Efficient snakelike heat exchange device utilizing Dean Vortice effect

A heat exchange equipment and serpentine technology, applied in the field of high-efficiency serpentine heat exchange equipment, can solve the problems of equipment volume, technical facilities and investment increase, restricting the wide application of chemical systems, high flow resistance operating costs, etc., to prevent impurities from depositing. Blockage and local corrosion, safe long-term operation, and optimal operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

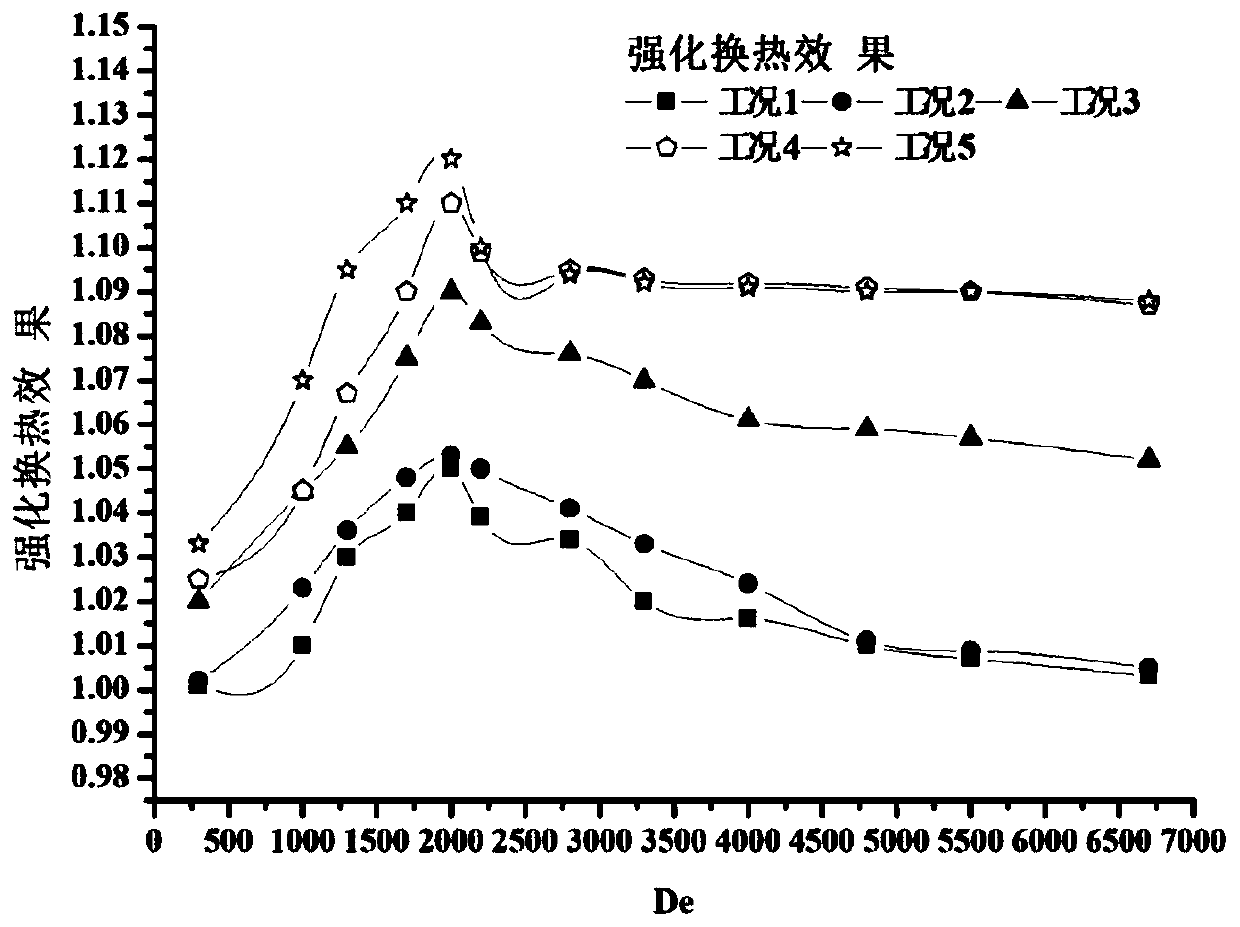

[0056] Heat exchange equipment is the basic unit of heat exchange, widely used in petroleum, chemical industry, light industry, nuclear power, shipbuilding, aviation and other industrial fields, accounting for an important proportion of enterprise equipment investment. With the intensification of the world's energy crisis, effectively improving the operating efficiency of heat exchange equipment has attracted great attention from experts and scholars in related fields, resulting in the rapid development of various enhanced heat transfer technologies. At present, the heat transfer enhancement methods widely used in industry mainly include the tube element method, the shell side turbulence method, the rough surface method, the external vibration method, etc., which enhance the operating efficiency of the heat exchange equipment to a certain extent, but usually lead to higher flow resistance and operating costs.

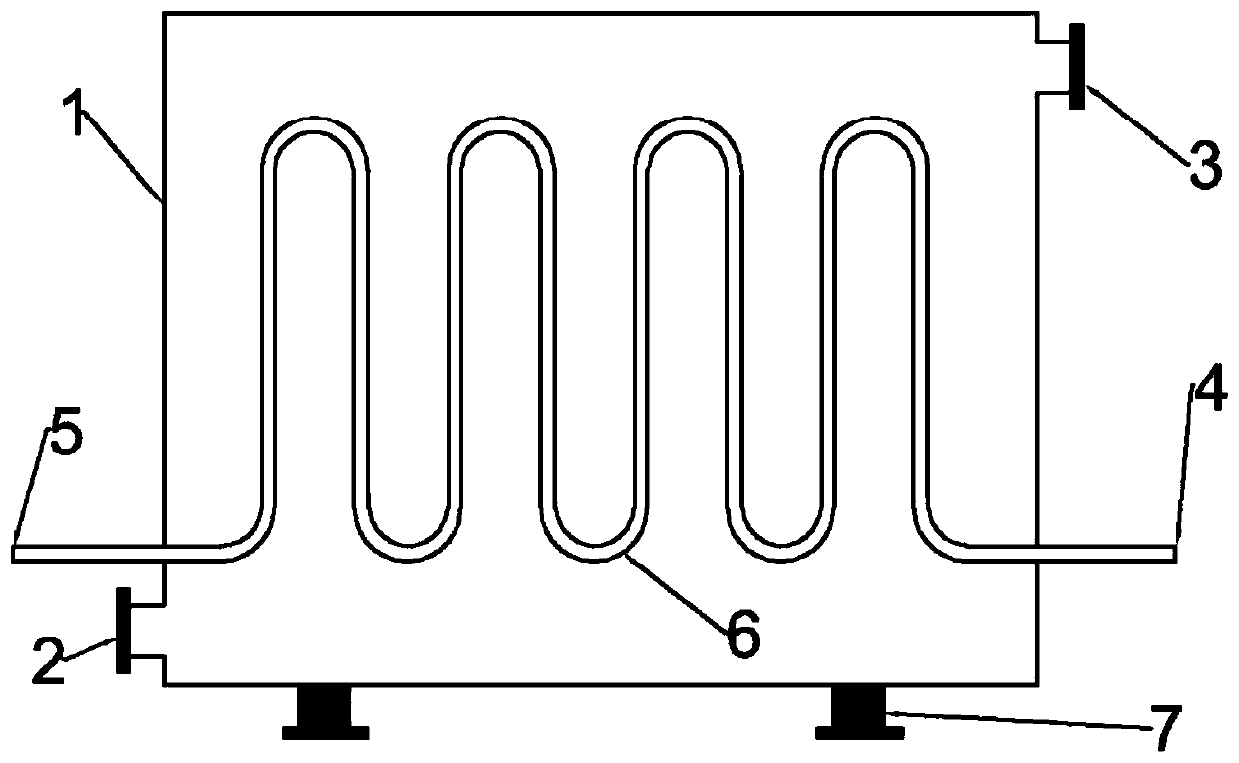

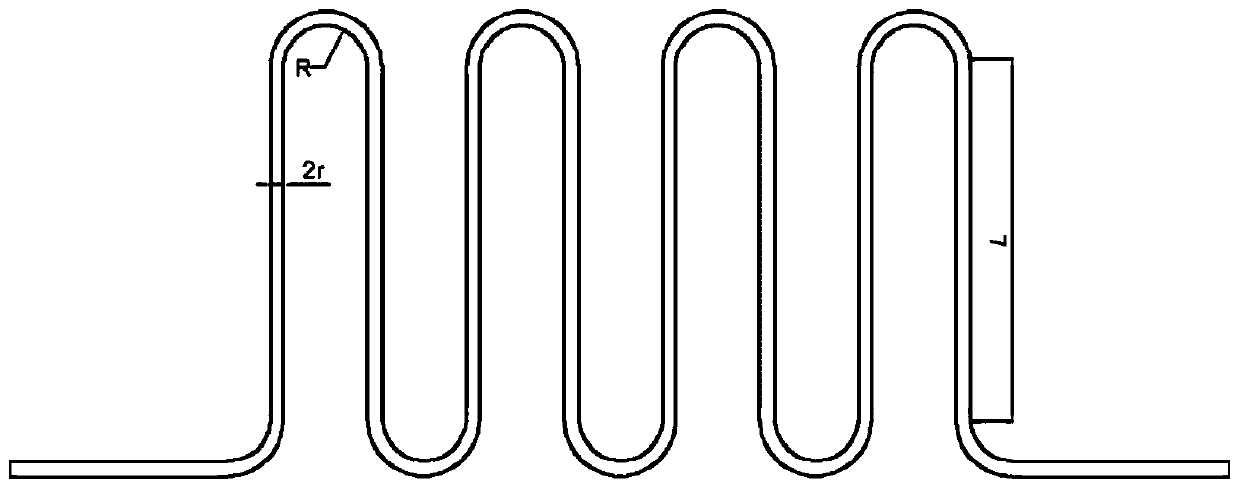

[0057] The invention provides a high-efficiency serpentine heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com