Process and system for producing refined salt by using salt production waste liquid

A technology for refining salt and waste liquid, which is applied in the field of salt production and can solve problems such as salt agglomeration and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

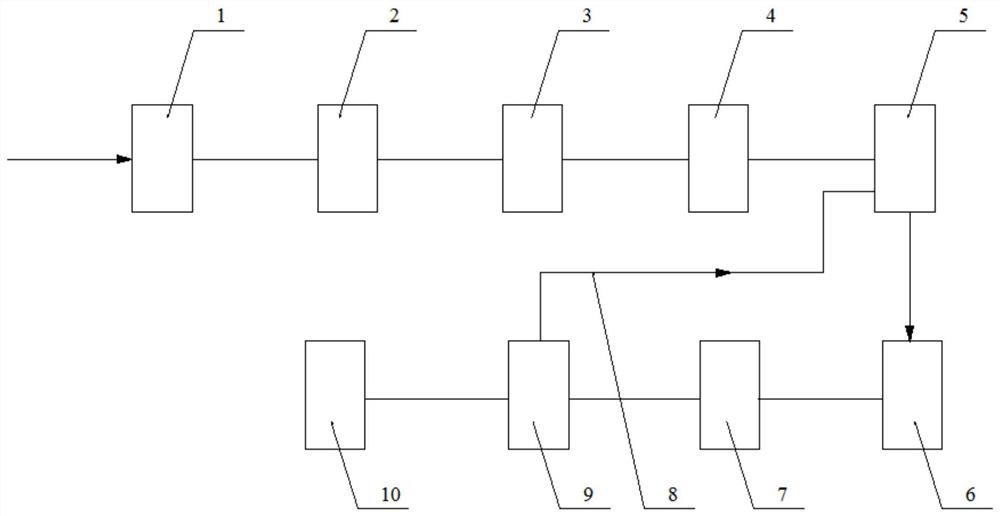

Method used

Image

Examples

Embodiment 1

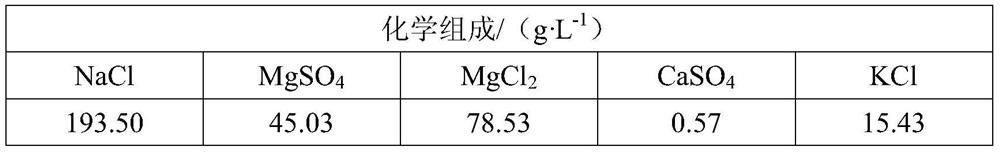

[0027] The salt-making waste liquid was collected from the first salt-making area of the company's salt factory, and the sampling and analysis results are shown in Table 1:

[0028] Table 1 The chemical composition of the salt-making waste liquid collected in the first salt-making district of our company

[0029]

[0030] A process for producing refined salt from salt-making waste liquid, comprising the steps of:

[0031] (1) Filtration and preheating: Use a semi-permeable membrane to filter the salt-making waste liquid, increase the concentration of the salt-making waste liquid to not less than 28°Be', and then enter the preheater for preheating. The preheating temperature is 80°C. The heat time is 15min, and the primary waste liquid is obtained;

[0032] (2) Evaporation and thickening: the primary waste liquid is heated to 110°C for 60 minutes for evaporation to generate a secondary waste liquid with a concentration of 35°Be';

[0033] (3) Cooling and crystallization:...

Embodiment 2

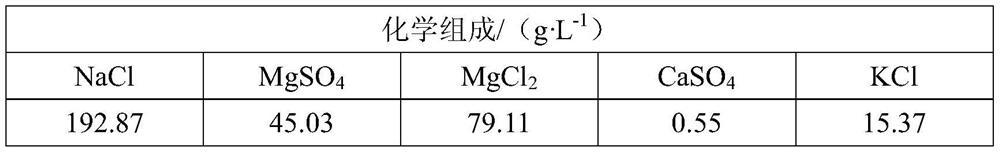

[0040] The salt-making waste liquid was collected from the fourth salt-making area of the company's salt factory, and the sampling and analysis results are shown in Table 3:

[0041] Table 3 The chemical composition of the salt-making waste liquid collected in the fourth salt-making district of our company

[0042]

[0043] A process for producing refined salt from salt-making waste liquid, comprising the steps of:

[0044] (1) Filtration and preheating: Use semi-permeable membrane to filter the salt-making waste liquid, increase the concentration of the salt-making waste liquid to not less than 28°Be', and then enter the preheater for preheating. The preheating temperature is 70°C. The heating time is 30min, and the primary waste liquid is obtained;

[0045] (2) Evaporation and thickening: the primary waste liquid is heated to 113°C for 45 minutes of evaporation time to generate a secondary waste liquid with a concentration of 32°Be';

[0046] (3) Cooling and crystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com