Heat exchanger with spiral baffle plate and corrugated tube for liquid food sterilization

A technology of helical baffles and liquid food, applied in the direction of heat exchanger shells, tubular elements, heat exchange equipment, etc., can solve the problems that have not been seen before, and achieve the effect of improving the overall heat transfer coefficient and overcoming discontinuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

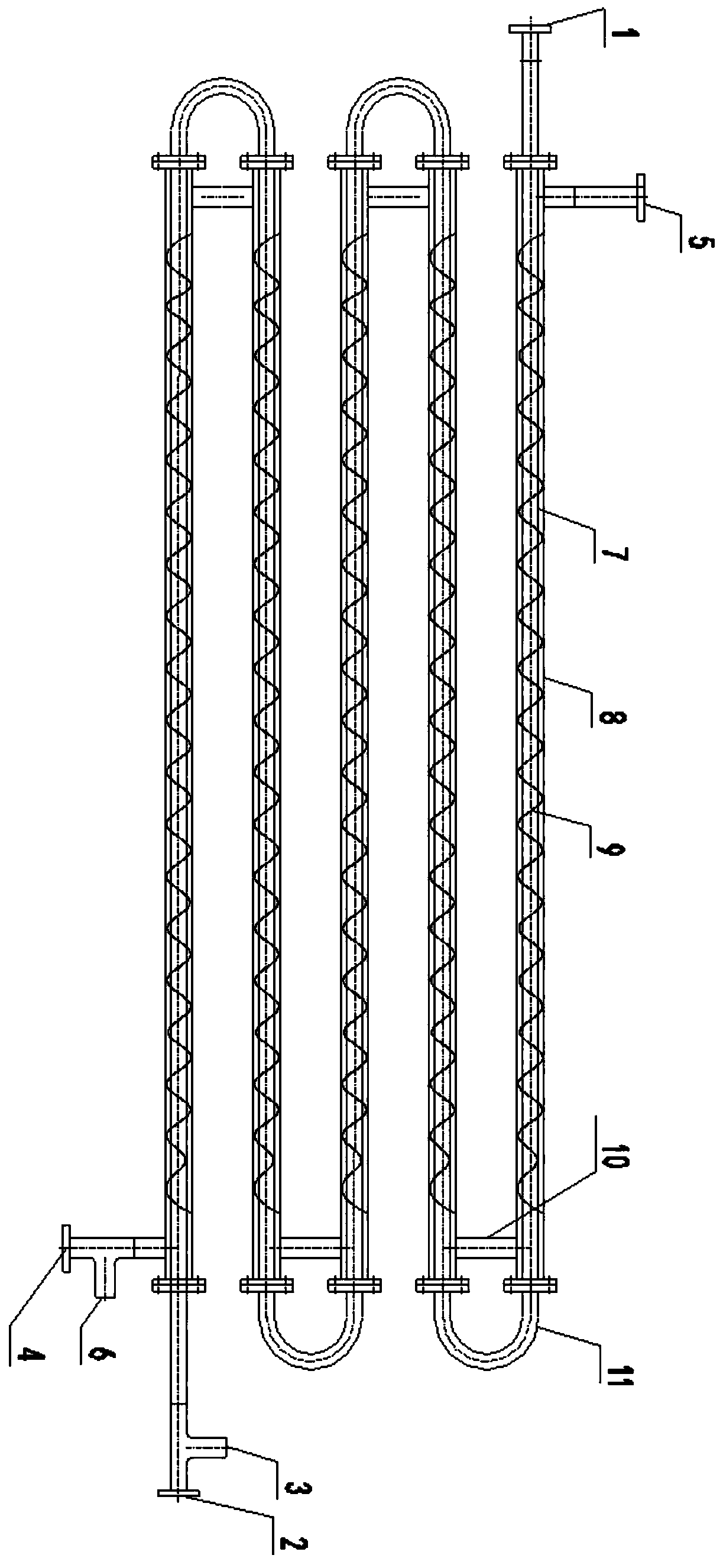

specific Embodiment

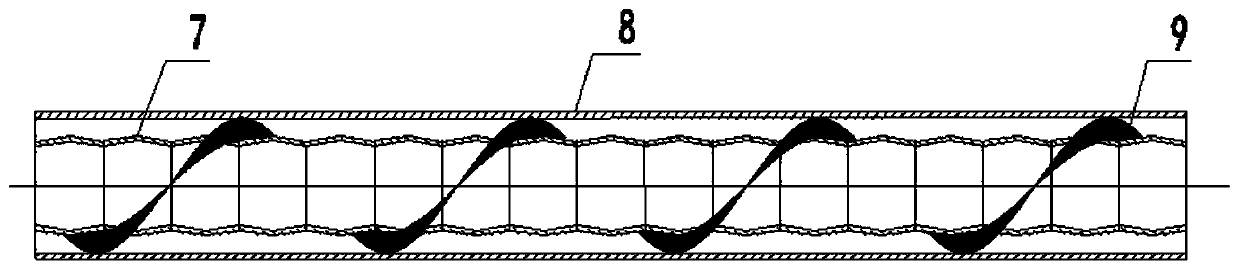

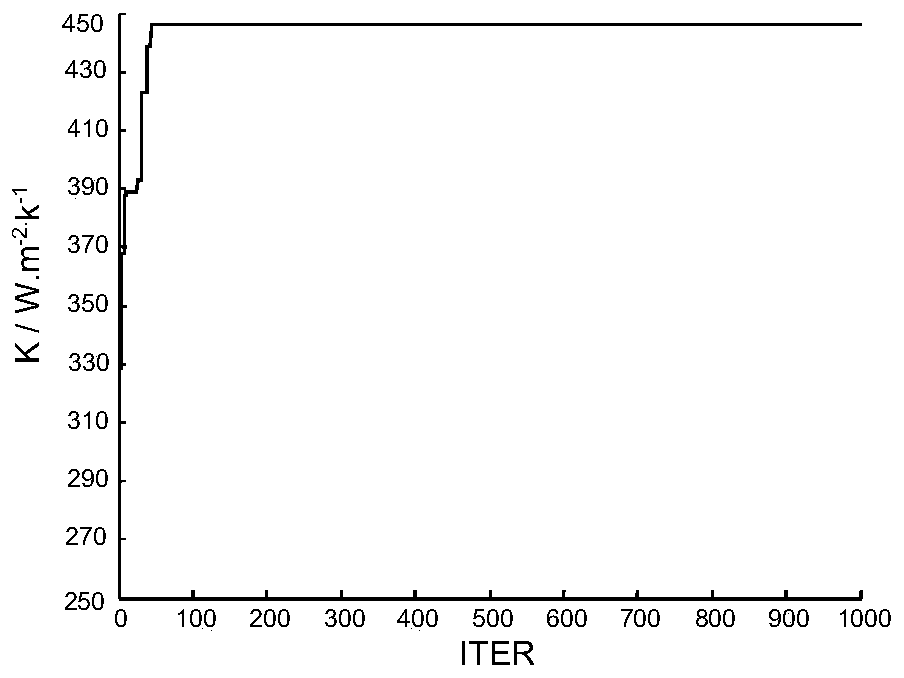

[0033] Specific example: the production capacity of a certain sauce factory is 1.2t / h, the temperature of the liquid food inlet pipe 1 is 20°C, the outlet temperature is required to be 80-85°C, heated by 120°C hot water, and the flow rate of hot water is 2.8m 3 / h. After thermodynamic calculation, the heating water is lowered from 120°C to 90°C, which can fully meet the sterilization temperature requirements of liquid food. The heat exchanger corrugated tube is DN32×1.5, the outer casing is DN50×1.5, and the helix angle of the continuous spiral baffle is 55. °, the length of a single heat exchange tube 7 is 3.0m, and the number of groups is 15 groups. The crest radius and pitch of the corrugated tube can be selected arbitrarily, but for a certain working condition, the optimal structural size can be found through a mathematical model. For this case, the particle swarm algorithm can be used to optimize the crest radius and pitch. The objective function can be established: K=f(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com