Method and device for removing coal dust and oil by enabling coal to be directly liquefied and generate sulphur-bearing waste water

A technology for direct liquefaction of coal and sewage, applied in the field of coal conversion, can solve the problems of long residence time of oil pollution, discontinuous operation, blockage of filters, etc., and achieve the effects of improving economic efficiency of the device, long continuous operation period, and reducing processing losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

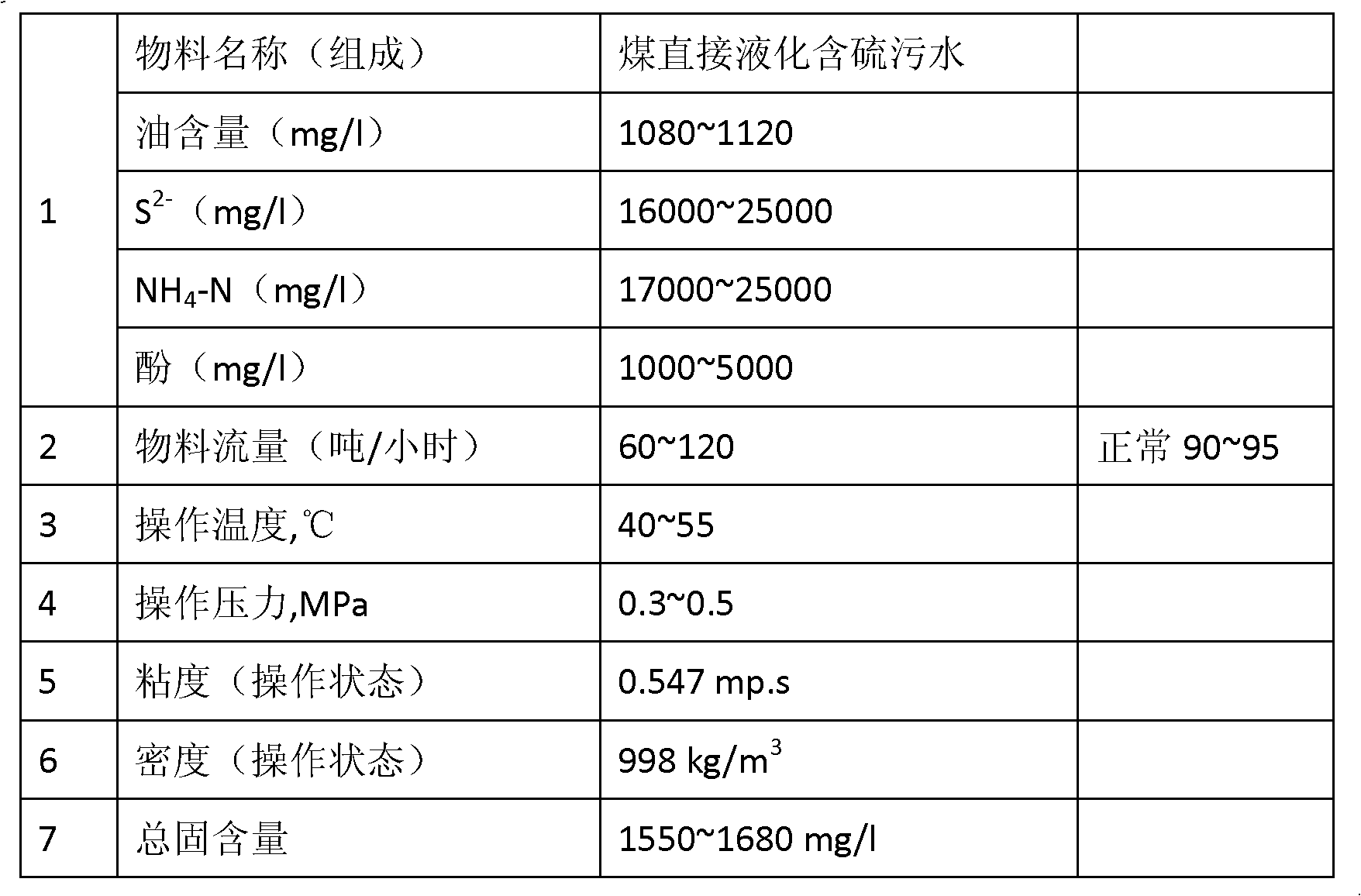

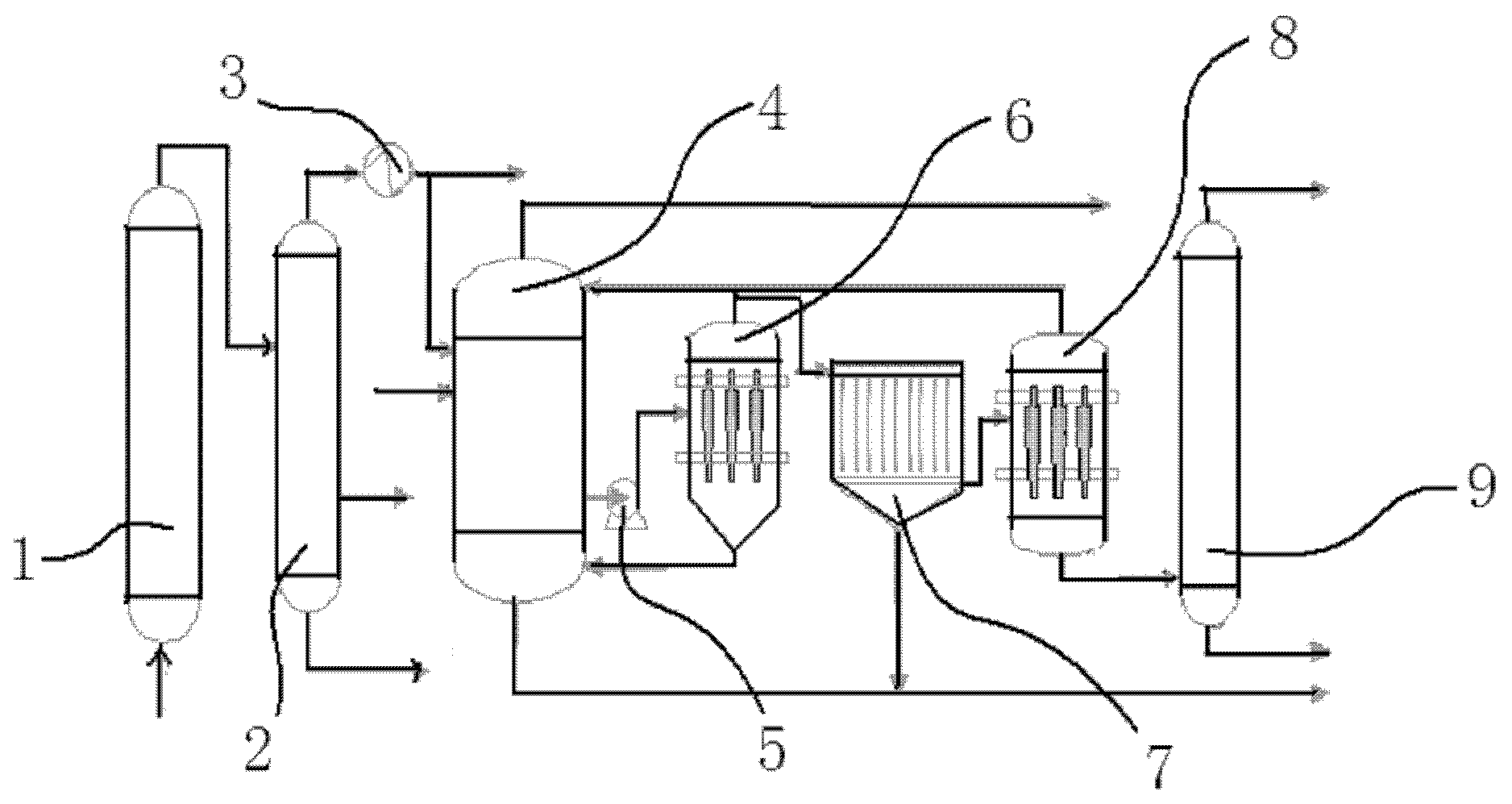

[0037] The sulfur-containing sewage produced by the reaction of a million-ton coal direct liquefaction device, according to the method and device described in the present invention, adopts the separation methods of gravity sedimentation, micro-swirl desolidification, precision filtration and swirl degreasing to contain coal powder and the sulfur-containing sewage of waste oil are processed to achieve the purpose of removing coal dust and reclaiming waste oil. The properties of the sulfur-containing sewage are shown in Table 1. The specific treatment steps and effects are as follows:

[0038] Table 1 The properties of sulfur-containing sewage required to be treated

[0039]

[0040] 1) Processing steps:

[0041] 1> After the reactor 1, the heat exchange device 2 and the fractionation tower 3, the sulfur-containing sewage entrained with coal powder and waste oil enters the regulating tank 4, and is gravity-settled under the action of the demulsifier, and the sulfur-containing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com