Double-injection pump continuous injection device applicable to particle well drilling

An injection device and double-injection technology are applied in liquid/gas jet drilling, construction, etc., which can solve problems such as increasing the coverage of high-pressure areas and increasing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

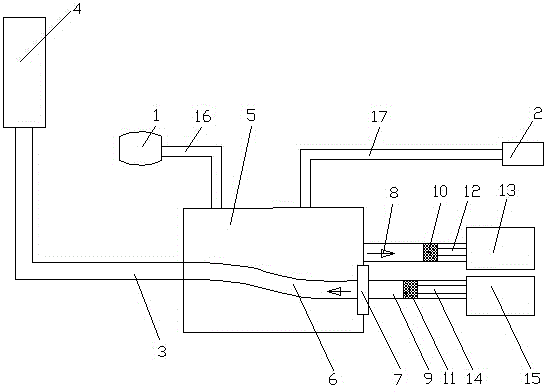

[0039] see figure 1 , a double injection pump continuous injection device suitable for particle drilling, including a slurry pump 1 and a screw conveyor 2, and also includes a particle mixing hopper 5 connected to the drilling riser 4 through a high-pressure pipeline 3, the particle mixing hopper 5 A reversing pipe 6 is arranged inside, and the reversing pipe 6 is connected with a swing hydraulic cylinder 7 that drives the reversing pipe 6 to swing left and right. The particle mixing hopper 5 is connected with a first conveying cylinder 8 and a second conveying cylinder 9. The first delivery cylinder 8 is provided with a first piston 10, the second delivery cylinder 9 is provided with a second piston 11, the first piston 10 is connected to the first hydraulic cylinder 13 through the first piston rod 12, and the second delivery cylinder 9 is connected to the first hydraulic cylinder 13. The piston 11 is connected to the second hydraulic cylinder 15 through the second piston rod...

Embodiment 2

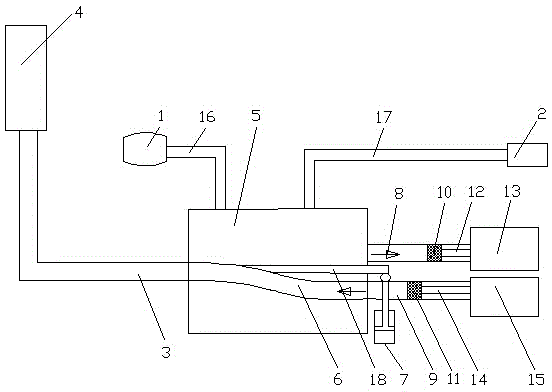

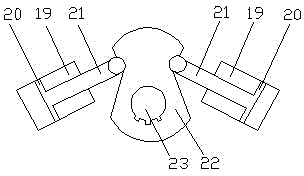

[0042] see figure 2 and image 3 , a double injection pump continuous injection device suitable for particle drilling, including a slurry pump 1 and a screw conveyor 2, and also includes a particle mixing hopper 5 connected to the drilling riser 4 through a high-pressure pipeline 3, the particle mixing hopper 5 A reversing pipe 6 is arranged inside, and the reversing pipe 6 is connected with a swing hydraulic cylinder 7 that drives the reversing pipe 6 to swing left and right. The particle mixing hopper 5 is connected with a first conveying cylinder 8 and a second conveying cylinder 9. The first delivery cylinder 8 is provided with a first piston 10, the second delivery cylinder 9 is provided with a second piston 11, the first piston 10 is connected to the first hydraulic cylinder 13 through the first piston rod 12, and the second delivery cylinder 9 is connected to the first hydraulic cylinder 13. The piston 11 is connected to the second hydraulic cylinder 15 through the se...

Embodiment 3

[0046] see image 3 and Figure 4 , a double injection pump continuous injection device suitable for particle drilling, including a slurry pump 1 and a screw conveyor 2, and also includes a particle mixing hopper 5 connected to the drilling riser 4 through a high-pressure pipeline 3, the particle mixing hopper 5 A reversing pipe 6 is arranged inside, and the reversing pipe 6 is connected with a swing hydraulic cylinder 7 that drives the reversing pipe 6 to swing left and right. The particle mixing hopper 5 is connected with a first conveying cylinder 8 and a second conveying cylinder 9. The first delivery cylinder 8 is provided with a first piston 10, the second delivery cylinder 9 is provided with a second piston 11, the first piston 10 is connected to the first hydraulic cylinder 13 through the first piston rod 12, and the second delivery cylinder 9 is connected to the first hydraulic cylinder 13. The piston 11 is connected to the second hydraulic cylinder 15 through the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com