Coal and gas fluidization co-mining system and method for low-permeability inclined coal seam

A fluidized, low-breathing technology, applied in the direction of gas discharge, mining equipment, mining fluids, etc., can solve the problems of difficult gas extraction, large amount of roadway excavation, high mining cost, etc., to achieve efficient reduction of gas content and increase recovery , Improve the cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

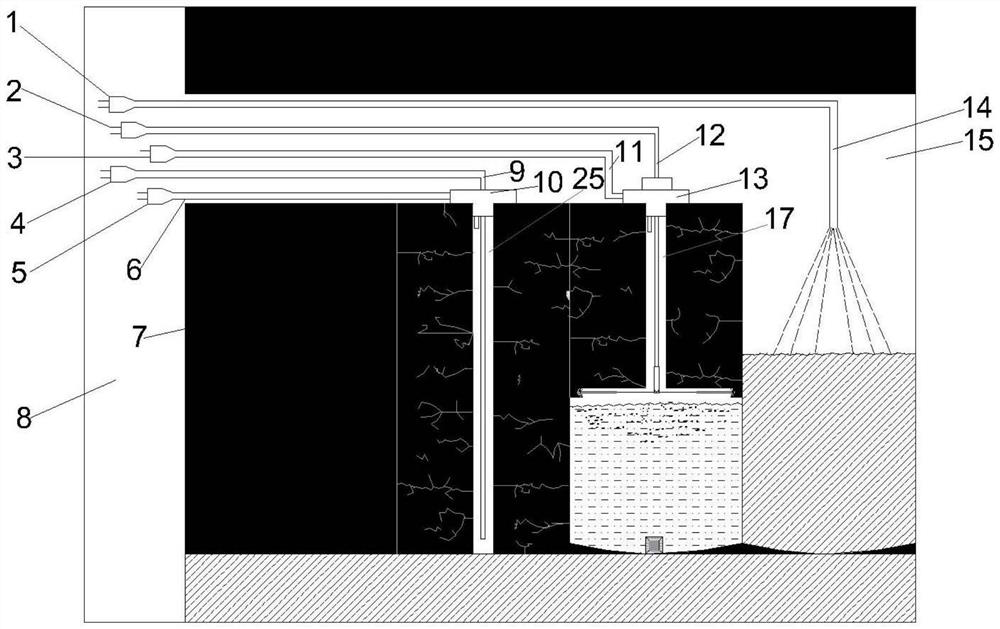

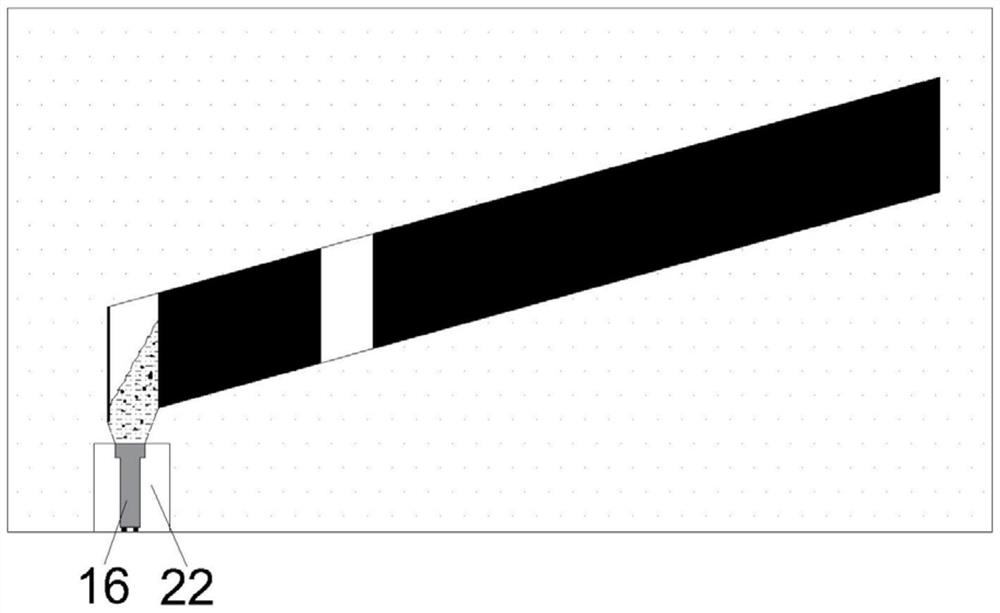

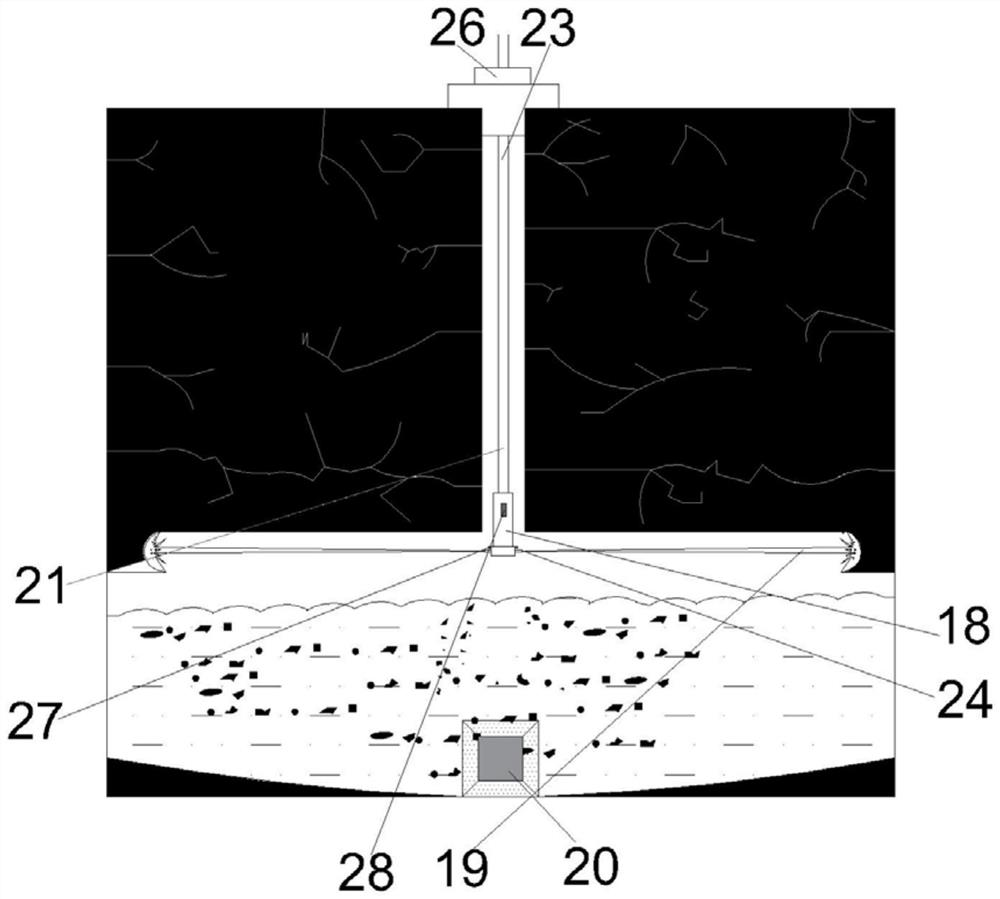

[0036] Such as Figure 1 to Figure 3 As shown, a coal and gas fluidized co-mining system in a low-permeability inclined coal seam includes drilling 1 25 and drilling 2 17 in the coal seam mining strip, and mining holes above and at the boundary of the coal seam mining strip respectively. Roadway 15 and track roadway 8, liquid nitrogen cycle fatigue fracturing anti-permeability unit, hydraulic fluidization mining and gas drainage unit, hydraulic fluidization transportation unit and goaf paste filling unit;

[0037] The first borehole 25 is a borehole that has not been processed by fatigue fracturing operations; the second borehole 17 is a borehole that has been processed by fatigue fracturing operations;

[0038] The liquid nitrogen cycle fatigue fracturing anti-reflection unit includes a liquid nitrogen pumping machine 4, an air pump I5, a sealing plug I10, a liquid nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com