Sample preparation method for ToF-SIMS test of hollow fiber membrane

A fiber membrane and hollow technology, applied in the field of ToF-SIMS test sample preparation, can solve the problems of ion beam ineffective focus, poor test signal, large enough elevation difference, etc., to achieve low sample preparation cost, simple operation, and smooth process short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

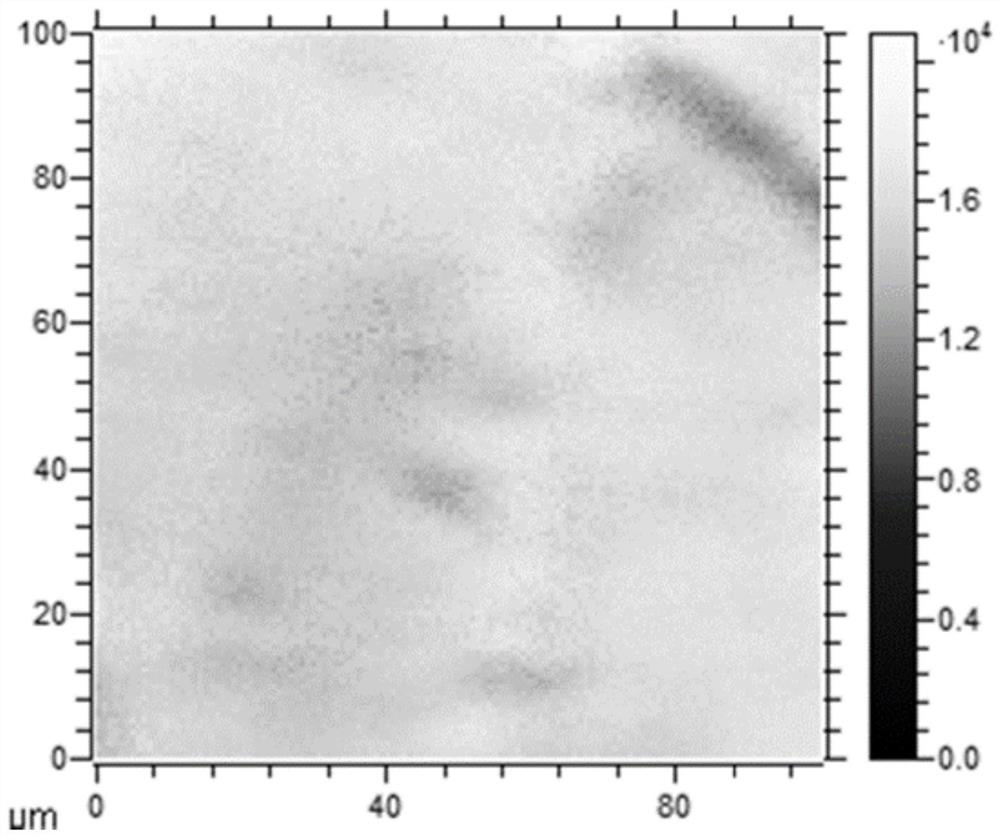

[0052] In this example, the hollow fiber membrane polluted by humic acid (HA) is taken as an example. The material of the hollow fiber membrane is polyvinylidene fluoride (PVDF), the outer diameter is about 1.3 mm, and the membrane surface is covered with a filter cake layer with a thickness of about 20 μm. , the composition of the filter cake layer is HA, and the ToF-SIMS test is performed on the filter cake layer on the surface of the hollow fiber membrane.

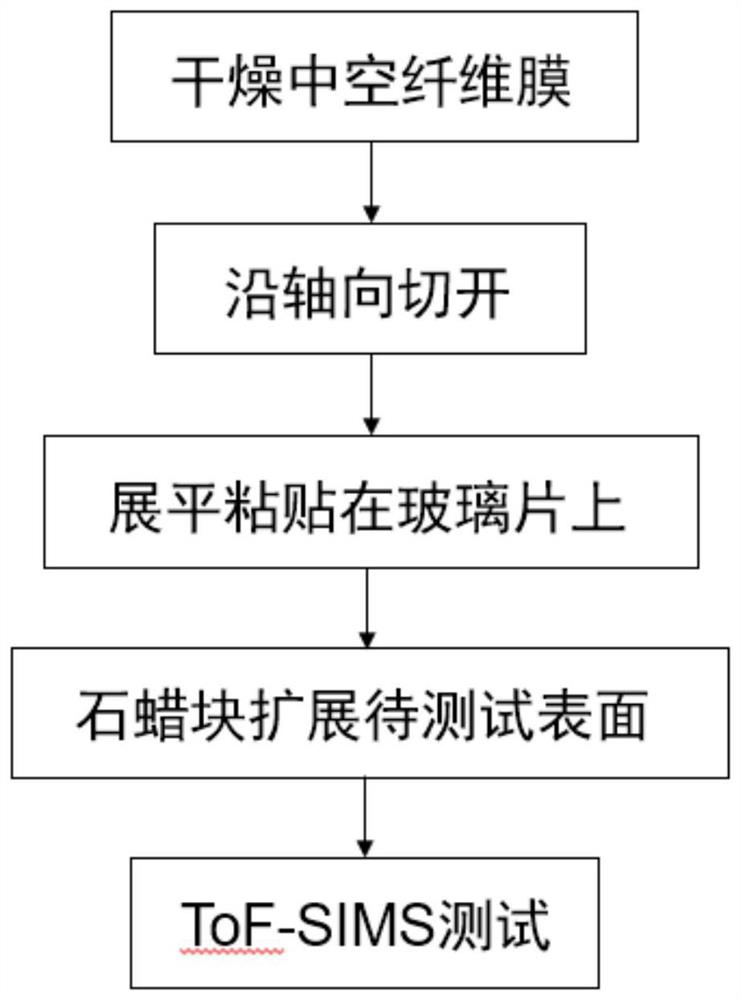

[0053] A kind of sample preparation method flow chart of hollow fiber membrane ToF-SIMS test is as follows figure 1 shown, including the following steps:

[0054] After the hollow fiber membrane was air-dried at room temperature, the HA-contaminated hollow fiber membrane with a length of 1 cm was cut, cut from one side along its axial direction, flattened with tweezers, and pasted on a glass slide with the same size as the expanded one.

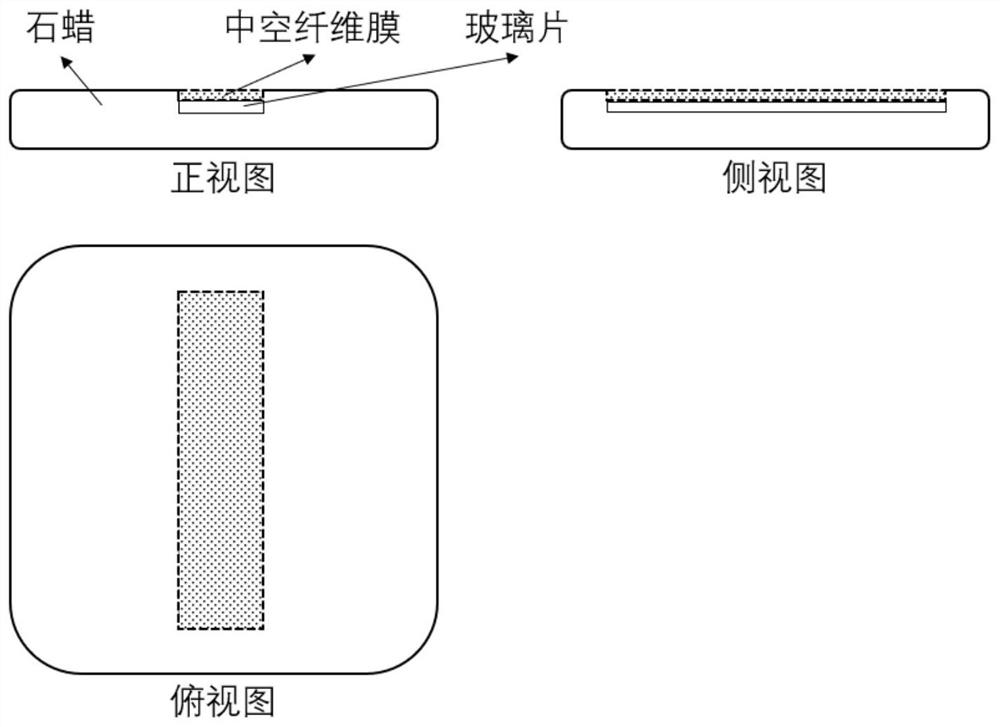

[0055] The stainless steel mold is pre-cooled to -20° C., and the stainless steel...

Embodiment 2

[0064] In this embodiment, a clean hollow fiber membrane is taken as an example, the material is polyvinylidene fluoride (PVDF), the outer diameter is about 1.3mm, and the ToF-SIMS test is carried out on the membrane material in the direction of the surface of the hollow fiber membrane.

[0065] A kind of sample preparation method flow chart of hollow fiber membrane ToF-SIMS test is as follows figure 1 shown, including the following steps:

[0066] After the hollow fiber membrane is naturally air-dried at room temperature, cut the hollow fiber membrane filament with a length of 1 cm, cut it from one side along its axial direction, flatten it with tweezers, and paste it on a glass sheet with the same unfolded size.

[0067] The stainless steel mold is pre-cooled to -20° C., and the stainless steel mold is 2.4 cm long, 1.8 cm wide, and 0.8 cm thick. Take out the pre-cooled stainless steel mold, press the hollow fiber membrane flattened on the glass sheet to the bottom of the mo...

Embodiment 3

[0071] In this example, the hollow fiber membrane polluted by humic acid (HA) is taken as an example. The material of the hollow fiber membrane is polyvinylidene fluoride (PVDF), the outer diameter is about 1.3 mm, and the membrane surface is covered with a filter cake layer with a thickness of about 20 μm. , the composition of the filter cake layer is HA, and the ToF-SIMS test is performed on the filter cake layer on the surface of the hollow fiber membrane.

[0072] A kind of sample preparation method flow chart of hollow fiber membrane ToF-SIMS test is as follows figure 1 shown, including the following steps:

[0073] After the hollow fiber membrane was air-dried at room temperature, the HA-contaminated hollow fiber membrane with a length of 1 cm was cut, cut from one side along its axial direction, flattened with tweezers, and pasted on a glass slide with the same size as the expanded one.

[0074] Pour the molten paraffin liquid into the stainless steel mold, the stainle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com