Micro-power gas-stripping mud and water constant-flow device and processing method thereof

A technology of muddy water and strength, applied in water supply devices, waterway systems, drainage structures, etc., can solve the problems of high energy consumption, small gas release, and restrictions on popularization and application, so as to prevent sludge sedimentation and clogging, stable water flow, The effect of low gas energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A kind of village and town sewage treatment integrated device and treatment method of the present invention will be further described below in conjunction with accompanying drawing:

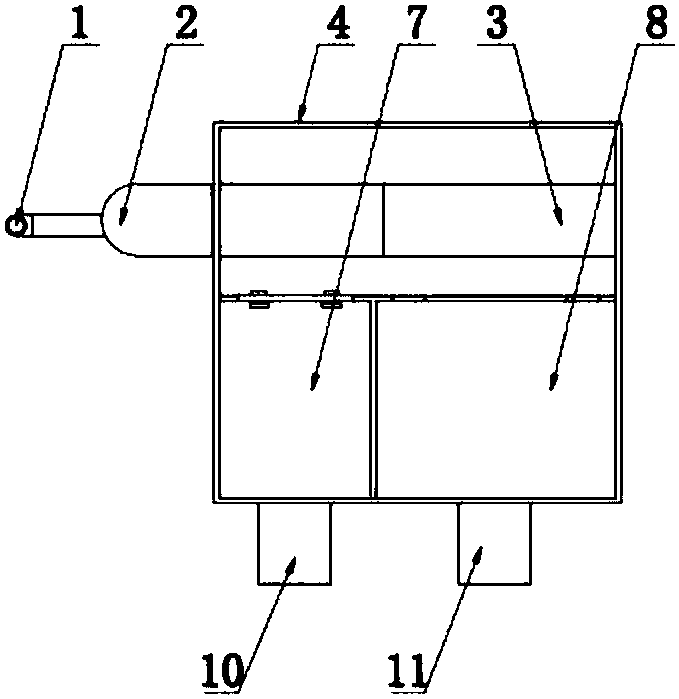

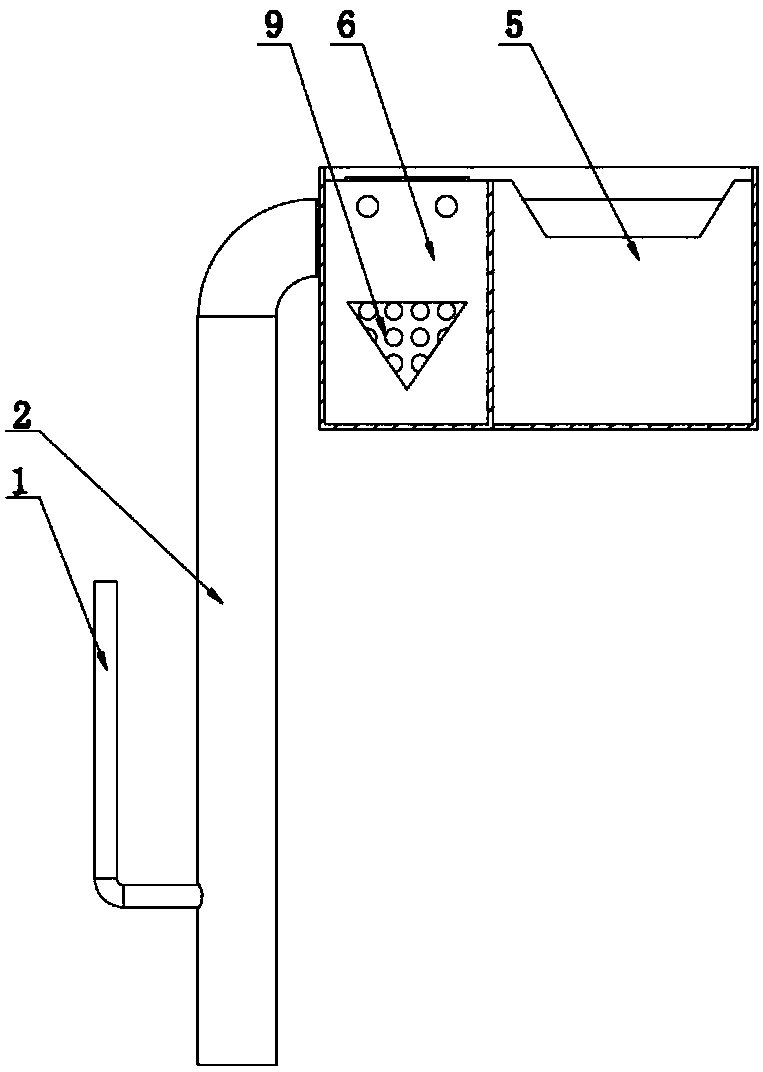

[0016] A kind of micro power air lift mud water constant flow device, the air lift mud water system includes an air intake pipe 1, an air lift mud suction pipe 2, and a mud water flushing head 3; the mud water volume adjustment system includes a mud water energy balance adjustment tank 4, Constant outflow water area 7, pulsating outflow water area 8, constant outflow water pipe 10 and pulsating outflow water pipe 11; the muddy water energy balance adjustment tank 4 and constant outflow water area 7 are connected through a partition 6, on which there are Flow holes 9; the muddy water energy balance adjustment tank 4 and the pulsating outflow water area 8 are connected through the overflow weir plate 5; the height of the top of the overflow weir plate 5 is greater than the flow hole 9 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com