Coal mine underground coal bed drilling and cave-building device and method of use

A technology for creating caves and coal mines, applied to drilling equipment and methods, drill pipes, drill pipes, etc., can solve problems such as complex procedures, long occupation time, gas outburst, etc., to prevent wear and tear, improve drainage efficiency, and use methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

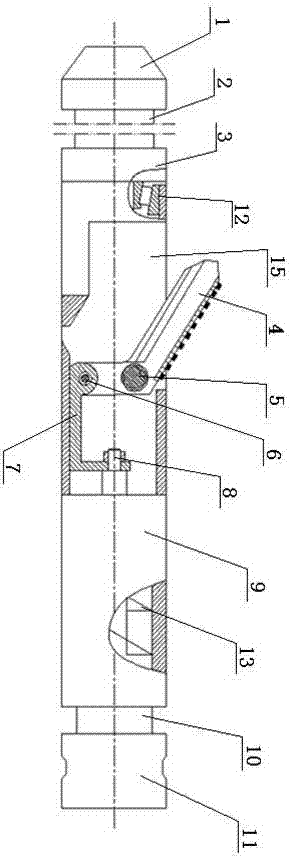

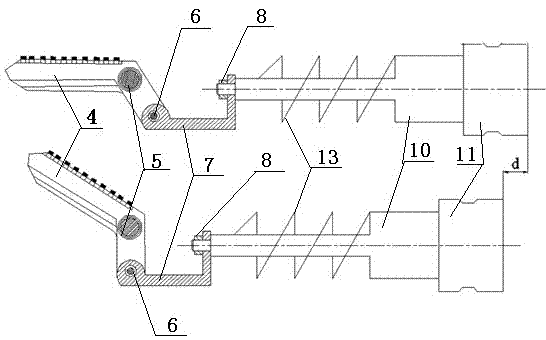

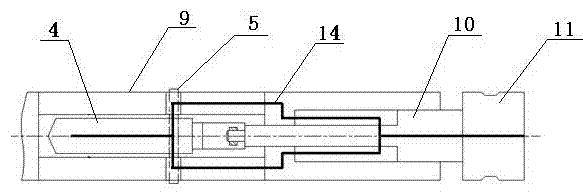

[0025] like figure 1 As shown, a coal mine underground coal seam drilling cavitation device includes a drill pipe joint 11, a transmission shaft 10, a pressure bearing 12 and a housing 9, and an "L"-shaped cutting arm 4 is arranged in the housing 9, and the cutting arm 4 The bending part is fixed on the casing 9 through a pin shaft, and a transmission shaft 10 is arranged in the casing 9, and a return spring 13 is arranged on the transmission shaft 10. One end of the transmission shaft 10 protrudes from the casing 9 and is connected with the drill pipe joint 11. The other end is movably connected with one end of the cutting arm 4 through the state control link 7, and the other end of the cutting arm 4 is arranged in the strip-shaped opening 15 of the housing 9, so that the transmission shaft 10 passes through the state under the action of axial thrust or pulling force. The control link 7 drives the cutting arm 4 to expand or contract.

[0026] The front end of the housing 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com