Bottom-flow distributing equipment for serous fluid cyclone station

A technology of distribution device and cyclone station, which is applied in the direction of distribution device, special distribution device, liquid flow control device, etc. It can solve the problems of easy deposition and scaling of gypsum slurry, inability to carry out slurry, and inconvenient opening, etc., and achieve simple components , avoid deposition clogging, and switch freely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Next, the underflow distribution device for the slurry cyclone station of the present invention will be described with reference to the accompanying drawings and examples.

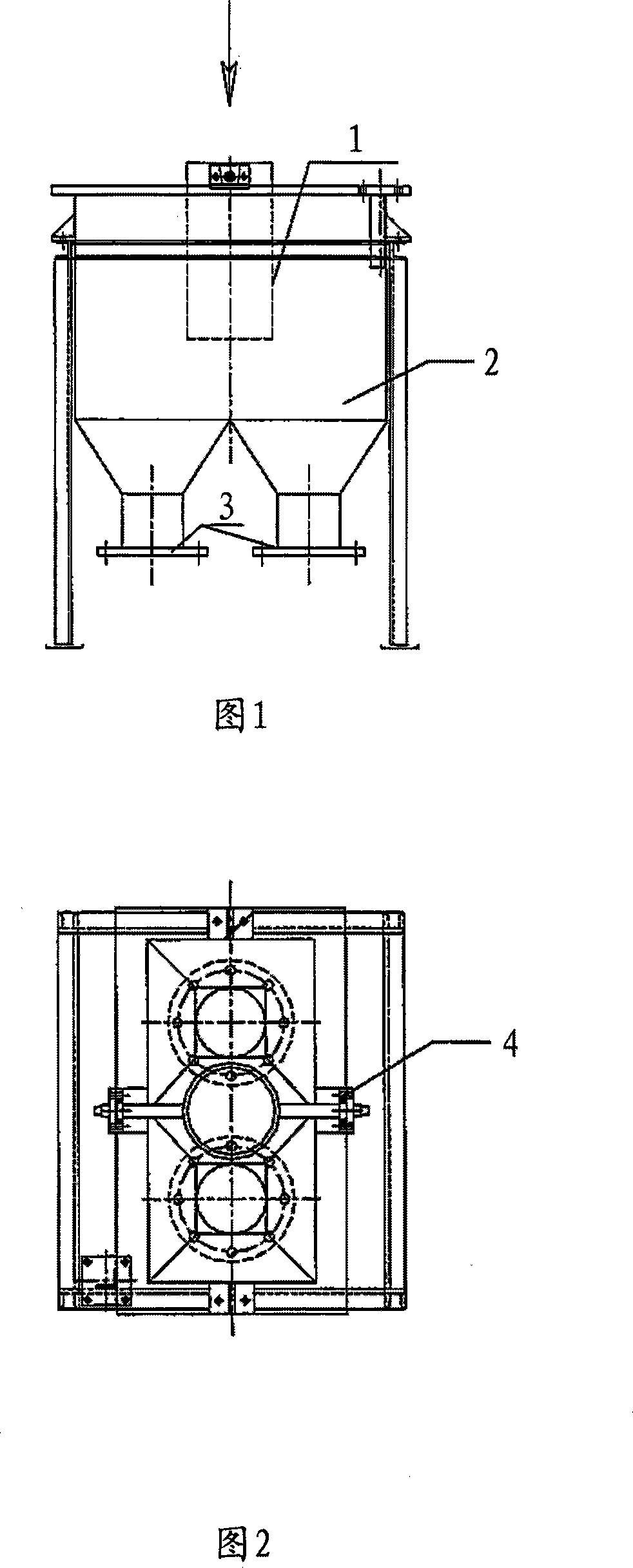

[0016] Fig. 1 is a front view of an underflow distribution device used in a slurry cyclone station according to the present invention. In FIG. 1 , reference numeral 1 denotes a feed pipe, 2 denotes a slurry tank, and 3 denotes a discharge port. Fig. 2 is a top view of the underflow distribution device used in the slurry cyclone station according to the present invention. In Fig. 2, 4 denotes a switching mechanism.

[0017] 1 and 2, it can be seen that the underflow distribution device for the slurry cyclone station of the present invention includes: a feed pipe 1, a slurry tank 2, a discharge port 3 and a switching mechanism 4, and the switching mechanism 4 has a push rod and a pair of parallel tracks.

[0018] Next, each part of the underflow distribution device used in the slurry cyclone statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com