Tundish breathable water inlet used for metal continuous casting plate blank and preparation method thereof

A tundish and slab technology, applied in the field of refractory melt conveying parts, can solve the problems of difficult to meet the casting process requirements, complex molding process, high manufacturing cost, etc., to improve the life of a single tundish, ensure the quality of the slab, and avoid The effect of nodulation blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

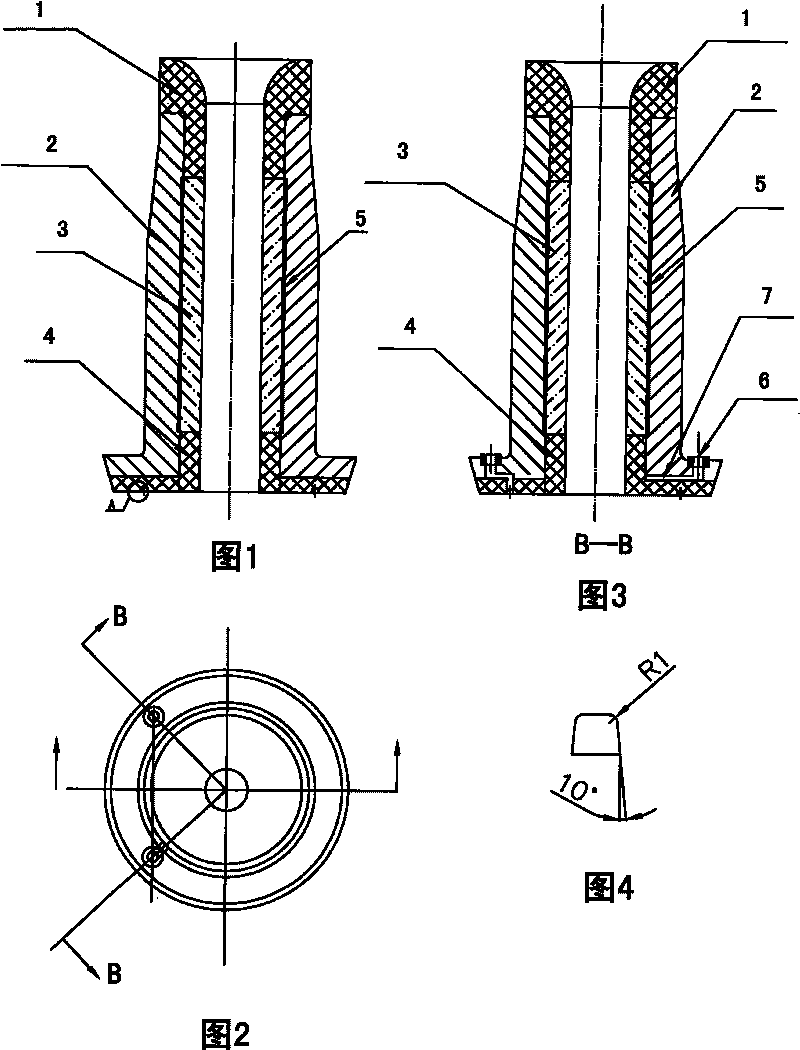

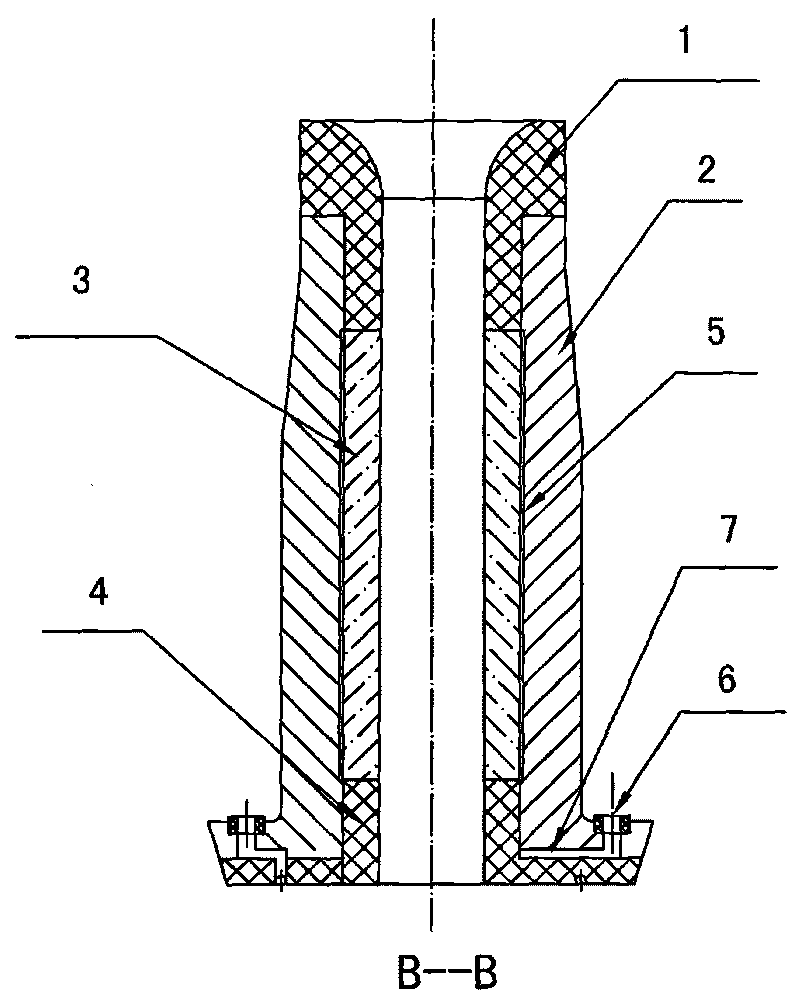

Image

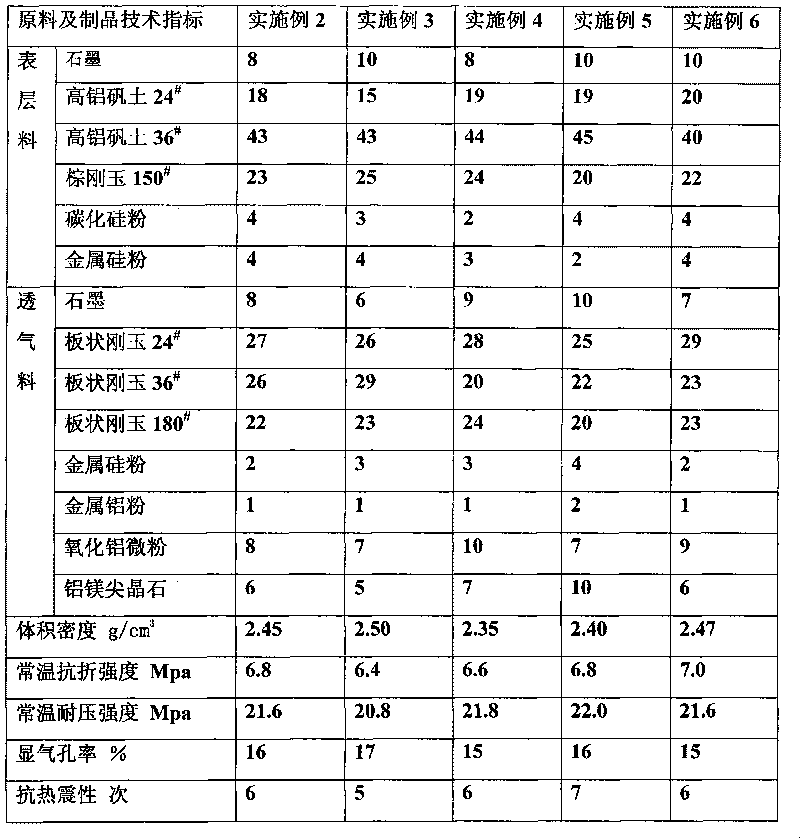

Examples

Embodiment 1

[0077] a. Ingredients mixing:

[0078] Topping ingredient mix:

[0079] Accurately weigh 6 parts by weight of graphite, 24 parts of high alumina bauxite # 20 parts by weight, high alumina bauxite 36 # 45 parts by weight, brown corundum 150 # 25 parts by weight, 2 parts by weight of silicon carbide powder, and 2 parts by weight of metal silicon powder, put into the surface layer material high-speed mixer, add a spraying type to add a binder, mix evenly at a high speed, and set aside;

[0080] Mixing of breathable material ingredients:

[0081] Accurately weigh 6 parts by weight of graphite, 24 parts of tabular corundum # 25 parts by weight, tabular alumina 36 # 30 parts by weight, tabular alumina 180 # 21 parts by weight, 3 parts by weight of metal silicon powder, 2 parts by weight of metal aluminum powder, 8 parts by weight of alumina powder, and 5 parts by weight of magnesium aluminum spinel are put into the high-speed mixing machine for air-permeable materials, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com