Radiator

A radiator and fin technology, applied in heat exchanger shells, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of fin shaking, defective phase, fin detachment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

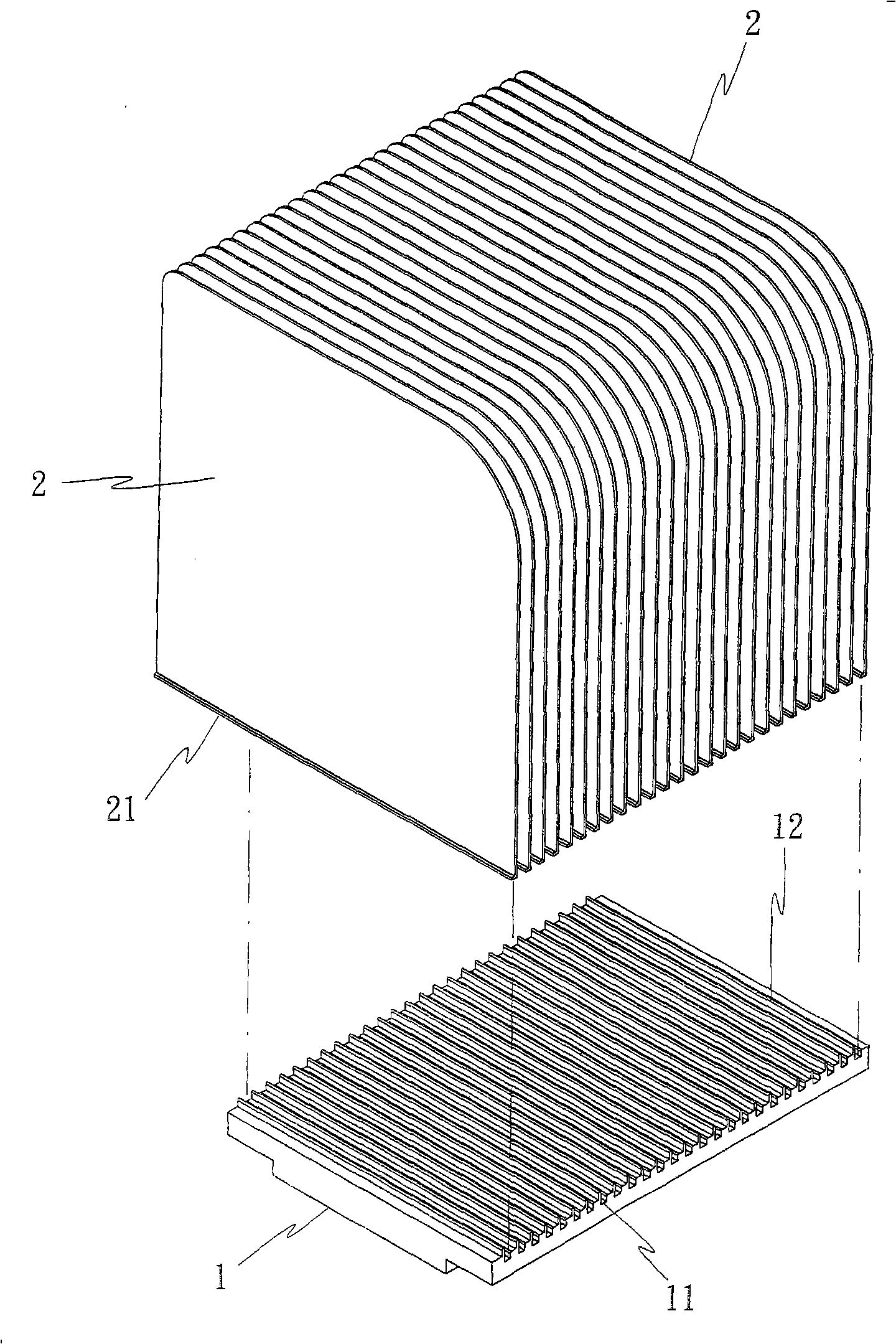

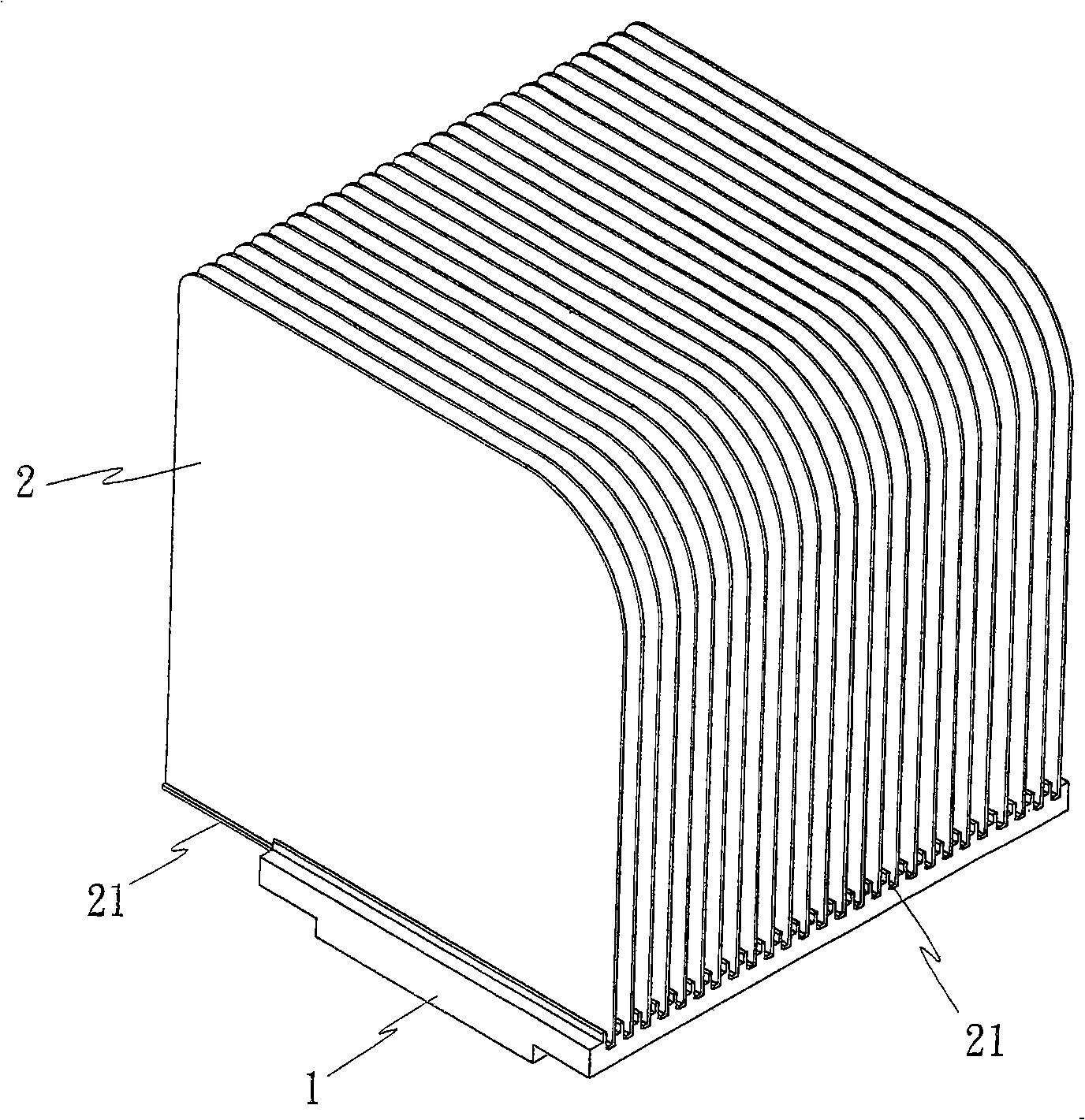

[0035] Such as figure 1 and figure 2 As shown, the radiator system of the present invention includes a base 1 and a plurality of cooling fins 2, wherein:

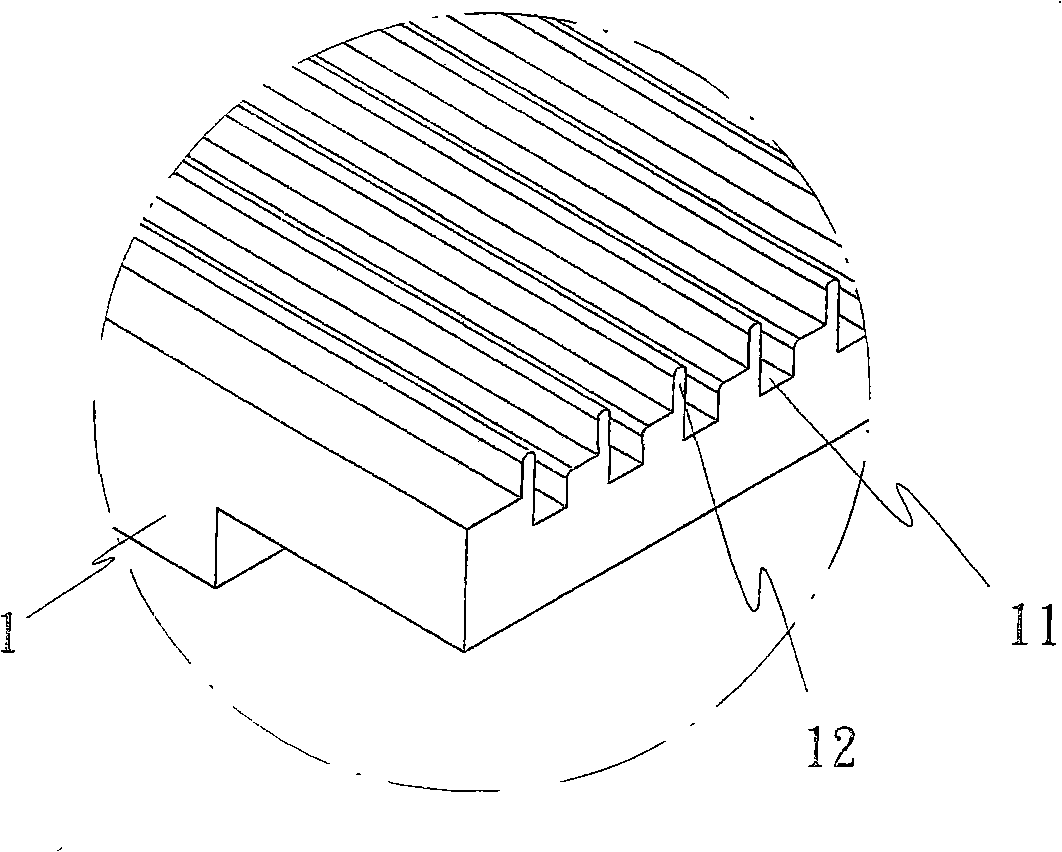

[0036] The seat body 1 is provided with a plurality of adjacent grooves 11 on the surface, and one side of the wall of each groove 11 is provided with a first protrusion 12 extending upwards (such as image 3 );

[0037] The plurality of cooling fins 2 all form a bent part 21 at the bottom of the fin body, so that the bent part 21 can be matched with the groove 11 implanted in the seat body 1;

[0038] Utilize above-mentioned seat body 1 and plural cooling fins 2, after each cooling fin 2 all matches and implants the groove 11 of seat body 1, can cooperate with the pressing down of stamping die 3 (such as Figure 4 ) to force the first protruding portion 12 to produce downward deformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com