Patents

Literature

57results about How to "Prevent sediment clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

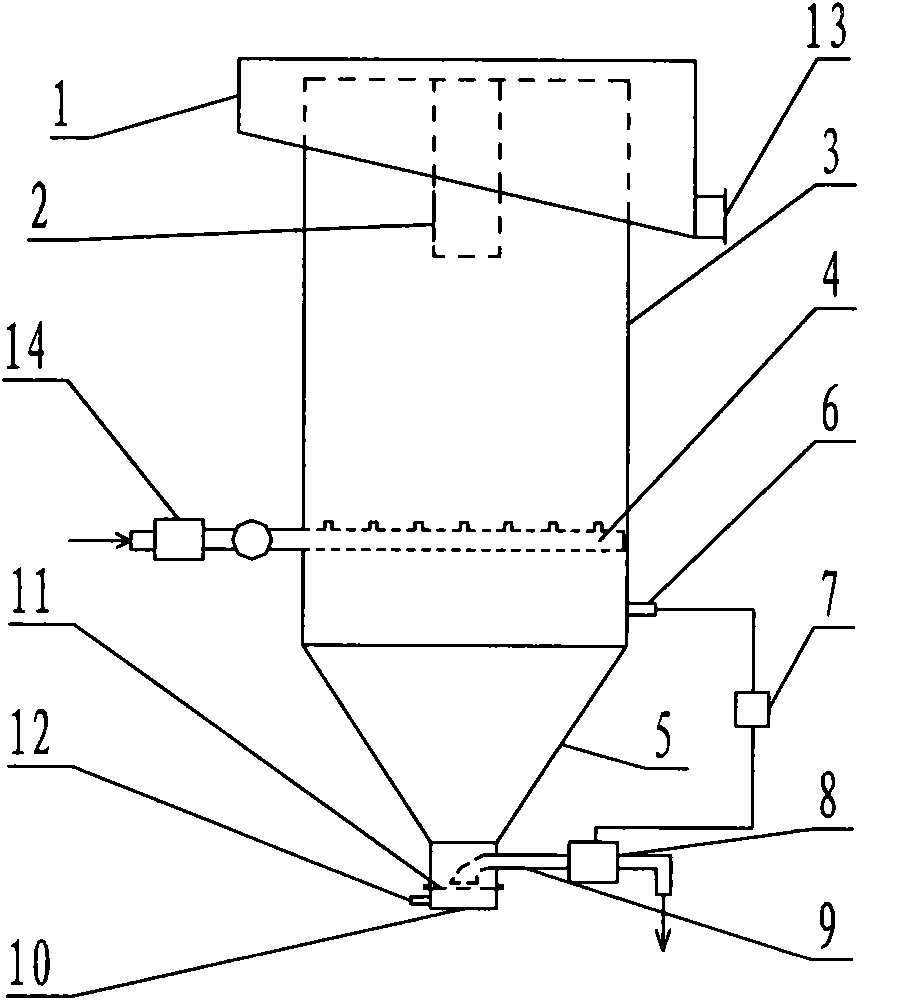

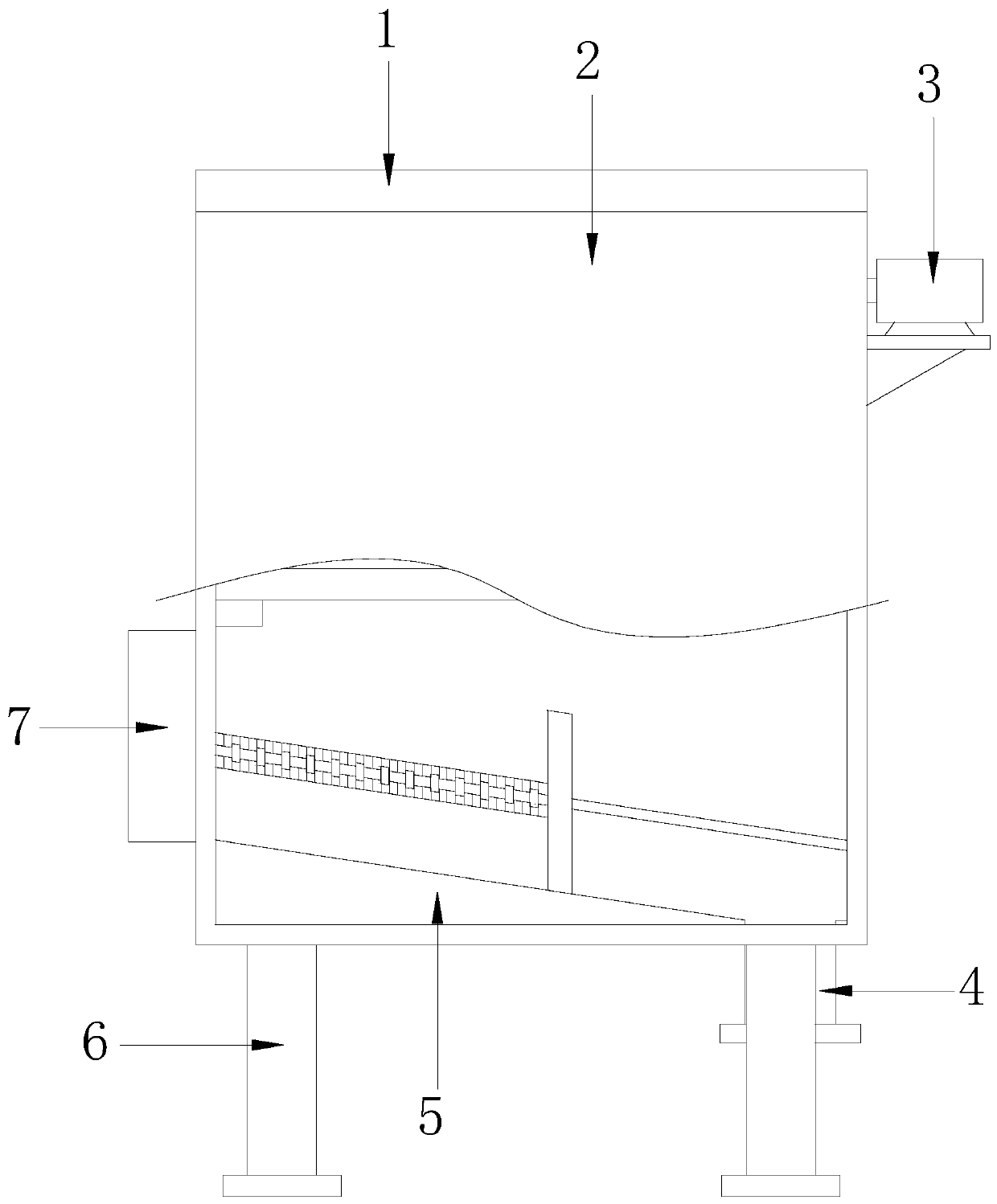

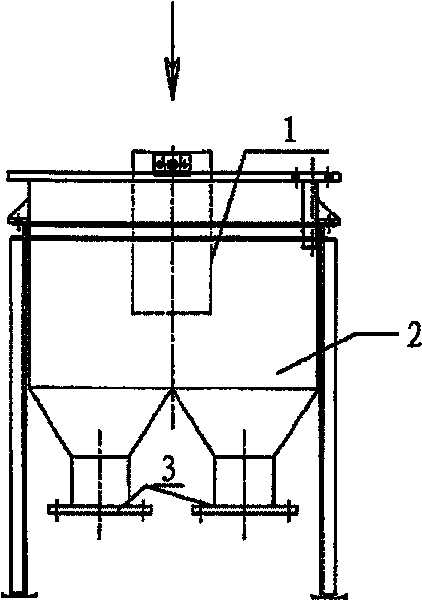

Sorting and grading device of pulsating liquid-solid fluidized bed and method thereof

InactiveCN101804382AGood for automatic dischargeHigh densityWet separationAutomatic controlVolumetric Mass Density

The invention provides a sorting and grading device of a pulsating liquid-solid fluidized bed and a method thereof. The sorting and grading device comprises a light product overflow trough, a central feed pipe, a sorting tank, a pulsating liquid distributor, a pulsating current generator, a heavy product collecting base-cone section, a sensor for measuring the concentration of the heavy product layer, a programmable controller, a heavy product discharging fluidized chamber and an underflow discharging automatic control actuator. The method comprises the following steps: firstly, water is thrown into a sorting machine in a pulsating way by the pulsating current generator, to form an upward varying-accelerated pulsating-type ascending current; accordingly, low-density or fine-fraction materials can be subjected to upward accelerated movement under the action of the accelerated pulsating-type ascending current, thus achieving the overflow discharge of the low-density or fine-fraction materials as the light or fine-fraction products; and high-density or coarse-fraction materials can be settled downwards in the fluidized bed, thus achieving the discharge of the high-density or coarse-fraction materials as the heavy or coarse-fraction products. Accordingly, the process for sorting materials by density on the basis of pulsating fluidization or the process for grading materials by fraction on the basis of pulsating fluidization can be achieved. The device and method of the invention have the advantages of simple operation, low energy consumption, low sorting lower limit, wide fraction range, high sorting accuracy and high reliability.

Owner:CHINA UNIV OF MINING & TECH

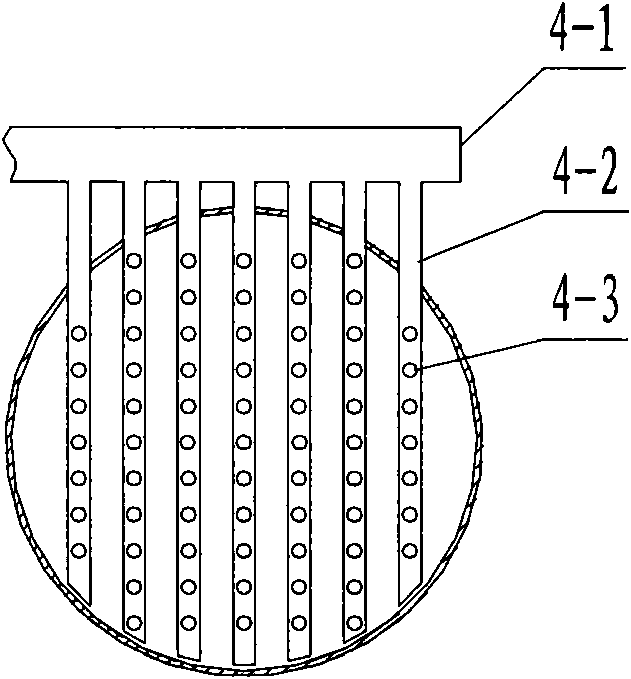

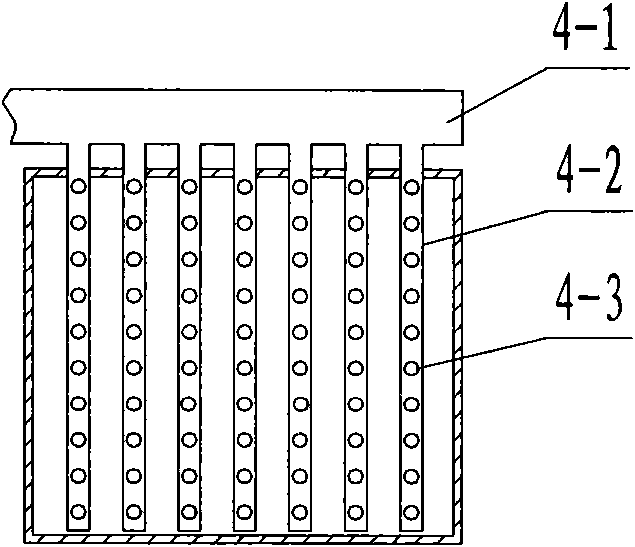

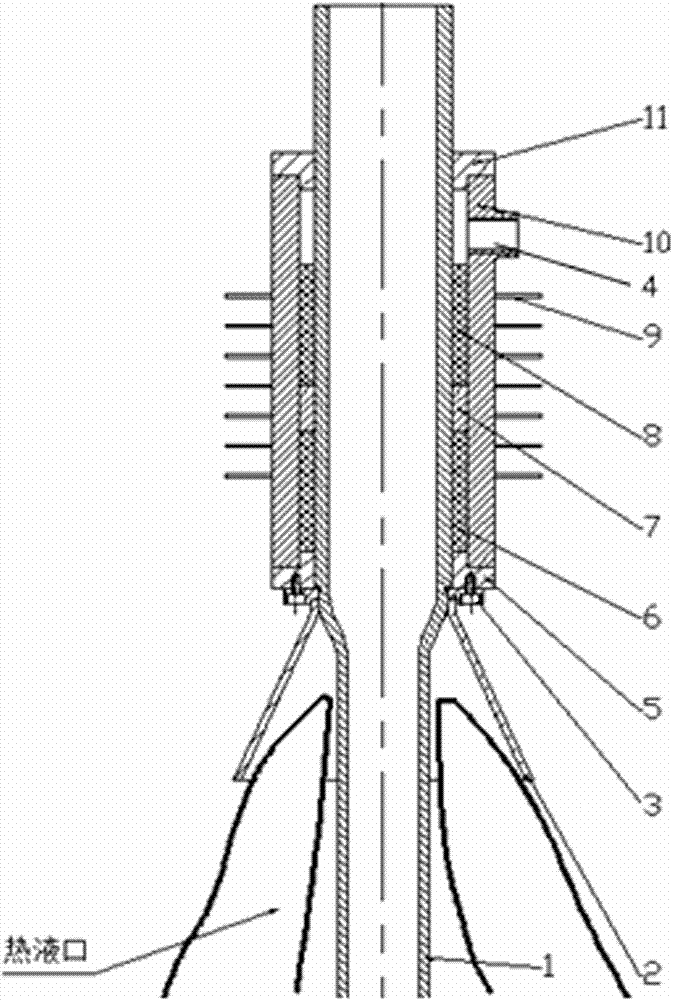

Seafloor hydrothermal vent temperature difference energy power generating device

InactiveCN104852634ALower cold junction temperatureIncrease the temperature difference between the hot and cold endsGenerators/motorsOcean bottomTemperature difference

The invention discloses a seafloor hydrothermal vent temperature difference energy power generating device. The seafloor hydrothermal vent temperature difference energy power generating device comprises a flow guide tube and a cavity; a top end cover and a flange end cover are fixed to two ends of the cavity respectively; the flow guide tube, the top end cover, the flange end cover and the cavity form a sealed cavity; a first temperature difference power generating sheet, a separation board and a second temperature difference power generating sheet are arranged in the sealed cavity; the hot ends of the first temperature difference power generating sheet and the second temperature difference power generating sheet are attached to the outer wall of the flow guide tube; the cold ends of the first temperature difference power generating sheet and the second temperature difference power generating sheet are attached to the inner wall of the cavity; the exterior of the cavity is provided with a plurality of ring ribs; and the lower end of the flow guide tube is provided with a flow guide tube flange and a trumpet-shaped flow separation hood. According to the seafloor hydrothermal vent temperature difference energy power generating device of the invention, a thermoelectric Seebeck effect is utilized, and the flow guide tube is adopted to guide hydrothermal fluid, and the temperature difference power generating sheets are adopted to convert heat energy into electric energy, and therefore, power generation can be realized. The seafloor hydrothermal vent temperature difference energy power generating device of the invention is simple and compact in structure; and the temperature difference of the two ends of each temperature difference power generating sheet is large, and therefore, the utilization rate of hydrothermal energy is high.

Owner:ZHEJIANG UNIV

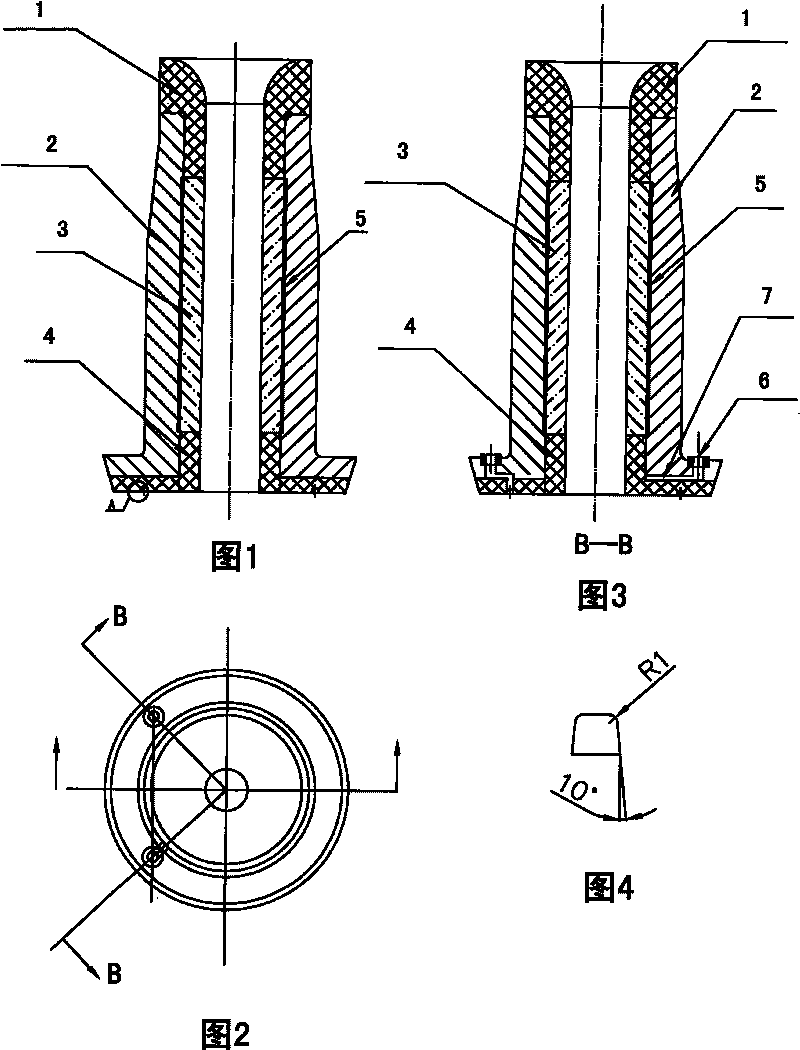

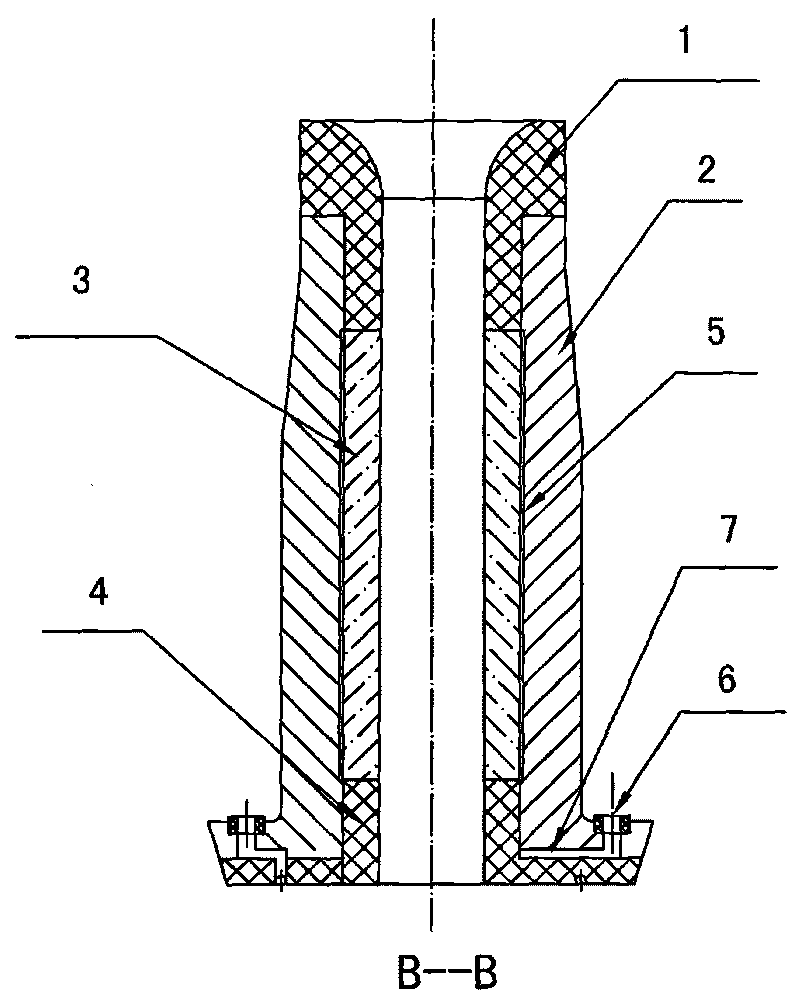

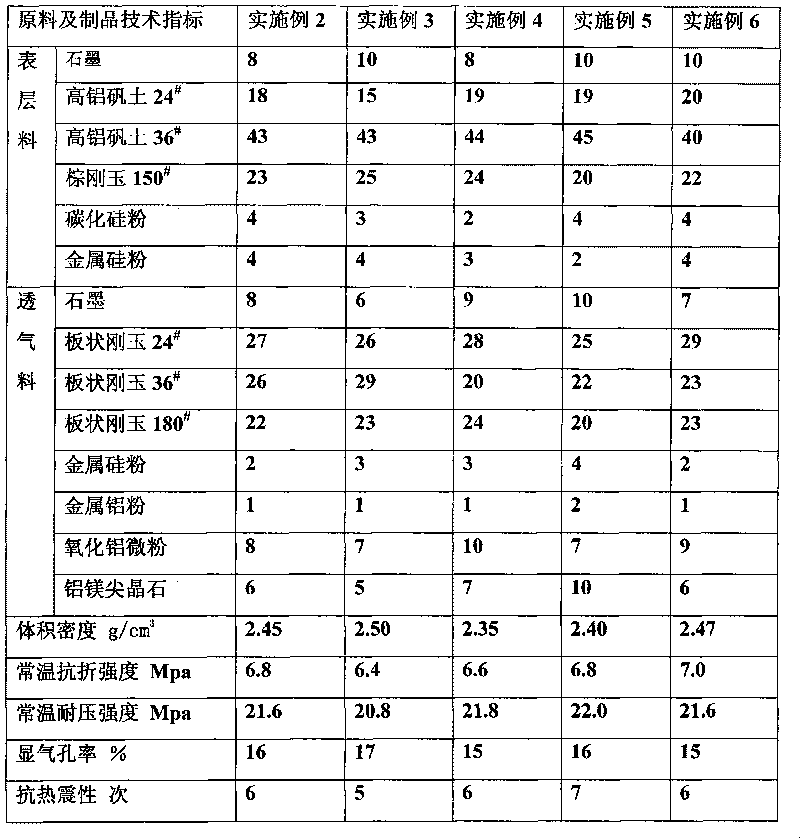

Tundish breathable water inlet used for metal continuous casting plate blank and preparation method thereof

ActiveCN101704100AIncrease the age of disposable single bagsAvoid nodule cloggingMelt-holding vesselsState of artRefractory

The invention relates to a tundish breathable water inlet used for the metal continuous casting plate blank and a preparation method thereof, belonging to the metal casting molten material conveying part. A surface material and a breathable material which are composite flame-resistant materials are adopted, the inner core material, bowl material and flat interface material all adopts the breathable material, and the surface material and the breathable material are separately made from flame-resistant materials with different components and different proportions, wherein the outer skin (surface) material which mainly used brown aluminium oxide before now mainly adopts bauxite with lower price than that of brown aluminium oxide so as to reduce the cost. The tundish breathable water inlet of the invention can be used to solve the problem that the tundish breathable water inlet used for the metal continuous casting plate blank has complicated forming technology, various varieties of materials, short service life of products, low mechanical strength and high production cost.

Owner:山东东耐高温材料股份有限公司

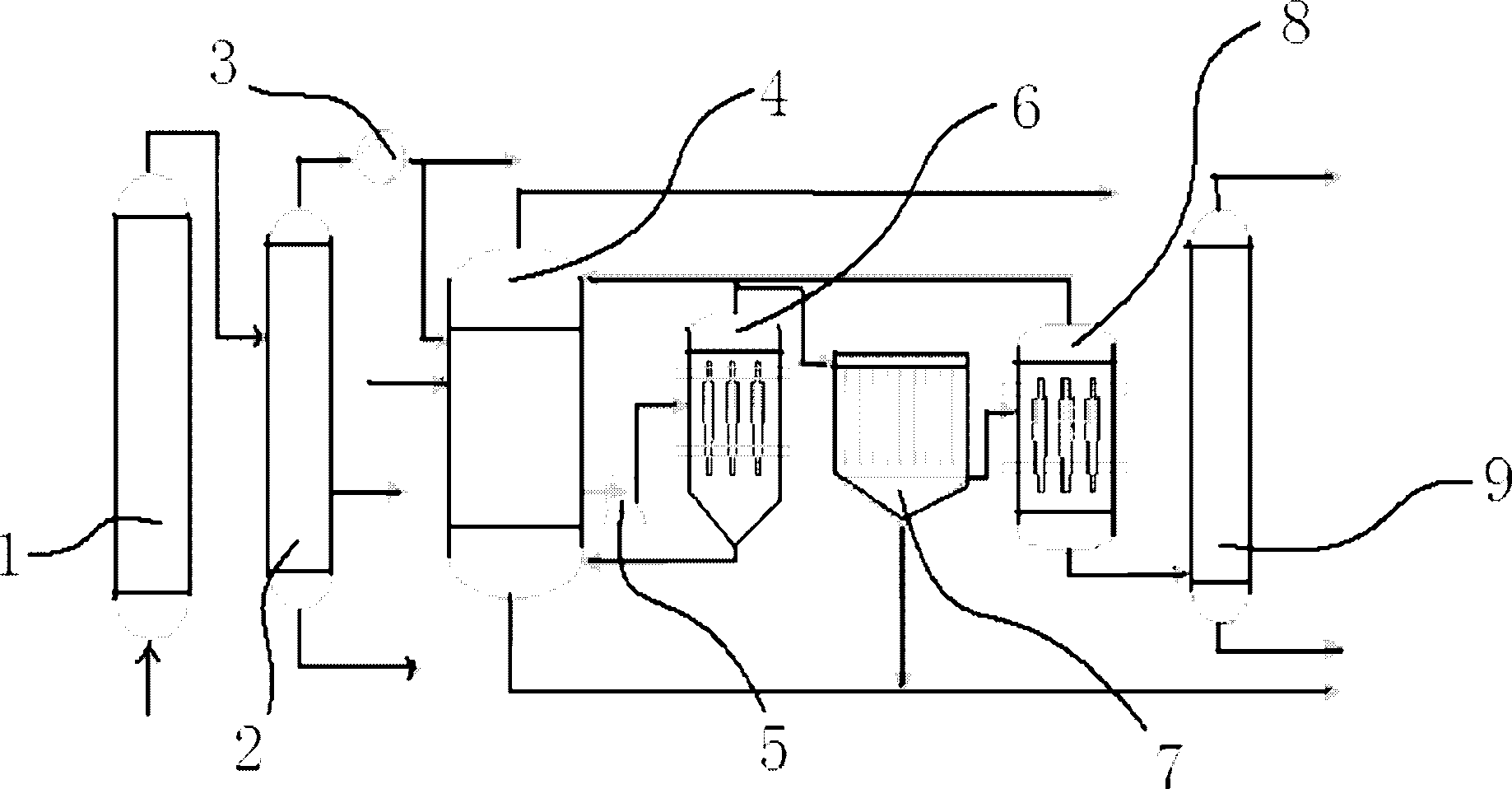

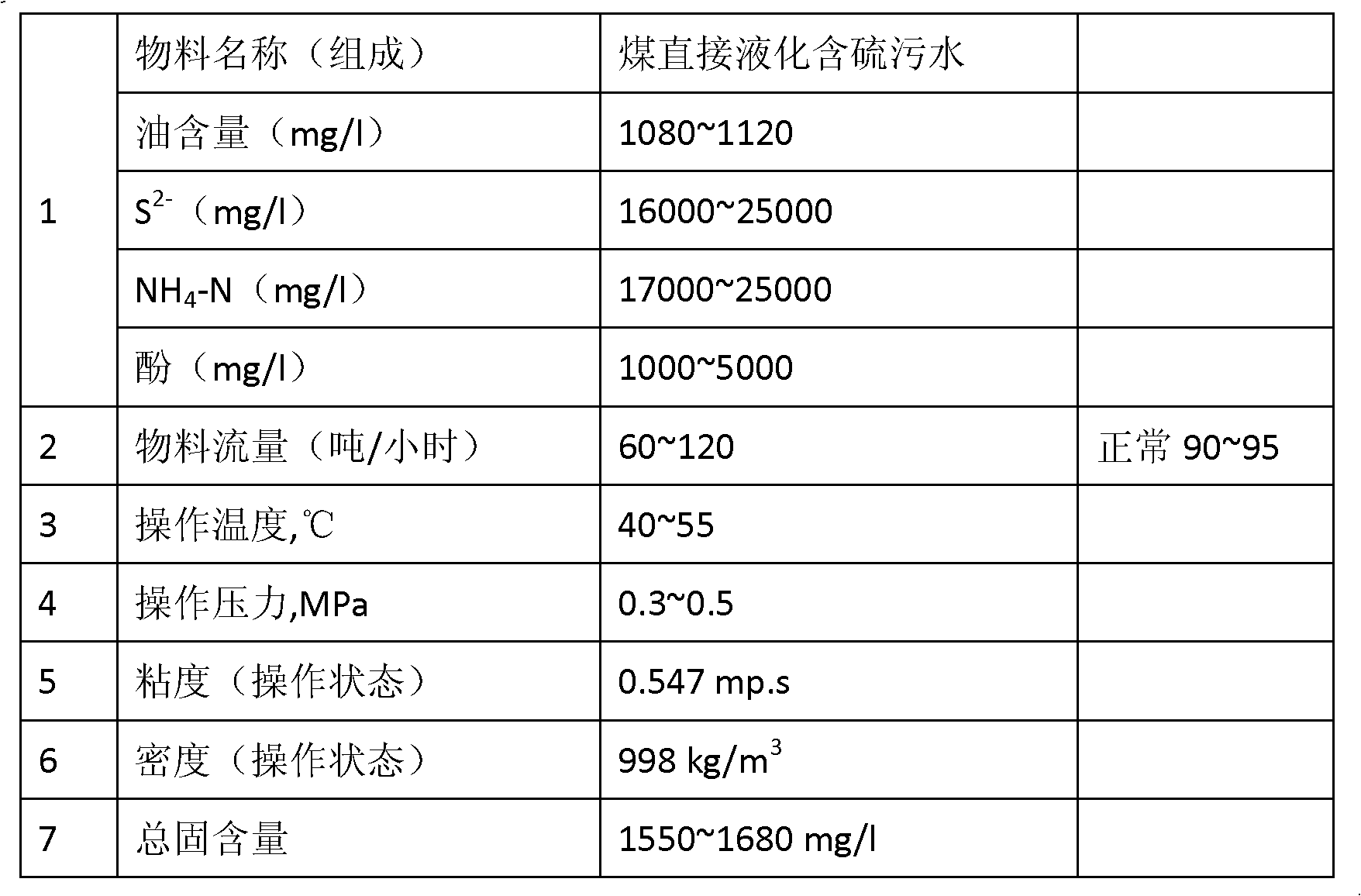

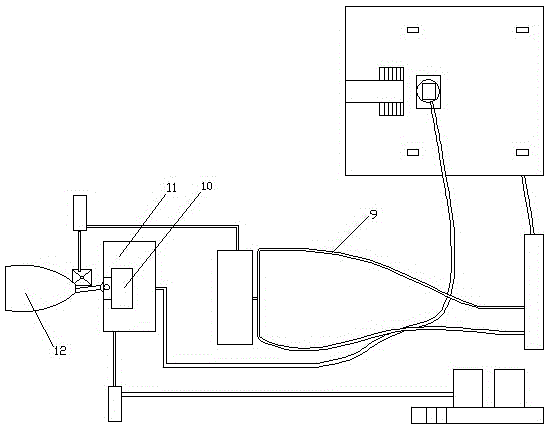

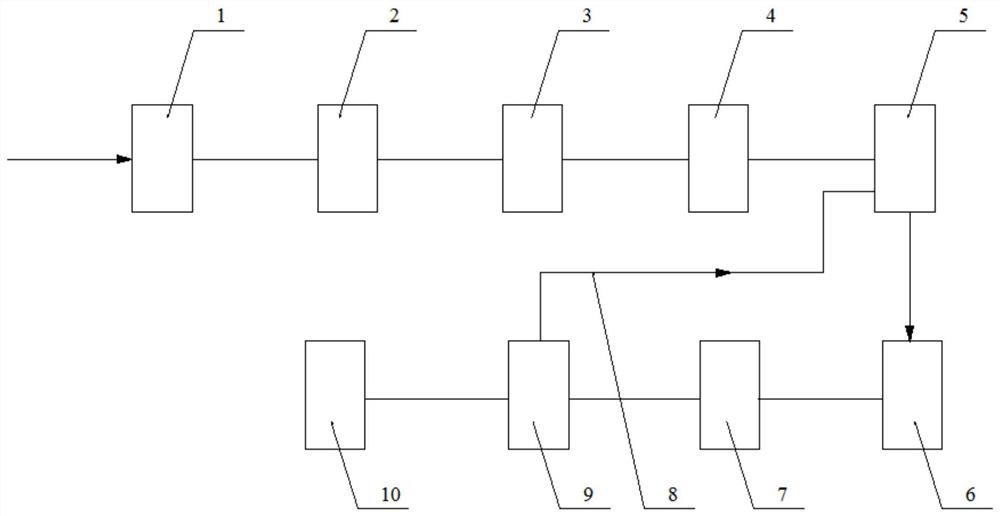

Method and device for removing coal dust and oil by enabling coal to be directly liquefied and generate sulphur-bearing waste water

ActiveCN102583821APrevent sediment cloggingReduce loadWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesCycloneCoal dust

The invention discloses a method and a device for removing coal dust and oil by enabling coal to be directly liquefied and generate sulphur-bearing waste water in the technical field of coal conversion. The method and the device can avoid deposition blocking of the coal dust in a stripping tower, reduce loads of a steam stripping device and improve steam stripping effect, the running cycle of the device is prolonged, simultaneously recycling of dirty oil is facilitated, the processing loss of the device is reduced, and the economic benefit of the device is improved. Besides, a micro cyclone separator and a cyclone deoiler which are adopted in the device are high in separating efficiency, long in continuous running cycle, small in occupied area, high in impact resistance and simple to operate and maintain. The method and the device are characterized in that the device for removing the coal dust and the oil by enabling the coal to be directly liquefied and generate the sulphur-bearing waste water comprises an adjusting tank, a sewage pump, the micro cyclone separator, a precision filter, the cyclone deoiler and the stripping tower; and sewage finally enters into the stripping tower to be treated after the sewage is treated by the adjusting tank, the sewage pump, the micro cyclone separator, the precision filter and the cyclone deoiler.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

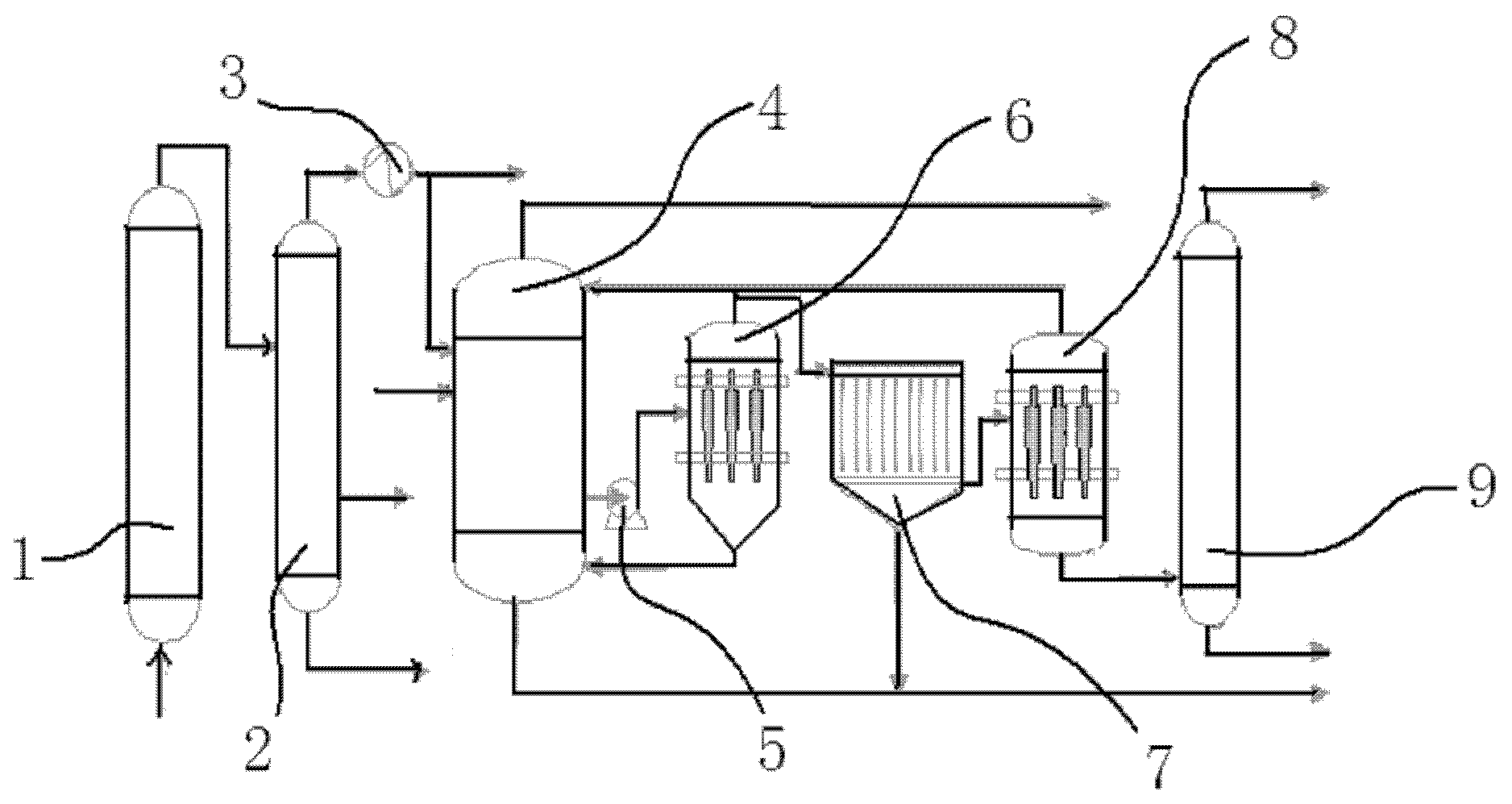

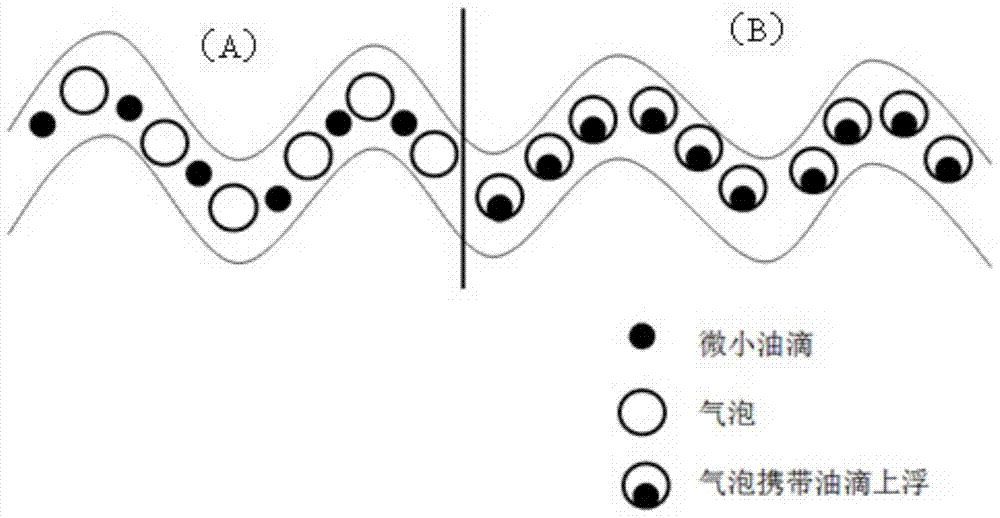

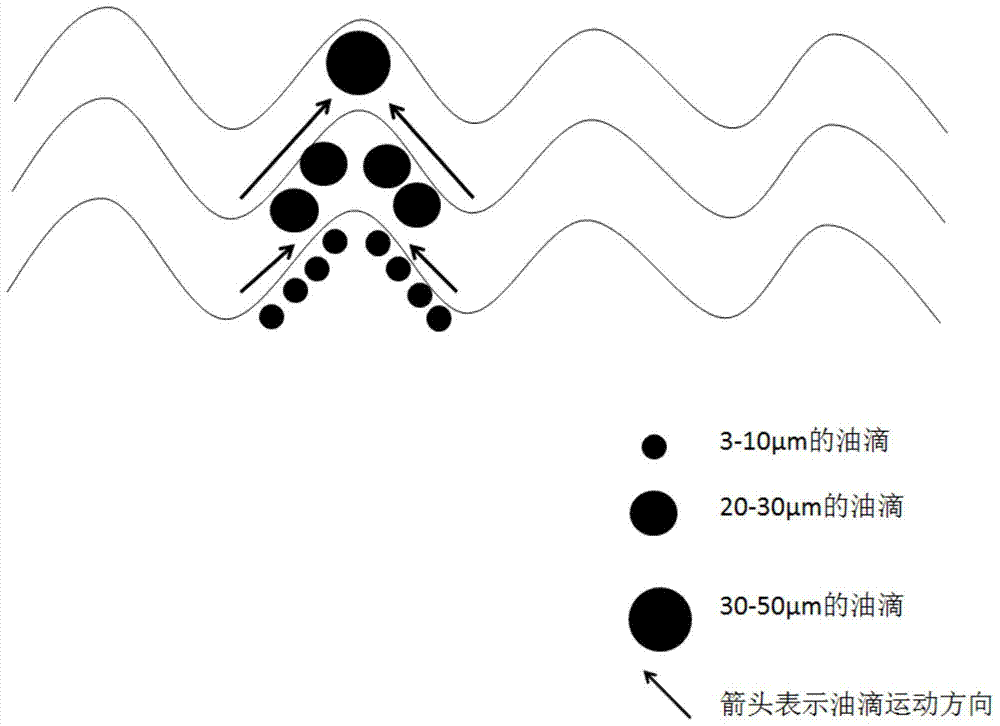

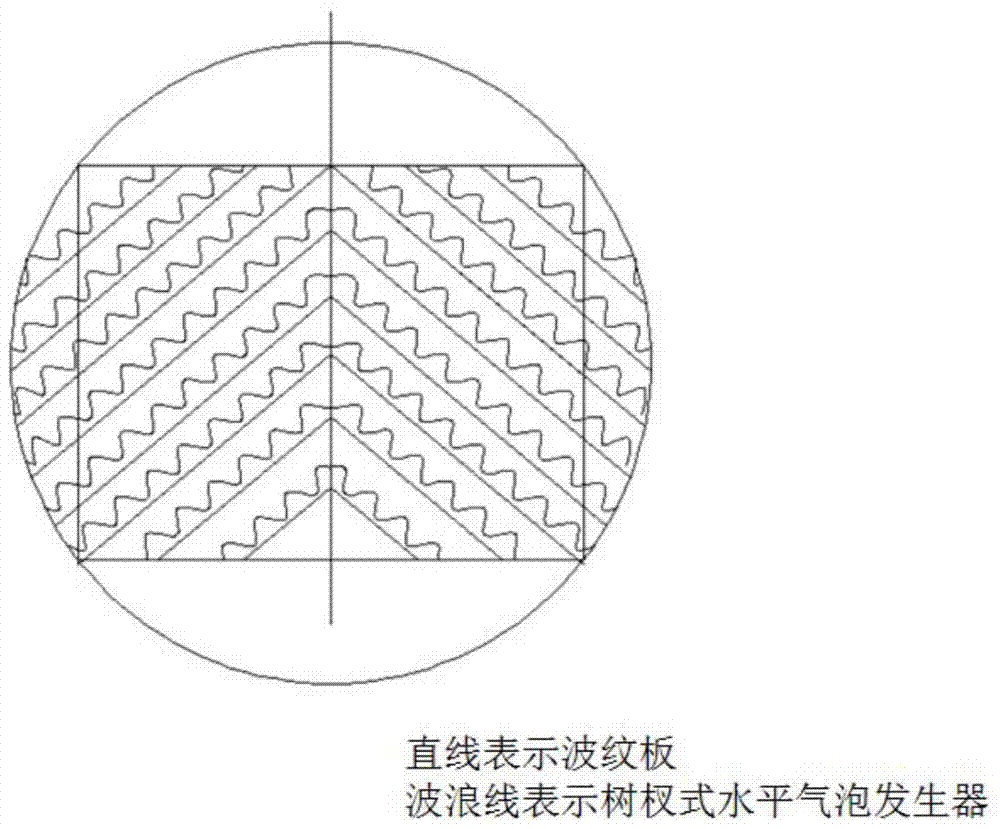

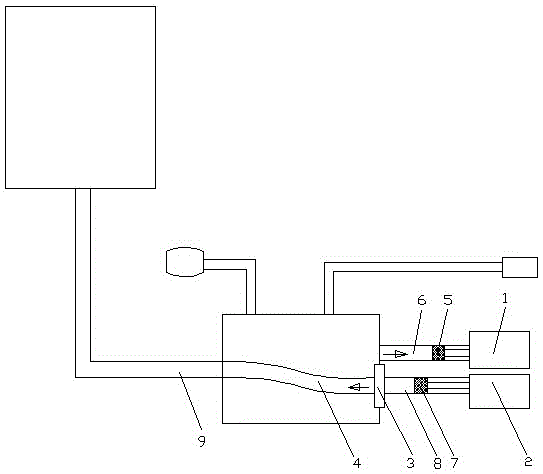

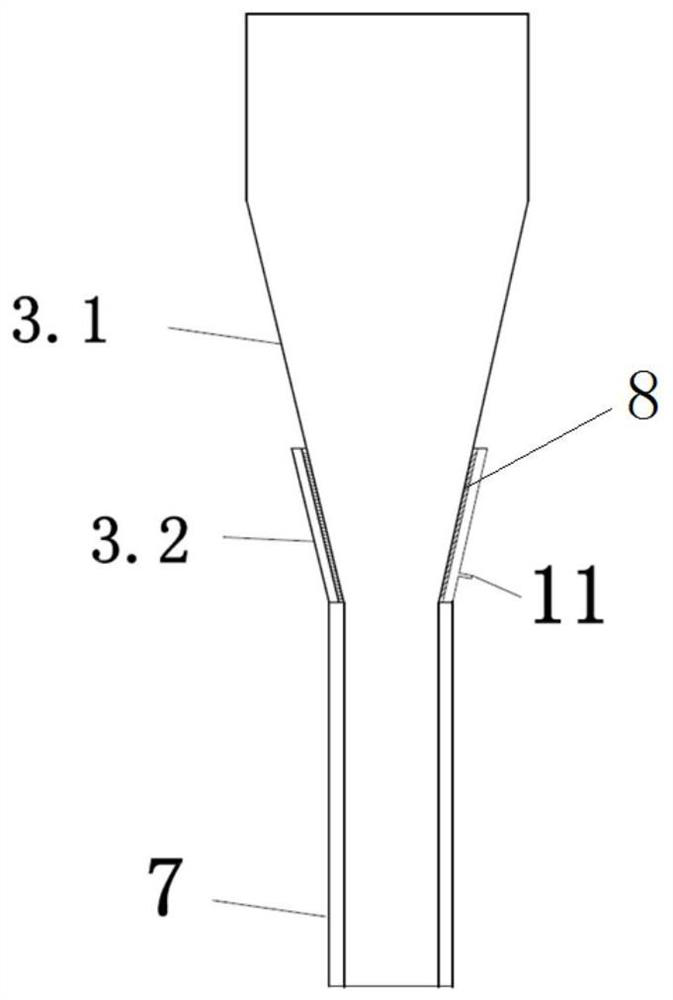

A method and device for removing oil from a horizontal air flotation coupled corrugated plate

ActiveCN104843817BPrevent sediment cloggingFast separationFatty/oily/floating substances removal devicesLiquid separationOil separationRapid processing

The invention relates to a method and a device for degreasing a horizontal air flotation coupling corrugated plate. The method is that the oily wastewater containing a small amount of solid particles passes through the branch-type horizontal air bubble generator installed in front of the corrugated plate, and the air bubbles of 10-30m are evenly brought into the interval between the inclined corrugated plates, and the oil droplets are rapidly discharged under the action of the air bubbles. Float up to the upper part of the two-layer corrugated plate, move to the crest of the corrugated plate, and quickly coalesce into large oil droplets to float and separate through the shallow pool settlement of the corrugated plate to realize the rapid separation of oil and water. The present invention also provides a set of devices for realizing the method, including a housing, a feed pipe, a branch-type horizontal bubble generator, a symmetrical perforated corrugated coalescing plate, a water outlet, an oil outlet, an oil separator, an air Several parts such as the bag and the boundary meter. The method of the present invention has fast separation speed and high efficiency, and prevents the deposition and clogging of solid particles through the inclined setting of the corrugated plate, and can be widely used in the rapid treatment process of oily wastewater containing trace solid particles.

Owner:EAST CHINA UNIV OF SCI & TECH

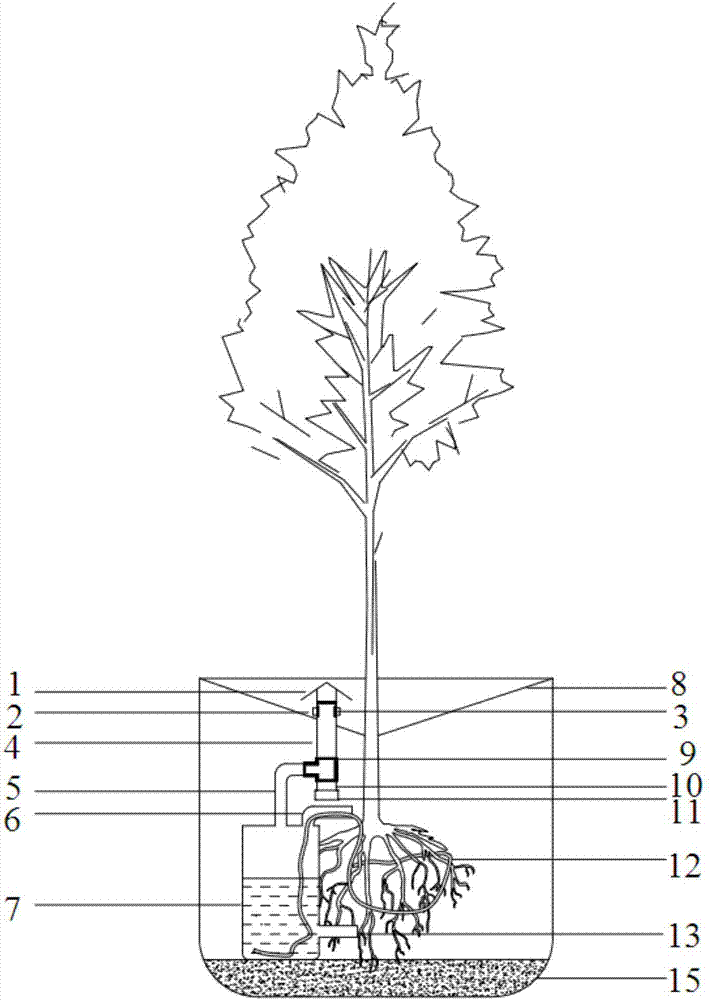

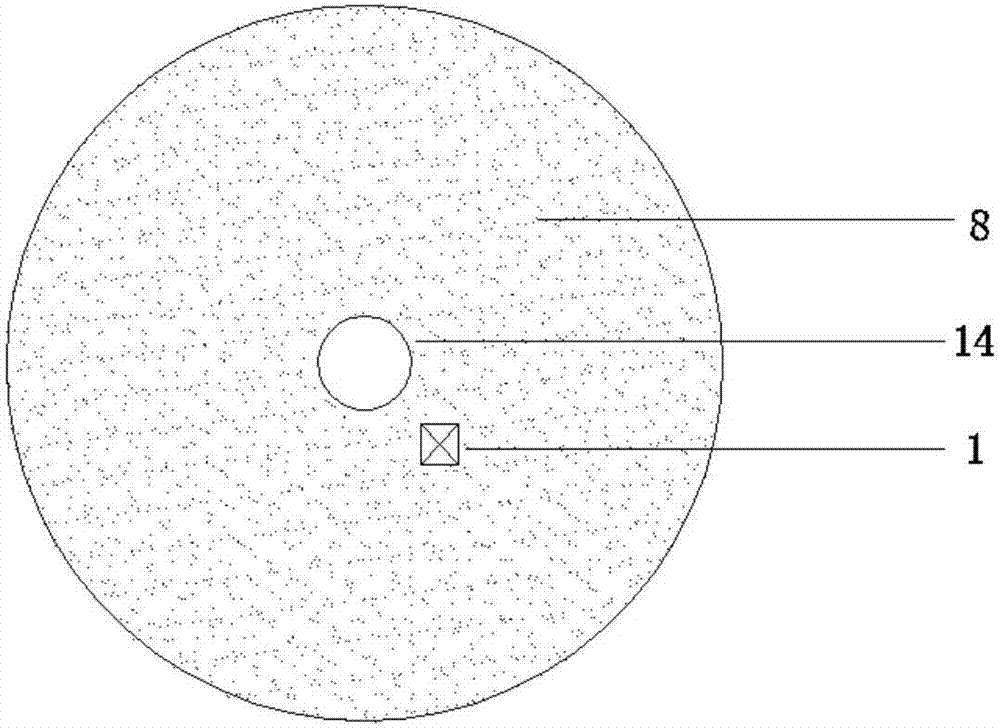

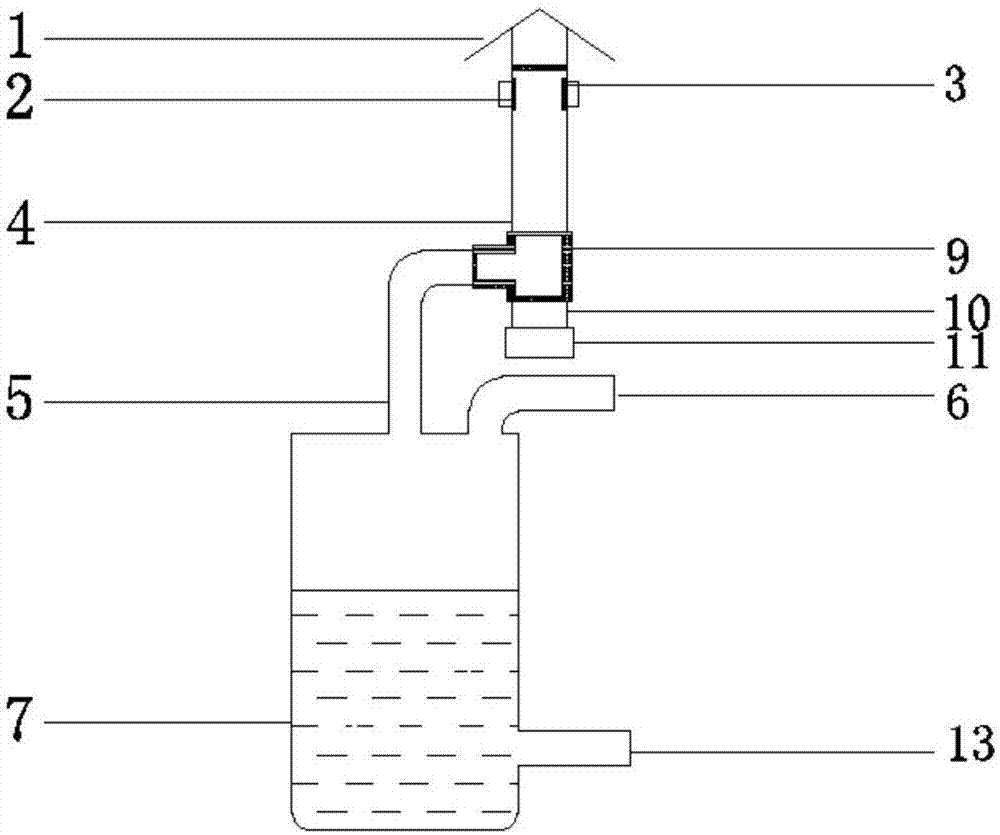

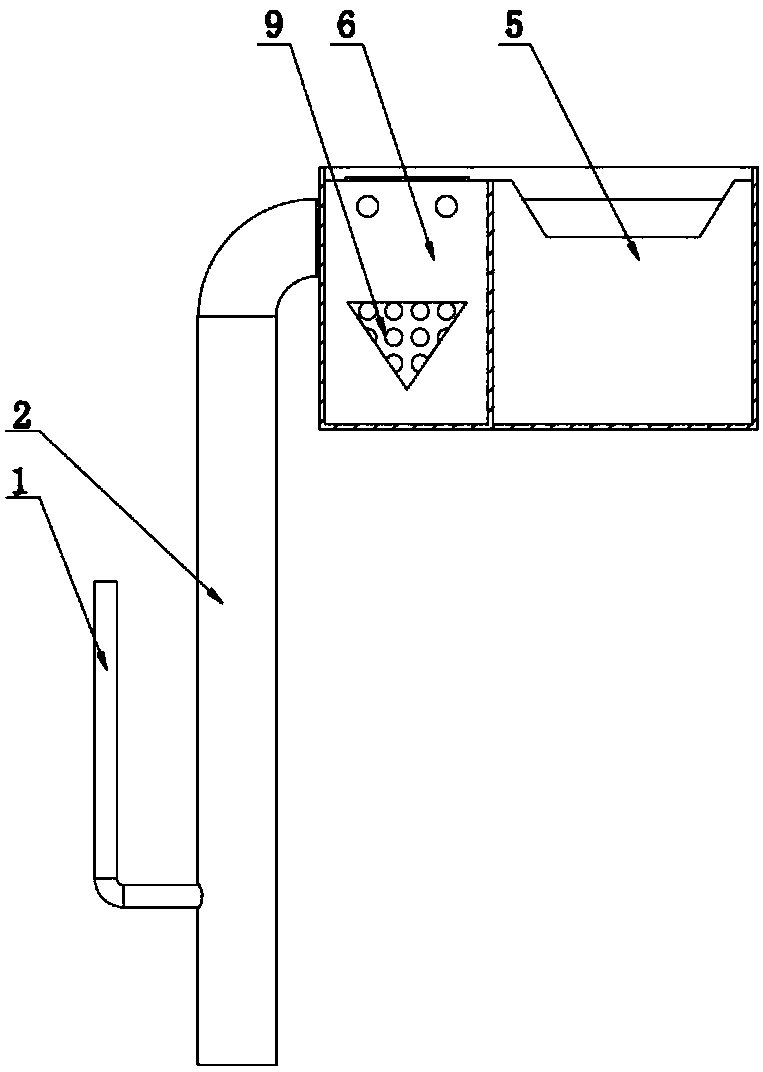

Method and device for planting trees by accumulating rain water

PendingCN107155785AImprove survival rateReduce water consumptionRoot feedersGeneral water supply conservationRainwater harvestingMoisture retention

The invention discloses a method for planting trees by accumulating rain water. The method comprises the following steps: spreading a culture medium at the bottom of a tree well; placing a tree seedling above the culture medium, and placing a water accumulation unit in the tree well; placing a water release unit between the water accumulation unit and the root of the tree seedling; fixing the tree seedling; placing a rain water collection unit above the water accumulation unit; and connecting the rain water collection unit with the water accumulation unit, so that rain water collected by the rain water collection unit is stored in the water accumulation unit and is supplied to the root of the tree seedling through the water release unit. According to the method disclosed by the invention, the culture medium having a moisture retention effect can effectively complete an automatic rain water collection process, an automatic water accumulation process and an automatic water release process, thereby providing required moisture for the tree seedling and ensuring survival of the tree seedling; the method effectively utilizes the water resource and saves high labor cost; and due to the effects of rain water interception and accumulation, the method can effectively relieve urban inland inundation and water discharge pressure. Besides, the invention also provides a device for the method.

Owner:王建军

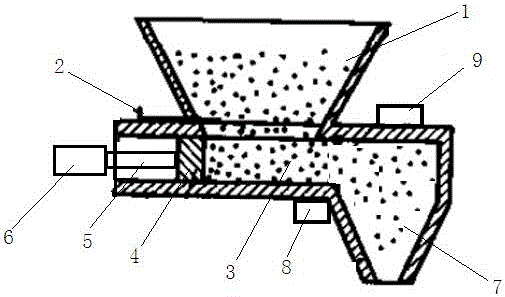

Plunger-type feed mechanism

InactiveCN105668268ASpeed up the flowPrevent sediment cloggingLarge containersLoading/unloadingEngineeringMechanical engineering

The invention discloses a plunger-type feed mechanism, which comprises a conical feed cabin; the discharge hole in the bottom part of the conical feed cabin is provided with a feed valve; the bottom part of the conical feed cabin is provided with a feed passage; a plunger is embedded into one end part of the feed passage; the outer side of the plunger is connected with a drive air cylinder through a connecting rod; the other end part of the feed passage is provided with a discharge cabin; the discharge hole of the discharge cabin is vertically down; a first vibration pump is arranged at a point where the feed passage and the discharge cabin are connected. According to the plunger-type feed mechanism disclosed by the invention, the plunger is added in the feed passage, and can move back and forth in the feed passage to push a material, so that flow velocity of the material is accelerated, and blockage is prevented; moreover, the vibration pump is added on the discharge cabin, so that material deposition and material blockage can be prevented, and the flow velocity of the material is further accelerated; and the plunger-type feed mechanism is simple in structure and easy to implement, and has a good application prospect.

Owner:SUZHOU HEYER PRECISION CO LTD

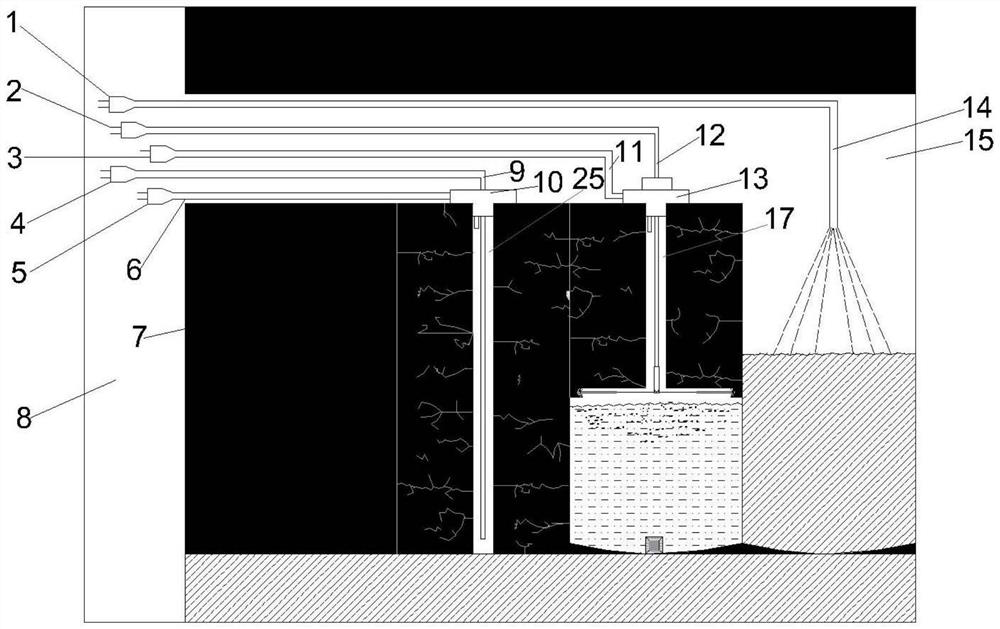

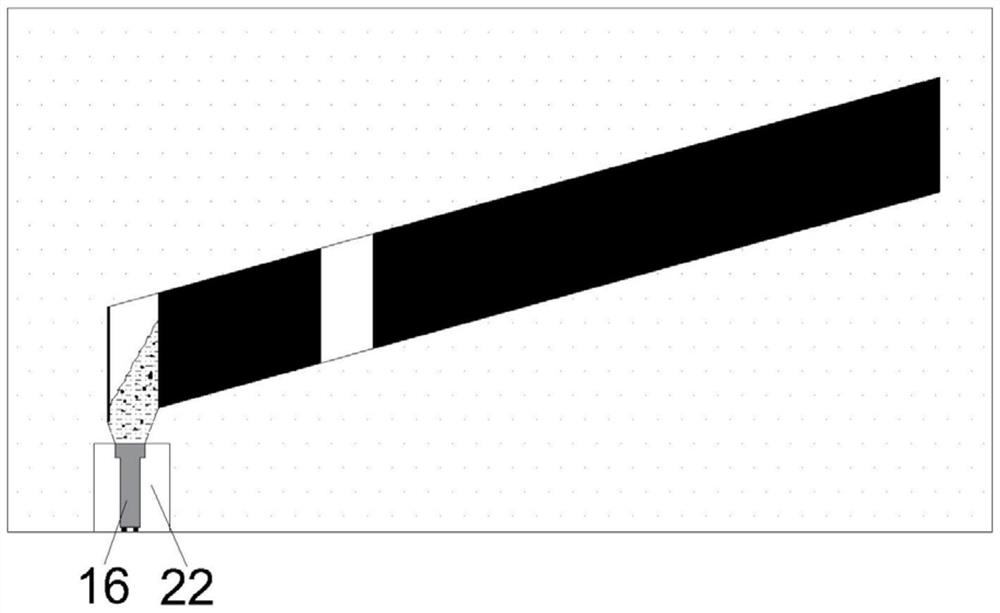

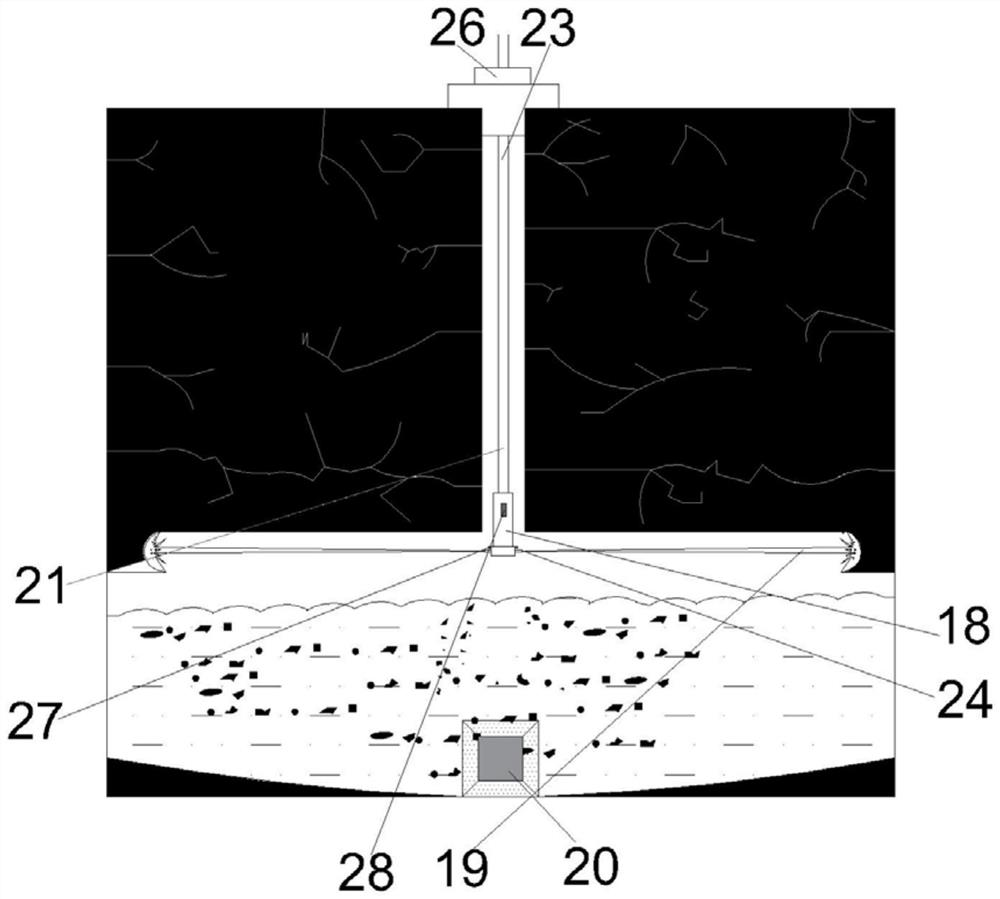

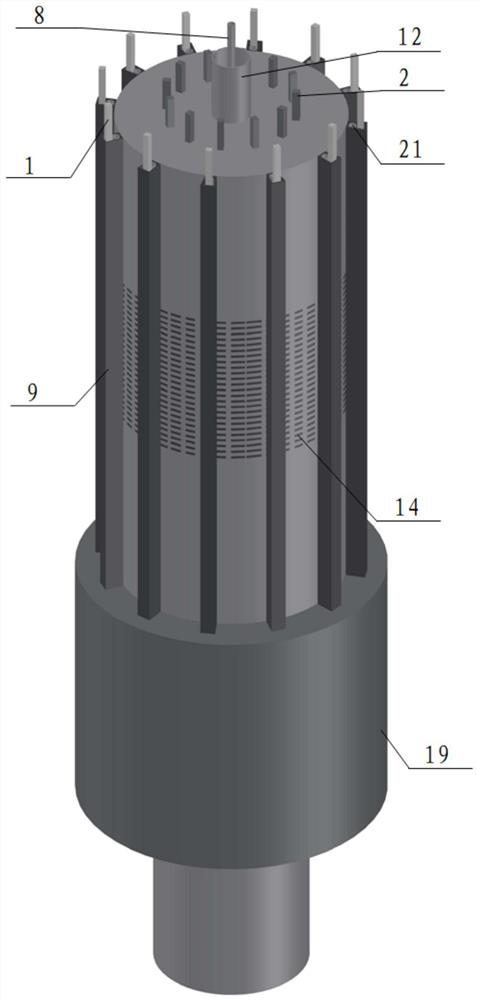

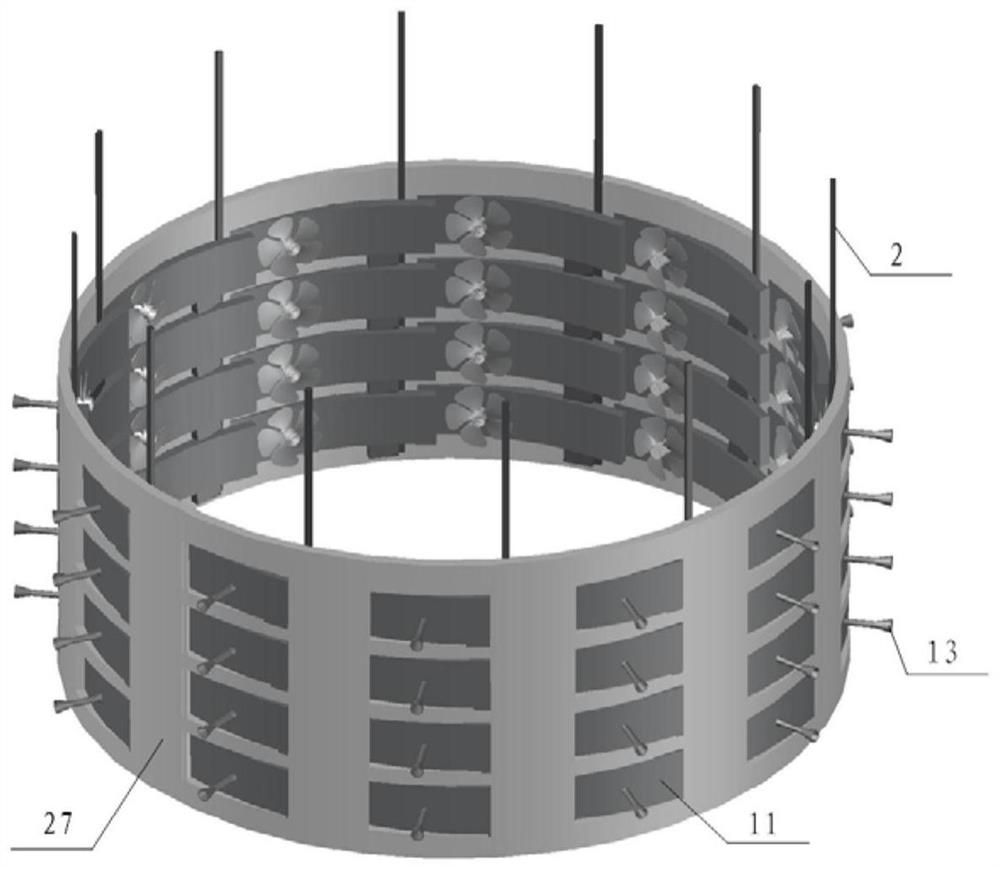

Coal and gas fluidization co-mining system and method for low-permeability inclined coal seam

ActiveCN114352345ATo achieve the effect of pressure relief and anti-reflectionEasy to recycleMining devicesDisloding machinesThermodynamicsCoal

According to the system, the outlet end of a liquid nitrogen conveying pipe in a liquid nitrogen circulation fatigue fracturing permeability increasing unit penetrates through a hole sealing plug I and then extends to the bottom, and the inlet end of a gas extraction pipe I penetrates through the hole sealing plug I and then stops at the top; a high-pressure jet device in the hydraulic fluidization mining and gas extraction unit is mounted at a hole sealing plug II, the high-pressure jet device is connected with the liquid outlet end of a high-pressure water conveying pipe, and the inlet end of a gas extraction pipe II penetrates through the hole sealing plug II and then stops at the top; the hydraulic fluidization transportation unit comprises a coal body fluidization transportation roadway and a coal body fluidization transportation pipe; the goaf paste filling unit comprises a paste pumping machine and a filling pipe. The method comprises the steps of roadway construction; coal seam drilling construction; liquid nitrogen cycle fatigue cracking permeability increasing and gas extraction are conducted; carrying out hydraulic fluidization mining and gas extraction; carrying out hydraulic fluidization transportation; and filling the goaf with paste. According to the system and the method, the fluidization co-mining operation of the coal and the gas in the low-permeability inclined coal seam can be efficiently realized.

Owner:CHINA UNIV OF MINING & TECH

Particle drilling method

InactiveCN105134080ASimplify the screening processImproving the efficiency of percussion drilling operationsDrilling machines and methodsWell drillingParticle injection

Owner:CCDC PETROLEUM CORING TECH

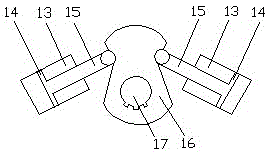

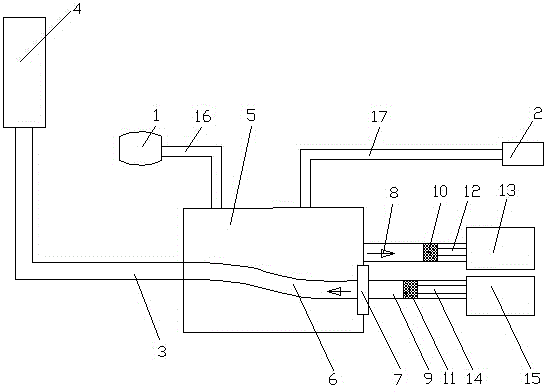

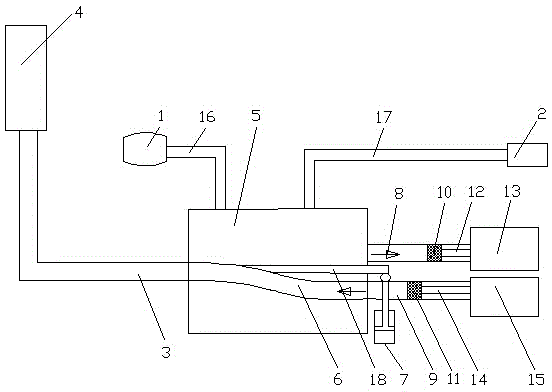

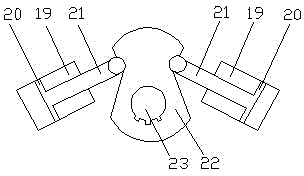

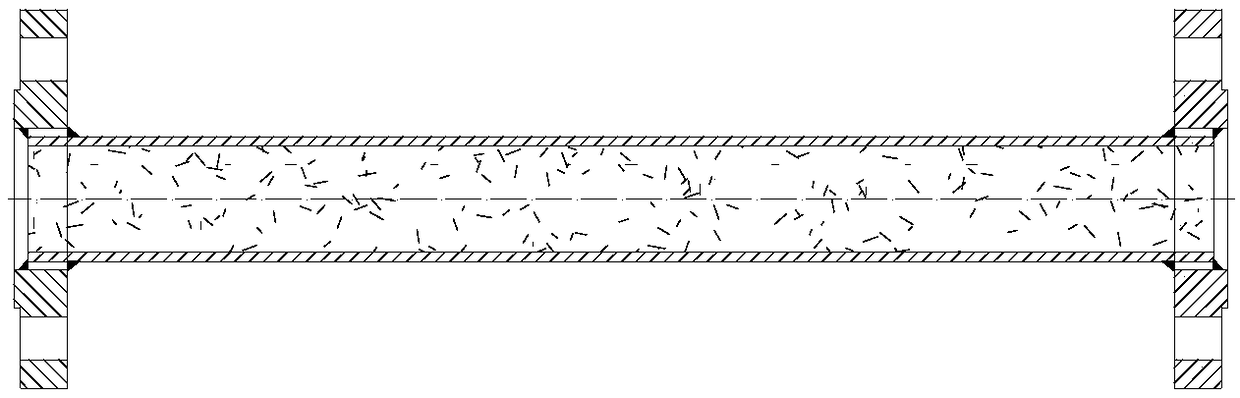

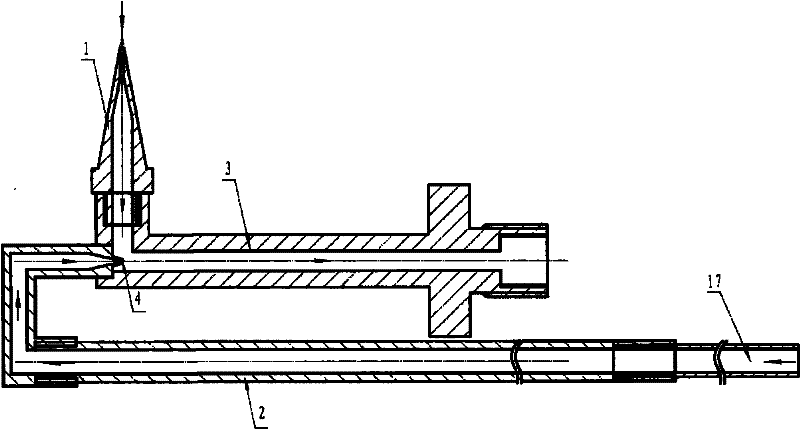

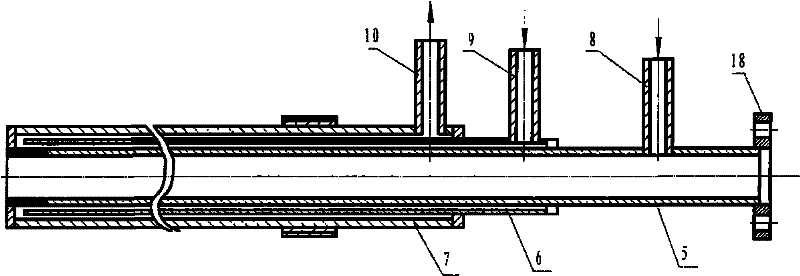

Double-injection pump continuous injection device applicable to particle well drilling

InactiveCN104963631AGuaranteed continuityPrevent sediment cloggingConstructionsLiquid/gas jet drillingHydraulic cylinderWell drilling

The invention discloses a double-injection pump continuous injection device applicable to particle well drilling, and belongs to the technical field of oil-gas drilling engineering. The double-injection pump continuous injection device comprises a particle mixing hopper. A reversing pipe is arranged inside the particle mixing hopper. A swing hydraulic cylinder is connected to the reversing pipe. A first conveying cylinder and a second conveying cylinder are connected to the particle mixing hopper. A first piston is arranged inside the first conveying cylinder. A second piston is arranged inside the second conveying cylinder. The first piston is connected to the first hydraulic cylinder through a first piston rod. The second piston is connected to the second hydraulic cylinder through a second piston rod. One end of the reversing pipe is communicated with a high-pressure pipeline, and the other end of the reversing pipe is communicated with the first conveying cylinder or the second conveying cylinder. A slurry pump is communicated with the particle mixing hopper through a first pipeline. A screw conveyor is communicated with the particle hopper through a second pipeline. According to the double-injection pump continuous injection device, injection continuity of particles into a well can be ensured, the working efficiency of particle impact drilling is effectively improved, the high-pressure area coverage range is small, and safety risk is lowered.

Owner:CCDC PETROLEUM CORING TECH

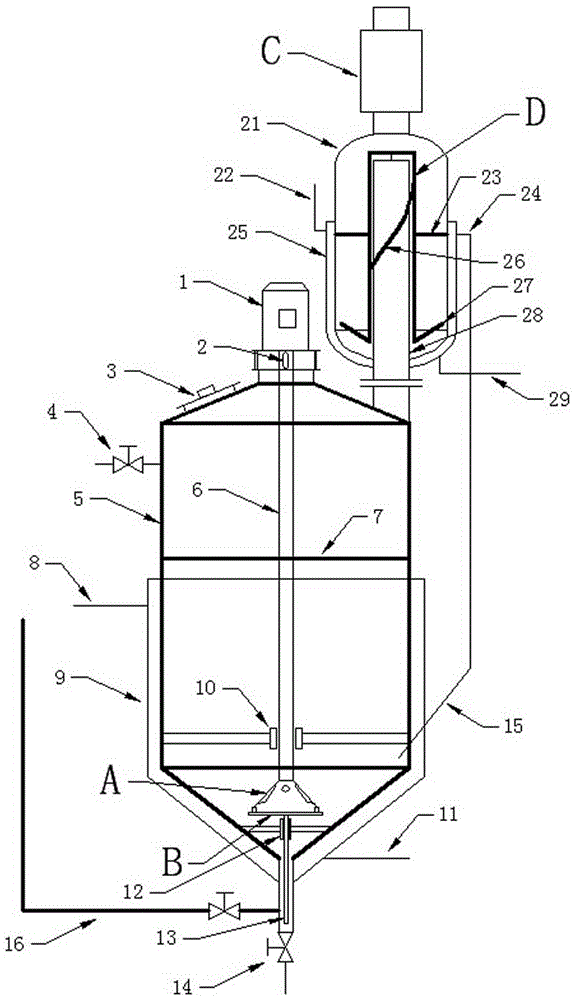

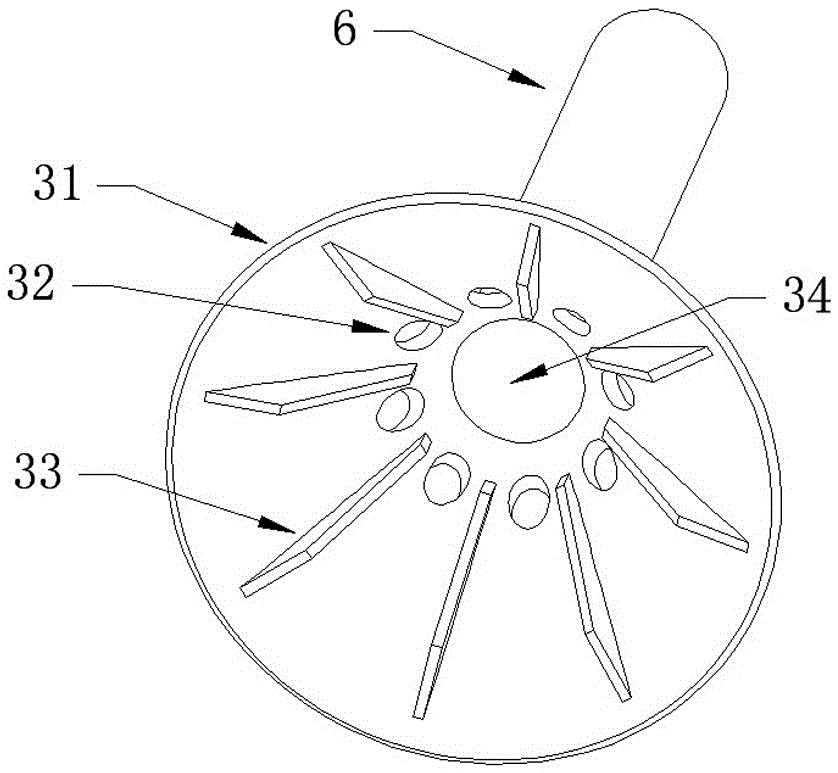

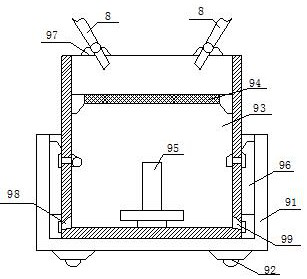

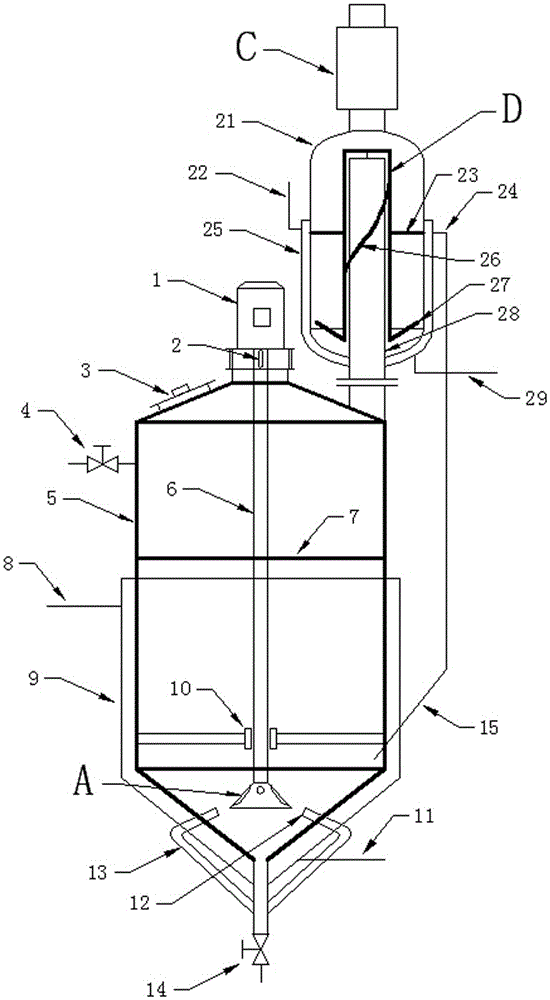

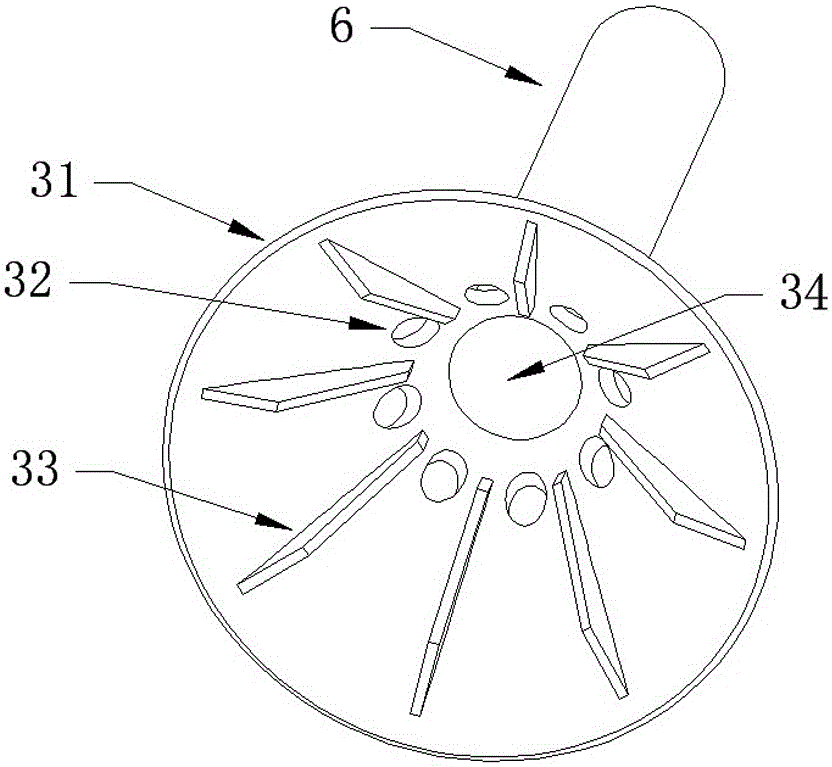

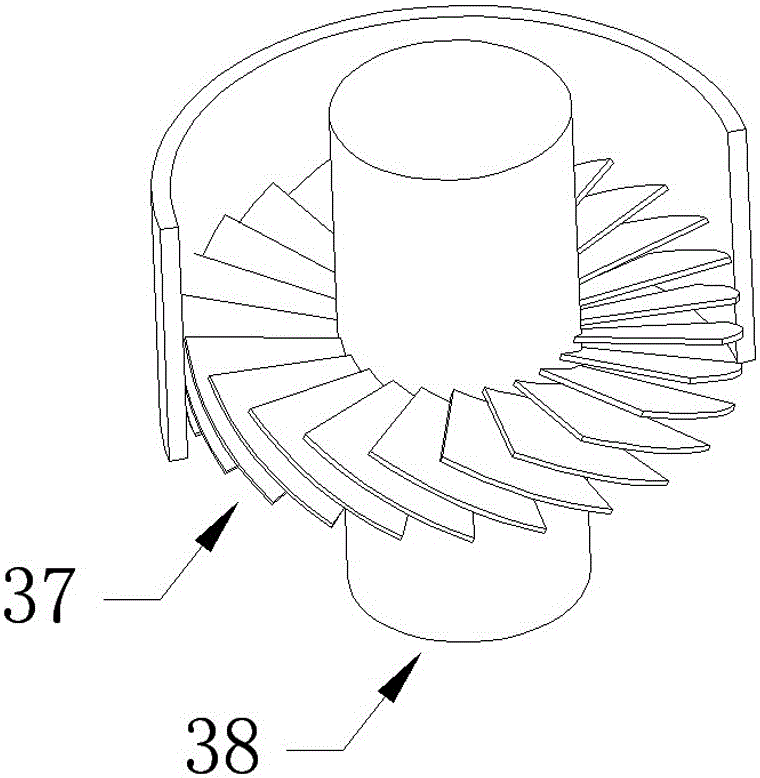

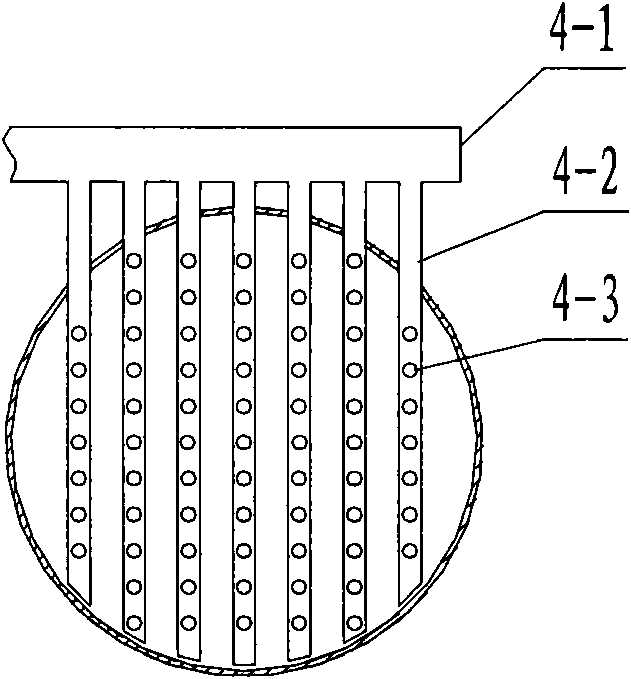

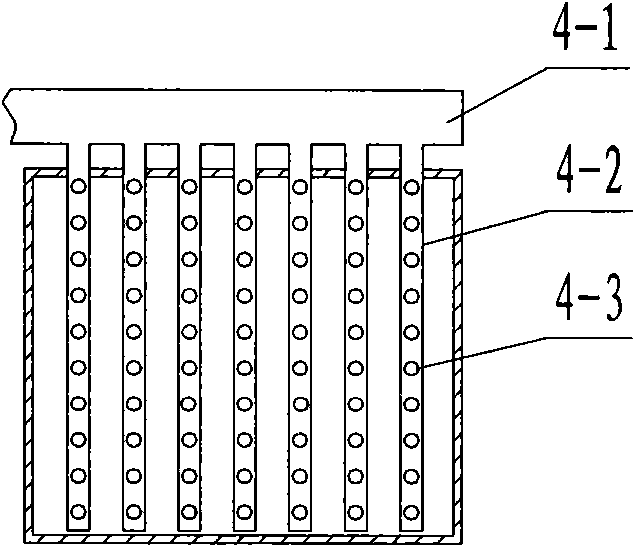

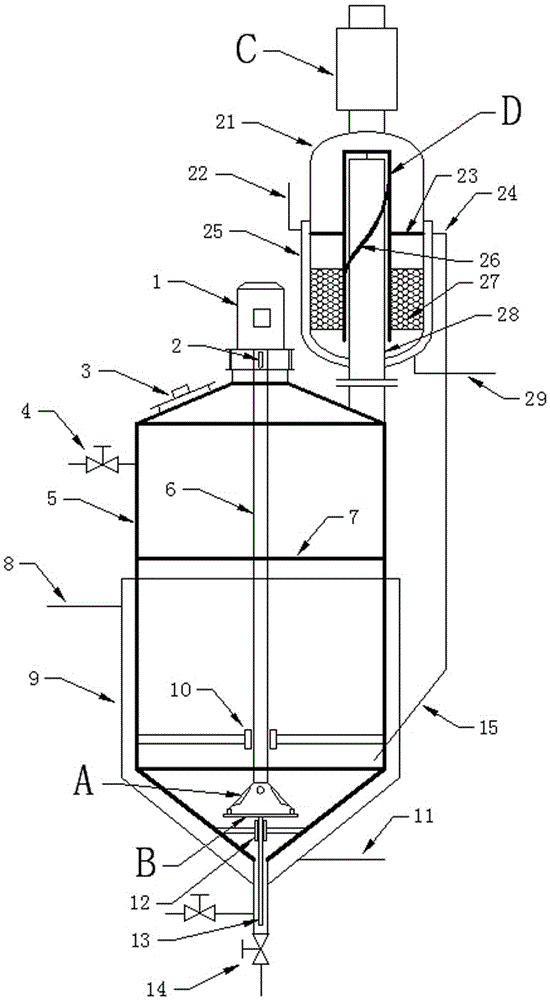

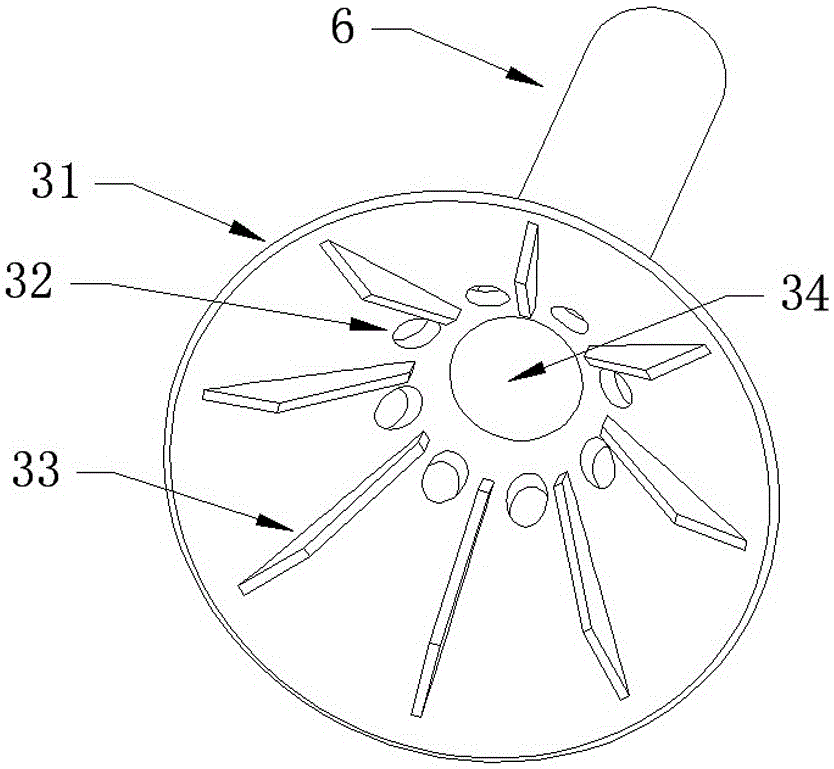

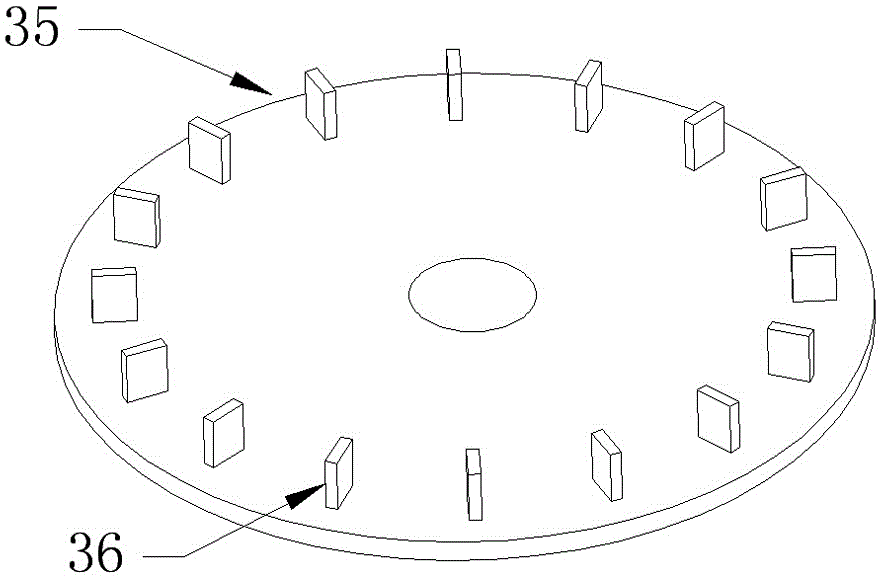

Efficient kiwi fruit wine fermentation device capable of realizing total aroma recovery

ActiveCN105087281AAchieve condensationAchieve effectivenessAlcoholic beverage preparationCycloneAgricultural engineering

The invention discloses an efficient kiwi fruit wine fermentation device capable of realizing total aroma recovery. A fermentation barrel and a tail gas purifier are connected through a flange; a stirring motor is connected with a conical cover through a hollow shaft and then inserted into the fermentation barrel, blades and liquid inlets are arranged in the conical cover, air inlets are evenly and circumferentially distributed and formed in the upper part of the hollow shaft, a liquid moving plate is arranged in the fermentation barrel and placed on a bottom valve after being connected with a hollow pipe shaft, and the conical bottom of the fermentation barrel is connected with a compressed air pipe; a jacket is arranged outside the tail gas purifier, a middle pipe and a spiral fin cylinder are arranged inside the tail gas purifier to form a jacket structure, and a cyclone is arranged at an outlet of the tail gas purifier. Supplement of air (oxygen) in the fermentation barrel is automatic and convenient, the liquid flow mixing action is complete and full, and the fermentation efficiency is very high; the device can prevent material deposition and blockage conveniently, reliably and efficiently; the tail gas purifier is multi-stage, efficient and very good in heat transfer, mass transfer and gas-liquid separation effect, aroma leakage is effectively prevented, and automatic and efficient fermentation of total aroma type kiwi fruit wine is realized.

Owner:韩雷

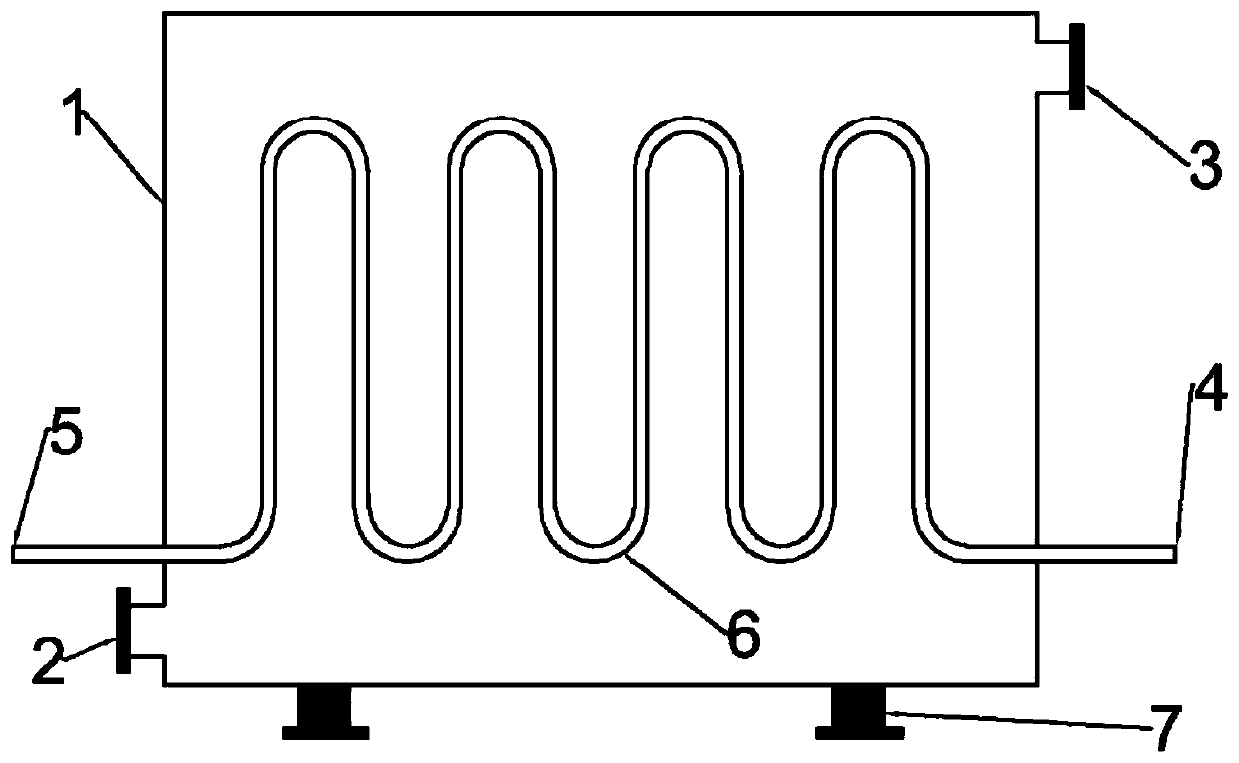

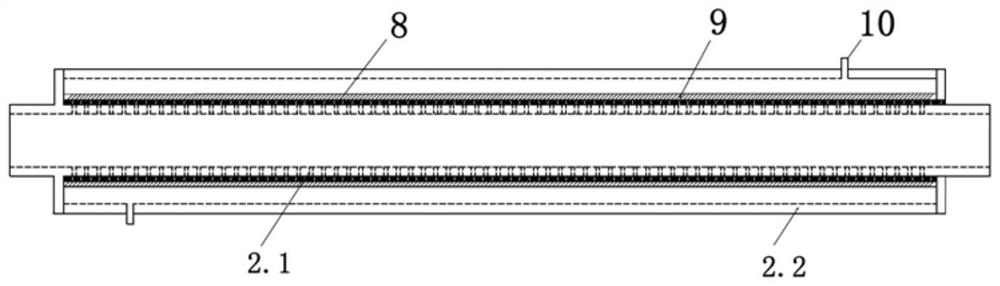

Heat exchanger with spiral baffle plate and corrugated tube for liquid food sterilization

PendingCN110160389AImprove heat transfer coefficientAchieving strong perturbationCorrosion preventionHeat exchanger casingsEngineeringThermal efficiency

The invention relates to a heat exchanger with a spiral baffle plate and a corrugated tube for liquid food sterilization. The heat exchanger comprises an outer sleeve, a heat exchange tube and the spiral baffle plate. The heat exchange tube is arranged in the outer sleeve and a cavity is formed between the inner wall of the outer sleeve and the outer wall of the heat exchange tube; liquid food, the flow direction of which is opposite to that of a heating fluid, is introduced into the heat exchange tube, and exchanges heat with the heating fluid to reach a sterilizing temperature, and the heatexchange tube is the corrugated tube, so that the flowing liquid food is disturbed continuously by cyclical fluctuation changes of expansion and compression; the spiral baffle plate is located in thecavity for increasing the flow rate of the heating fluid and forms a structure which increases the turbulence effect of the heating fluid together with the heat exchange tube. The heat exchanger playsefficient heating and sterilizing roles to non-Newtonian fluid food such as seafood sauce and overcomes the defects that a common sterilizing pot is discontinuous in production, other heat exchangershave flowing dead angles for sterilizing the liquid food such as seafood sauce, the liquid food is likely to deposit to block the heat exchangers, and the heat efficiency is not high.

Owner:广西壮族自治区特种设备检验研究院

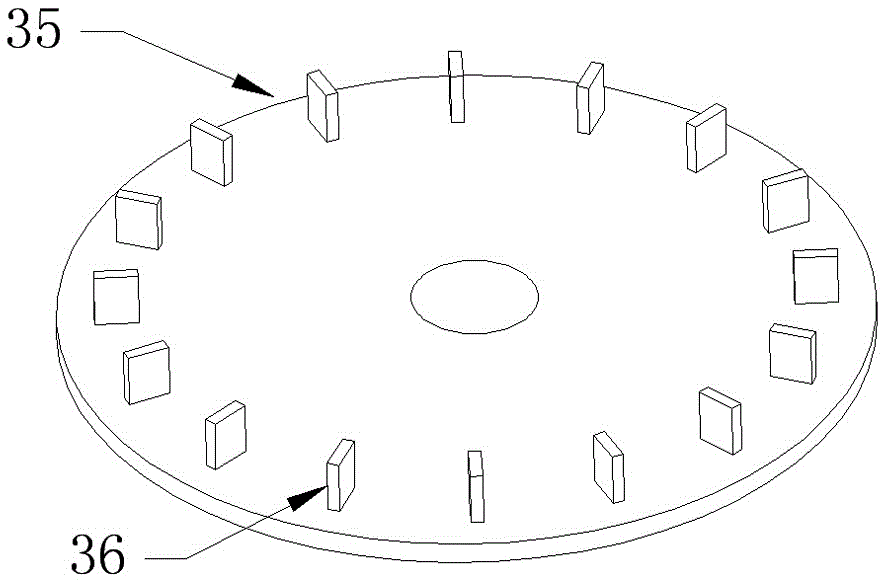

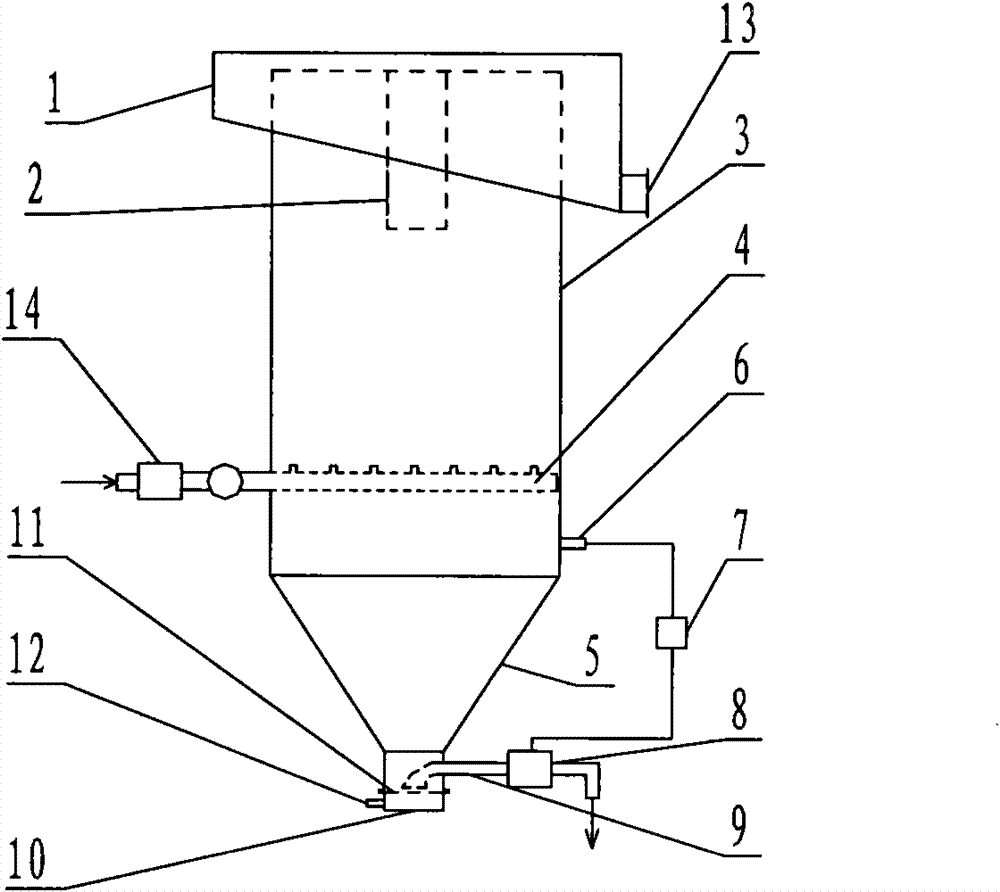

Floating valve type anti-blocking fluidization ash conveying method and system for dust remover

PendingCN108639592APrevent sediment cloggingSolve the blockageLarge containersBulk conveyorsEngineeringNitrogen gas

The invention provides a floating valve type anti-blocking fluidization ash conveying method and system for a dust remover. The floating valve type anti-blocking fluidization ash conveying system comprises the dust remover, a fluidization device and a nitrogen gas gun, wherein an ash hopper is arranged at the lower end of the dust remover; an ash guiding pipe penetrates through the side wall of the ash hopper, and an outlet of the ash guiding pipe is connected with an ash-conveying gas-supplying pipe; the fluidization device is fixedly arranged at the lower end of the ash hopper, the fluidization device is located below an inlet of the ash guiding pipe, a fluidization device gas-supply pipe is connected with an inlet at the lower end of the fluidization device, and a plurality of floatingvalves capable of ventilating are arranged at intervals at the upper end of the fluidization device; and the nitrogen gas gun comprises a nitrogen gas tank and a plurality of injection pipes, whereinthe injection pipes penetrate through the fluidization device at intervals in the circumferential direction, inlets of the injection pipes are connected with the nitrogen gas tank, and outlets of theinjection pipes penetrate through the fluidization device and are provided with torrent injectors. According to the floating valve type anti-blocking fluidization ash conveying method and system for the dust remover, dense-phase pneumatic ash conveying is realized in a mode of combining fluidization with ash conveying, continuous blockage of ash is solved, ash conveying is reliable, and the cost is low.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

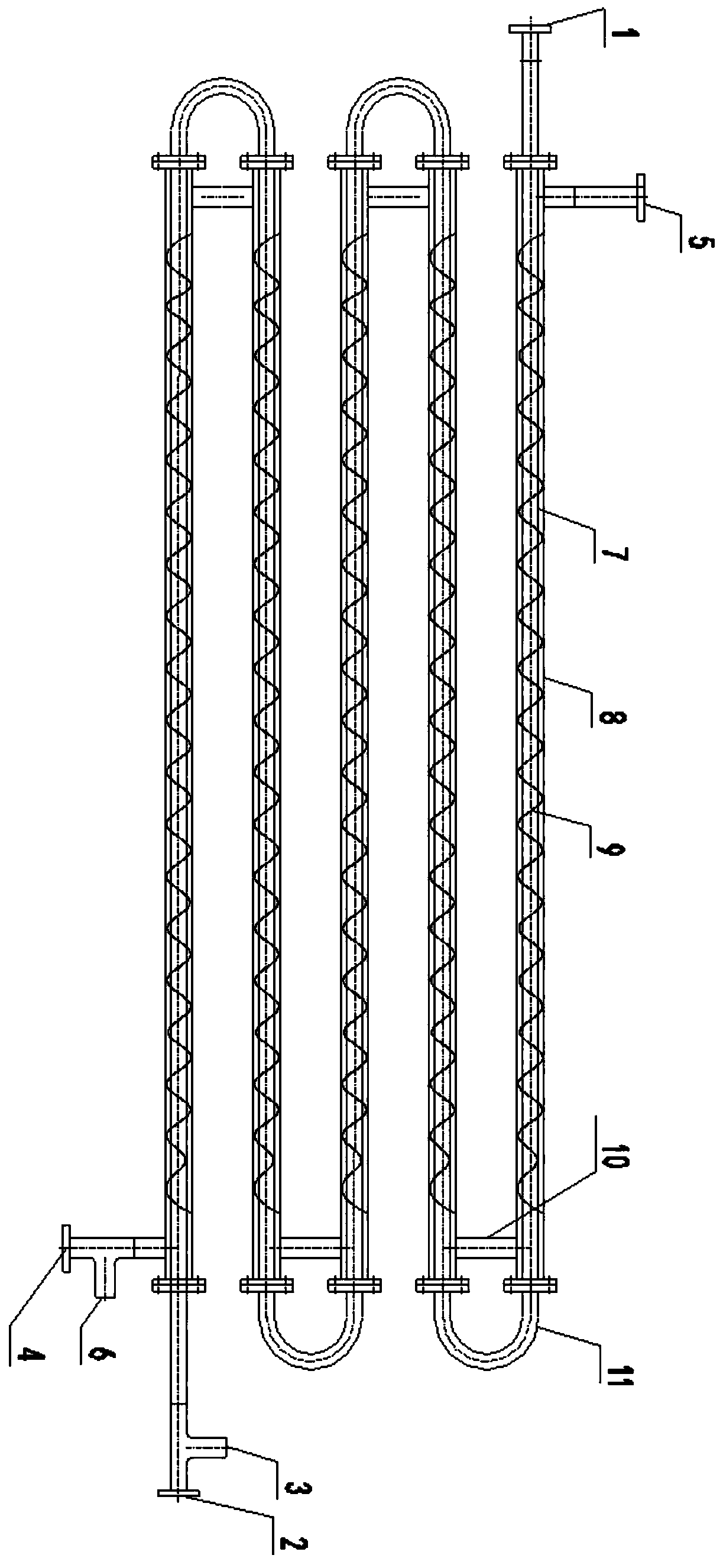

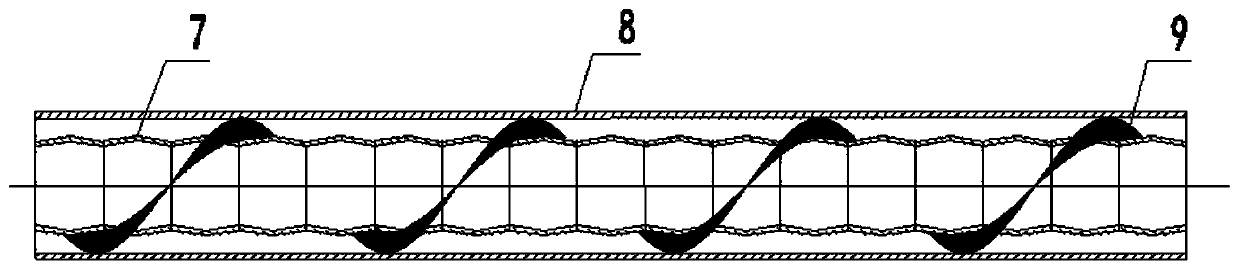

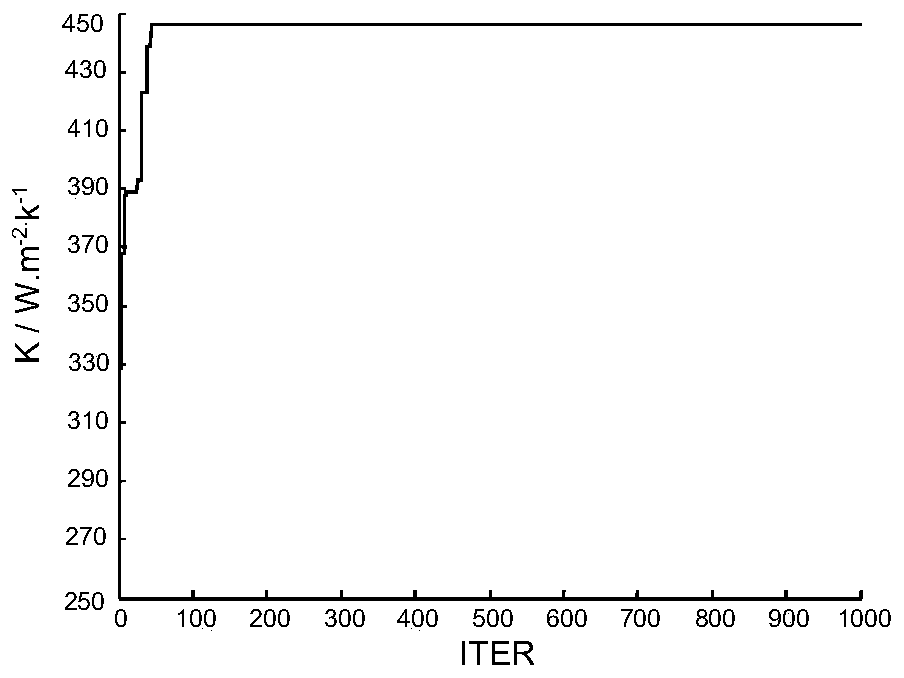

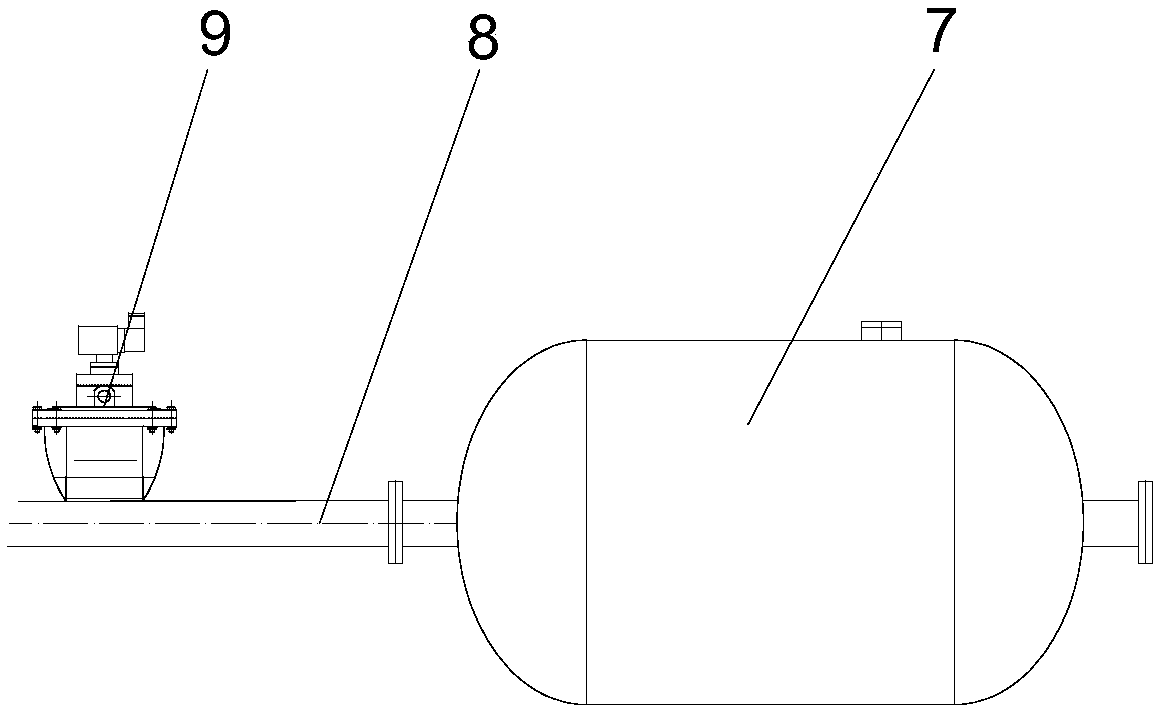

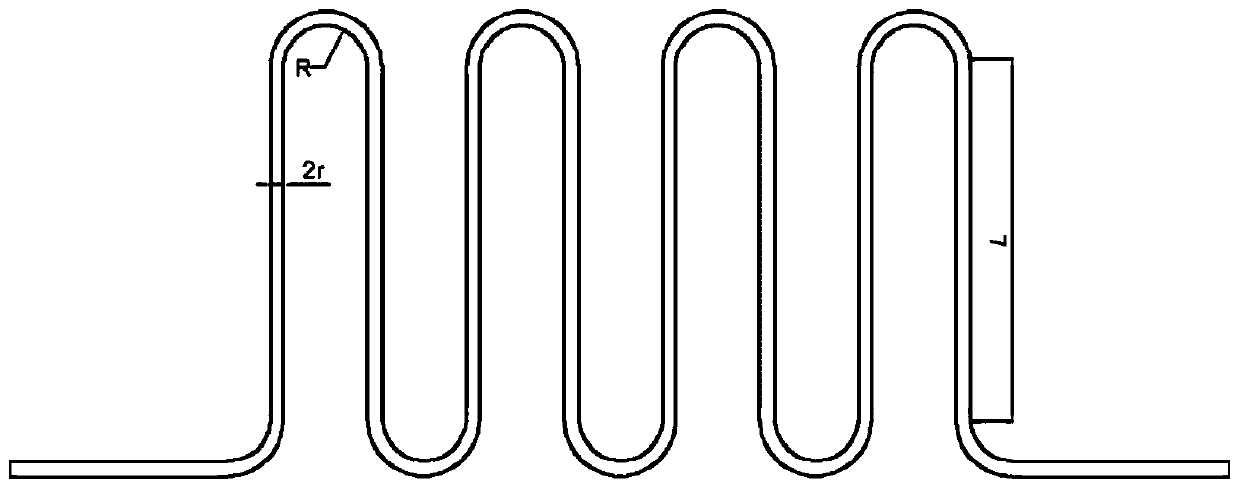

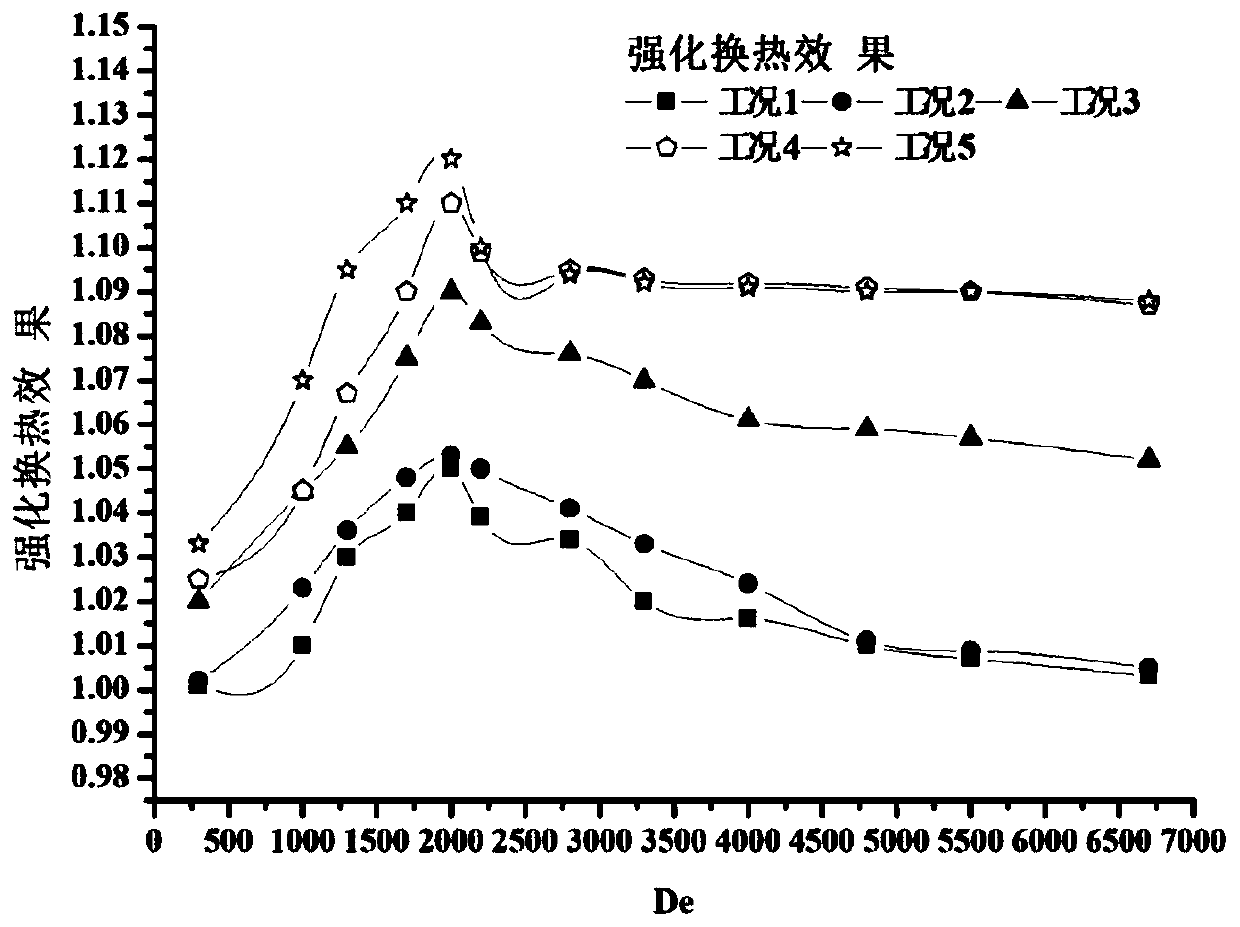

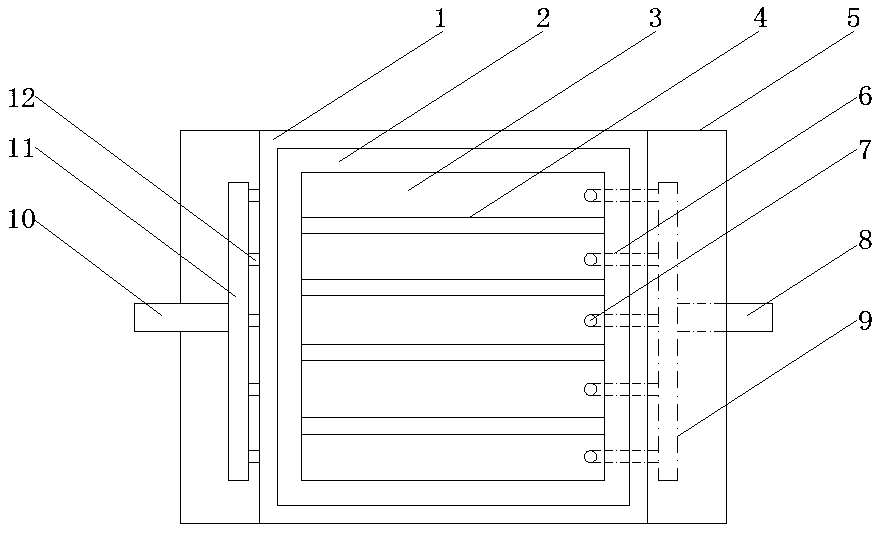

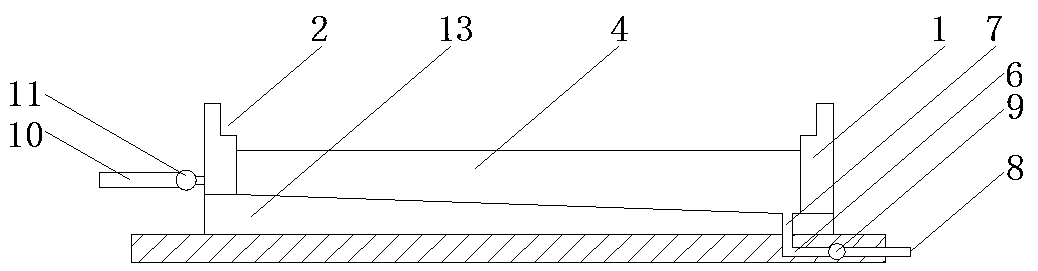

Efficient snakelike heat exchange device utilizing Dean Vortice effect

InactiveCN109945691AImprove heat transfer efficiencyImprove operational efficiencyChemical industryStationary tubular conduit assembliesChemical industryLinear loss

The invention relates to an efficient snakelike heat exchange device utilizing the Dean Vortice effect. The efficient snakelike heat exchange device utilizing the Dean Vortice effect comprises a shell, a cooling medium inlet, a cooling medium outlet, a process medium inlet, a process medium outlet, a support and the like. When fluid medium flows in a snakelike heat exchange pipe, the Dean Vorticewith symmetrical vertex core distribution can be formed, and a remarkable acceleration function is achieved on fluid heat exchange. According to the efficient snakelike heat exchange device utilizingthe Dean Vortice effect, by analyzing and evaluating the intensity of the Dean Vortice and the heat exchange efficiency, the Dean Vortice intensity index corresponding to the optimum heat exchange efficiency is selected, optimal design is conducted on the structural parameter of the snakelike heat exchange pipe and the dimension parameter of the shell of the efficient snakelike heat exchange device, so that the fluid medium can reach the full turbulence state in the tube pass flowing process under the conditions of a small resistance force and linear loss, the thicknesses of a flow boundary layer and a temperature boundary layer close to the tube wall can be effectively lowered, the initiative convection heat exchange process is enhanced in the medium flow process, and the overall heat exchange efficiency of the efficient snakelike heat exchange device utilizing the Dean Vortice effect is improved. The efficient snakelike heat exchange device utilizing the Dean Vortice effect can be widely applied to the fields of oil refining, chemical industry, light industry, sewage treatment and the like and is wide in application range, high in heat exchange efficiency, excellent in performance and high in practicability,

Owner:通孚能环(南通)科技有限公司

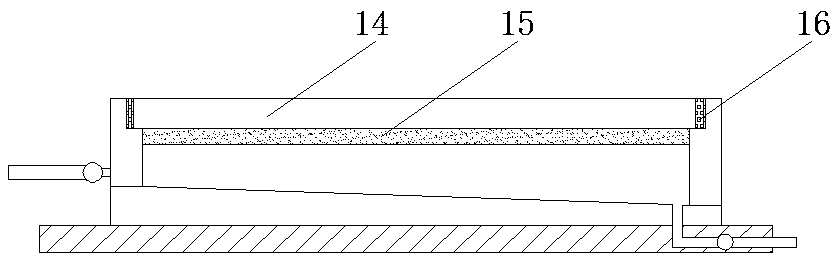

Base plate device used for printing circuit board plug holes

PendingCN108633184APrevent sediment cloggingSimple structurePrinted circuit aspectsPrinted circuit manufactureEngineeringProcessing cost

The invention discloses a base plate device for printed circuit board plug holes. The base plate device comprises a frame plate, a flow guide plate, a fixed base, a water outlet collecting pipe and awater inlet shunting pipe, and an inclined bottom plate is fixedly arranged at the top of the fixed base and located in the middle position, the width of the inclined bottom plate is the same as the width of the fixed base, frame plates are fixedly arranged at the top of the inclined bottom plate and located at the four edges, limiting grooves are formed in the top of the frame plates, and the limiting grooves are formed in the inner sides of the frame plates, a cavity is formed between the inclined bottom plate and the frame plates, a plurality of flow guide plates are fixedly arranged in thecavity, and the four flow guide plates divide the cavity into five flow guide cavities, each flow guide cavity is an independent cavity with a trapezoid cross section, and water inlet branch pipes are fixedly arranged on the left sides of the flow guide cavities. The base plate device used for printing the circuit board plug holes is simple in structure, convenient to use, convenient to dischargeresidual oil ink, convenient to clean after being used, and capable of improving the utilization rate, reducing the processing cost and being worthy of popularization.

Owner:湖北荣宝电子科技有限公司

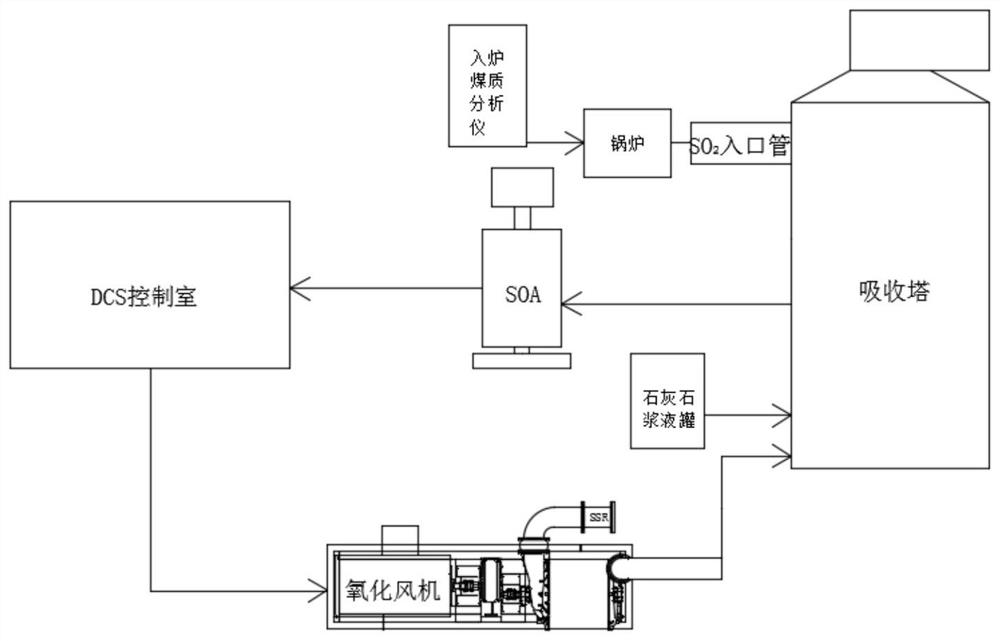

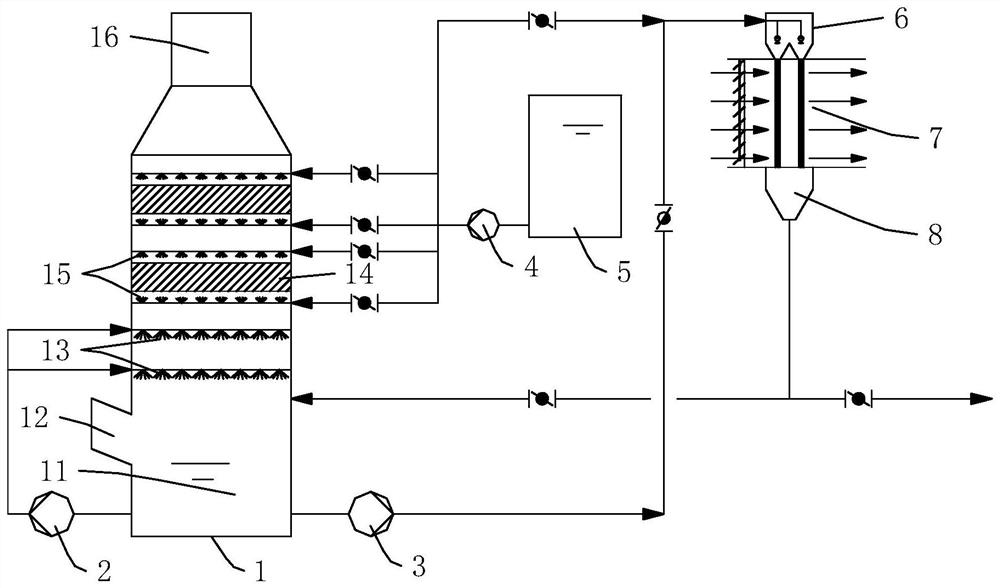

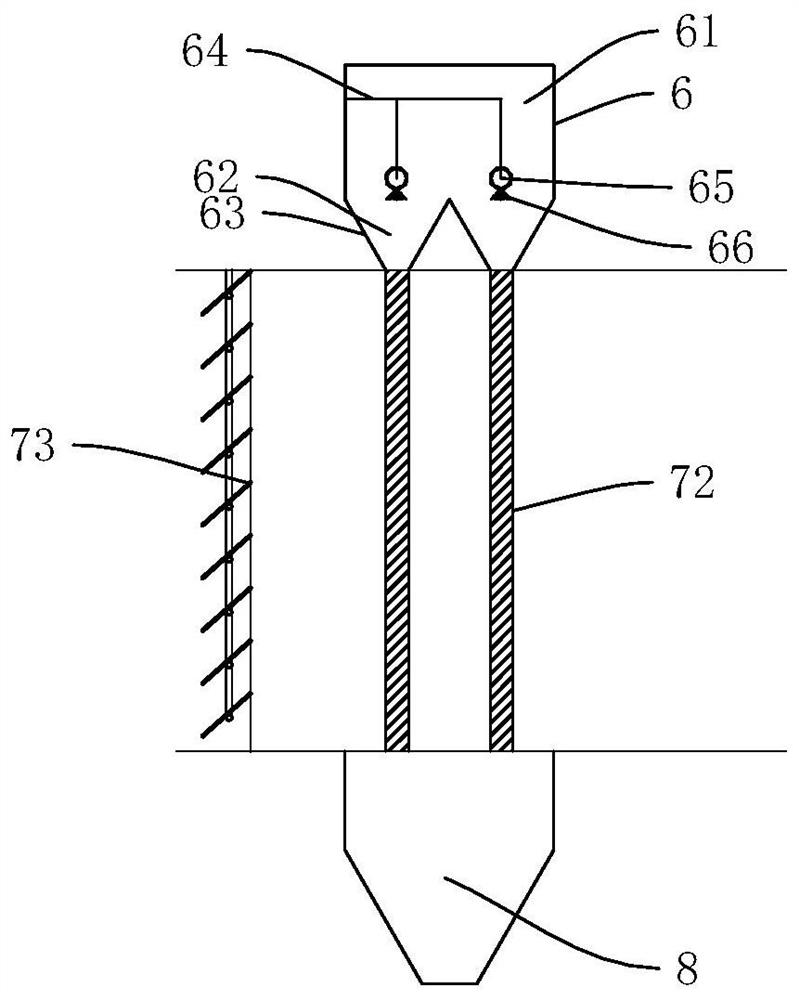

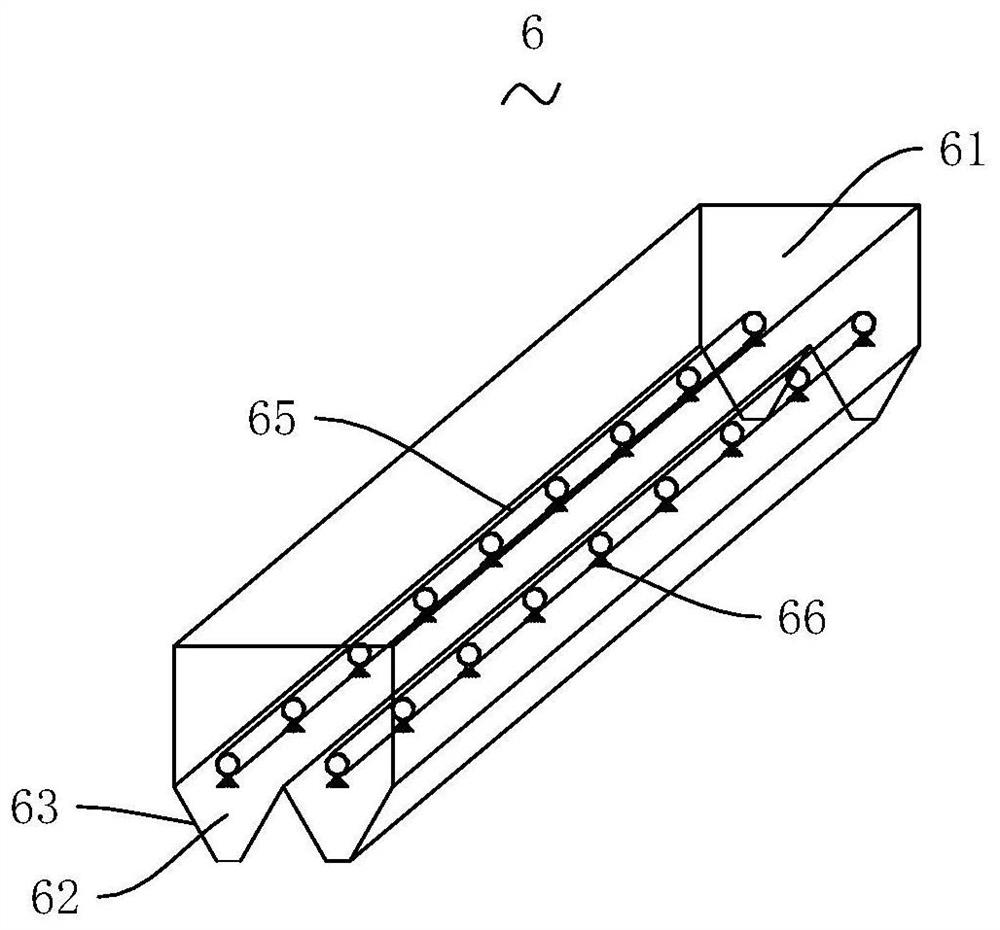

System and method for wet flue gas desulfurization and oxidation monitoring in cooperation with sulfur mixing and blending combustion of thermal power plant

PendingCN113357659AImprove adaptabilityIncrease diversityEmission preventionSolid fuel pretreatmentCombustionFlue gas

The invention discloses a system and method for wet flue gas desulfurization and oxidation monitoring in cooperation with sulfur mixing and blending combustion of a thermal power plant, and belongs to the technical field of sulfur mixing and blending combustion of thermal power plants. The system comprises an absorption tower for desulfurization reaction, an SO2 inlet pipe, a boiler and a slurry oxidation analyzer, wherein the SO2 inlet pipe is arranged on the outer side of the absorption tower, an SO2 outlet is formed in one side of the upper end of the absorption tower, and detection equipment is arranged at the SO2 outlet; the boiler is arranged at the upstream of the absorption tower, a flue gas channel of the boiler communicates with the SO2 inlet pipe, and a furnace coal quality analyzer is arranged at the upstream of the boiler; and the slurry oxidation analyzer is arranged at the downstream of the absorption tower. According to the system, the sulfur mixing and blending combustion function is integrally guided by desulfurization, so that the desulfurization potential is excavated to the maximum extent, the actual desulfurization maximum output is found out, the sulfur content of fire coal can be further increased from a design value and determined by a blending combustion experiment, the purchasing range of the coal coming market of a power plant is enlarged, the adaptability and diversity of the fire coal are improved, economic coal with higher sulfur content is purchased, and the power generation cost is greatly reduced.

Owner:安徽科力德能源环境科技有限公司

Micro-power gas-stripping mud and water constant-flow device and processing method thereof

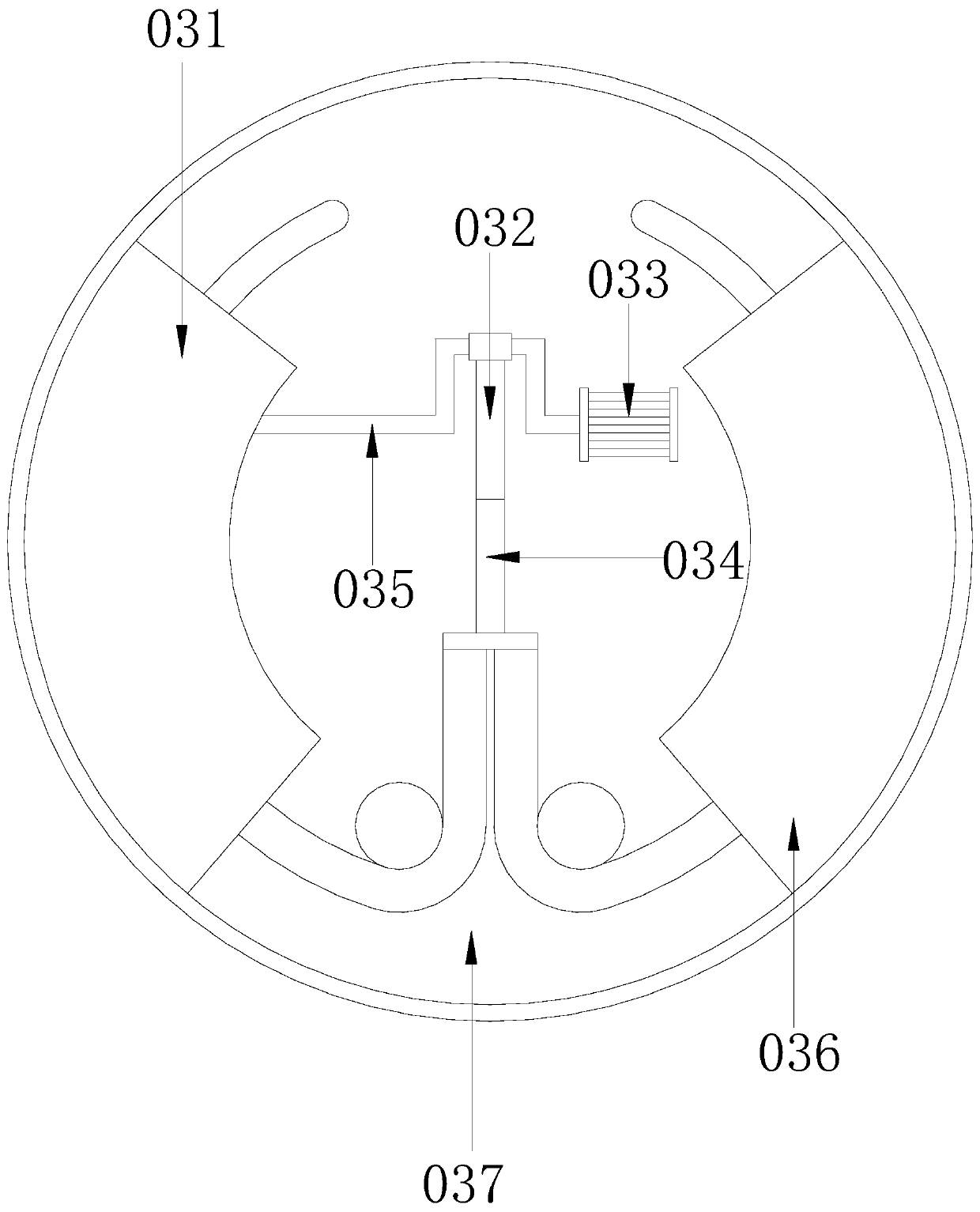

PendingCN107795003ANot easy to release splashPrevent sediment cloggingSewerage structuresSludgeStream flow

The invention discloses a micro-power gas-stripping mud and water constant-flow device. A gas-stripping mud and water system comprises a gas inlet, a gas-stripping mud and water absorbing pipe and a mud and water outlet flushing head; a mud and water volume regulating system comprises a mud and water energy balance regulating tank, a constant flow water outlet area, a pulsating flow water outlet area, a constant flow water outlet pipe and a pulsating flow outlet pipe; the mud and water energy balance regulating tank and the constant flow water outlet area are connected through a separating plate which is provided with flow holes. The micro-power gas-stripping mud and water constant-flow device has the advantage of being controllable in regulation of gas-stripping mud and water constant flow, stable in outflow, less prone in splashing of output mud and water, capable of effectively avoiding blocking led by settled mud, smooth in gas-stripping mud and water pipes, and low in gas and energy consumption, thereby being applicable to industrial promotion and application and filling the gap in the fields of constant-flow gas stripping and accurate gas-stripping outflow control.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

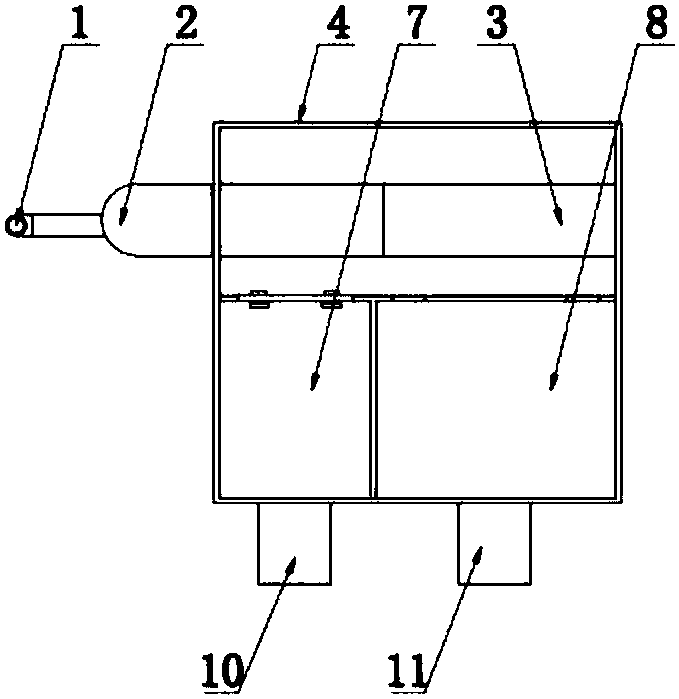

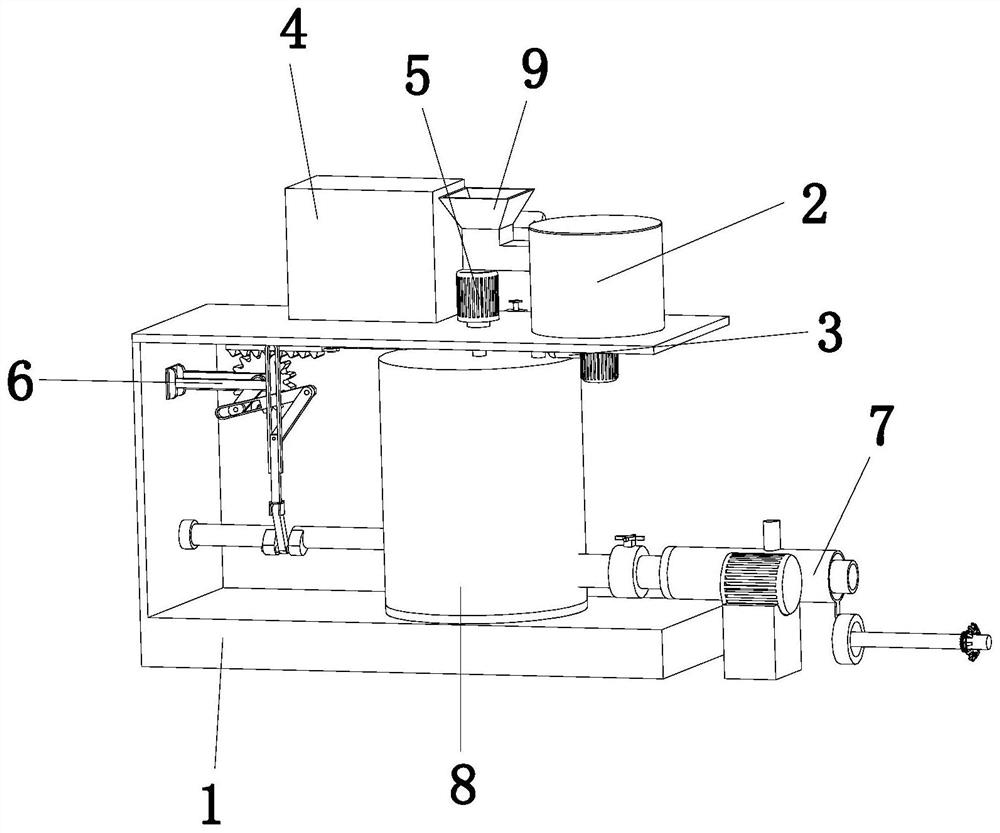

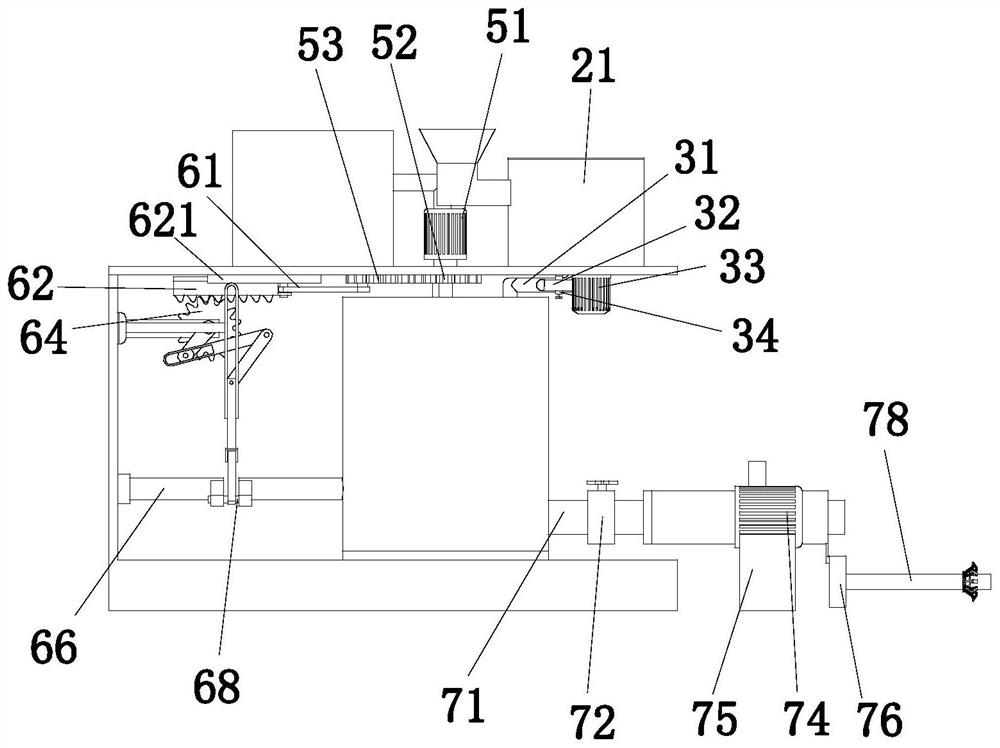

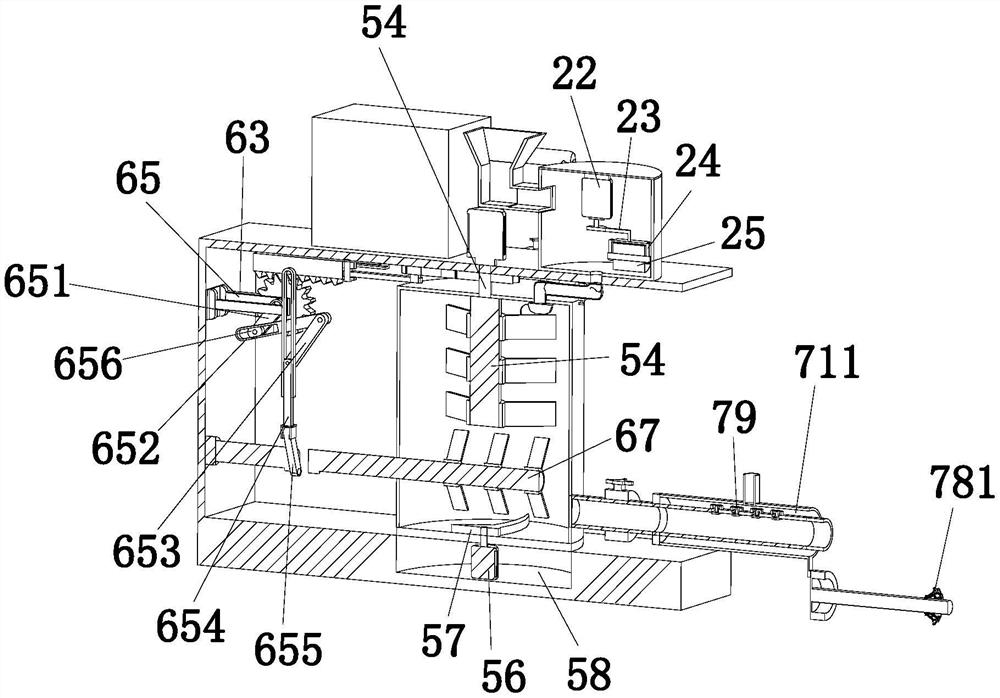

Household garbage incineration device

InactiveCN111520725ASmall footprintPrevent sediment cloggingIncinerator apparatusElectric energyMechanical engineering

The invention discloses a household garbage incineration device. The device structurally comprises a top cover, a household garbage incinerator body, a household garbage smashing mechanism, an ash outlet, an ash accumulating table, supporting feet and an ash pushing mechanism, wherein the supporting feet are perpendicularly connected to the bottom of the household garbage smashing mechanism, and the bottom of the household garbage smashing mechanism is also provided with the ash outlet. The household garbage incineration device has the advantages that through combined arrangement of a power disk, a first corrugated pipe, a connecting guide sheet, a guide rod, a guide strip, an ash-pushing plate and a second corrugated pipe, the occupied space is small; and electric energy is used as a power source, the ash pushing plate is pneumatically pushed to perform ash pushing, manual ash pushing is not needed, ash obtained after burning can be pushed out in time and prevented from accumulating together, therefore, deposition blockage at the ash outlet can be prevented, garbage incineration can be performed normally, and garbage incineration efficiency can be improved.

Owner:赵金山

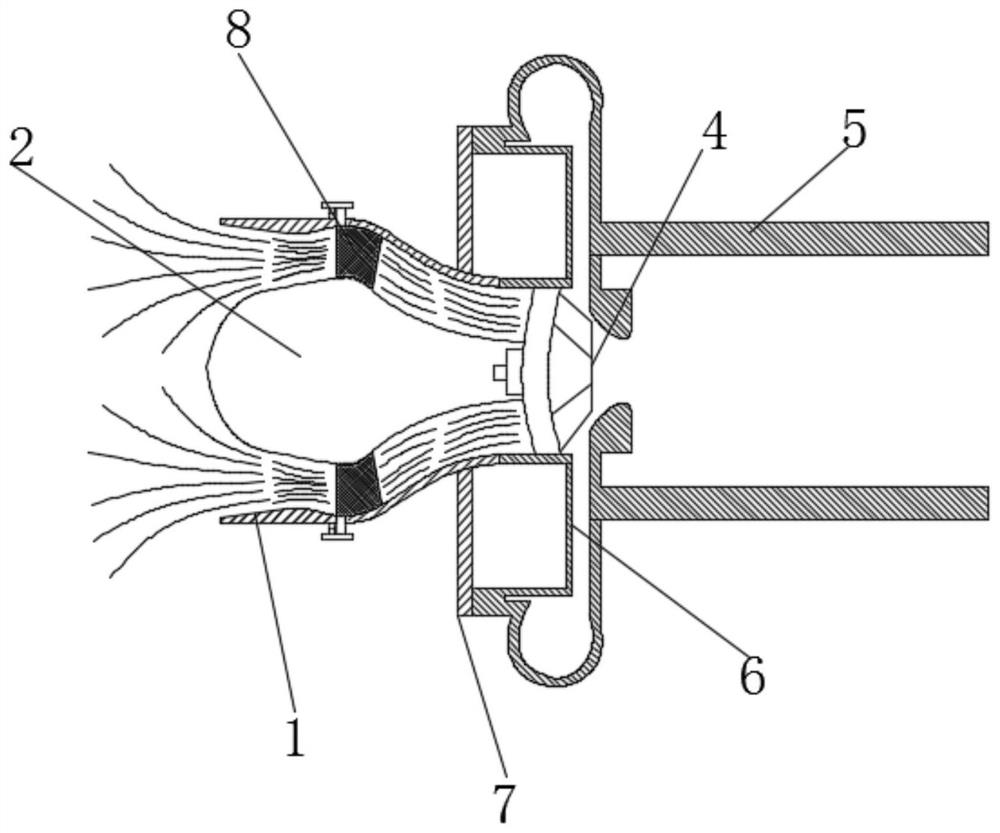

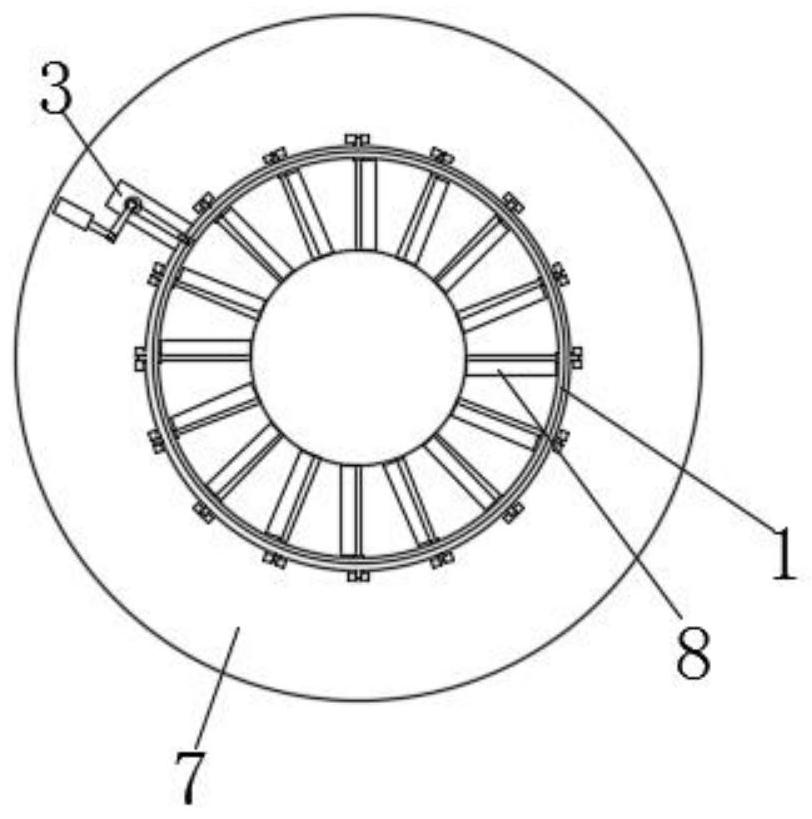

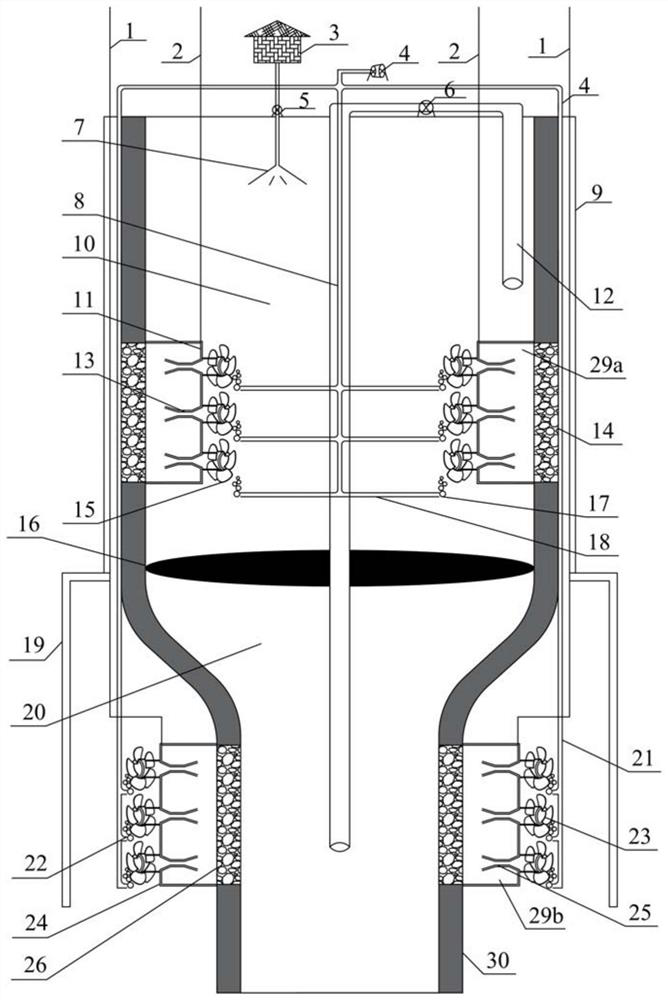

Underground water circulating well system

ActiveCN114804291AReduced risk of cloggingHigh activityWater/sewage treatment with mechanical oscillationsHollow article cleaningWater circulationPipe

A circulating well body of the underground water circulating well system is integrally formed by a plurality of screen pipe sections and solid pipe sections which are separated from one another in the axial direction, variable-direction hydrodynamic cavitation assemblies capable of forming wake flow cavitation bubbles are further arranged in the different screen pipe sections, and the variable-direction hydrodynamic cavitation assemblies are arranged at the corresponding screen pipe positions in the circumferential direction. And a liquid flow containing cavitation bubbles for removing dirt of the respective screen pipe is formed at the water inlet front end of the corresponding screen pipe by means of flowing of underground water to be purified. Blockages around the sieve tube of the circulating well are broken through the hydrodynamic cavitation effect, and blockage of a well body of the circulating well is relieved; the cavitation erosion speed of the screen pipe is reduced / increased by changing the direction of the cavitation pipe, and the service life of the circulating well is prolonged.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY +1

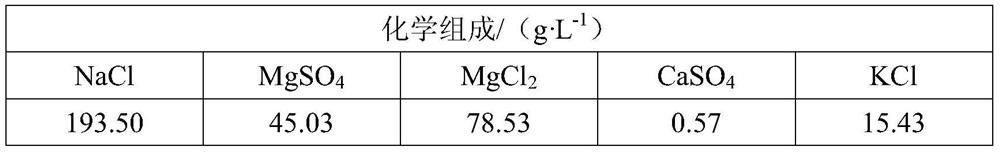

Process and system for producing refined salt by using salt production waste liquid

ActiveCN112811441AAvoid cloggingPrevent sediment cloggingAlkali metal chloridesProcess engineeringSlurry

The invention relates to the technical field of salt production, in particular to a process for producing refined salt by using salt production waste liquid. The process comprises the following steps of: (1) filtering and preheating: filtering the salt production waste liquid by using a semipermeable membrane, and preheating the waste liquid in a preheater to obtain primary waste liquid; (2) evaporation and thickening: heating and evaporating the primary waste liquid to generate secondary waste liquid with the concentration of 32-35 degrees Be'; (3) cooling and devitrifying: cooling the secondary waste liquid, and filtering to remove the secondary waste liquid to obtain crystallized salt slurry; (4) washing and devitrification: enabling crystallized salt slurry to enter a salt leaching device for saturated brine washing, enabling the washed crystallized salt slurry to enter a salt storage bin and then enter a centrifugal machine through a cyclone to dewater the washed crystallized salt slurry so as to obtain wet salt, and enabling brine mother liquor removed by the centrifugal machine to flow back to the salt leaching device; and (5) drying. By optimizing the process, the phenomena of blockage and refined salt caking in the salt manufacturing process are avoided, and the continuity and stability of salt manufacturing production are ensured.

Owner:肥城胜利盐业有限公司

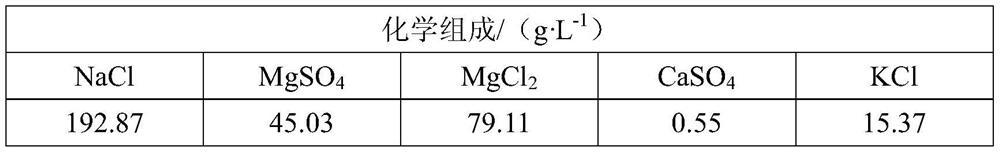

High-temperature aerosol particle sampling gun

ActiveCN101672733BInhibition of condensation nucleation processPrevent sediment cloggingWithdrawing sample devicesParticulatesCoal

A high-temperature aerosol particle sampling device belongs to the technical field of coal combustion and environmental pollution emission and comprises two parts of a sampling head and a gun body, wherein the sampling head consists of a sampling nozzle, a diluent gas heating pipe and a mixing channel, and the gun body comprises a water cooled shell assembly and a two-stage diluent mixing tube. Aiming at the complicated conditions of a high temperature combustion environment, the device inhibits the condensation and nucleation of gaseous inorganic substances in high temperature smoke gas during sampling process through two-stage diluent sampling, and meanwhile, holds back the collision and conglobation process of particles during sampling process, thus obtaining the real distribution of particulate matter in the high temperature smoke gas. The sampling device is applicable to sampling of aerosol particulate matter under high temperature environment (such as various combustion apparatuses).

Owner:北京华控煤燃烧工程研究中心有限公司 +1

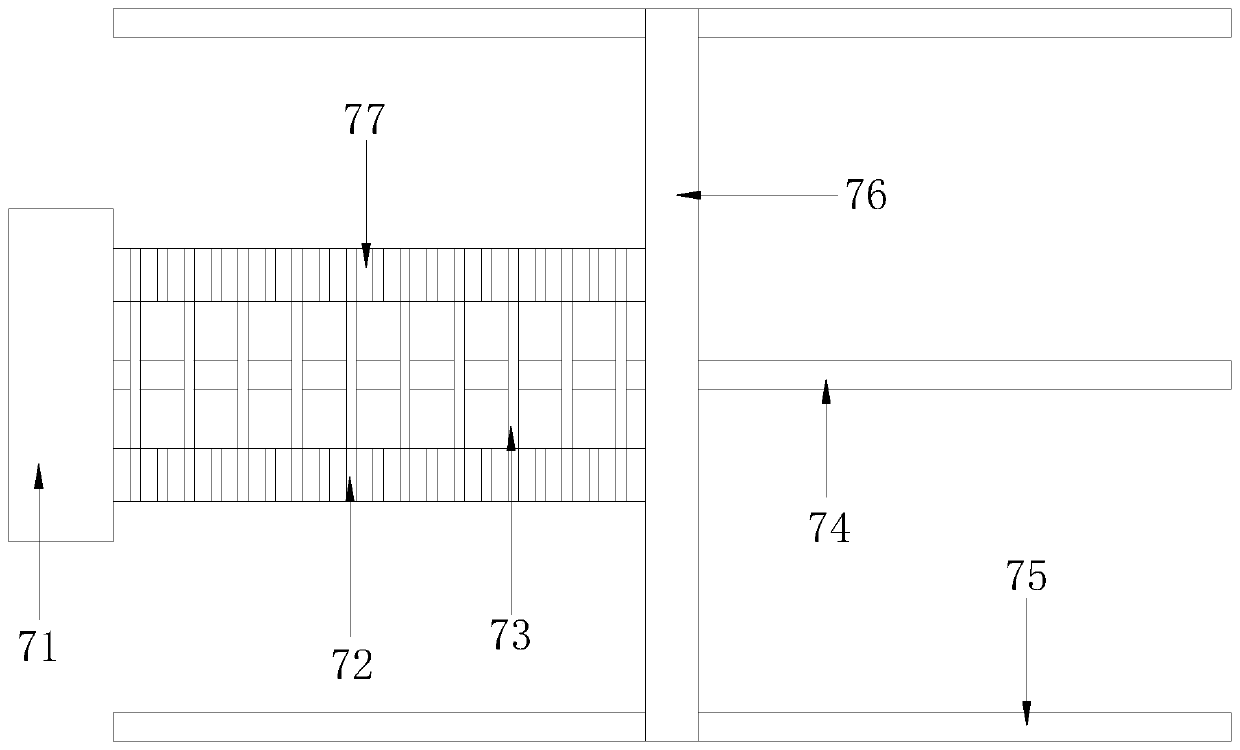

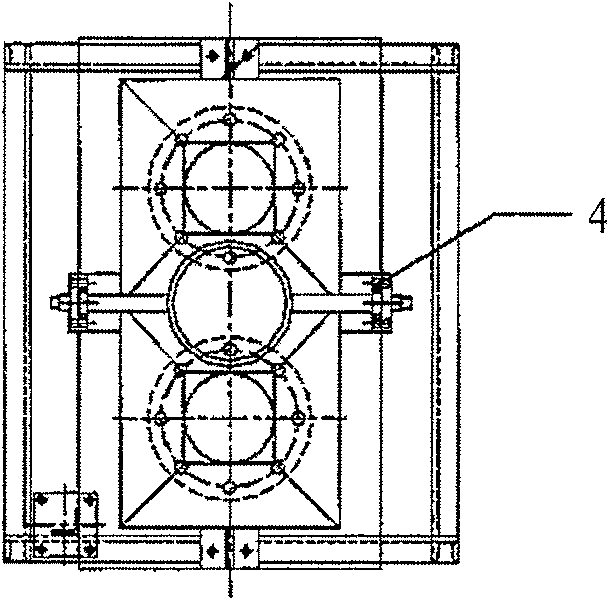

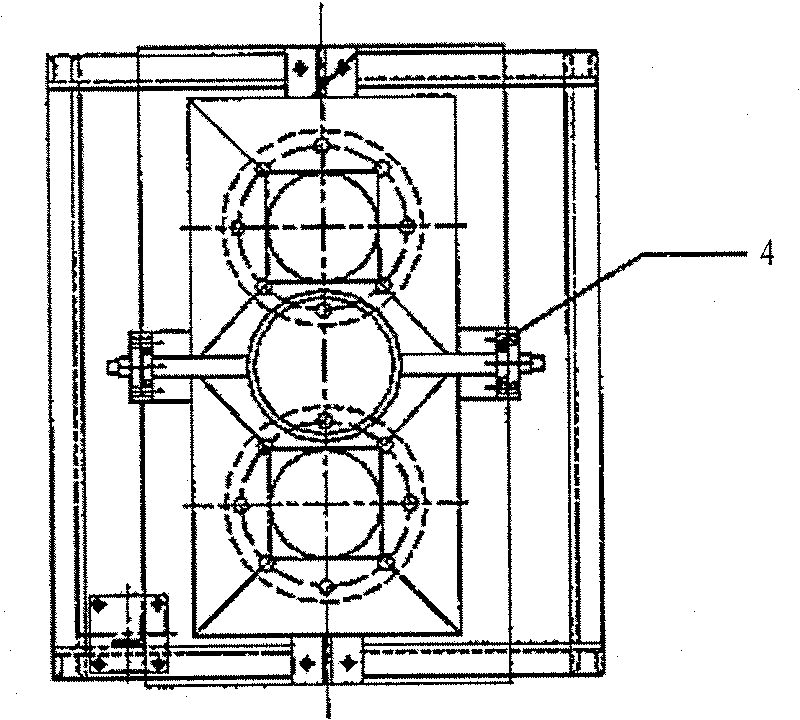

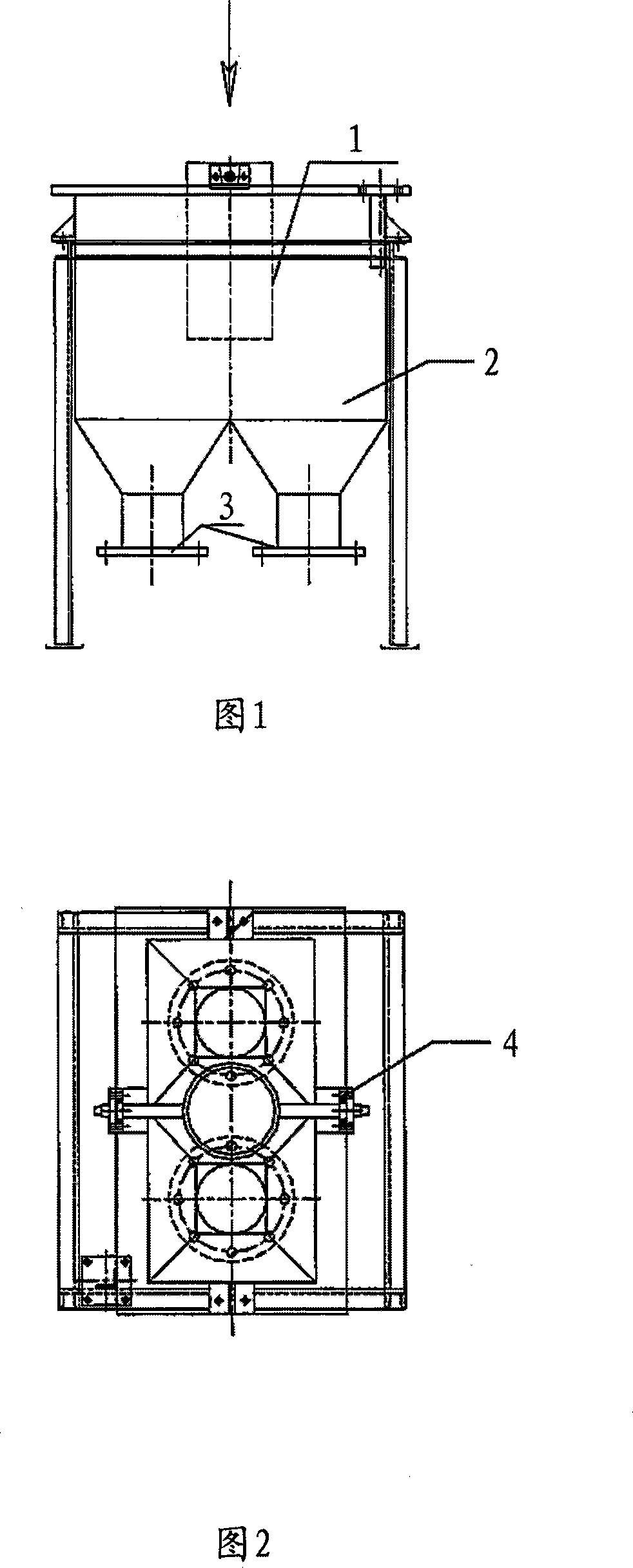

Bottom-flow distributing equipment for serous fluid cyclone station

ActiveCN101117204BEasy to switchNo overflowLiquid flow controllersLiquid dispensingCycloneEngineering

The invention provides an underflow distributing device used in serum swirl station, comprising a feed pipe (1), a serum distributing box (2), discharge ports (3) and a switching mechanism (4) provided with a push rod and a pair of parallel tracks, wherein the switching mechanism (4) is positioned above the serum distributing box (2); the parallel tracks are also arranged above the serum distributing box (2); both ends of the push rod are arranged on the tracks; the feed pipe (1) is fixed on the push rod, while the push rod is connected with a drive mechanism; the inlet part of the feed pipe (1) is connected with the underflow pipe positioned at the serum outlet of a swirl station, while the outlet part is communicated with the serum distributing box (2); the bottom of the serum distributing box (2) is provided with two discharge ports (3), while the outlet part of the feed pipe (1) is opposite to the discharge ports (3); in addition, the line of centers of both discharge ports (3) isparallel to the parallel tracks. The invention can guarantee smooth switching of serum without blockage and overflow.

Owner:CHINA SHENHUA ENERGY CO LTD +1

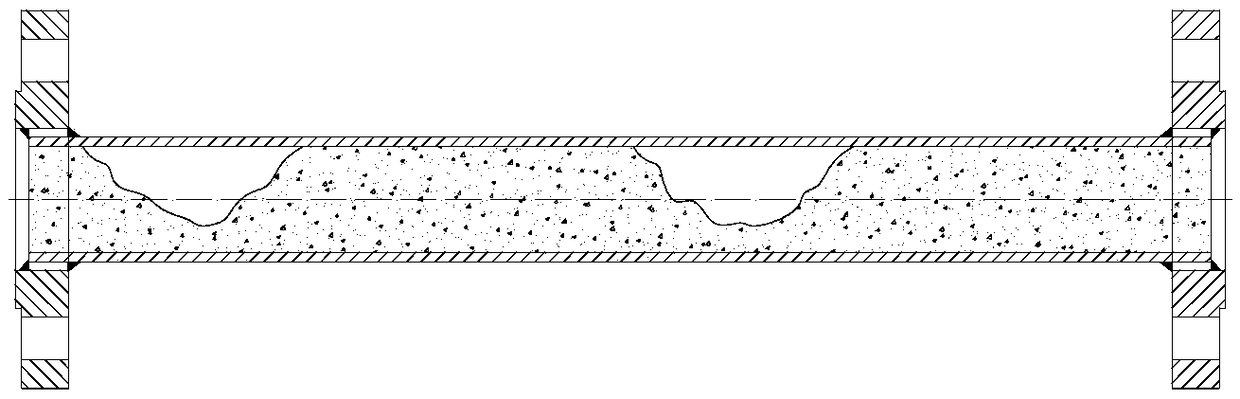

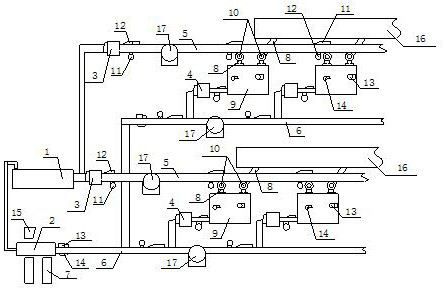

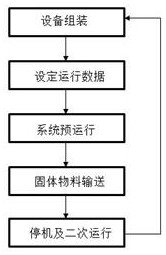

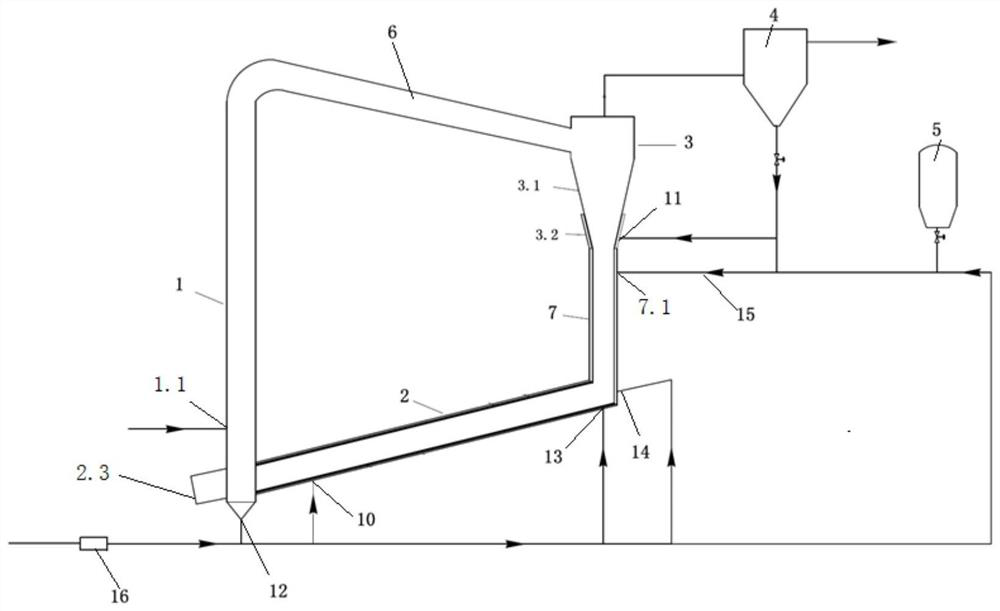

Efficient hydraulic remote particle material collecting and conveying system and method thereof

ActiveCN112573114AStrong adaptability to transportationMeet the needs of synchronous supporting operationConveyorsControl devices for conveyorsPipeDelivery system

The invention relates to an efficient hydraulic remote particle material collecting and conveying system. The efficient hydraulic remote particle material collecting and conveying system comprises a clean water tank, a solid-liquid separation device, a water feeding pump, a material conveying pump, a water supply pipeline, a material conveying pipeline, a material conveyor, a flow guide branch pipe, a solid-liquid mixing cabin and a control system, wherein the upper end surface of the solid-liquid mixing cabin is communicated with a solid material source and a water supply pipeline through theflow guide branch pipe; the water supply pipeline is communicated with the clean water tank through the water feeding pump; the lower end surface of the solid-liquid mixing cabin is communicated withthe material conveying pipeline through the material conveying pump; and the material conveying pipeline is communicated with a solid-liquid separation device. The conveying method comprises the fivesteps of assembling equipment, setting operation data, carrying out preoperation of the system, conveying solid materials, shutting down, and carrying out secondary operation. According to the efficient hydraulic remote particle material collecting and conveying system and the method thereof, on one hand, the requirement that the system can be matched with various materials in different positionsand various types of materials can be effectively met; on the other hand, the fluidity of the solid materials in the conveying process can be effectively improved; the resource recycling rate is effectively increased; and the water resource loss can be reduced.

Owner:河南焦煤能源有限公司

Air feeding system and method for desulfurizing slurry liquid pre-heating boiler

PendingCN112628791ARaise the inlet air temperatureReduce operating energy consumptionEmission preventionIndirect carbon-dioxide mitigationEngineeringSlurry

The invention discloses an air feeding system and method for a desulfurizing slurry liquid pre-heating boiler. The air feeding system comprises a desulfurizing tower, a desulfurizing pump, a technological water tank, a demister cleaning pump, an energy-saving pump, a liquid distributor, an air warmer and a liquid returning device, wherein the air warmer comprises an air feeding air channel and an air warming pipe grid; an air inlet of the air feeding air channel communicates with environmental air and an air outlet of the air feeding air channel communicates with a boiler air inlet; a liquid inlet of the energy-saving pump communicates with a desulfurizing slurry chest, and a liquid outlet of the energy-saving pump communicates with a liquid inlet of the liquid returning device; and a liquid outlet of the liquid returning device separately communicates with the desulfurizing slurry chest and a liquid inlet of a gypsum dehydration system. By adopting the system and the method disclosed by the invention, low-grade afterheat in wet-process desulfurizing slurry liquid is effectively recycled, and the recycled afterheat is used for feeding air into the pre-heating boiler, so that the air inlet temperature of the boiler is improved, and the water consumption volume for operation of a wet-process desulfurizing device is reduced while energy consumption of operation of the boiler is reduced at the same time.

Owner:新疆天富环保科技有限公司 +1

Fast bed reaction method and fast reaction bed for ultrafine particles

ActiveCN112588213BDoes not affect throughAchieve independenceMicroballoon preparationMicrocapsule preparationGas solidThermodynamics

Owner:WUHUAN ENG

Reverse cone sieve disk ammonia leakage-free efficient chemical combination leaching device of copper ore

ActiveCN105112653AEfficient condensationEffectivenessProcess efficiency improvementRefluxChemical combination

The invention relates to a reverse cone sieve disk ammonia leakage-free efficient chemical combination leaching device of a copper ore. A chemical combination leaching barrel and a tail gas purifier are connected by a flange; a stirring motor is connected with a conical shield by a hollow shaft and then inserted into the chemical combination leaching barrel; blades and liquid inlets holes are formed in the cone shield; air inlet holes are peripherally uniformly distributed and formed in the upper part of the hollow shaft; liquid inlets are formed in the chemical combination leaching barrel, and a reflux pipe penetrating out of the barrel body on a bottom valve; the tail gas purifier is externally provided with a jacket and is internally provided with a middle pipe forming a jacket structure together with spiral fins; the outlet of the tail gas purifier is provided with a swirler. Air (oxygen) is automatically conveniently replenished in the chemical combination leaching barrel having a perfect and complete liquid flow mixing action, and chemical combination leaching efficiency is high; material deposition and blockage is prevented, and convenience and efficiency are realized; tail gas purifier is multi-level, capable of efficiently finishing heat and medium transfer, and very good in gas liquid separation effect, ammonia leakage is effectively avoided, environment friendliness, automation and efficiency of chemical combination leaching of the copper ore is realized and important application value is realized.

Owner:济宁高新科达科技项目服务有限公司

Flocculating agent blending equipment for wastewater treatment

InactiveCN111841413AWell mixedIncrease profitTransportation and packagingMixer accessoriesProcess engineeringWater treatment

The invention discloses flocculating agent blending equipment for wastewater treatment, belonging to the technical field of wastewater treatment equipment. The flocculating agent blending equipment comprises a base, a grinding device, a conveying device, a stirring device, a mixing device, a water supply device and a drainage device, wherein a reaction cylinder is arranged in the base; the base isprovided with a groove at a position below the reaction cylinder; the grinding device is fixedly arranged at the top of the base; the conveying device is arranged on the bottom side of the top of thebase; the stirring device is arranged on the inner side of the bottom of base; one end of the stirring device penetrates through the base; the mixing device is arranged on the side wall of the base;one end of the mixing device penetrates through the reaction cylinder; the water supply device is arranged at the top of the base; the water supply device communicates with the reaction cylinder; thedrainage device is arranged beside the reaction cylinder; and the drainage device communicates with the reaction cylinder. According to the flocculating agent blending equipment for wastewater treatment, the flocculating agent blending equipment can be cleaned in the process of flocculating agent blending, and the utilization efficiency of raw materials is improved.

Owner:盛亚林

Bottom-flow distributing equipment for serous fluid cyclone station

ActiveCN101117204APrevent sediment cloggingSimple partsLiquid flow controllersLiquid dispensingEngineeringCyclone

The invention provides an underflow distributing device used in serum swirl station, comprising a feed pipe (1), a serum distributing box (2), discharge ports (3) and a switching mechanism (4) provided with a push rod and a pair of parallel tracks, wherein the switching mechanism (4) is positioned above the serum distributing box (2); the parallel tracks are also arranged above the serum distributing box (2); both ends of the push rod are arranged on the tracks; the feed pipe (1) is fixed on the push rod, while the push rod is connected with a drive mechanism; the inlet part of the feed pipe (1) is connected with the underflow pipe positioned at the serum outlet of a swirl station, while the outlet part is communicated with the serum distributing box (2); the bottom of the serum distributing box (2) is provided with two discharge ports (3), while the outlet part of the feed pipe (1) is opposite to the discharge ports (3); in addition, the line of centers of both discharge ports (3) is parallel to the parallel tracks. The invention can guarantee smooth switching of serum without blockage and overflow.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Sorting and grading device of pulsating liquid-solid fluidized bed and method thereof

InactiveCN101804382BGood for automatic dischargeHigh densityWet separationLower limitAutomatic control

Owner:CHINA UNIV OF MINING & TECH

Ammonia full recovery type copper ore high-efficiency chemical leaching device

ActiveCN105087928BEfficient condensationEffectivenessVapor condensationProcess efficiency improvementCycloneFull recovery

The invention discloses a total-ammonia recovery type copper mine efficient chemical combination leaching device. A chemical combination leaching barrel and a tail gas purifier are connected through a flange. After being connected with a conical cover through a hollow shaft, a stir motor is inserted in the chemical combination leaching barrel. The conical cover is internally provided with blades and liquid inlet holes. Air inlets evenly distributed and formed in the shaft circumference are formed in the upper portion of the hollow shaft. A hydraulic drive disc is arranged in the chemical combination leaching barrel and connected with a hollow pipe shaft, and the hollow pipe shaft is arranged on a bottom valve. A jacket is arranged outside the tail gas purifier, and the tail gas purifier is internally provided with an intermediate pipe to form a jacket structure with a spiral finned barrel. A cyclone is arranged at an outlet of the tail gas purifier. Supplement of air (oxygen) in the chemical combination leaching barrel is automatic and convenient, the liquid flow mixing function is improved sufficiently, and the chemical combination leaching efficiency is very high. Material deposition blockage can be conveniently, reliably and efficiently prevented. Heat transfer and medium transfer are efficiently finished through the tail gas purifier in a multi-stage manner, and the gas-liquid separation effect is particularly good. Ammonia leakage is effectively prevented, environment-friendly, automatic and efficient copper mine chemical combination leaching is achieved, and high application value is achieved.

Owner:嘉善县魏塘资产管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com