Borate salt solution for cold-rolling plate bonderizing prediction

A borate and cold-rolled plate technology, applied in the field of borate solution, can solve the problems of lack of extensiveness, time-consuming, high cost, etc., to avoid major coating quality problems, reduce sample preparation costs, and simplify peripheral conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

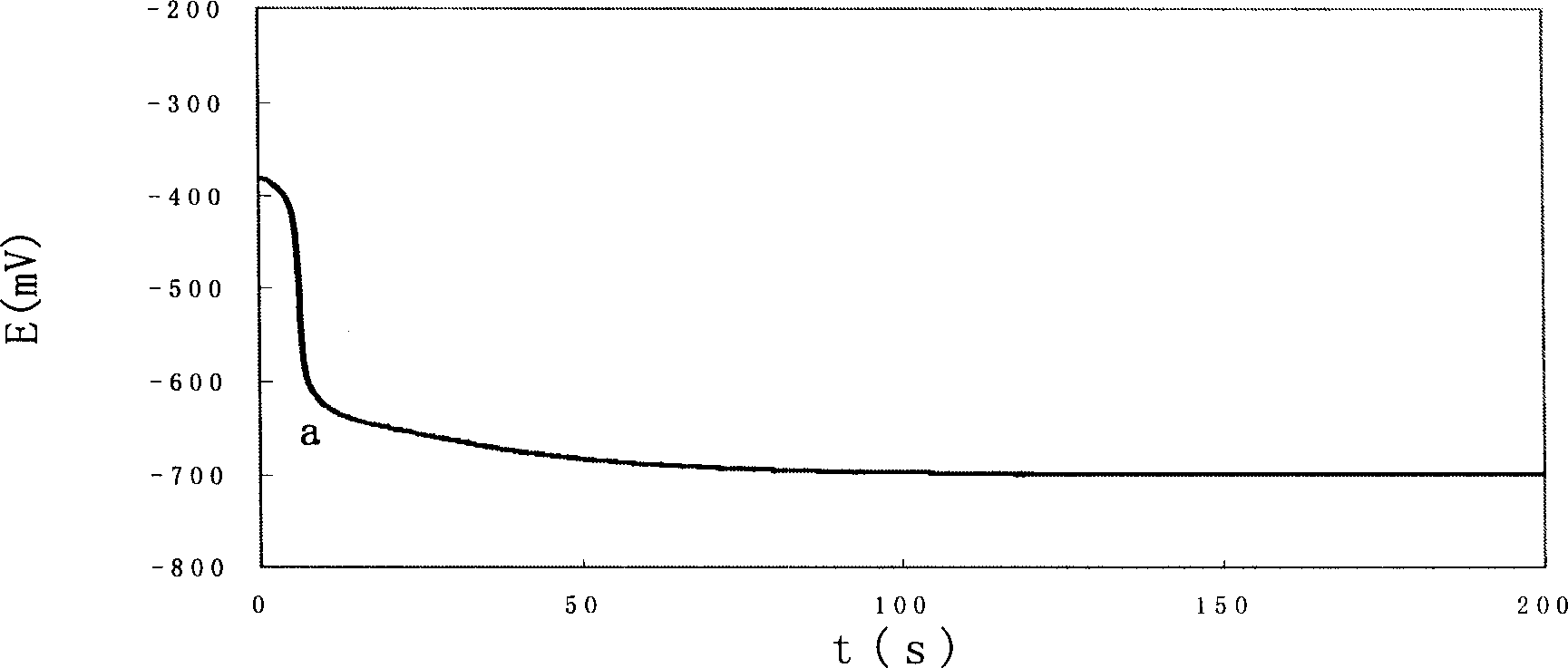

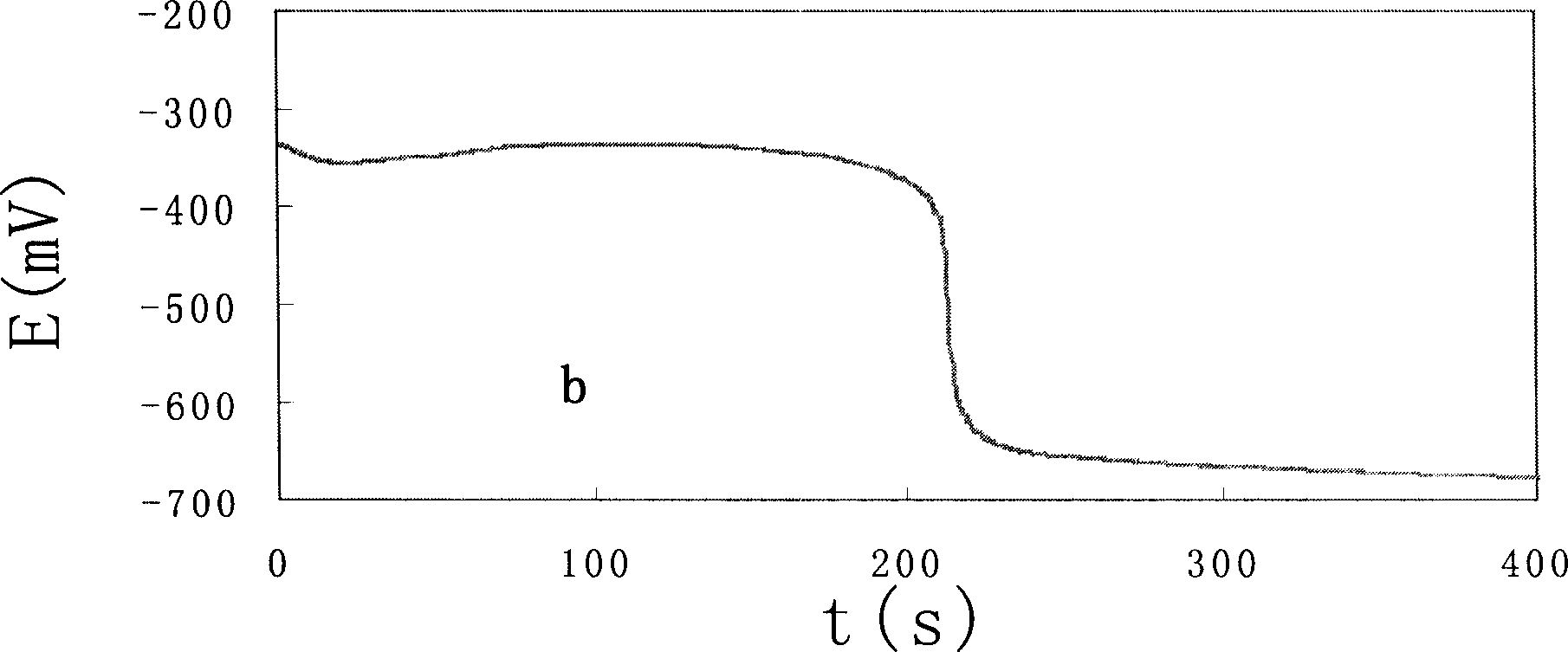

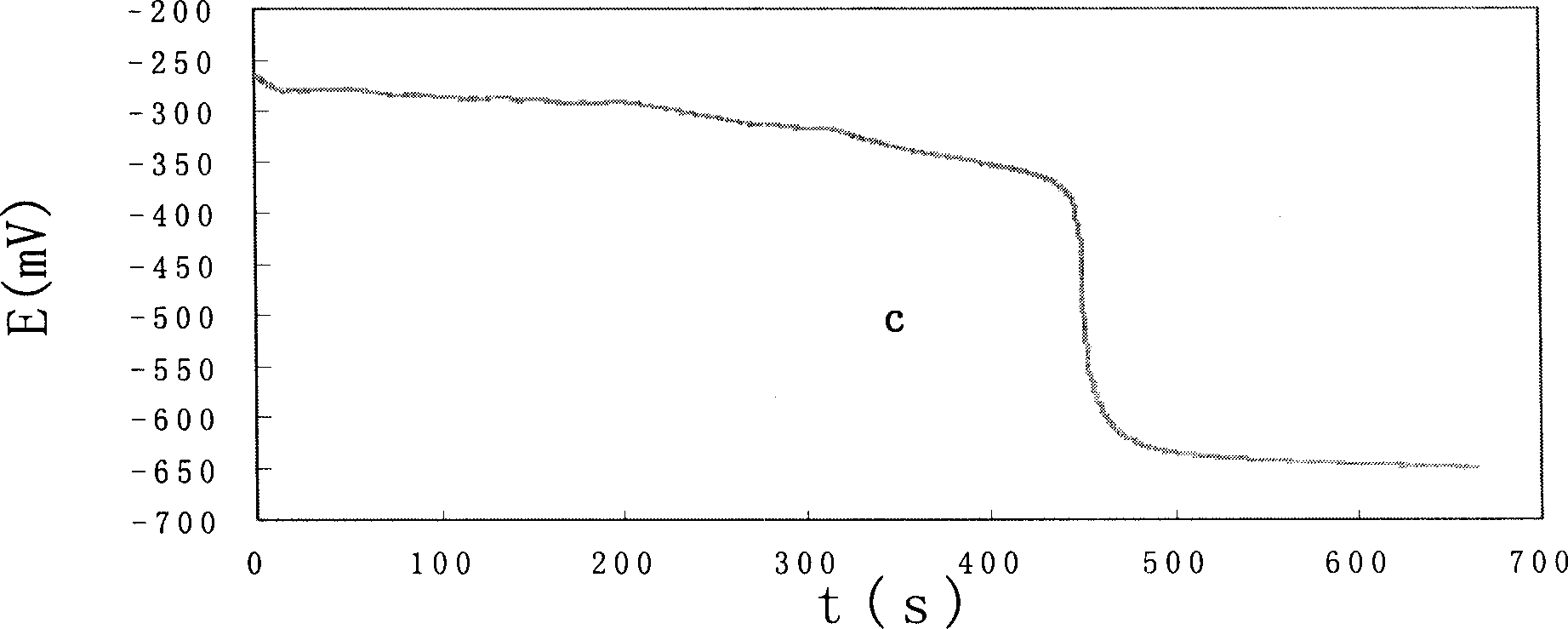

[0024] The following is an evaluation of the phosphating quality of the three cold-rolled sheets, combined with Figure 1 ~ Figure 3 , to illustrate a preferred embodiment of the present invention.

[0025] Step 1, the Na 2 B 4 o 7 10H 2 O (sodium tetraborate) is placed in distilled water, dissolved and prepared into a sodium tetraborate solution, and then hydrochloric acid with a concentration of 1:1 is used as a pH regulator to adjust the pH value of the solution. After adjustment, the solute concentration of the sodium tetraborate solution is 0.05 / mol, and the pH value of the solution at 25°C is between 5.5 and 6.9.

[0026] Step 2, respectively placing the three kinds of cold-rolled sheet a, cold-rolled sheet b and cold-rolled sheet c to be tested in the above-mentioned sodium tetraborate solution.

[0027] Step 3. Use a potentiostat to record the dynamic change process of the potential value of the cold-rolled sheet after entering the above-mentioned sodium tetrabor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com