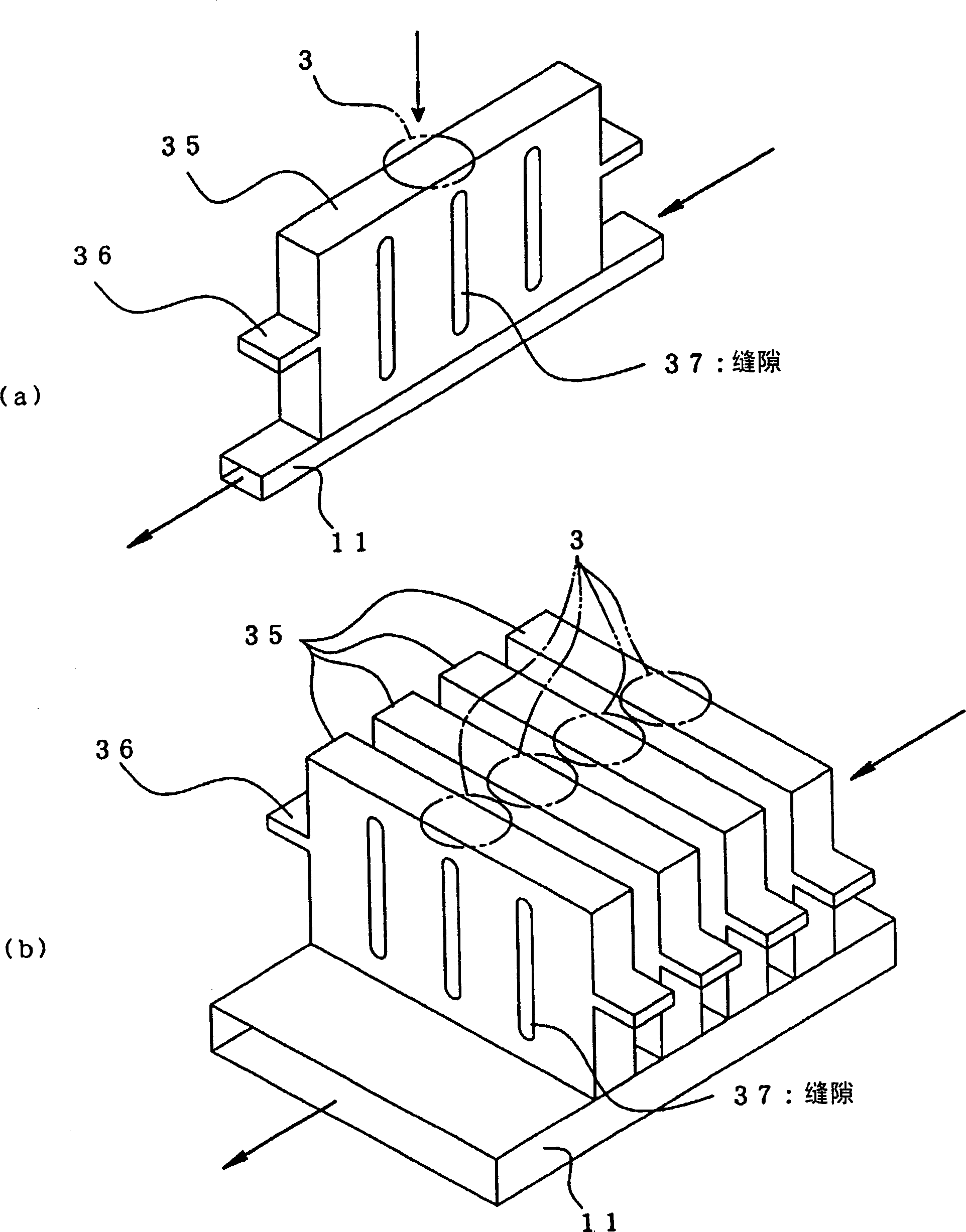

[0057] figure 1 It is a cross-sectional view of a die of an extruder equipped with a horn of an ultrasonic oscillator in the first embodiment of the present invention. In addition, in the "resin material" in the following description, unless otherwise specified, the resin material in a narrow sense naturally means a resin material containing a thermoplastic synthetic rubber (elastomer).

[0058] The resin material heated and melted by the cylinder 2 is supplied to the nozzle 13 through the passage 11 in the die 1 and extruded from the tip of the nozzle 13 . In the middle part of the mold 1, a vibrating body 3 is mounted. The vibrating body 3 is composed of a vibrator 31 connected to an ultrasonic supply source (not shown), and a horn 32 as a vibration transmission member attached to the tip of the vibrator 31 . In the middle part of the mold 1, a horn insertion hole 12 that reaches the passage 11 is formed. The horn 32 is inserted through the horn insertion hole 12 , and it...

no. 1 example

[0108] Resin material PP (polypropylene) / hard rubber

[0109] (1) Extruder: A TEX30H two-shaft extruder made by Nippon Steel Works was used, the cylinder temperature was 180°C, the die temperature was 180°C, the output was 2kg / h, and the number of screw revolutions was 100RPM.

[0110] Screw Size A: Standard Size

[0111] Screw size B: Strong stirring size

[0112] (2) Ultrasonic wave: A die with a horn for applying vibration was attached to the outlet of the biaxial extruder in the vertical direction with respect to the resin composition.

[0113] Frequency: 19.5kHz

[0114] Amplitude: 7μm

[0115] Speaker material: hard aluminum Eh=7×10^10Pa

[0116] (3) Material composition: In order to prevent the composition from being unbalanced, the master batch with the composition of PP / EPDM=JSR (mixing ratio 25:75) is diluted with PP, or diluted with PP and anhydrous maleic acid, and the following A The materials that are dry mixed by the combination of B and B are put into the ...

Embodiment 1

[0134] - Example 1: The vibration of the mold was suppressed by the spacer and the gap (the same applies to Examples 2 to 4). The impact strength is increased to a level that cannot be achieved in intensive stirring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com