Sponge cement blanket and preparation method thereof

A sponge and cement technology, applied in chemical instruments and methods, mining equipment, shaft equipment, etc., can solve the problems of poor working environment, short exposure time, low efficiency, etc., and achieve the effect of low cost, simple production and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

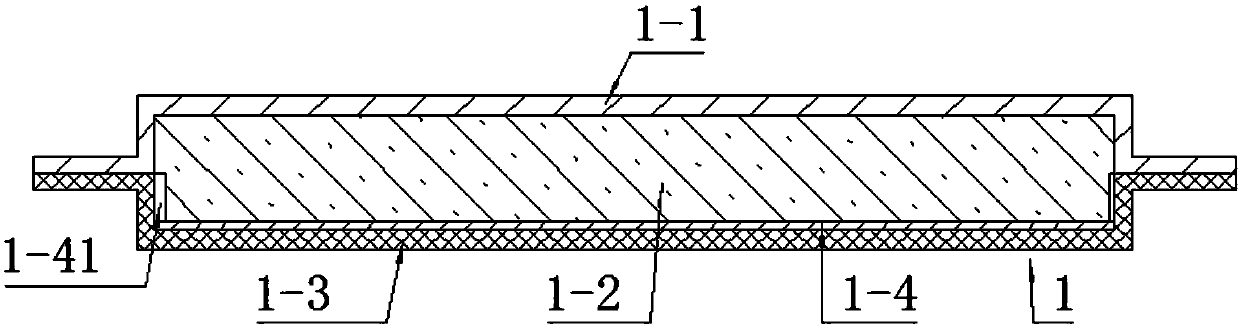

[0039] Such as figure 1 As shown, it includes an upper fabric 1-1, a lower fabric 1-3, and a sponge cement layer 1-2 and a wire mesh sandwiched between the upper fabric 1-1 and the lower fabric 1-3, and the upper fabric 1-1 And the outer contour size of the lower fabric 1-3 is greater than the size of the sponge cement layer 1-2 and the wire mesh, the upper fabric 1-1, the sponge cement layer 1-2, the wire mesh and the lower fabric 1 -3 stitched together by fiber thread;

[0040] The wire mesh at least includes a lower wire mesh 1-4 arranged between the lower fabric 1-3 and the sponge cement layer 1-2;

[0041] Both sides of the lower wire mesh 1-4 are provided with handles 1-41.

[0042] The sponge cement layer 1-2 includes a sponge and the cement or the mixture of cement, quick-setting agent and sodium silicate filling the gaps of the sponge.

[0043] The density of the sponge is less than 18kg / m 3 .

Embodiment 2

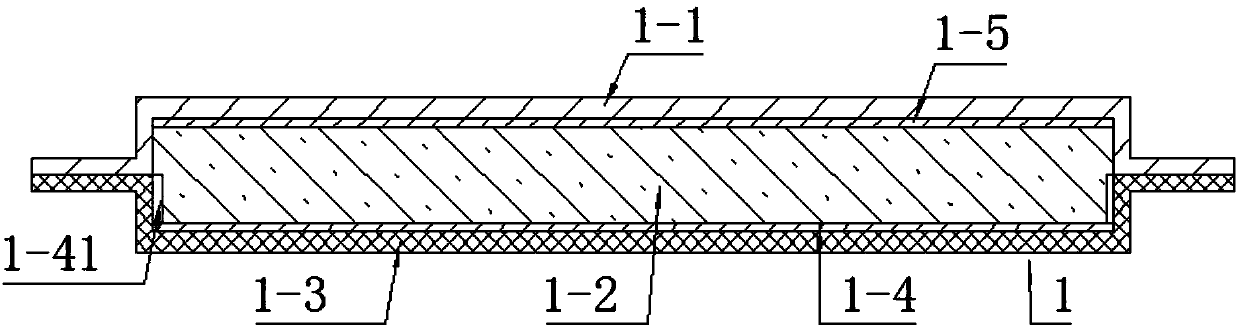

[0045] Such as figure 2 As shown, the difference from Embodiment 1 is that: it also includes an upper layer wire mesh 1-5 arranged between the upper layer fabric 1-1 and the sponge cement layer 1-2.

[0046] The present invention also relates to a kind of preparation method of sponge cement blanket, comprises following embodiment:

Embodiment 3

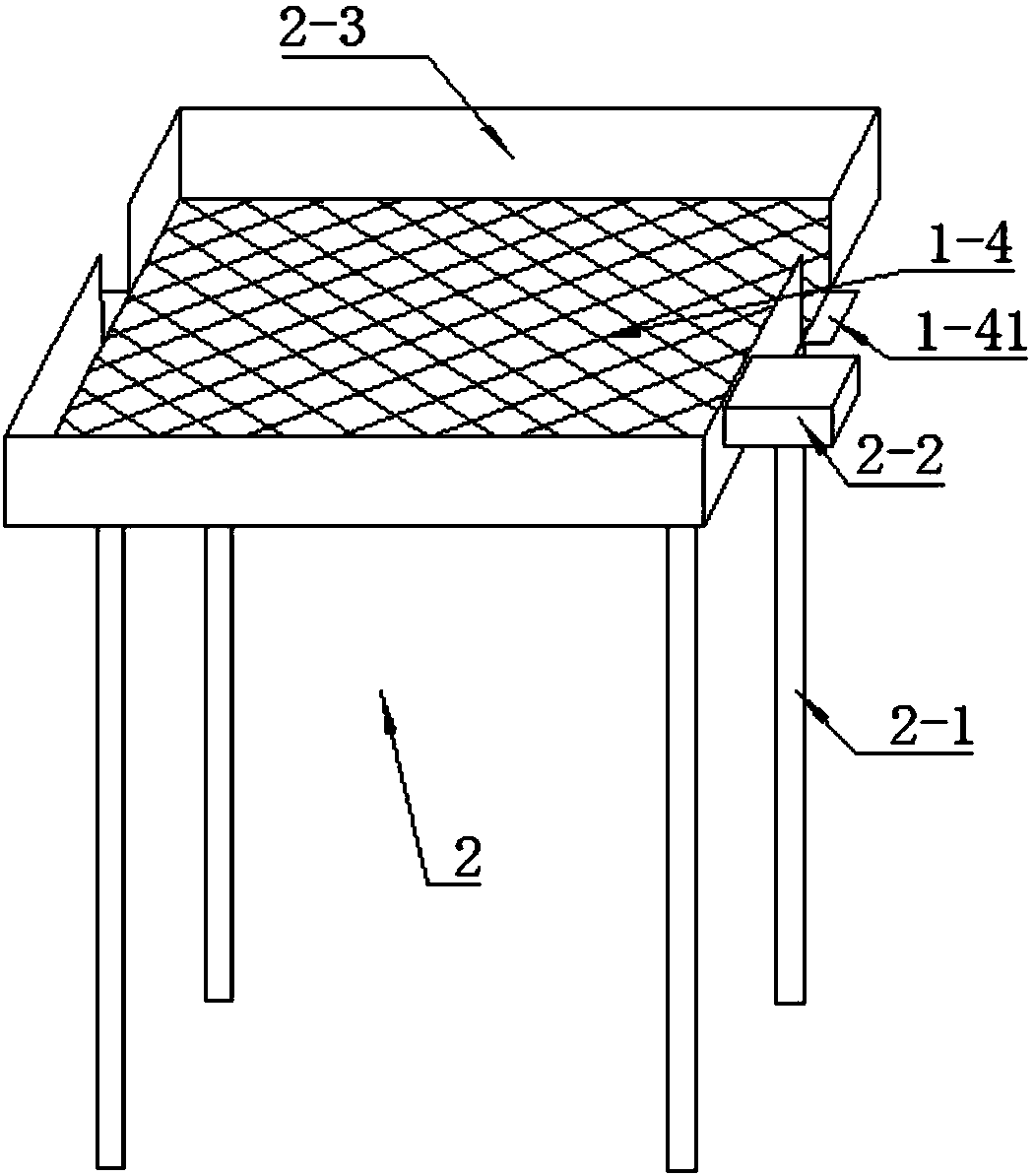

[0048] Such as figure 1 , image 3 and Figure 4 As shown, the steps are as follows:

[0049] Step 1. Prepare materials, prepare upper fabric 1-1, sponge and lower fabric 1-3, the size of the lower fabric 1-3 and the upper fabric 1-1 are the same, the size of the sponge cement layer 1-2 Smaller than the size of the upper and lower fabrics, the density of the sponge is less than 18kg / m 3 ;

[0050]Step 2. Prepare the sponge cement layer 1-2, place the sponge on the vibrating platform 2, and the bottom of the vibrating platform 2 is provided with a cement recovery device (not shown in the figure), including the vibrating platform supporting leg 2-1, installed on the vibrating platform 2. The surrounding frame 2-3 on the support leg 2-1 of the vibration platform and the vibration motor 2-2 installed on the side of the surrounding frame 2-3, the lower floor wire mesh is provided in the described surrounding frame, and the surrounding frame The frame is provided with a groove,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com