Non-dismantling formwork pouring mortar layer heat insulation board and production process of non-dismantling formwork pouring mortar layer heat insulation board

A technology that does not disassemble formwork and insulation boards. It is applied in the direction of heat preservation, formwork/formwork/working frame connectors, formwork/formwork components, etc. It can solve problems such as waste of resources, difficult cutting, material leakage, etc., and achieve institutional The effect of precision and stability, stable connection relationship and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

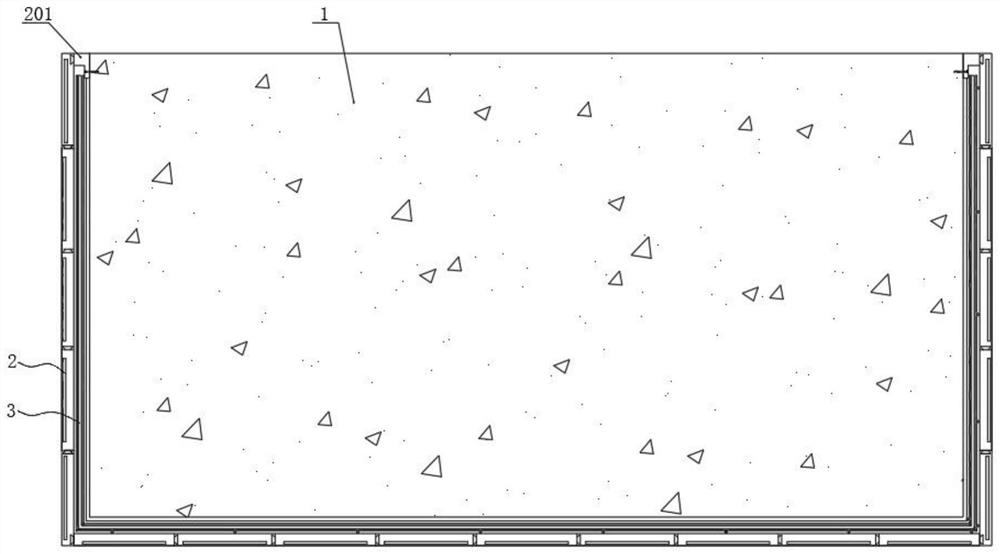

[0034] like figure 1 As shown, a formwork-free pouring mortar layer thermal insulation board includes an outer formwork mechanism 2 detachably connected to the wall 1, a pouring and forming mechanism 3 arranged between the outer formwork mechanism 2 and the wall 1, and a cast on the wall 1. The outer formwork mechanism 2, the mortar insulation layer between the casting molding mechanism 3 and the wall body 1;

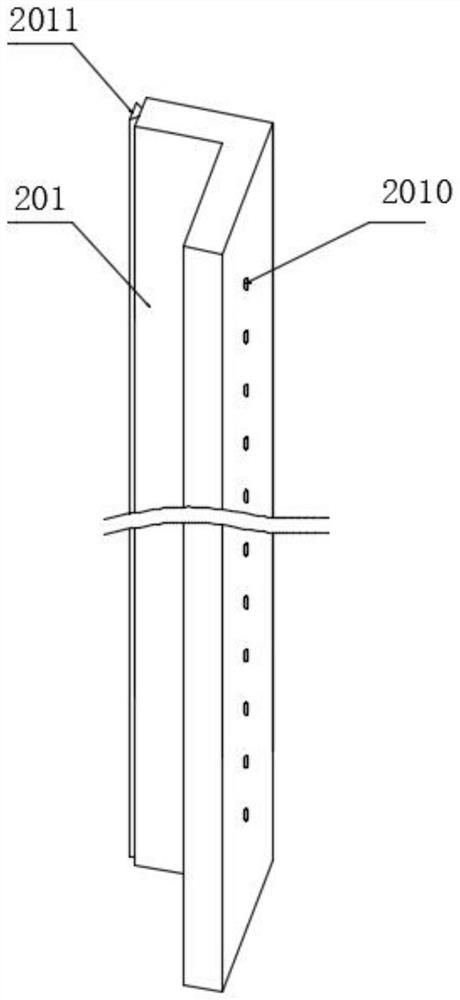

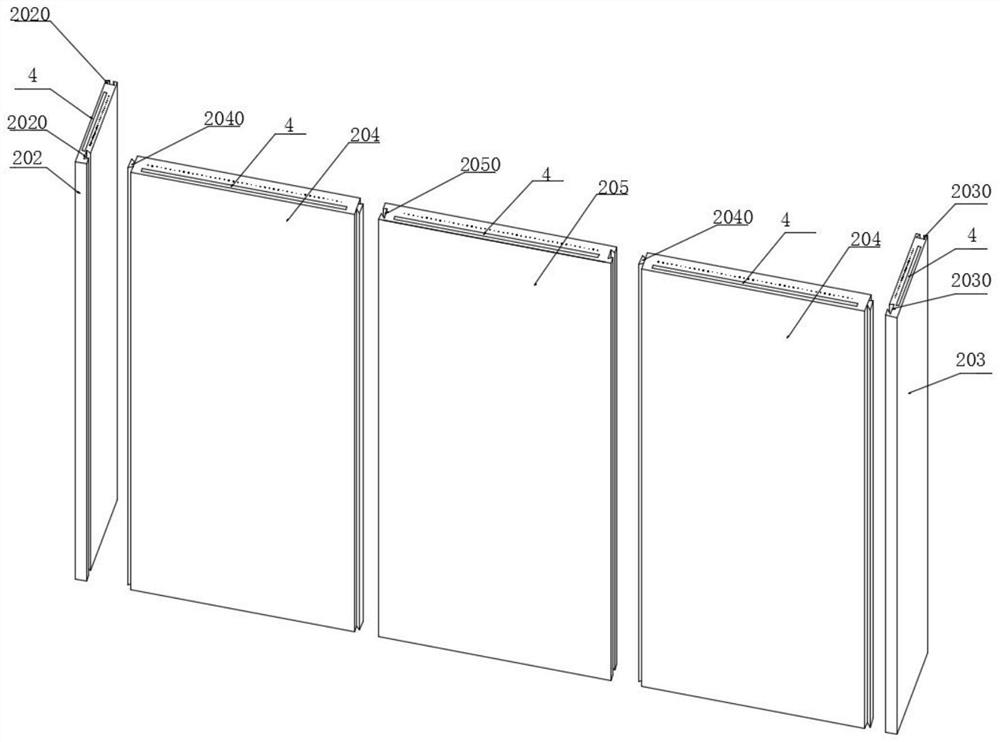

[0035] The outer formwork mechanism 2 includes several L-shaped positioning connection formwork 201 detachably connected to the wall body 1, a bottom formwork mechanism connected between several L-shaped positioning connection formwork 201, and a number of upper formwork mechanisms, the bottom formwork mechanism. The upper ends of several upper-layer formwork mechanisms are provided with several self-locking mechanisms 4, and the lower ends of several upper-layer formwork mechanisms are all connected with self-locking boards 5 matched with the self-locking mechanisms 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com