A kind of composite polymer solid electrolyte, solid lithium battery and preparation method thereof

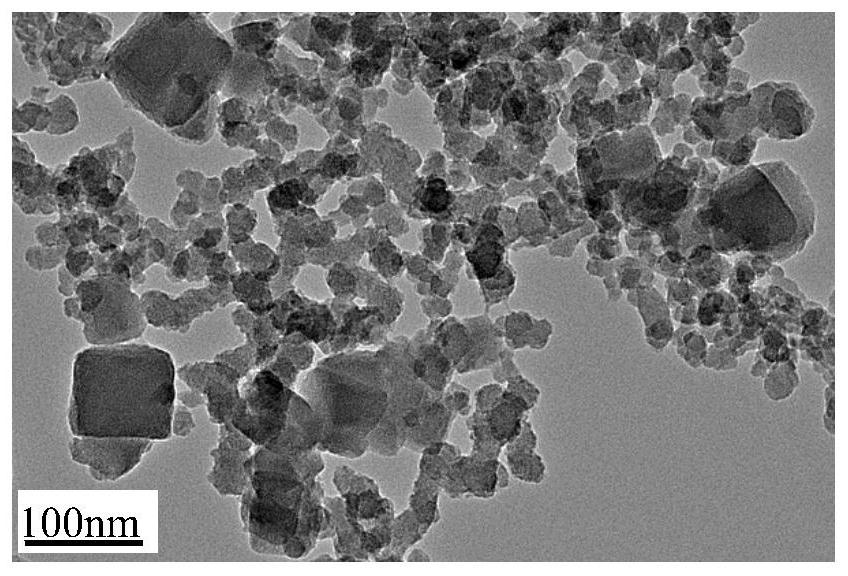

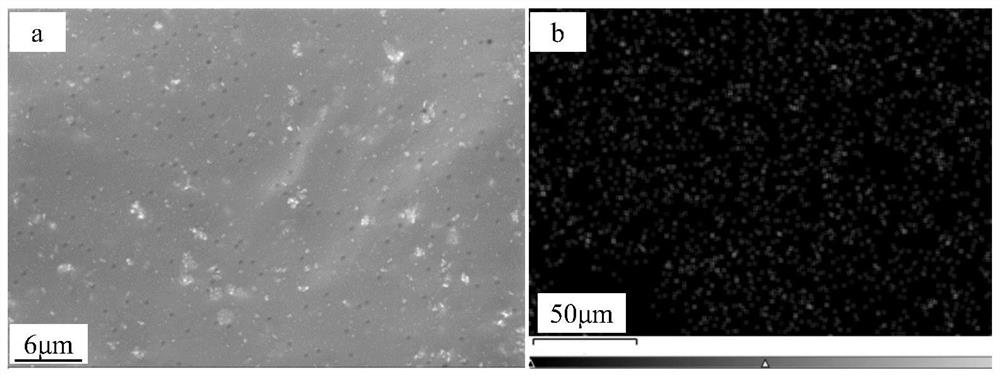

A solid electrolyte and composite polymer technology, applied in solid electrolyte, non-aqueous electrolyte battery, lithium battery, etc., can solve the problems of unfavorable composite polymer solid electrolyte performance, uneven distribution, particle agglomeration, etc., to improve lithium ion conductivity The effect of high efficiency and migration number, low preparation energy consumption, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The metal-organic framework structure that adsorbs lithium-containing ionic liquid: the preparation of a composite solid electrolyte of (PEO+LiTFSI)=1:4 and the corresponding solid-state lithium battery prepared from the electrolyte, the specific steps are as follows:

[0059] Take 0.15g of the activated metal-organic framework and 0.24g of the lithium-ion-containing liquid, grind and mix them in a mortar, and heat at 120°C for 24 hours in a vacuum to obtain a metal-organic framework that adsorbs the lithium-ion-containing liquid;

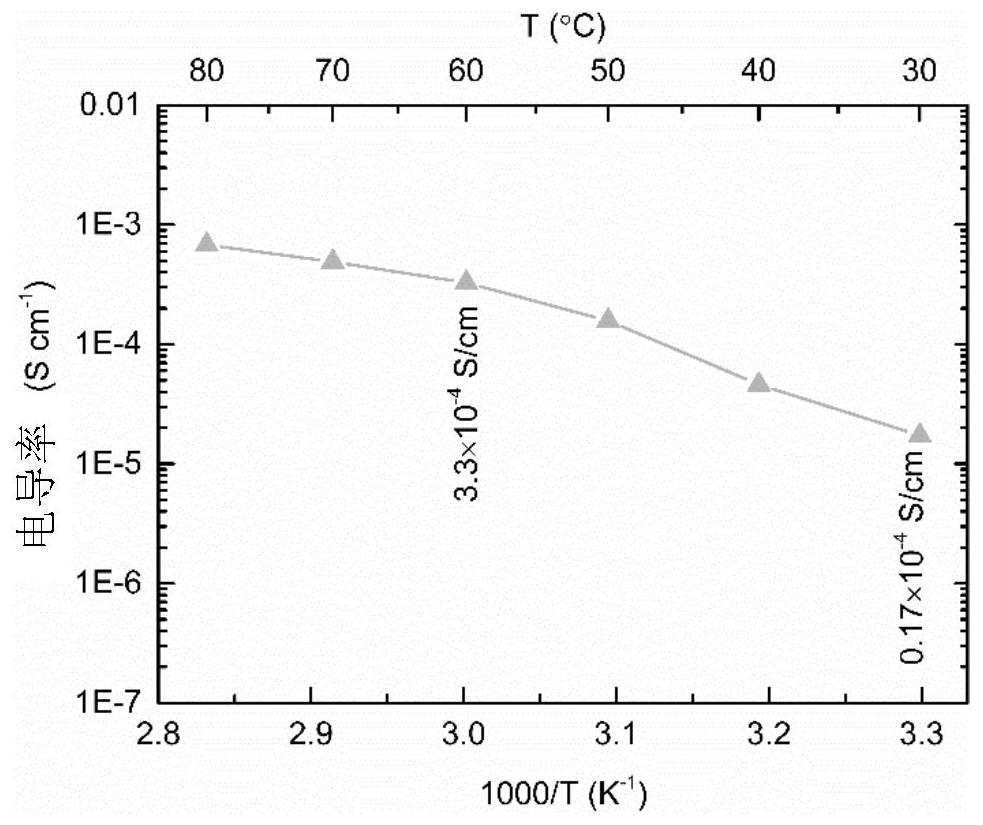

[0060] Disperse 0.1349g of the metal-organic framework structure that adsorbs lithium-containing ionic liquids in 6ml of anhydrous acetonitrile, then add 0.396g of PEO and 0.1435g of LiTFSI, heat to 60°C in a glove box, and stir for 24h to obtain a colloidal solution; Pour it on a polytetrafluoroethylene plate, and after the surface solvent is completely evaporated, dry it in vacuum at 60°C for 24 hours to obtain a composite polymer solid ele...

Embodiment 2

[0065] The metal-organic framework structure that adsorbs lithium-containing ionic liquid: (PEO+LiTFSI)=1:9 The preparation of the composite solid electrolyte, the specific steps are as follows:

[0066] Take 0.15g of the activated metal-organic framework and 0.15g of the lithium-ion-containing liquid, grind and mix them in a mortar, and heat at 110°C for 22 hours in a vacuum to obtain a metal-organic framework that adsorbs the lithium-ion-containing liquid;

[0067]Disperse 0.06g of the metal-organic framework structure for adsorbing lithium-containing ionic liquids in 6ml of anhydrous acetonitrile, then add 0.396g of PEO and 0.1435g of LiTFSI, heat to 60°C in a glove box, and stir for 24h to obtain a colloidal solution; Pour it on a polytetrafluoroethylene plate, and after the surface solvent is completely volatilized, dry it in vacuum at 70°C for 20 hours to obtain a composite polymer solid electrolyte with a conductivity of 0.049×10 -4 S / cm.

Embodiment 3

[0069] The metal-organic framework structure for adsorbing lithium-containing ionic liquid: (PEO+LiTFSI) = 3:7 preparation of composite solid electrolyte, the specific steps are as follows:

[0070] Take 0.15g of the activated metal-organic framework and 0.24g of the lithium-ion-containing liquid, grind and mix them in a mortar, and heat at 120°C for 24 hours under vacuum to obtain a metal-organic framework that adsorbs the lithium-ion-containing liquid;

[0071] Disperse 0.2314g of the metal-organic framework structure that adsorbs lithium-containing ionic liquids in 6ml of anhydrous acetonitrile, then add 0.396g of PEO and 0.1435g of LiTFSI, heat to 60°C in a glove box, and stir for 24h to obtain a colloidal solution; Pour it on a polytetrafluoroethylene plate, and after the surface solvent is completely volatilized, dry it in vacuum at 60°C for 24 hours to obtain a composite polymer solid electrolyte with a conductivity of 0.68×10 -4 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com