Dust barrel with double dust compressing function

A technology of dust bucket and function, applied in the field of dust bucket, can solve the problem of low dust compression efficiency and achieve the effect of improving compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0027] The working principle of the vacuum cleaner of the present invention is the same as that of the prior art, and the prior art can be referred to, so it will not be described again, and the same symbols as those of the prior art will be used. The differences between the present invention and the prior art will be described below Detailed explanation:

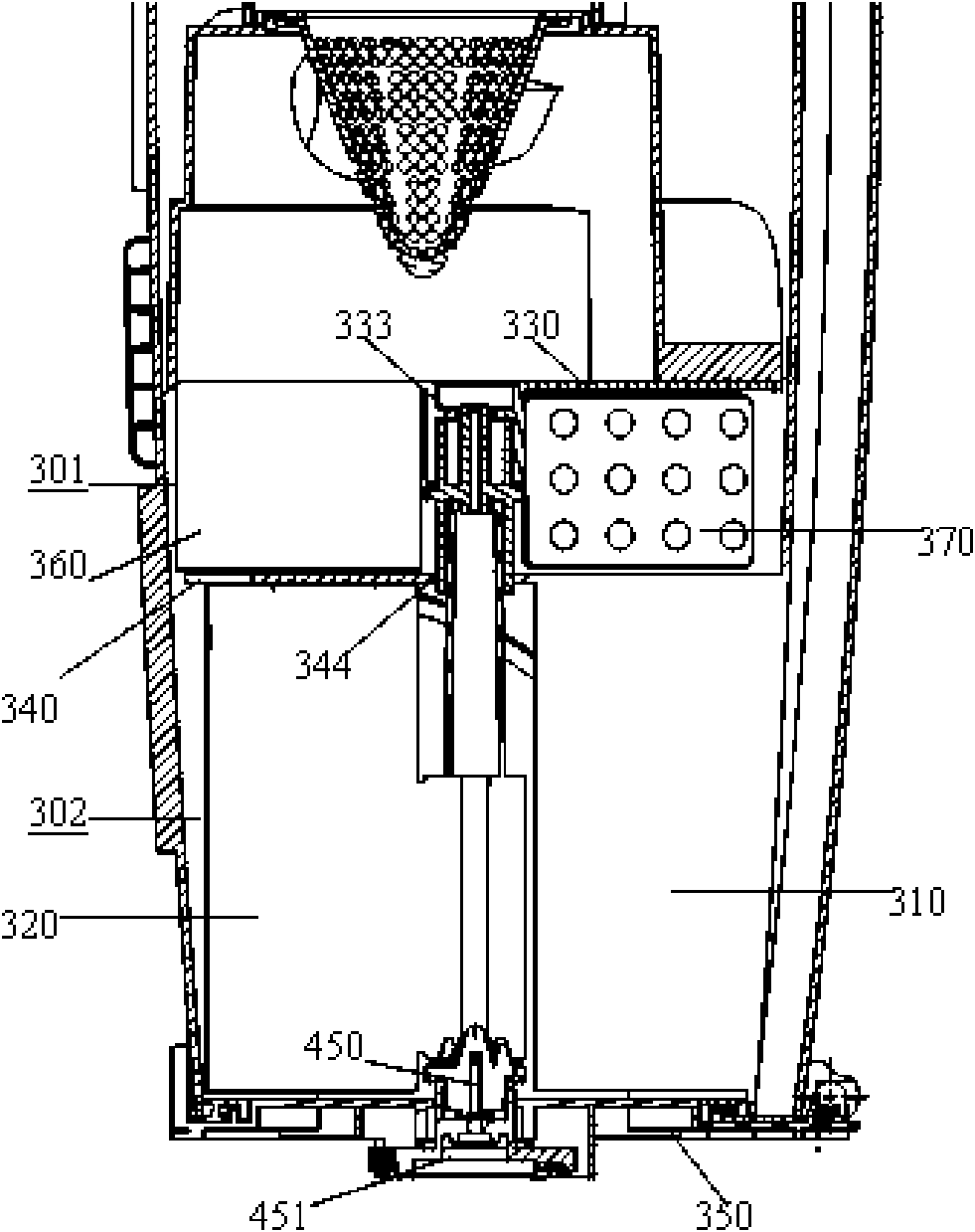

[0028] Such as image 3 As shown in FIG. 6 , the partition plate 340 horizontally fixed in the middle of the dust bucket divides the dust bucket 202 into two parts: the area between the upper partition plate 330 and the partition plate 340 is the upper compression chamber 341, which is hinged in the collection The area between the bottom cover 350 and the partition plate 340 on the dust bucket housing is the lower compression chamber 342 .

[0029] A circular through hole 344 is disposed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com