Treatment method of steel smoke dust

A treatment method and steel technology, applied to the improvement of process efficiency, furnace type, furnace, etc., to achieve the effect of easy industrial operation, simple steps, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

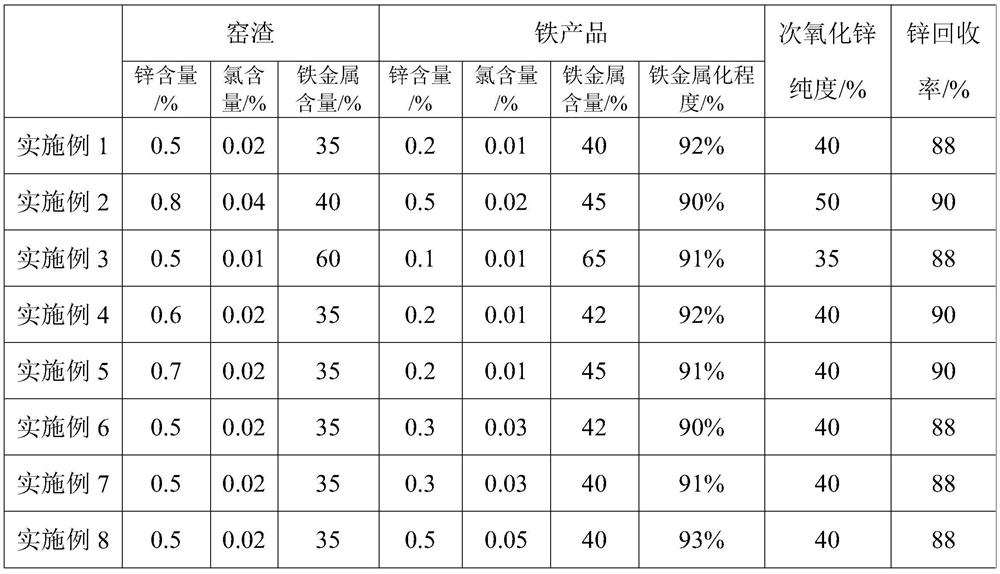

Examples

Embodiment 1

[0055] The present embodiment provides a method for processing iron and steel dust, and the processing method includes the following steps:

[0056] (1) Iron and steel dust with a chlorine content of 2.4%, a zinc content of 3.5%, a carbon content of 23.8%, and an iron content of 27.5% is processed in a rotary kiln to recover secondary zinc oxide. The temperature in the kiln is 1150°C and the pressure is 0~ -50Pa, the discharge temperature is 900°C, and the rotary kiln speed is adjusted to obtain kiln slag with a particle size range of 1-9mm;

[0057] (2) The kiln slag in step (1) is processed in a rotary hearth furnace with a processing temperature of 1250° C. and a processing time of 40 minutes to recover iron products, which are returned to the steel production system.

Embodiment 2

[0059] The present embodiment provides a method for processing iron and steel dust, and the processing method includes the following steps:

[0060] (1) Iron and steel dust with a chlorine content of 4%, a zinc content of 12%, a carbon content of 18.4%, and an iron content of 19.6% is processed in a rotary kiln to recover secondary zinc oxide. The temperature in the kiln is 1250°C and the pressure is -10 ~-50Pa, the discharge temperature is 1000°C, and the rotary kiln speed is adjusted to obtain kiln slag with a particle size of 3-8mm;

[0061] (2) The kiln slag in step (1) is processed in a rotary hearth furnace with a processing temperature of 1300°C and a processing time of 35 minutes to recover iron products, which are returned to the iron and steel production system.

Embodiment 3

[0063] The present embodiment provides a method for processing iron and steel dust, and the processing method includes the following steps:

[0064] (1) Iron and steel dust with a chlorine content of 1.5%, a zinc content of 3%, a carbon content of 29.3%, and an iron content of 61.3% is processed in a rotary kiln to recover secondary zinc oxide. The temperature in the kiln is 1200°C and the pressure is 0~ -50Pa, the discharge temperature is 950°C, and the rotary kiln speed is adjusted to obtain kiln slag with a particle size range of 1-10mm;

[0065] (2) The kiln slag in step (1) is processed in a rotary hearth furnace with a processing temperature of 1200° C. and a processing time of 50 min to recover iron products, which are returned to the iron and steel production system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com