Membrane electrode assembly and proton exchange membrane fuel cell

A membrane electrode assembly and fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, electrical components, etc., can solve the problems of uneven gas distribution, affecting the performance and life of fuel cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

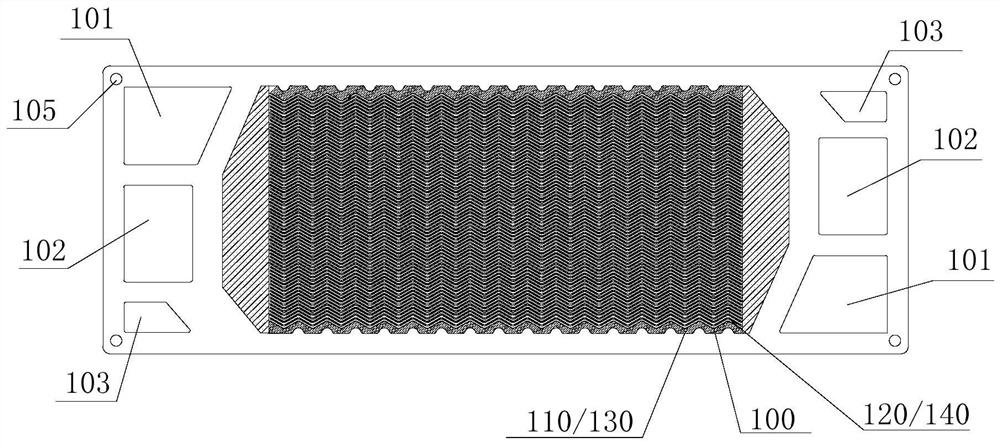

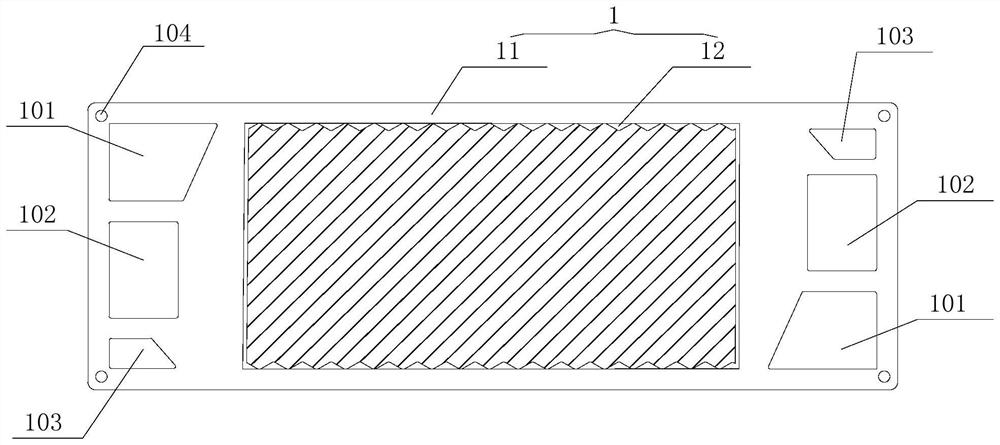

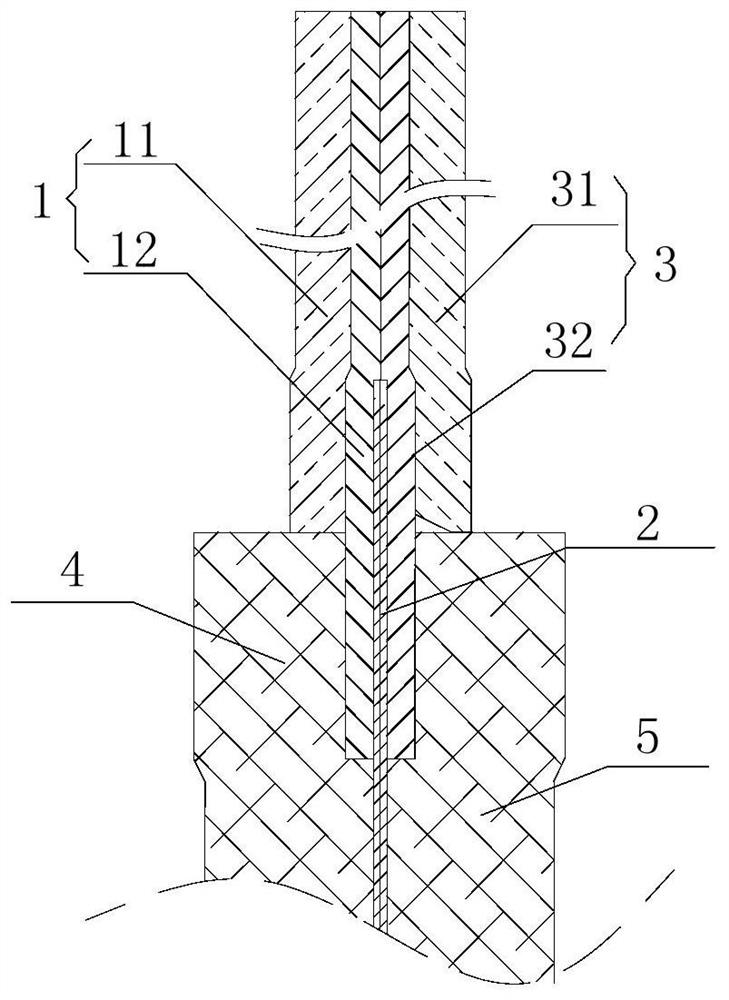

[0050] This embodiment provides a membrane electrode assembly, refer to figure 2 and image 3 , combined with figure 1 , the membrane electrode assembly is applied to a fuel cell using a meandering flow channel bipolar plate, including an anode frame 1 , a catalyst coating membrane 2 , a cathode frame 3 , an anode gas diffusion layer 4 and a cathode gas diffusion layer 5 .

[0051] Specifically, along the thickness direction of the membrane electrode assembly: the anode frame 1 and the cathode frame 3 are respectively arranged on both sides of the catalyst coating membrane 2; the anode gas diffusion layer 4 is arranged on the side of the catalyst coating membrane 2 where the anode frame 1 is arranged , the cathode gas diffusion layer 5 is arranged on the other side of the catalyst coating film 2 .

[0052] In the direction perpendicular to the thickness of the membrane electrode assembly: the anode frame 1 surrounds the anode gas diffusion layer 4; the cathode frame 3 surro...

Embodiment 2

[0064] This embodiment provides a proton exchange membrane fuel cell, the proton exchange membrane fuel cell includes a cathode plate using a meandering flow channel, an anode plate using a meandering flow channel, and the membrane provided by any one of the optional implementations of the first embodiment electrode assembly.

[0065] Among them, along the thickness direction of the membrane electrode assembly: the anode plate is fixed on the side of the anode frame 1 away from the catalyst coating membrane 2; the inner edge of the anode frame 1 coincides with the inner edge of the outer ridge 110 of the anode plate; the cathode plate is fixed on the cathode The side of the frame 3 away from the catalyst coating film 2; the inner edge of the cathode frame 3 coincides with the inner edge of the outer ridge 130 of the cathode plate.

[0066] In an optional implementation manner of this embodiment, the edge of the anode frame 1 is sealed and connected to the anode plate through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com