Efficient hydraulic remote particle material collecting and conveying system and method thereof

A granular material and conveying system technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of high maintenance costs of energy-consuming conveying systems, a large number of conveying system equipment, frictional resistance and frictional loss, etc. It achieves the effects of high degree of operation automation, high control precision, flexible and convenient structure adjustment, and strong transmission adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The present invention is illustrated by taking the high-pressure water mining and transportation of a certain coal mine as an example: the average particle size of the pulverized coal in the coal mining operation is 10mm, and the average flow rate of the coal-water mixture obtained by mining is 28m 3 / h.

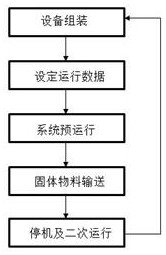

[0048] Its concrete conveying method comprises the following steps:

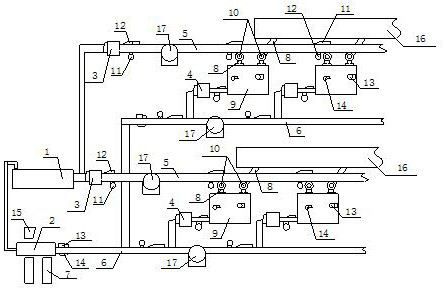

[0049] S1, equipment assembly, first of all, according to the drilling position of the coal mining operation in the roadway, a solid-liquid mixing cabin is equipped for the coal mining hole currently located at the farthest end of the coal mining operation in the roadway, and each mixing operation cabin is connected to the coal mining hole through the diversion branch pipe The coal mining holes of at least one coal mining operation are connected to each other, and then the solid-liquid mixing cabins in several roadways are connected to each other through the water supply pipeline and the clean water...

Embodiment 2

[0067] The present invention is illustrated by taking the high-pressure water mining and transportation of a certain coal mine as an example: the average particle size of the pulverized coal in the coal mining operation is 20mm, and the average flow rate of the coal-water mixture obtained by mining is 24m 3 / h.

[0068] A conveying method of a high-efficiency hydraulic remote collection and conveying system for granular materials includes the following steps:

[0069] S1, equipment assembly, equipment assembly, first of all, according to the drilling position of the coal mining operation in the roadway, a solid-liquid mixing cabin is equipped for the coal mining hole currently located at the farthest end of the coal mining operation in the roadway, and each mixing operation cabin is passed through the guide The flow branch pipes are connected to each other in at least one coal mining hole of coal mining operation, and then the solid-liquid mixing tanks in several roadways are ...

Embodiment 3

[0087] The present invention is illustrated by taking the transportation of gravel materials at the wharf as an example: wherein the average particle size of the gravel material is 15mm, and the average flow rate of the coal-water mixture obtained by coal mining is 25m 3 / h.

[0088] A conveying method of a high-efficiency hydraulic remote collection and conveying system for granular materials includes the following steps:

[0089] S1, equipment assembly, first, according to the number and position of the silos and conveyors for sand and gravel materials, set up a solid-liquid mixing tank for each conveyor of sand and gravel materials, and then pass each solid-liquid mixing tank through the water supply pipeline on the one hand It communicates with the clean water pool, and on the other hand, communicates with the solid-liquid separation device through the material conveying pipeline, and then connects the filtrate outlet of the solid-liquid separation device with the clean wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com