Patents

Literature

36results about How to "Easy handling for transport" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

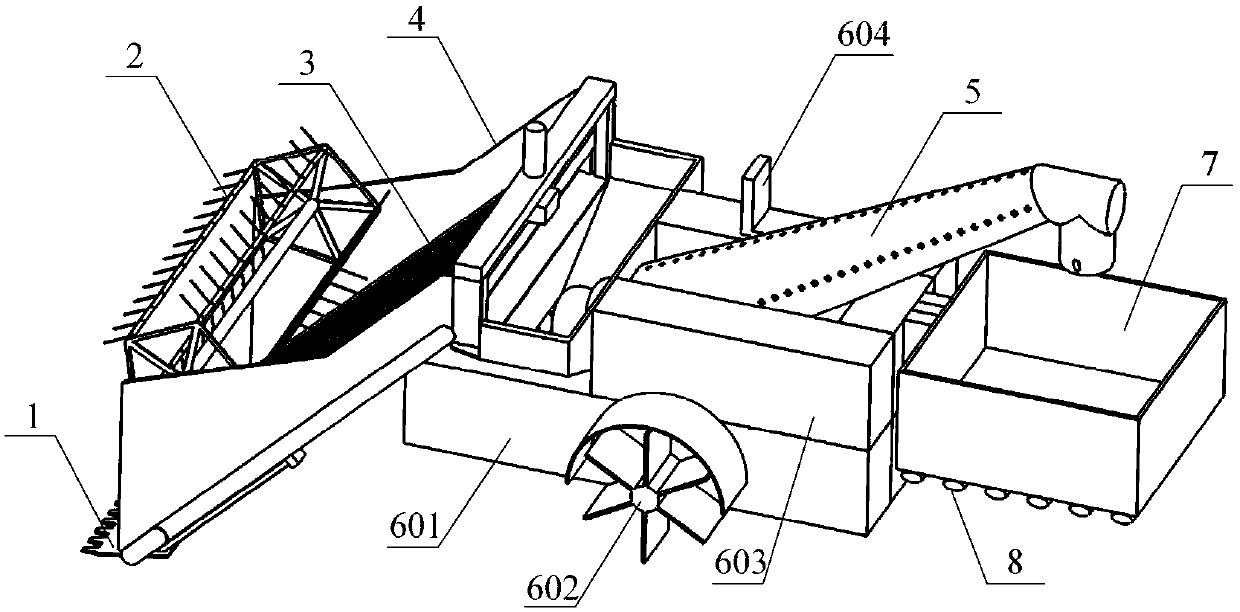

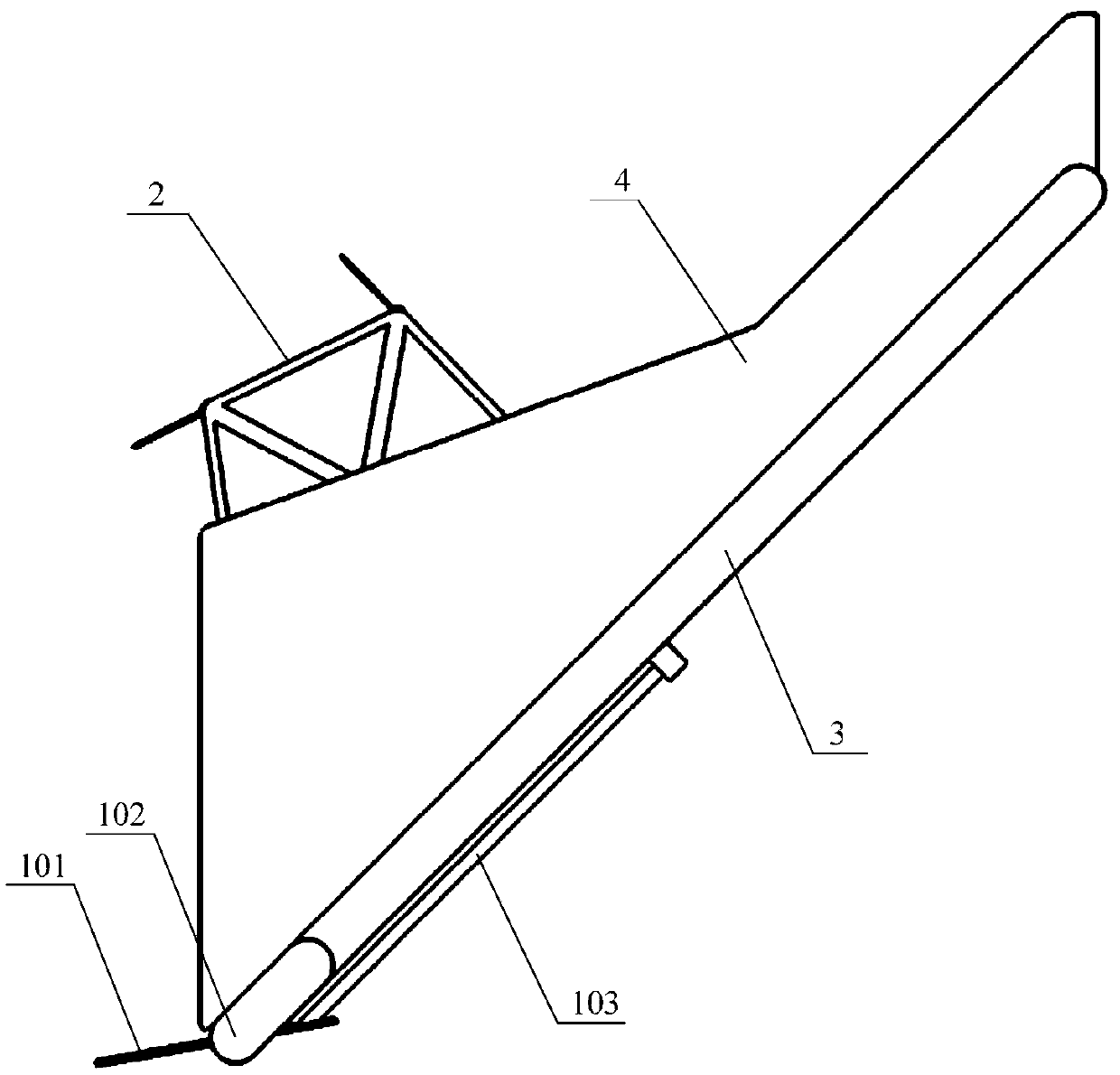

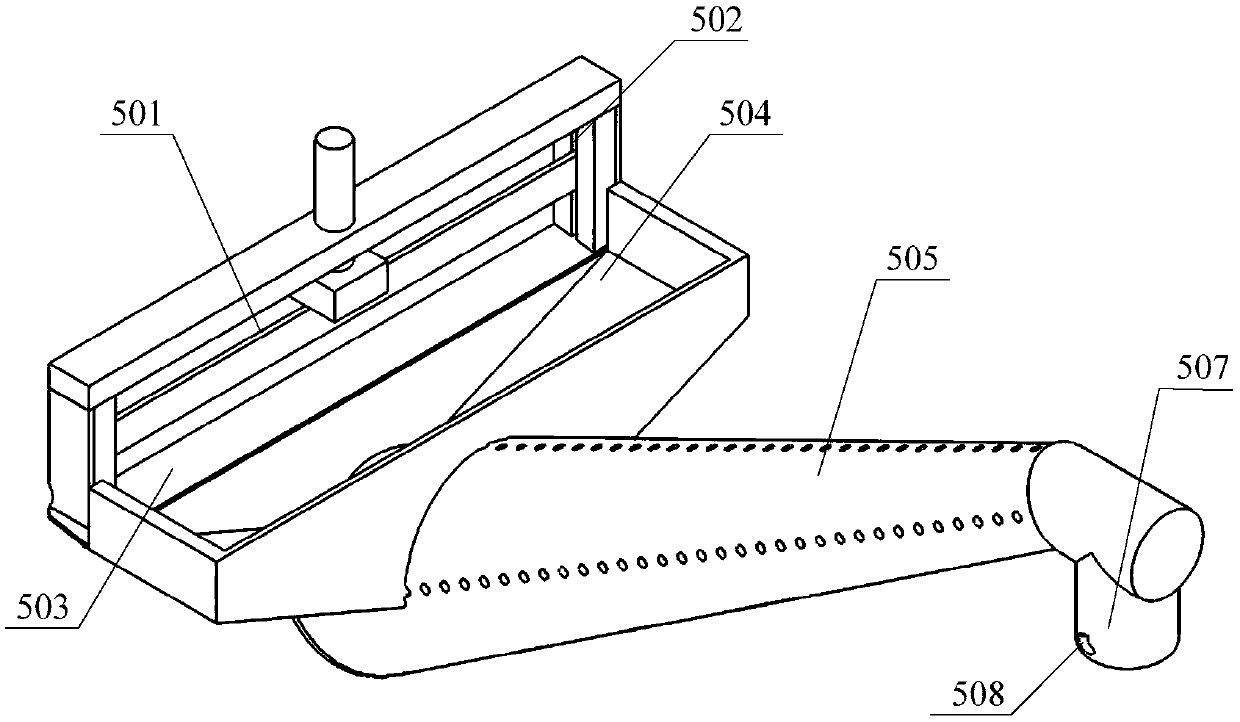

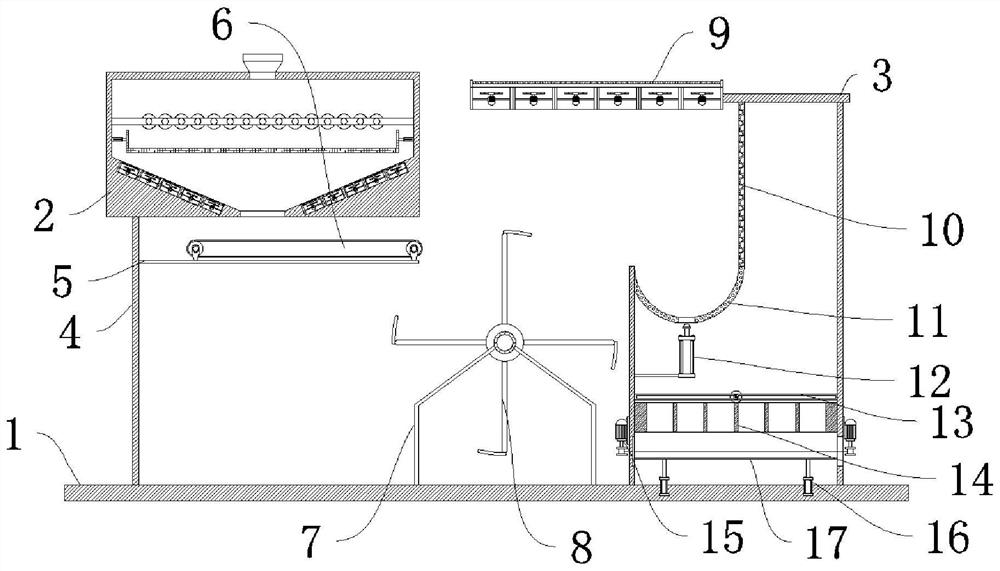

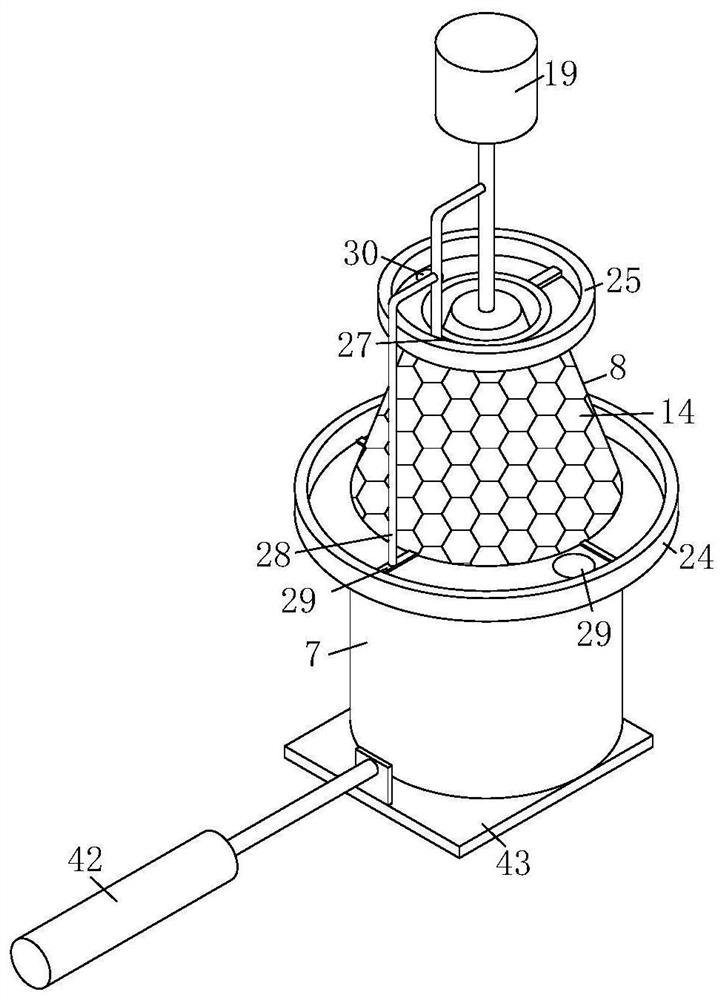

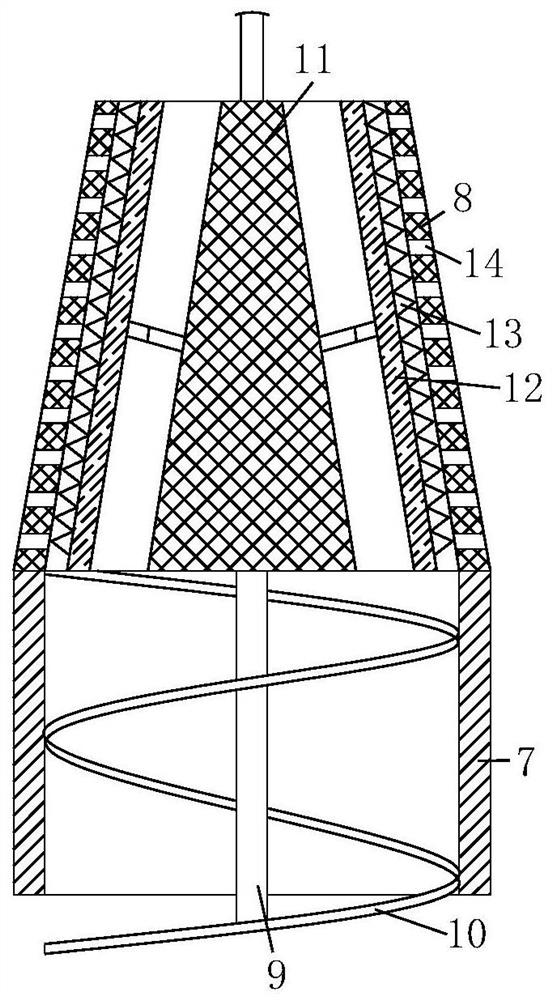

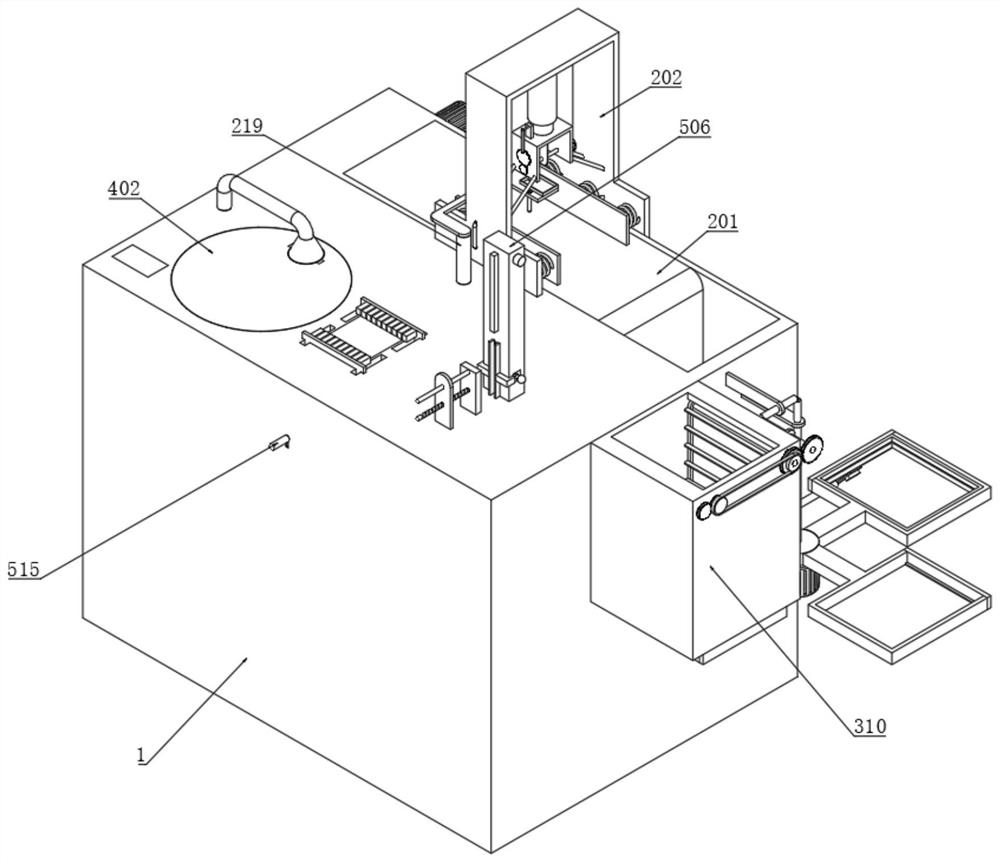

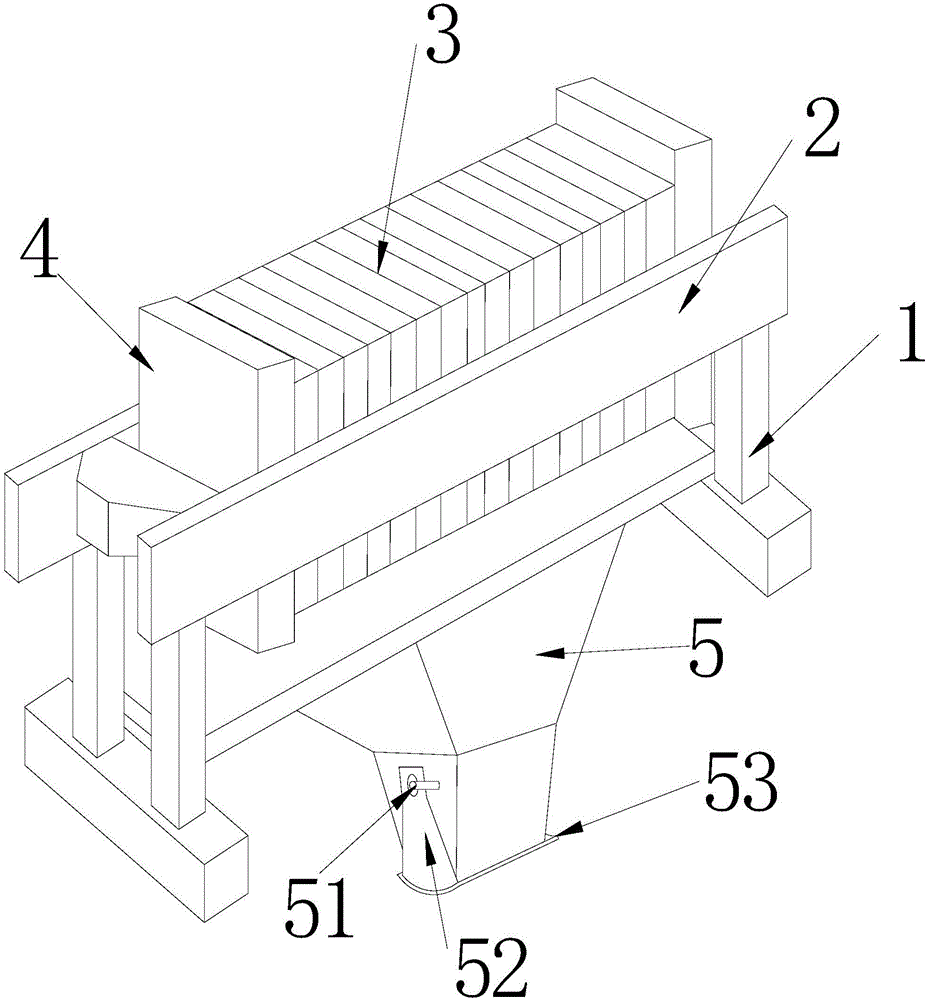

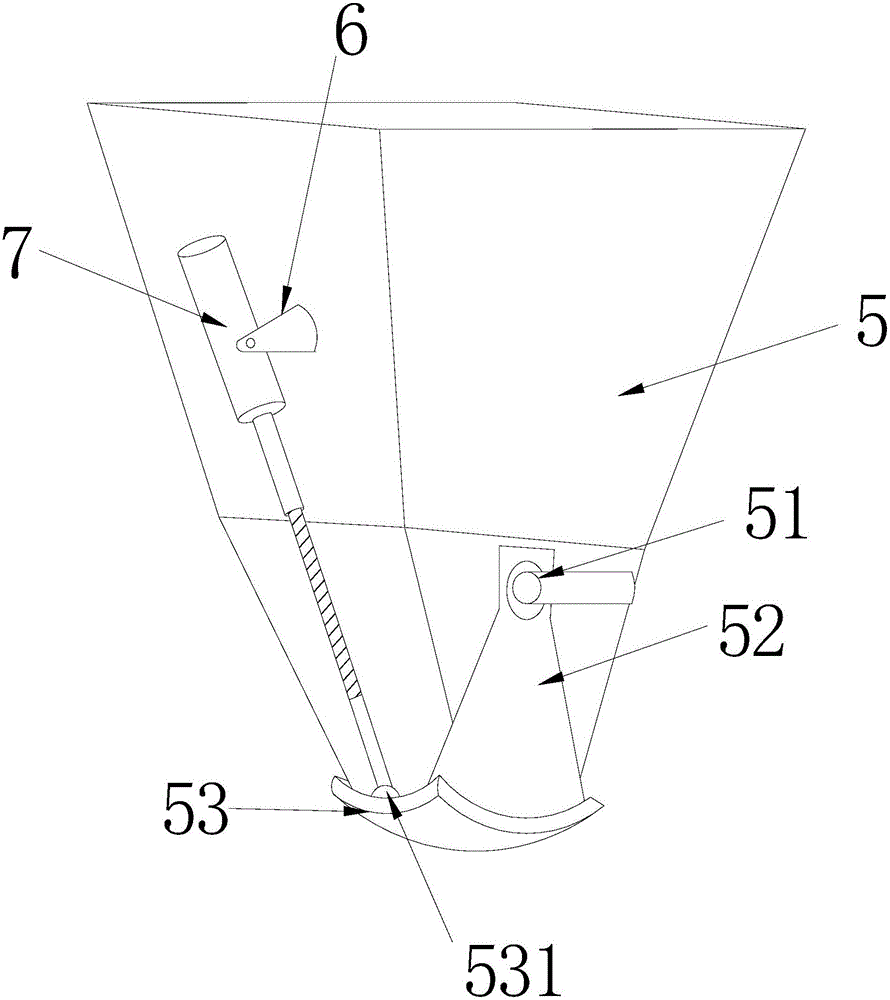

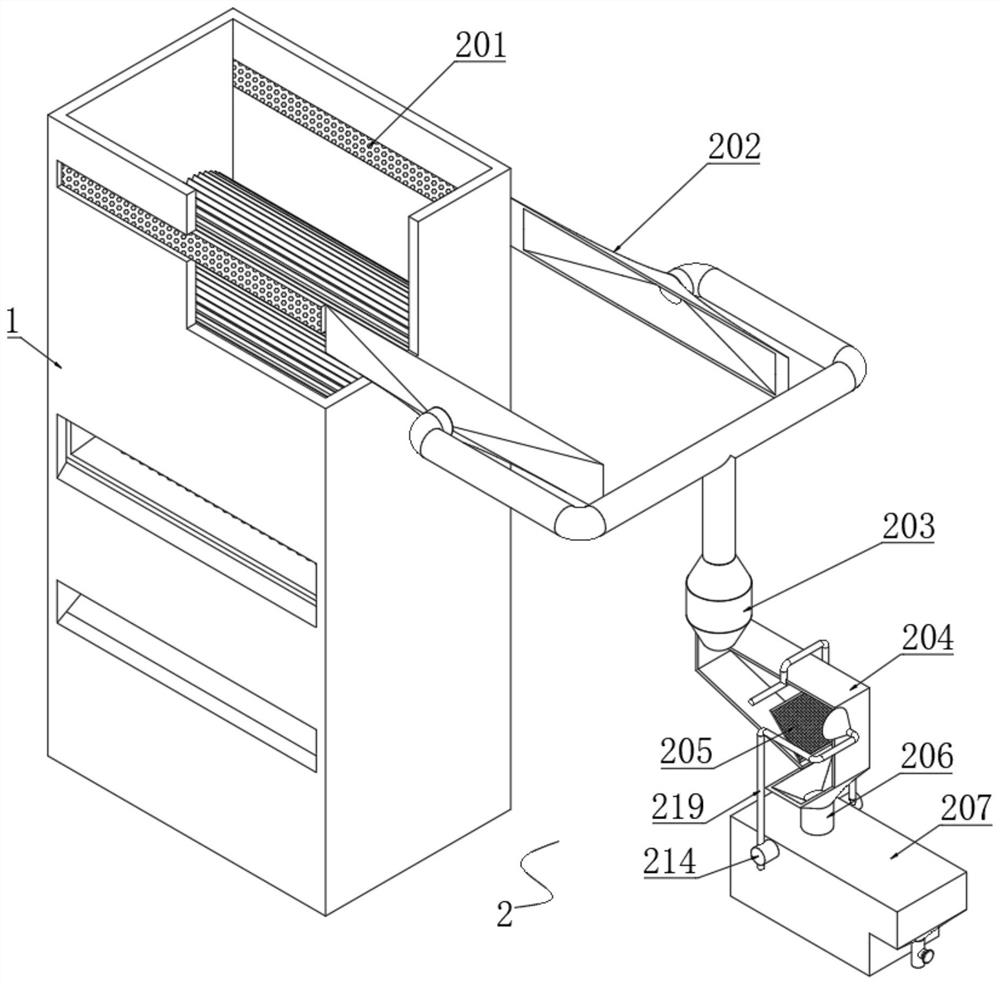

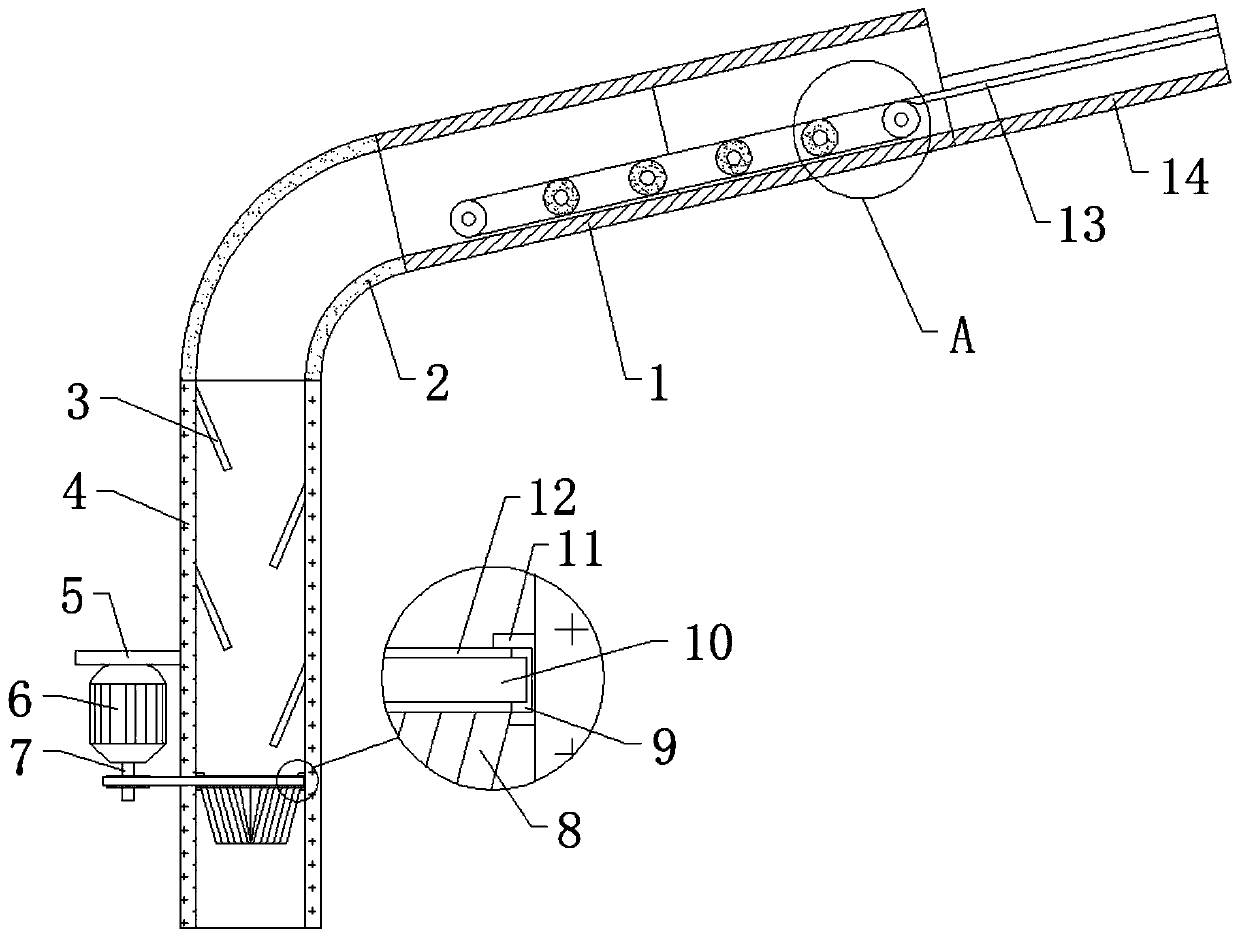

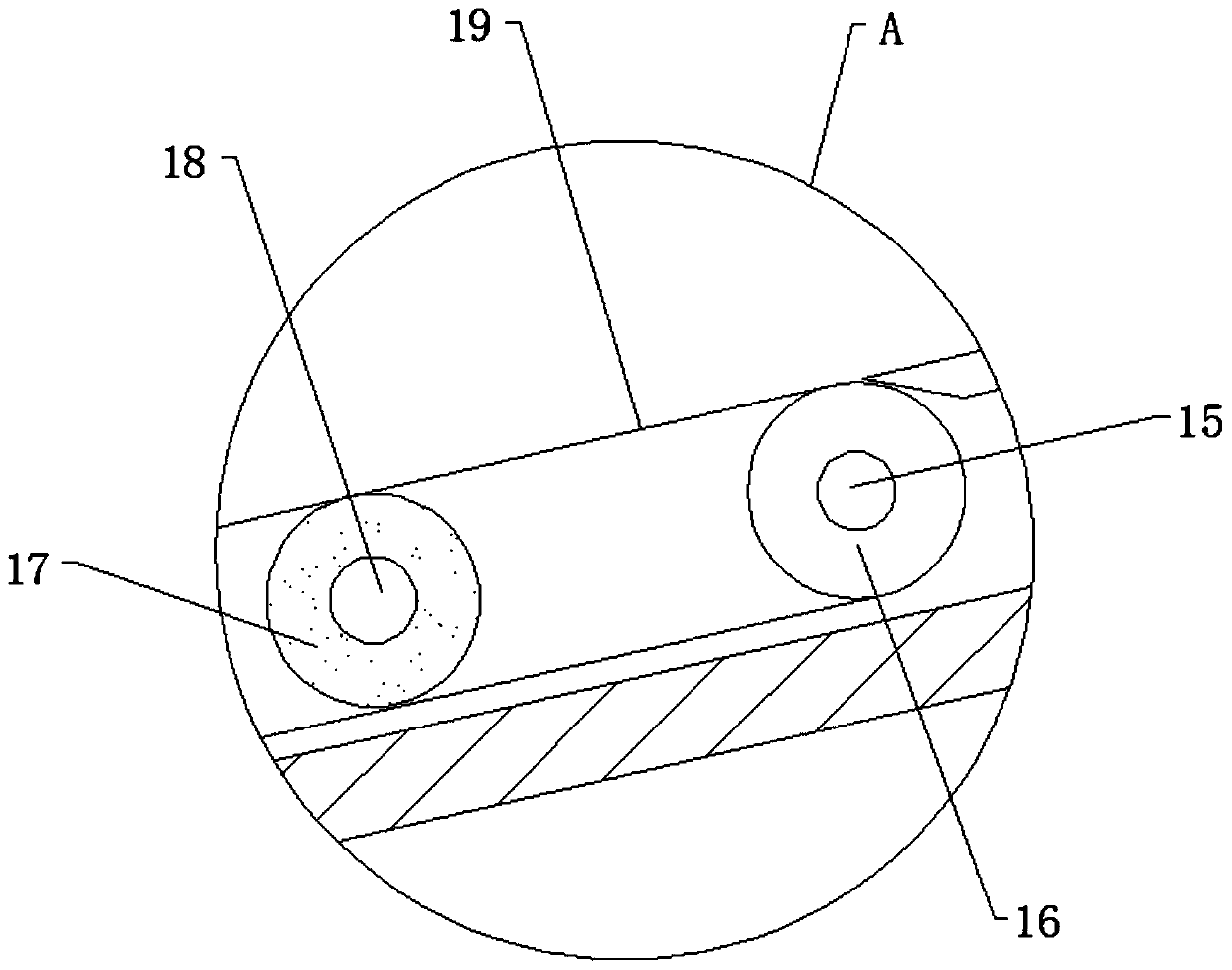

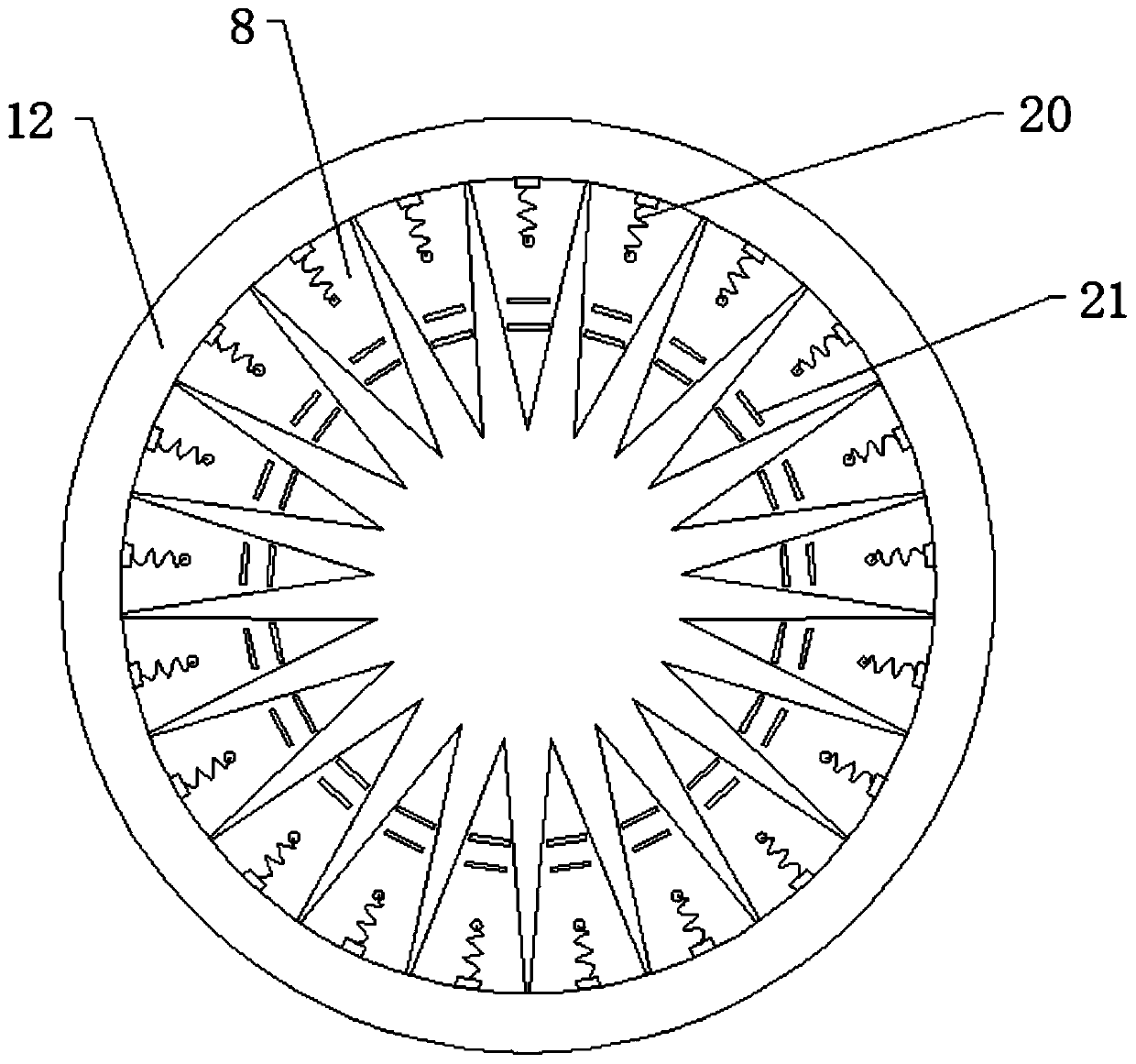

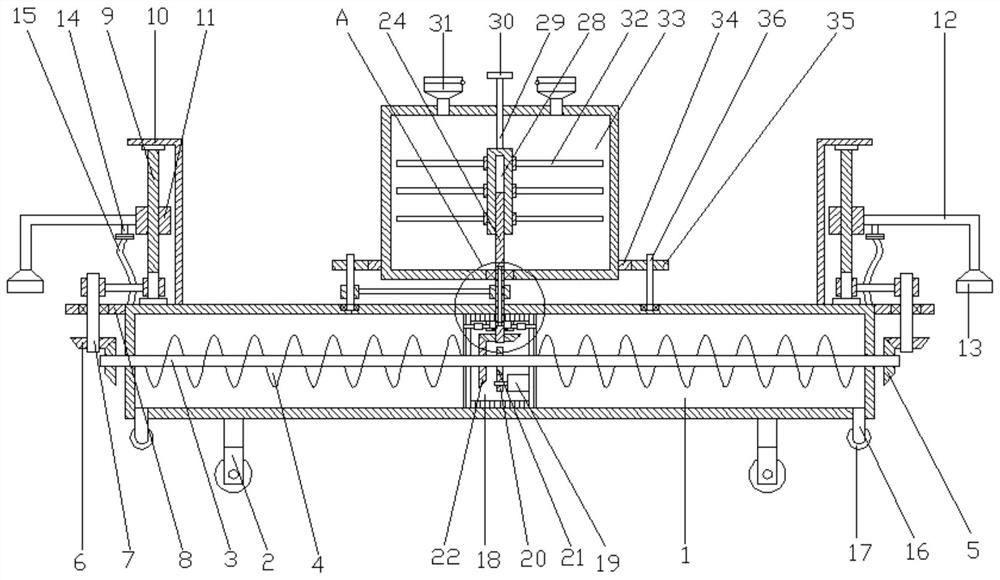

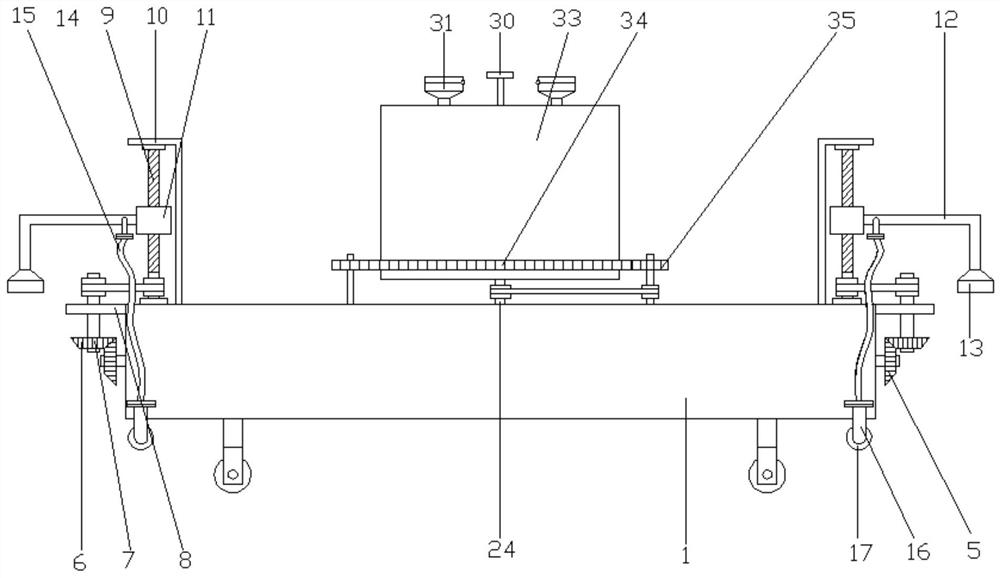

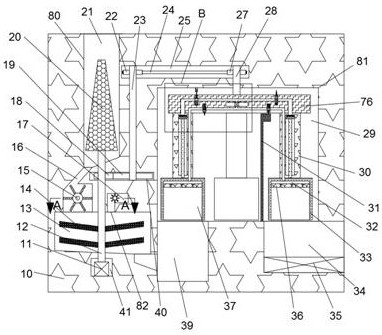

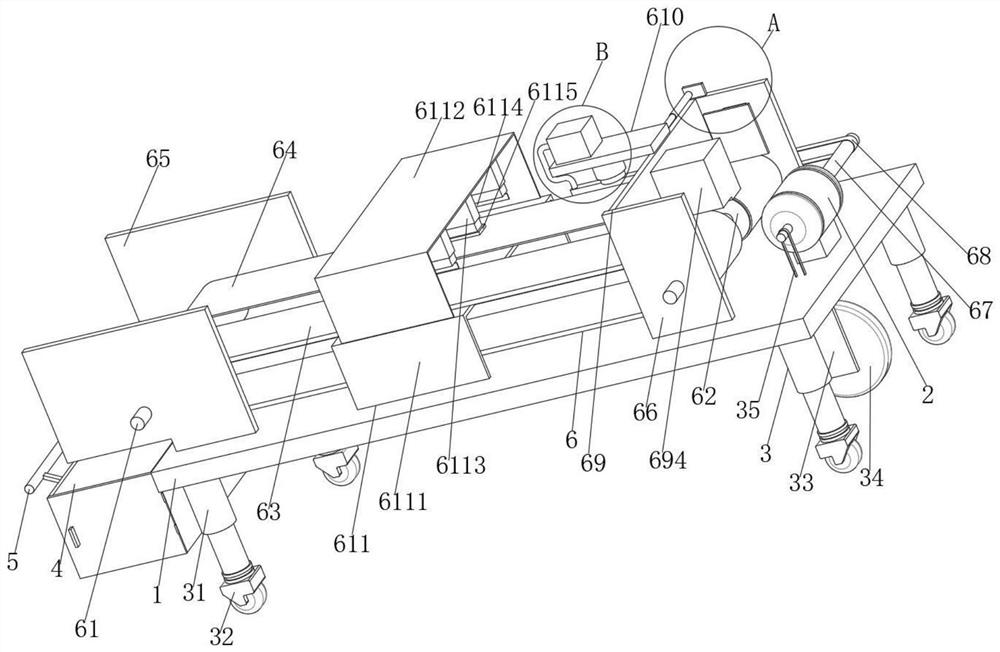

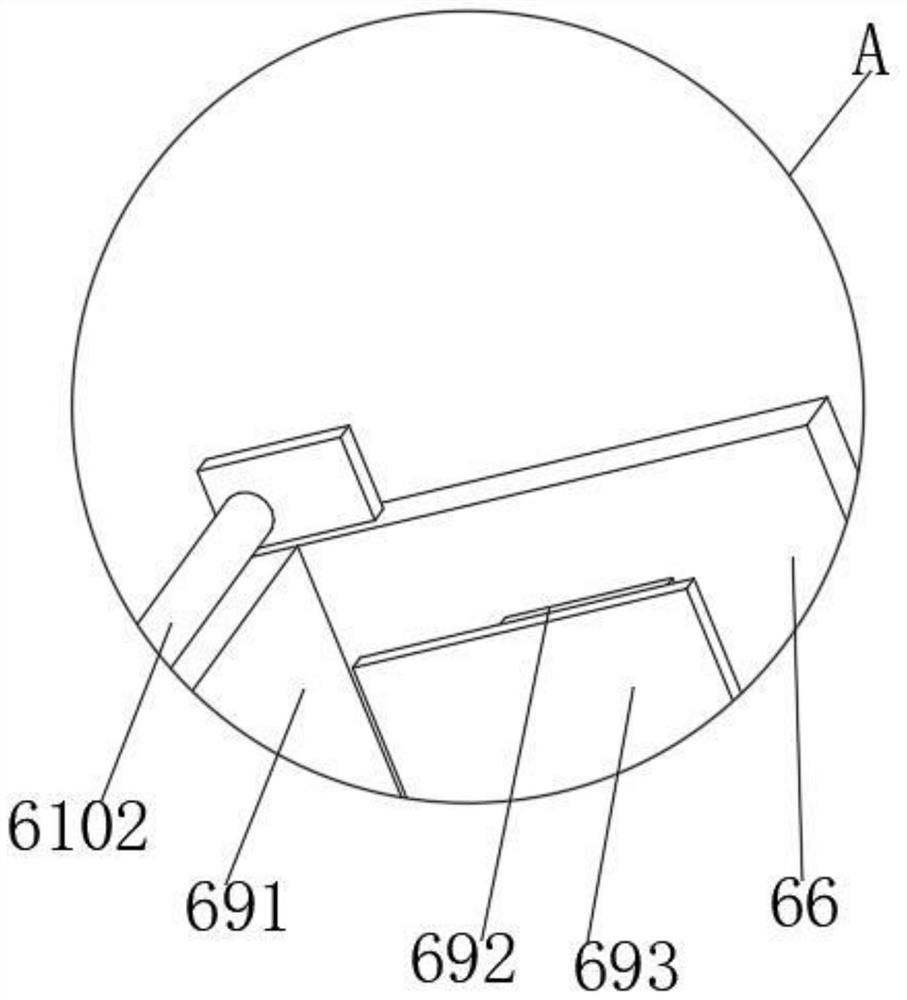

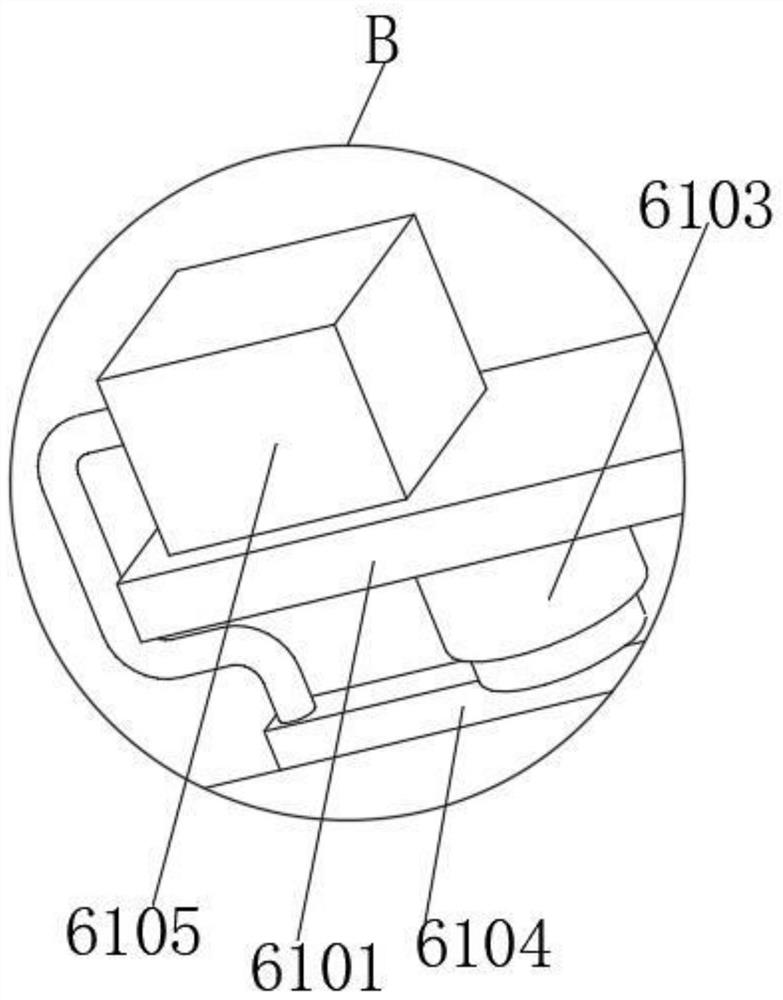

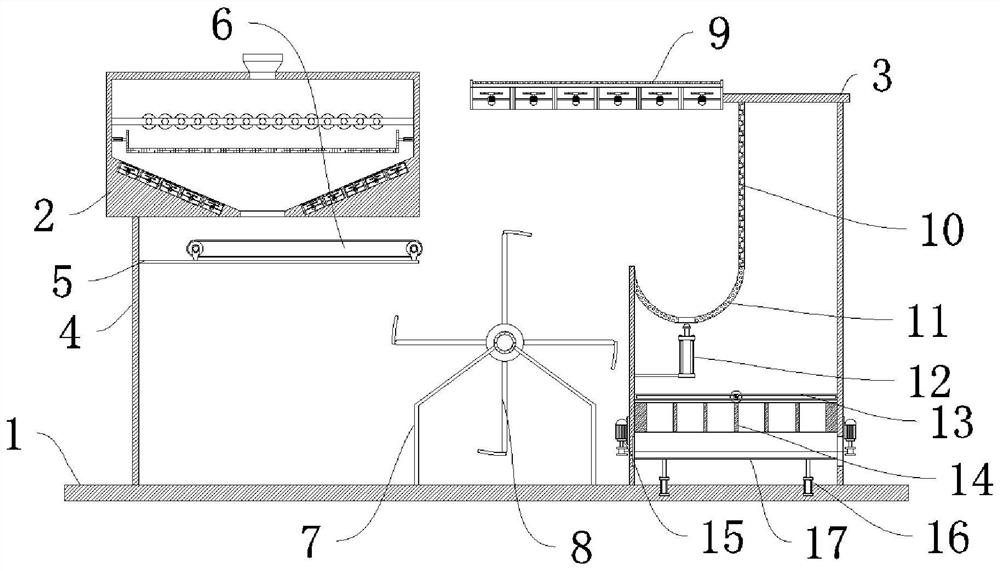

Multifunctional aquatic weeds harvester

The invention discloses a multifunctional aquatic weeds harvester, which mainly comprises a ship body, wherein a grabbing cutter for cutting aquatic weeds, a reticular conveyor belt for conveying theharvested aquatic weeds, a spiral extruding conveying device for extruding water from aquatic weeds, and a storehouse for collecting weeds after squeezing are arranged successively on the ship body. The front and back ends of the ship body are respectively connected with the reticular conveyor belt and the storehouse. The spiral extrusion conveying device is arranged above the middle part of the ship body. A grabbing cutter comprises a reciprocating cutter and a drum-type cutter which are arranged at the front of the reticular conveyor belt. Aquatic weeds are collected and stored by the storehouse through the grabbing cutter, the reticular conveyor belt and the spiral extrusion conveying device in sequence during harvesting operation. The storehouse and the ship body are separable. According to the multifunctional aquatic weeds harvester, the processes of cutting and squeezing of the aquatic weeds can be simultaneously achieved. The aquatic weeds are arranged in the detachable storehouse after being dewatered; so that further transportation and utilization are facilitated and one-stop treatment is achieved. The grabbing cutter can simultaneously harvest the aquatic weeds on the water surface and underwater and the aquatic weeds can be harvested in a wide range.

Owner:HUNAN UNIV +1

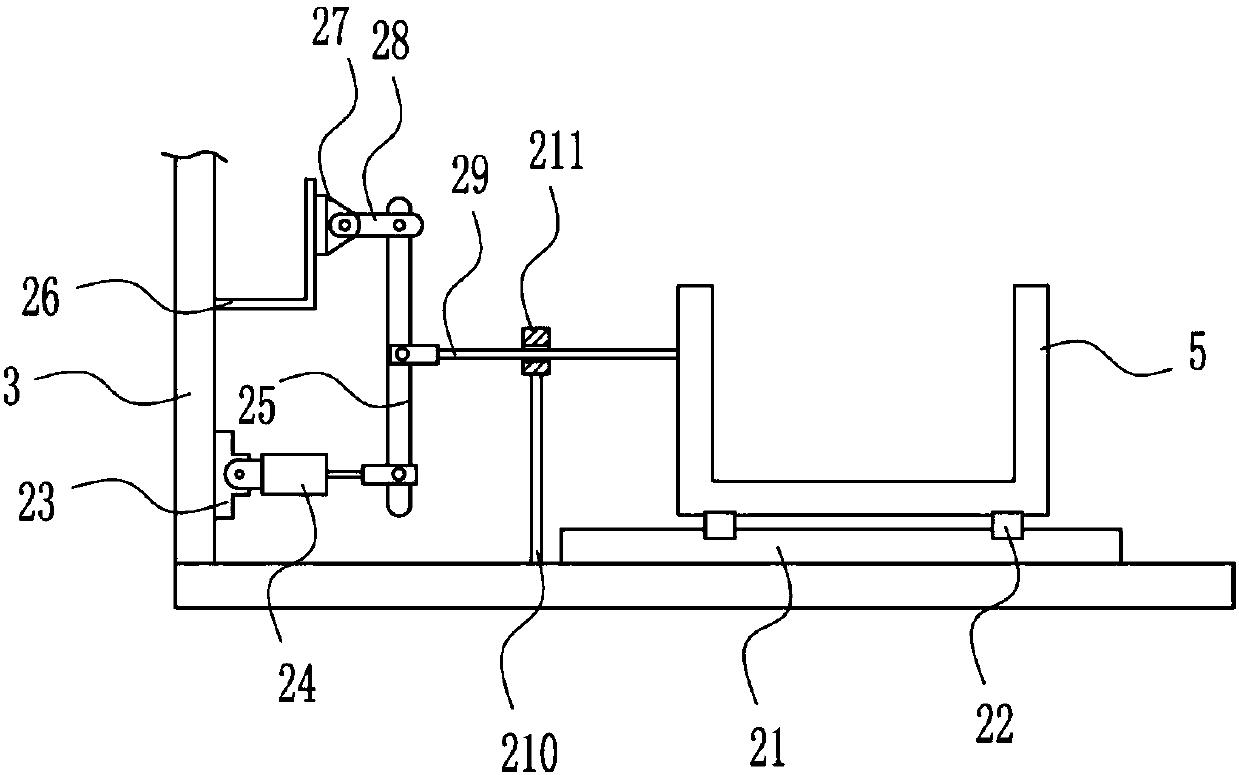

Equipment for rapidly compacting scraps generated in hardware machining process

The invention relates to equipment for compacting scraps generated in the hardware machining process, in particular to equipment for rapidly compacting the scraps generated in the hardware machining process, aims to provide the equipment for rapidly compacting the scraps generated in the hardware machining process, and the equipment is time-saving and labor-saving, and is good in compacting effect. The equipment comprises a bottom plate, a moving device, a left frame, a right frame, a moving frame, a top plate, a lifting device and the like, wherein the left frame is arranged on the left sideof the top of the bottom plate, and the right frame is arranged on the right side of the top of the bottom plate; the moving device is arranged on the position, located on the left side of the left frame, of the top of the bottom plate; the moving device is provided with the moving frame; the top plate is arranged on the top of the left frame and the top of the right frame; and the right side of the bottom of the top plate is provided with the lifting device. The equipment is good in compacting effect, time-saving, labor-saving, novel in structure and high in practicability; and according to the equipment, the labor intensity of workers can be reduced, and the transportation and treatment of the scraps can be facilitated.

Owner:王森杰

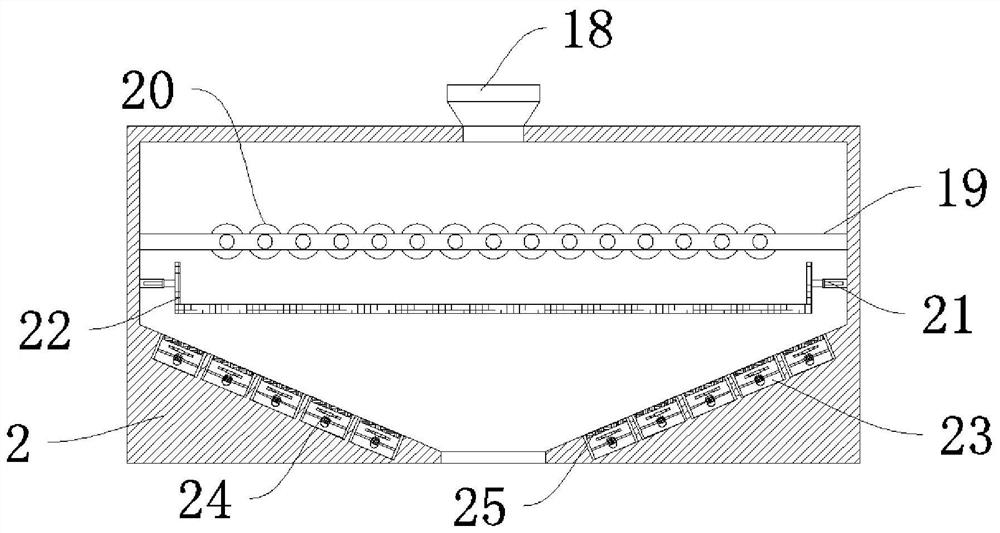

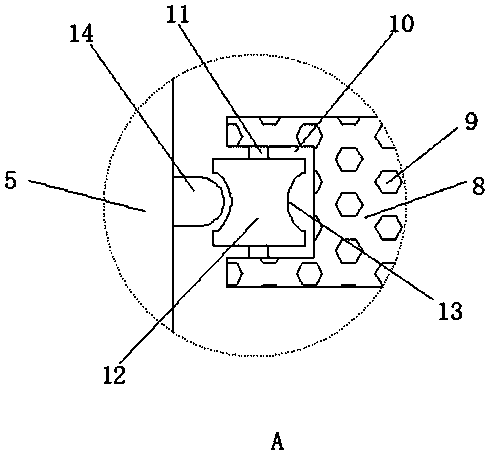

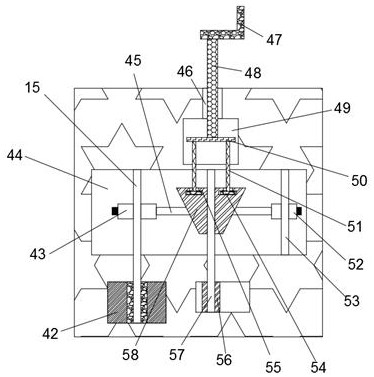

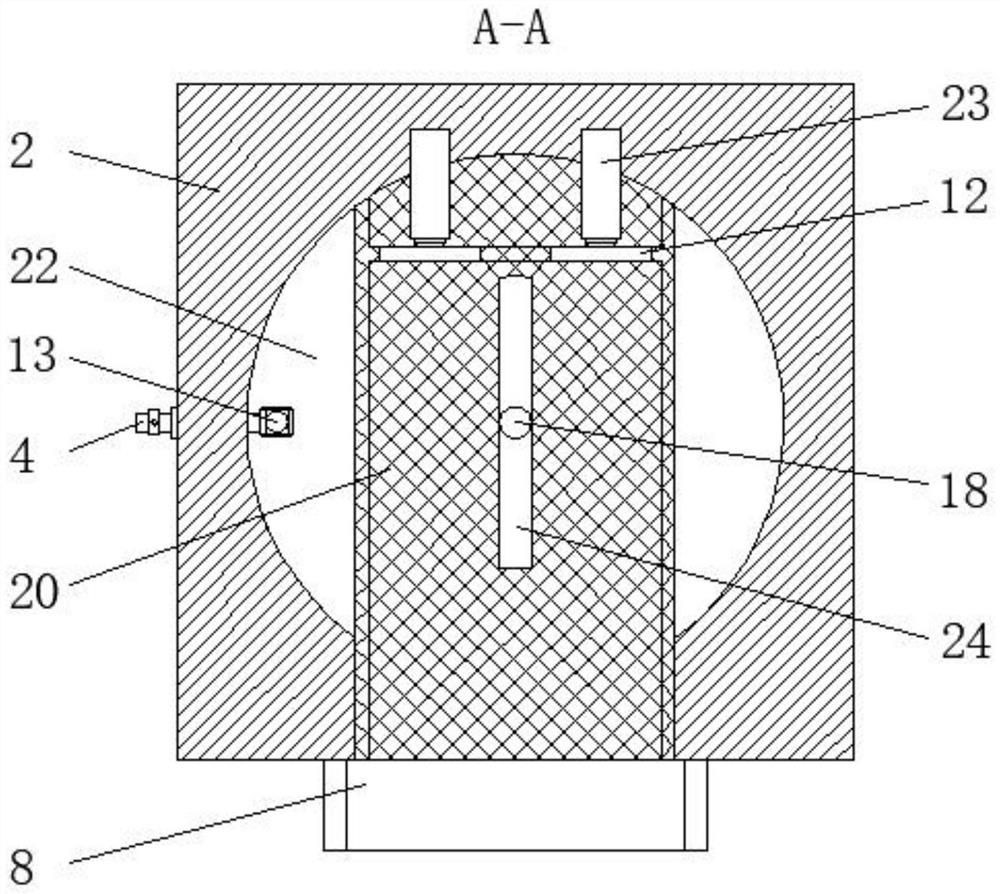

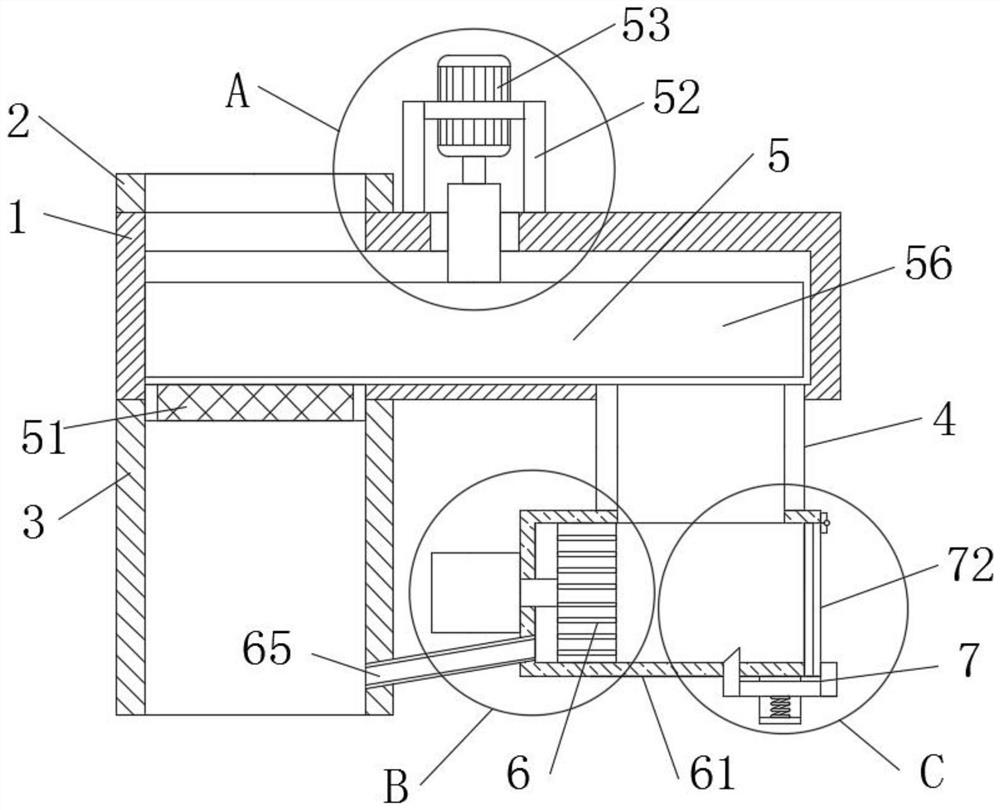

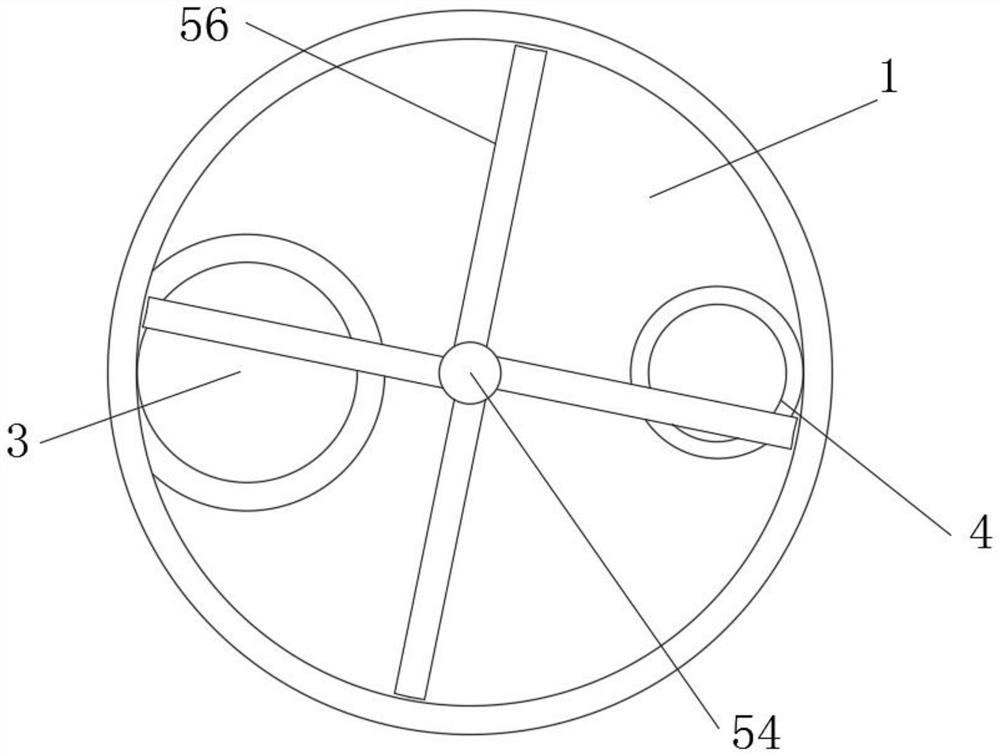

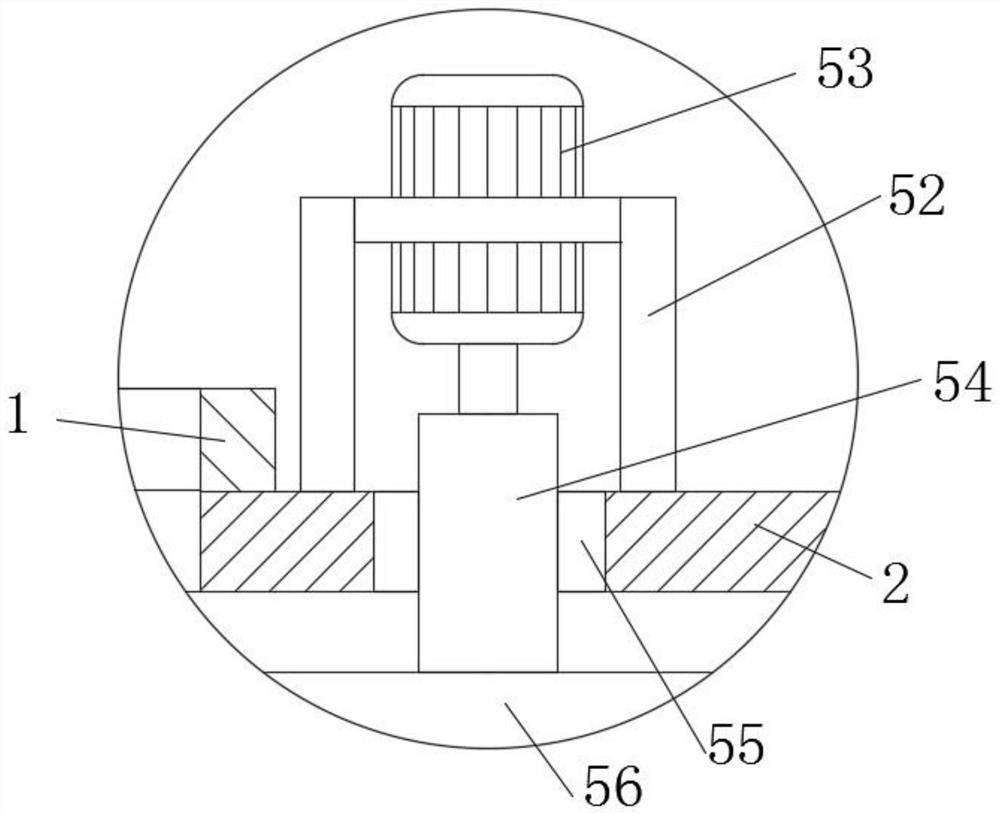

Rare earth waste drying device for rare earth waste recovery

ActiveCN112404105AFor subsequent dryingLimit flyawayDispersed particle filtrationTransportation and packagingThermodynamicsElectric machine

The invention discloses a rare earth waste drying device for rare earth waste recovery, and relates to the technical field of rare earth waste treatment. The rare earth waste drying device comprises afixed base, a pretreatment box and a storage box, a micro motor in the pretreatment box drives a grinding cylinder to rotate to achieve material grinding, and a second air cylinder drives a vibrationfiltering net to shake, materials fall off after being well separated, and subsequent drying is convenient; a second motor drives a rotary drum to rotate, the rotary drum drives a connecting plate and an arc-shaped baffle to rotate, and the second motor is controlled to move in a pause mode in actual use, so that it is guaranteed that the materials can be conveyed into the storage box, and further heating can be conducted; harmful gas generated during material drying is sucked in through a gas suction fan in a gas suction box; the filtering and adsorbing effects are achieved through the filtering net; and the dried materials can be pressed into blocks and then pushed out through cooperation of a pressing assembly, a forming base and a pushing assembly, and subsequent transportation treatment is facilitated.

Owner:萍乡鑫森新材料有限责任公司

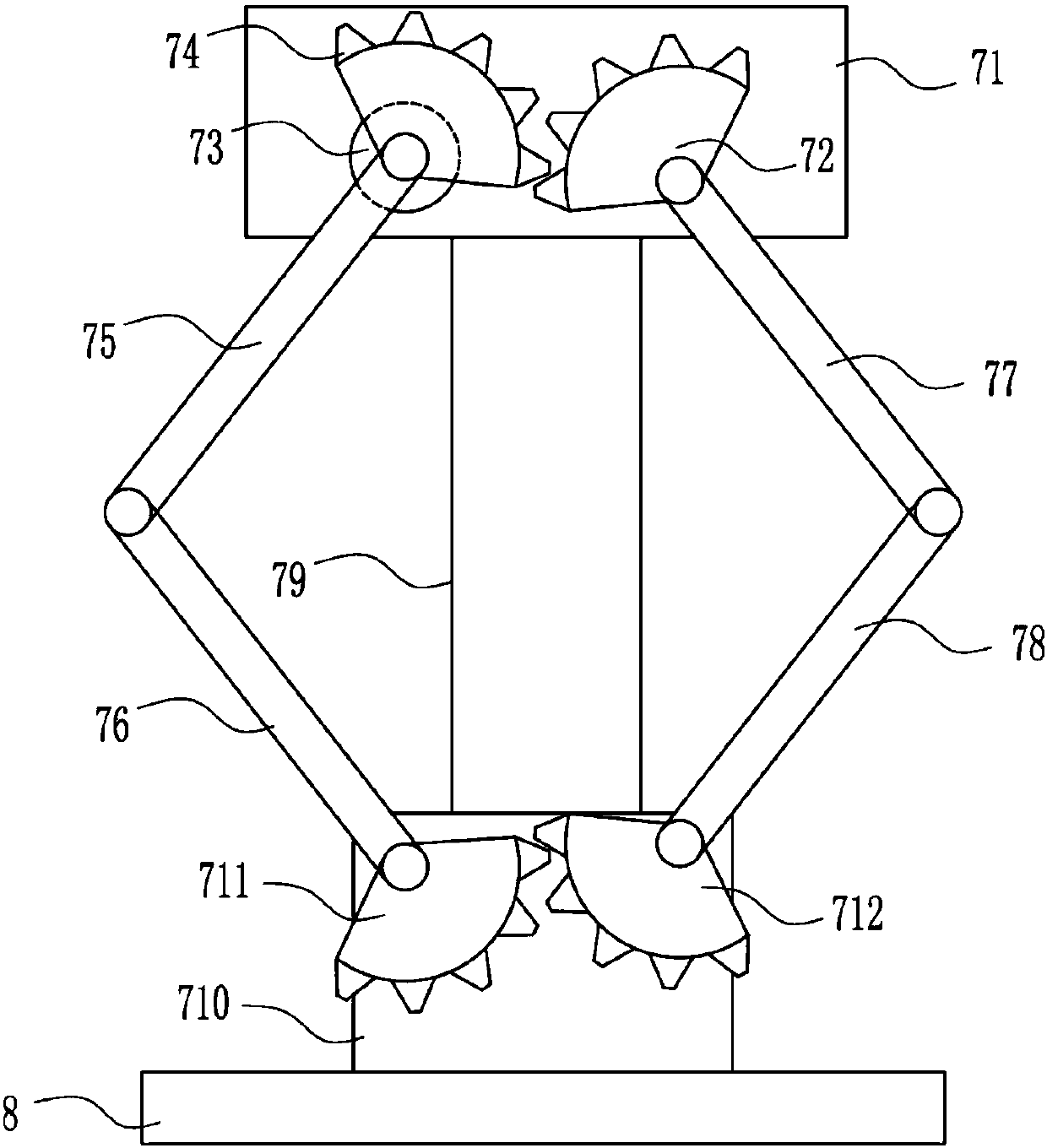

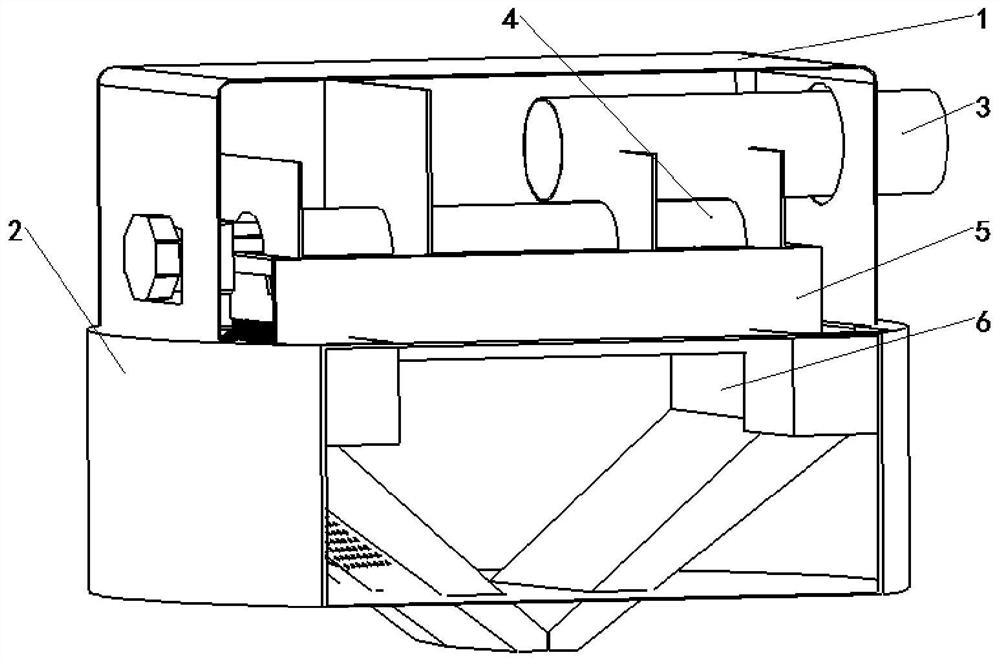

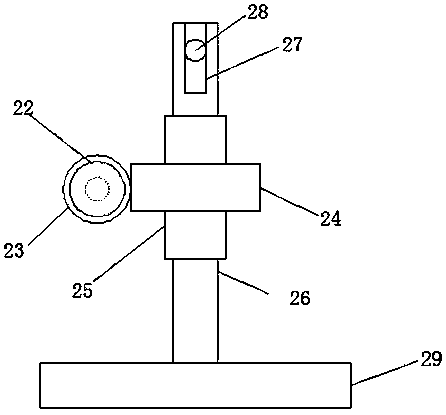

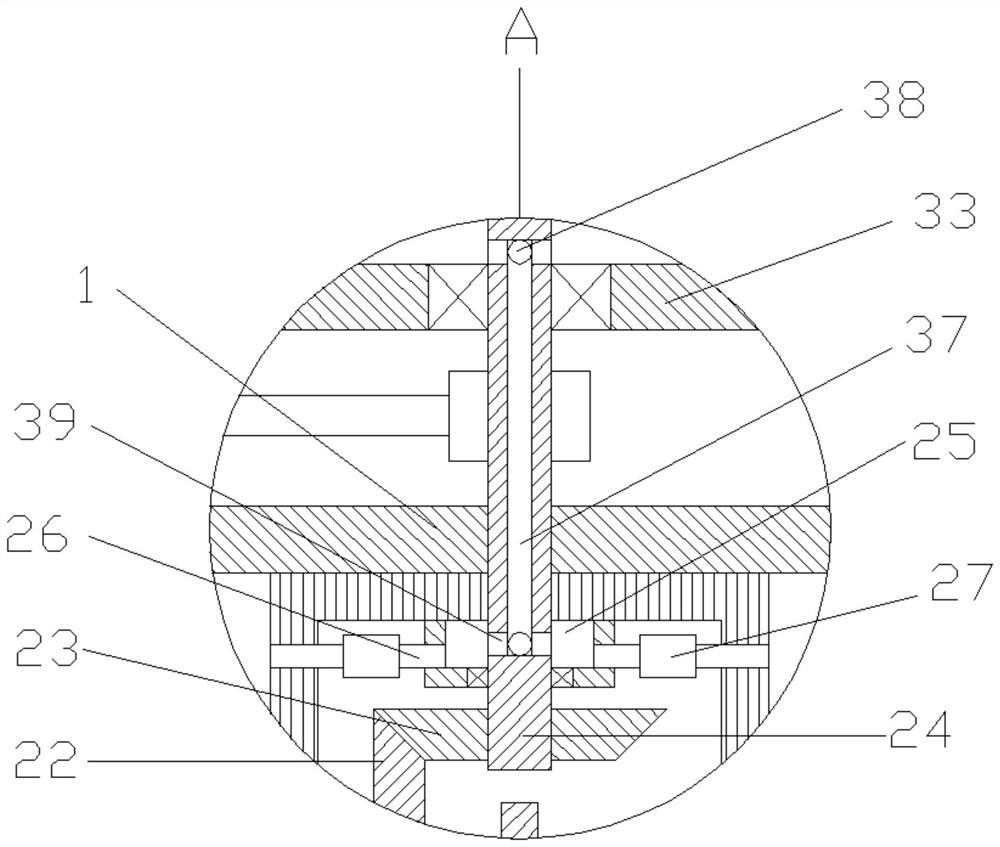

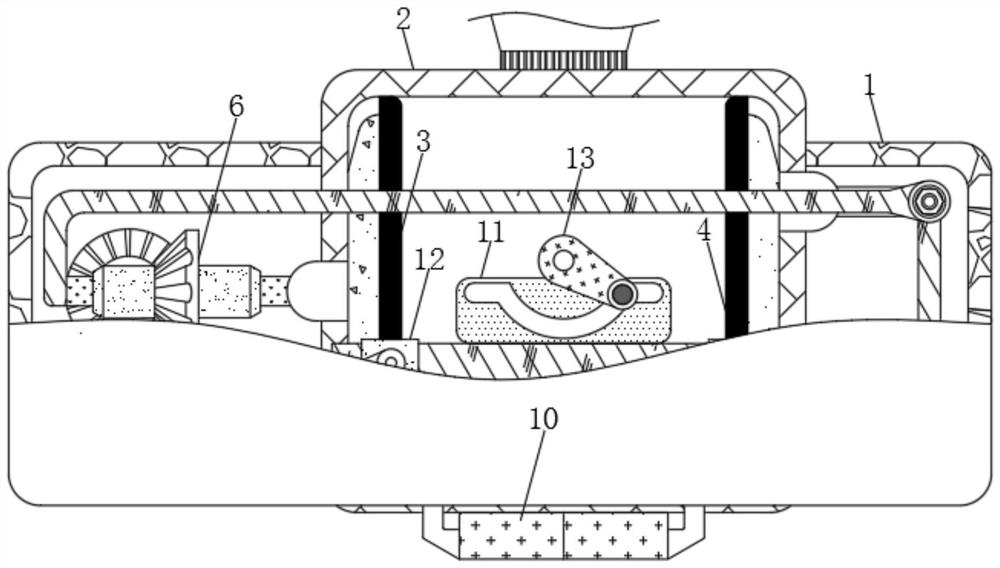

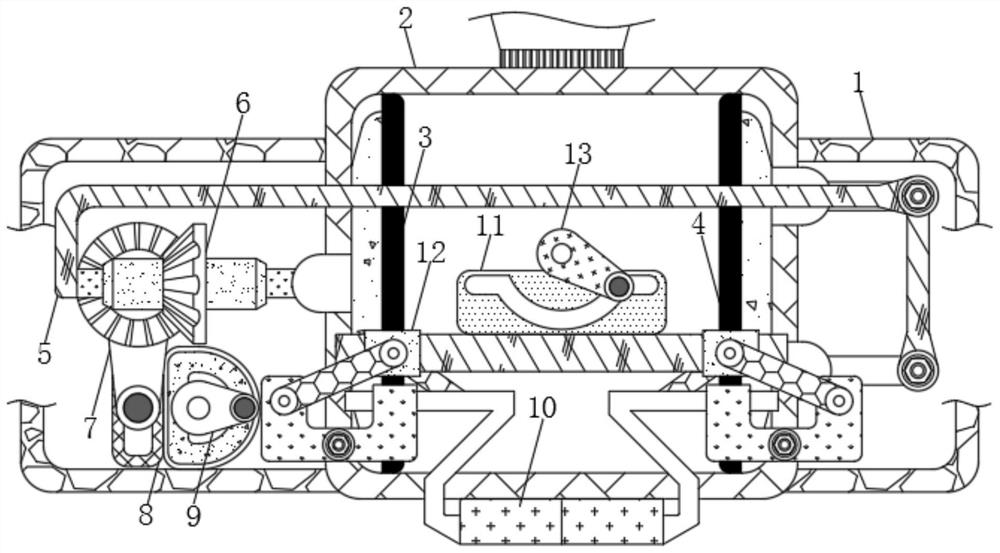

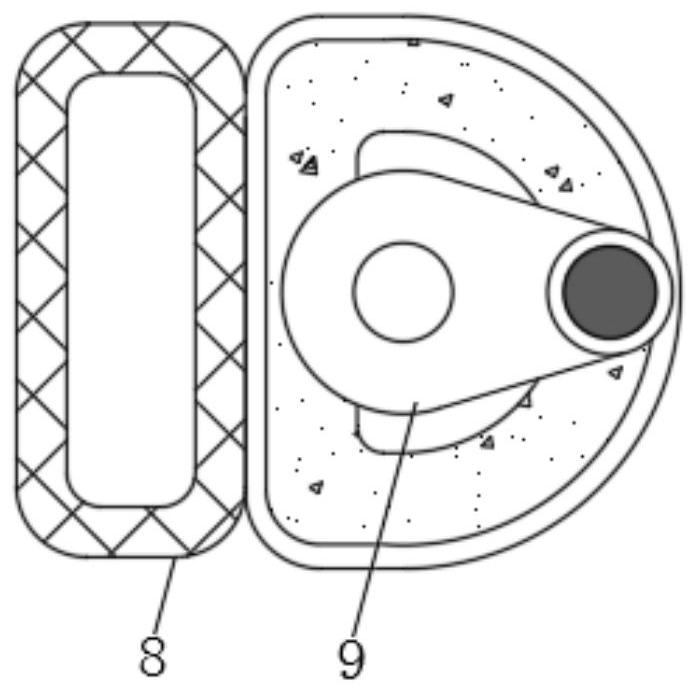

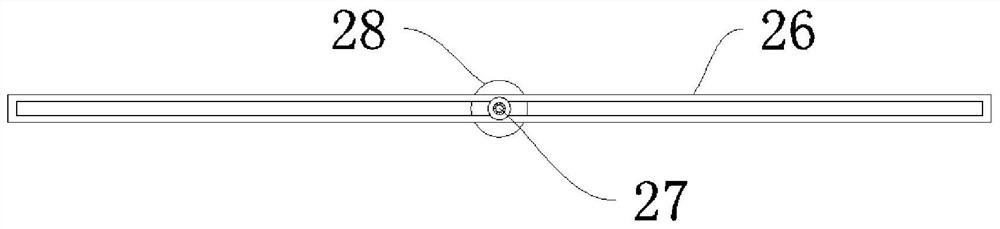

Grabbing mechanism for industrial intelligent robot

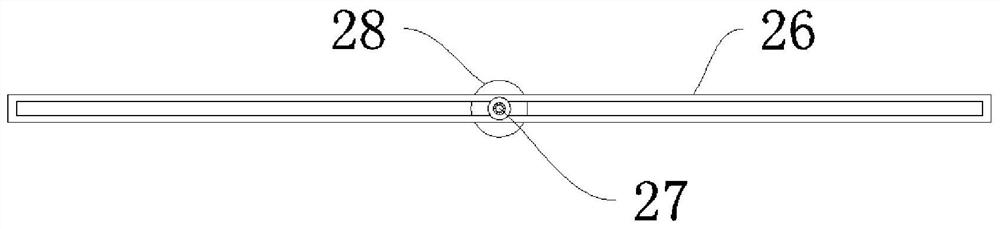

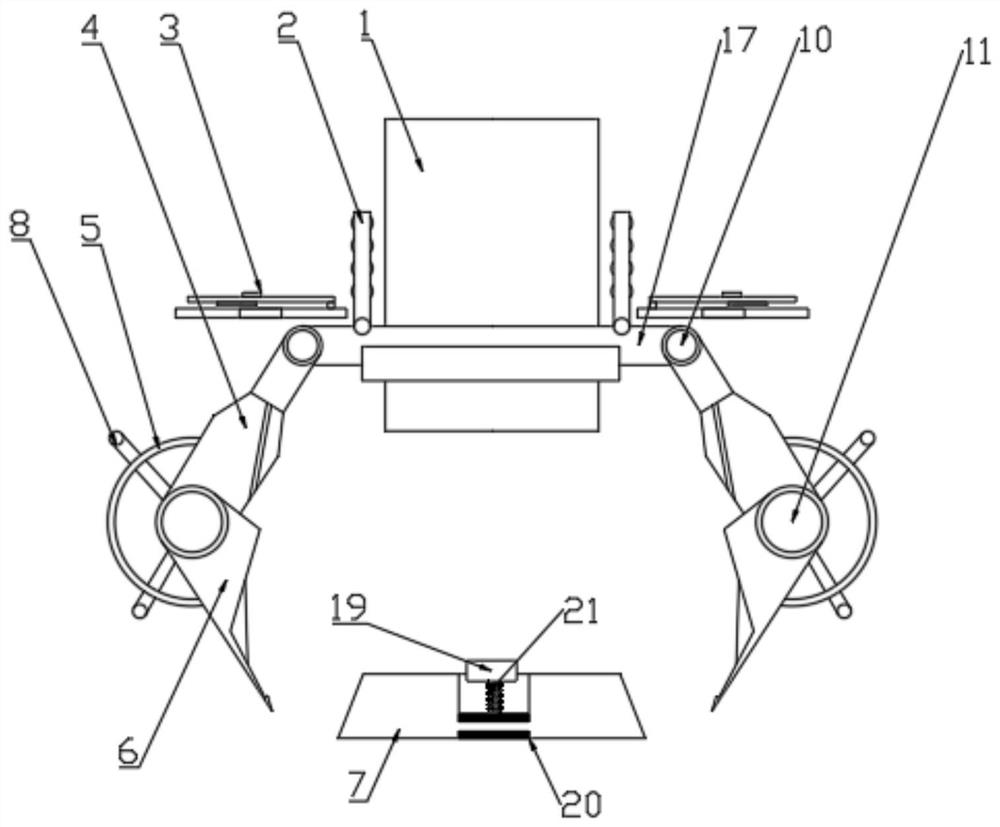

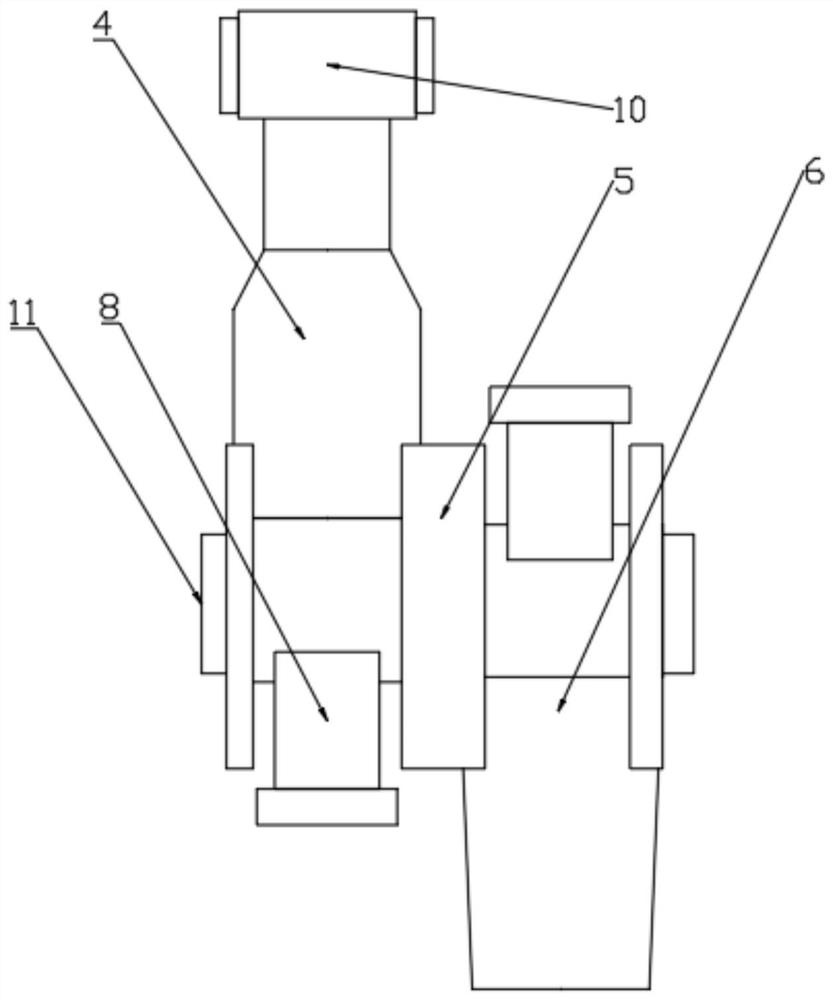

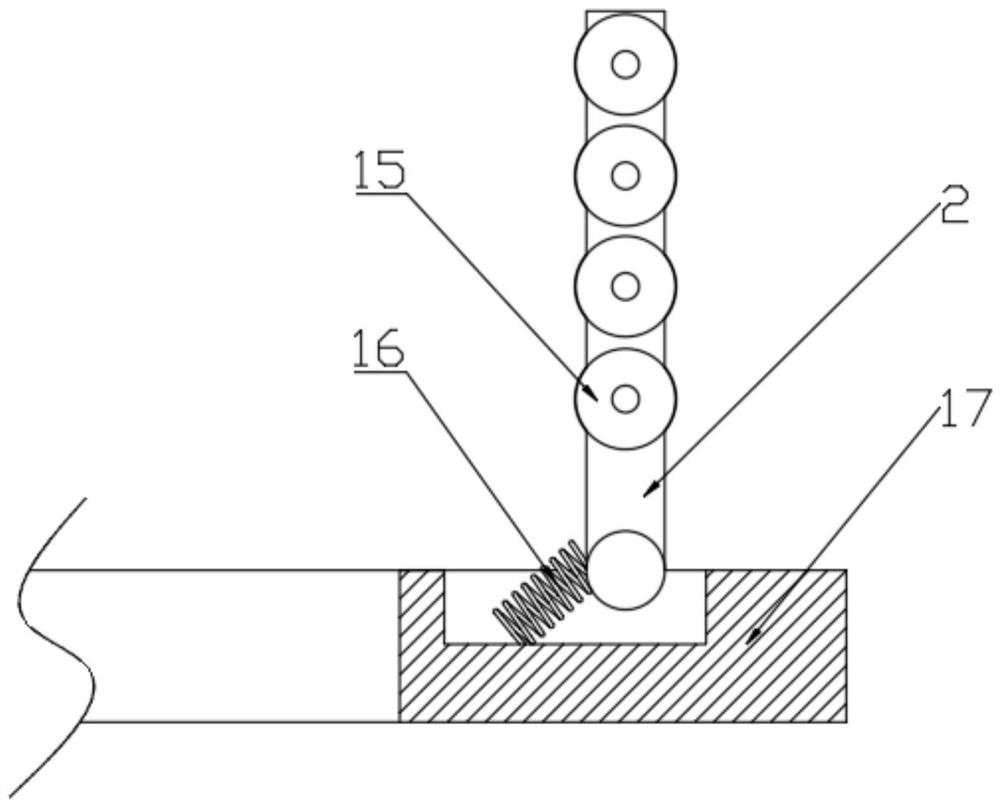

InactiveCN112025757ANot affected by curvatureEasy handling for transportGripping headsStructural engineeringMechanical engineering

The invention discloses a grabbing mechanism for an industrial intelligent robot. The grabbing mechanism comprises a clamping jaw module and a limiting frame, wherein the clamping jaw module comprisestwo sets of clamping jaws; each clamping jaw comprises a connecting plate and a clamping jaw body, one end of the connecting plate is hinged to the circumferential face of the limiting frame througha first rotating shaft, and the other end of the connecting plate is rotationally connected with the clamping jaw body through a second rotating shaft; two material bearing plates are rotationally connected into the limiting frame and are matched with the two sets of clamping jaws in a one-to-one mode; and a bearing plate module used for bearing materials is arranged below the limiting frame, anda material stirring module used for conveying the materials is arranged above the limiting frame; The included angles between the limiting frame and the connecting plates and the included angles between the connecting plates and the clamping jaw bodies are adjusted, and then the clamping jaw bodies are controlled to conduct clamping from the bottoms of the materials. A connecting rod is opened, sothat the connecting rod stretches out, and then a poking cover generates a second lifting effect on the materials. The clamping mode is not affected by the curvature of the materials.

Owner:王偏

Building setting-up frame with waste material conveying pipelines

InactiveCN106869500AReduce impactEasy handling for transportBuilding material handlingBuilding scaffoldsWaste materialCoating

The invention discloses a building setting-up frame with waste material conveying pipelines. The building setting-up frame comprises a building setting-up frame body, the waste material convening pipelines and a waste material box body. Movable supporting frames are installed at the two ends of the building setting-up frame body, the bottom of each movable supporting frame is provided with a universal wheel, and a plurality of operation platforms are installed in the middle of each movable supporting frame; inner side frame bodies of the movable supporting frames are provided with the waste material conveying pipelines which are vertically laid in a downward mode, a plurality of oblique discharging openings are formed in the outer sides of the pipe walls of the waste material conveying pipelines which are each composed of a plurality of stand pipes and a plurality of bent pipes, and waste material box bodies are installed below guiding-out openings at the lower ends of the bent pipes and connected with the movable supporting frames through connecting pieces; and universal wheels are also installed at the bottoms of the waste material box bodies which comprise filtering nets and rubber coatings. In this way, the building setting-up frame with the waste material conveying pipelines can bring convenience for constructors at operation platforms of all layers to convey engineering waste materials.

Owner:WUXI LONGHAIJIE MACHINERY MFG CO LTD

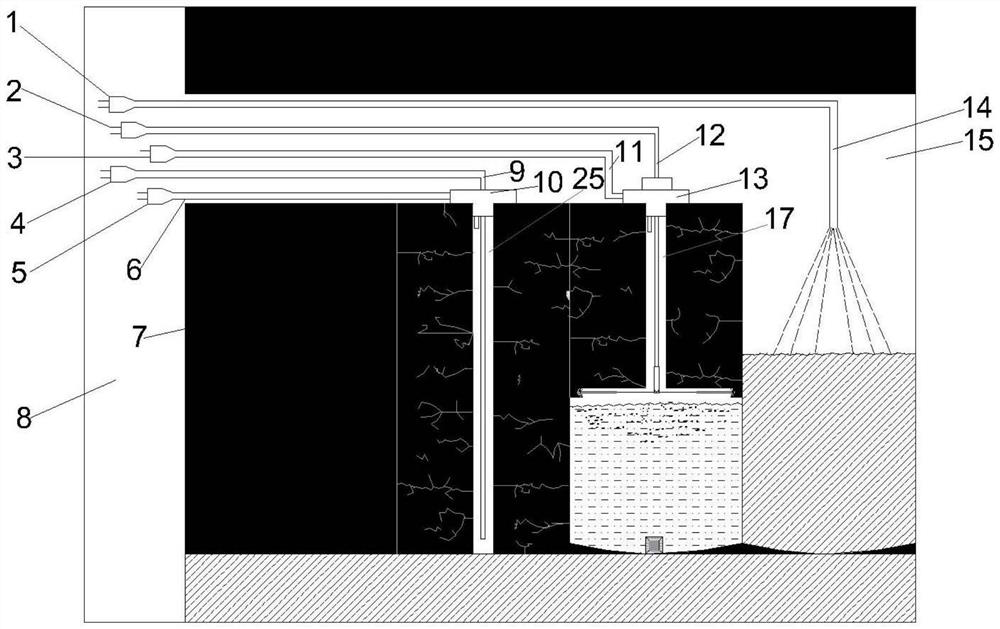

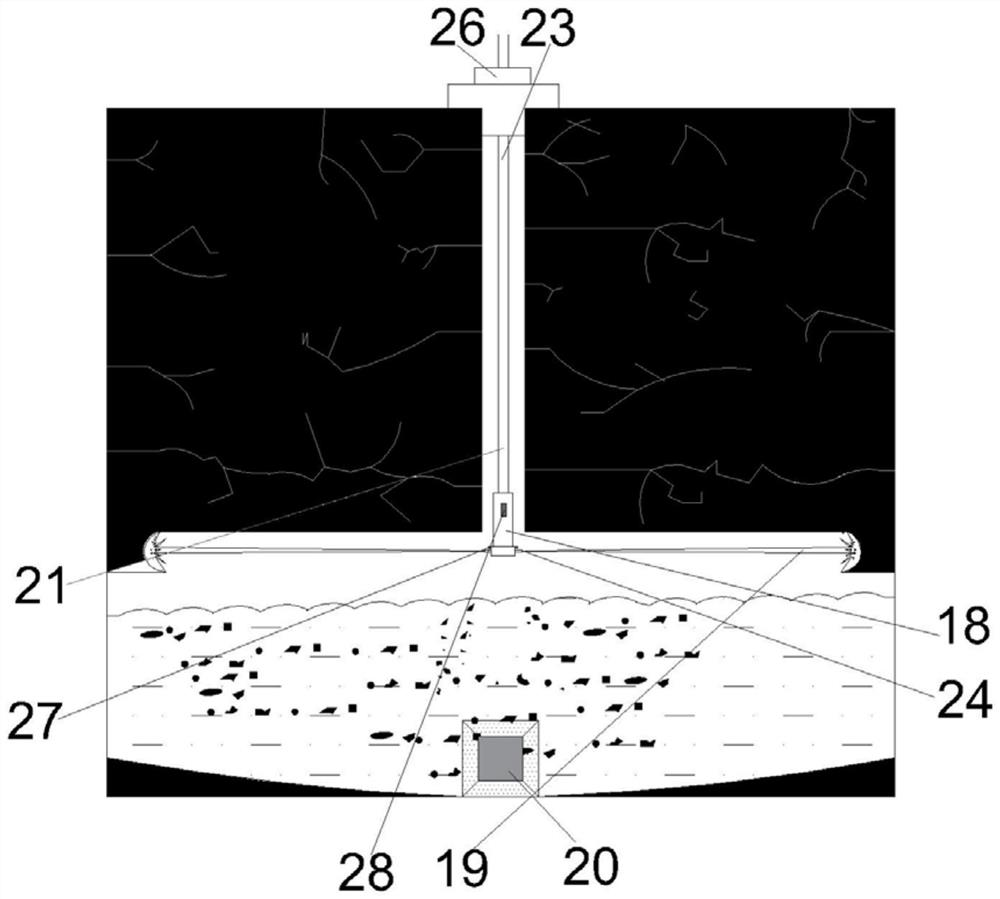

Coal and gas fluidization co-mining system and method for low-permeability inclined coal seam

ActiveCN114352345ATo achieve the effect of pressure relief and anti-reflectionEasy to recycleMining devicesDisloding machinesThermodynamicsCoal

According to the system, the outlet end of a liquid nitrogen conveying pipe in a liquid nitrogen circulation fatigue fracturing permeability increasing unit penetrates through a hole sealing plug I and then extends to the bottom, and the inlet end of a gas extraction pipe I penetrates through the hole sealing plug I and then stops at the top; a high-pressure jet device in the hydraulic fluidization mining and gas extraction unit is mounted at a hole sealing plug II, the high-pressure jet device is connected with the liquid outlet end of a high-pressure water conveying pipe, and the inlet end of a gas extraction pipe II penetrates through the hole sealing plug II and then stops at the top; the hydraulic fluidization transportation unit comprises a coal body fluidization transportation roadway and a coal body fluidization transportation pipe; the goaf paste filling unit comprises a paste pumping machine and a filling pipe. The method comprises the steps of roadway construction; coal seam drilling construction; liquid nitrogen cycle fatigue cracking permeability increasing and gas extraction are conducted; carrying out hydraulic fluidization mining and gas extraction; carrying out hydraulic fluidization transportation; and filling the goaf with paste. According to the system and the method, the fluidization co-mining operation of the coal and the gas in the low-permeability inclined coal seam can be efficiently realized.

Owner:CHINA UNIV OF MINING & TECH

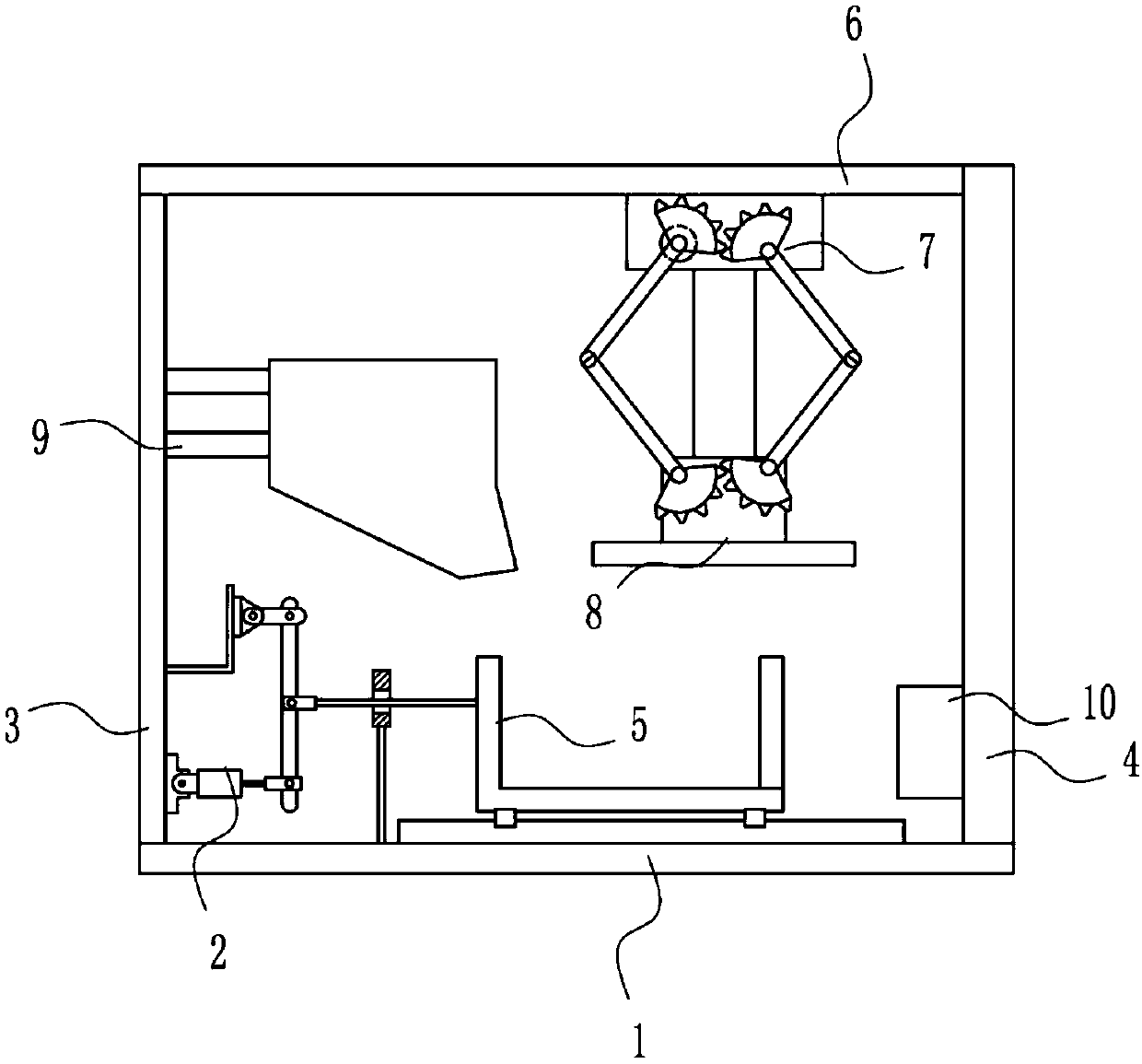

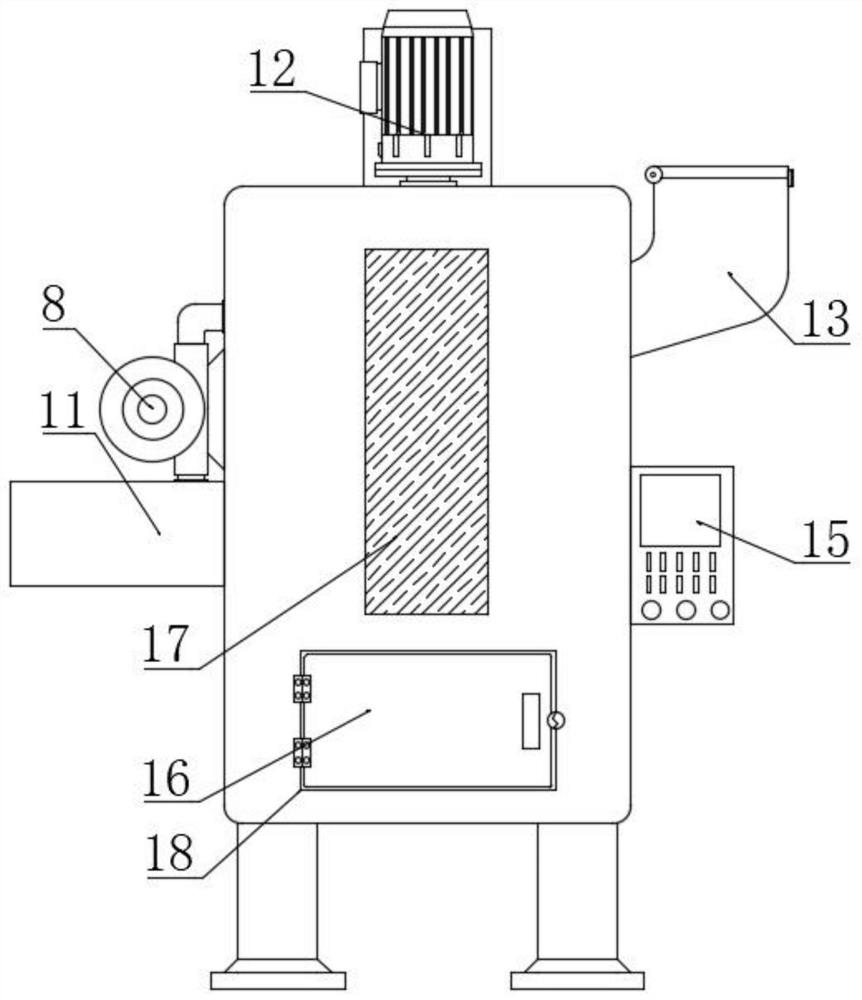

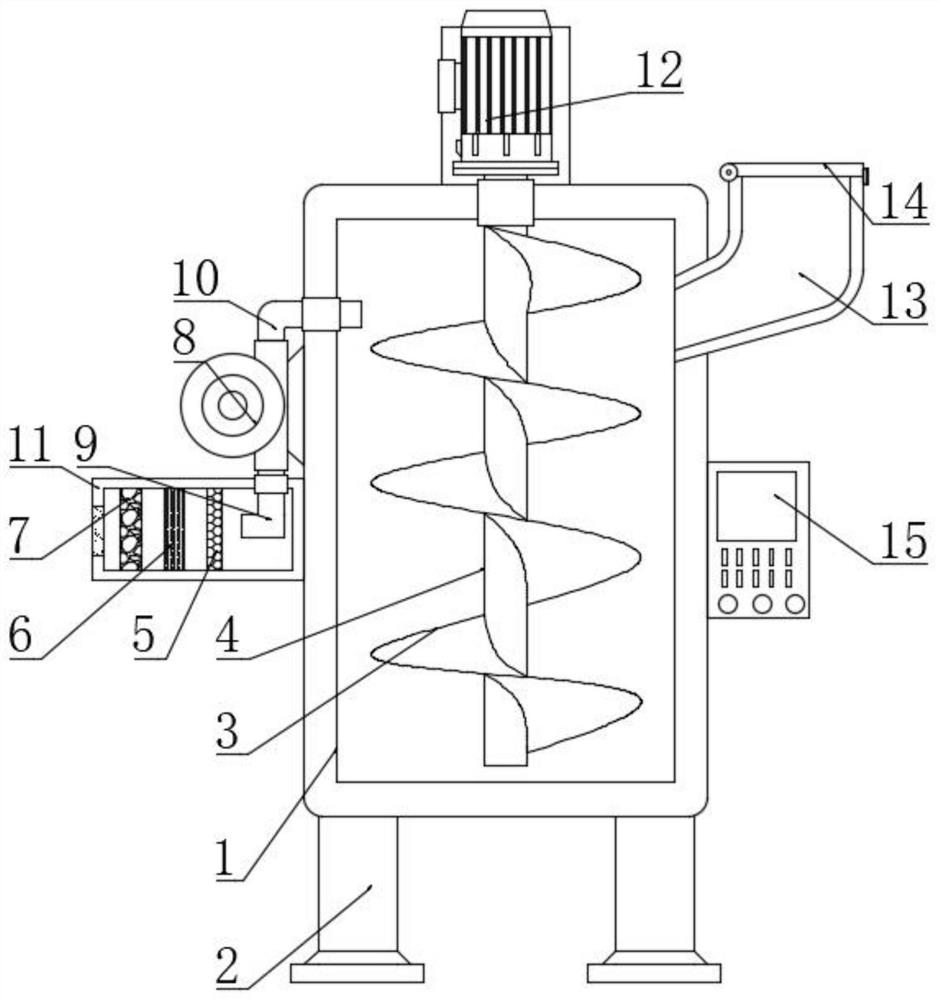

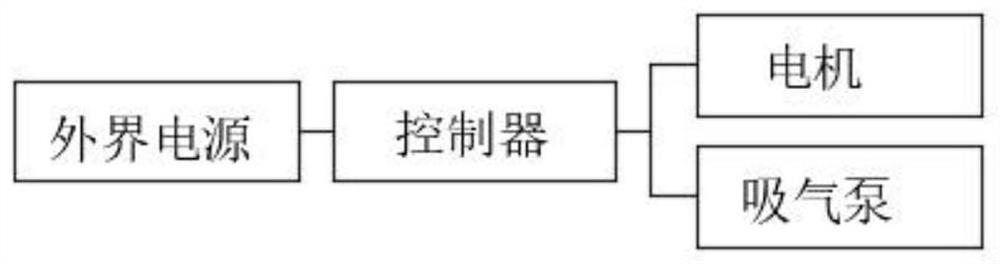

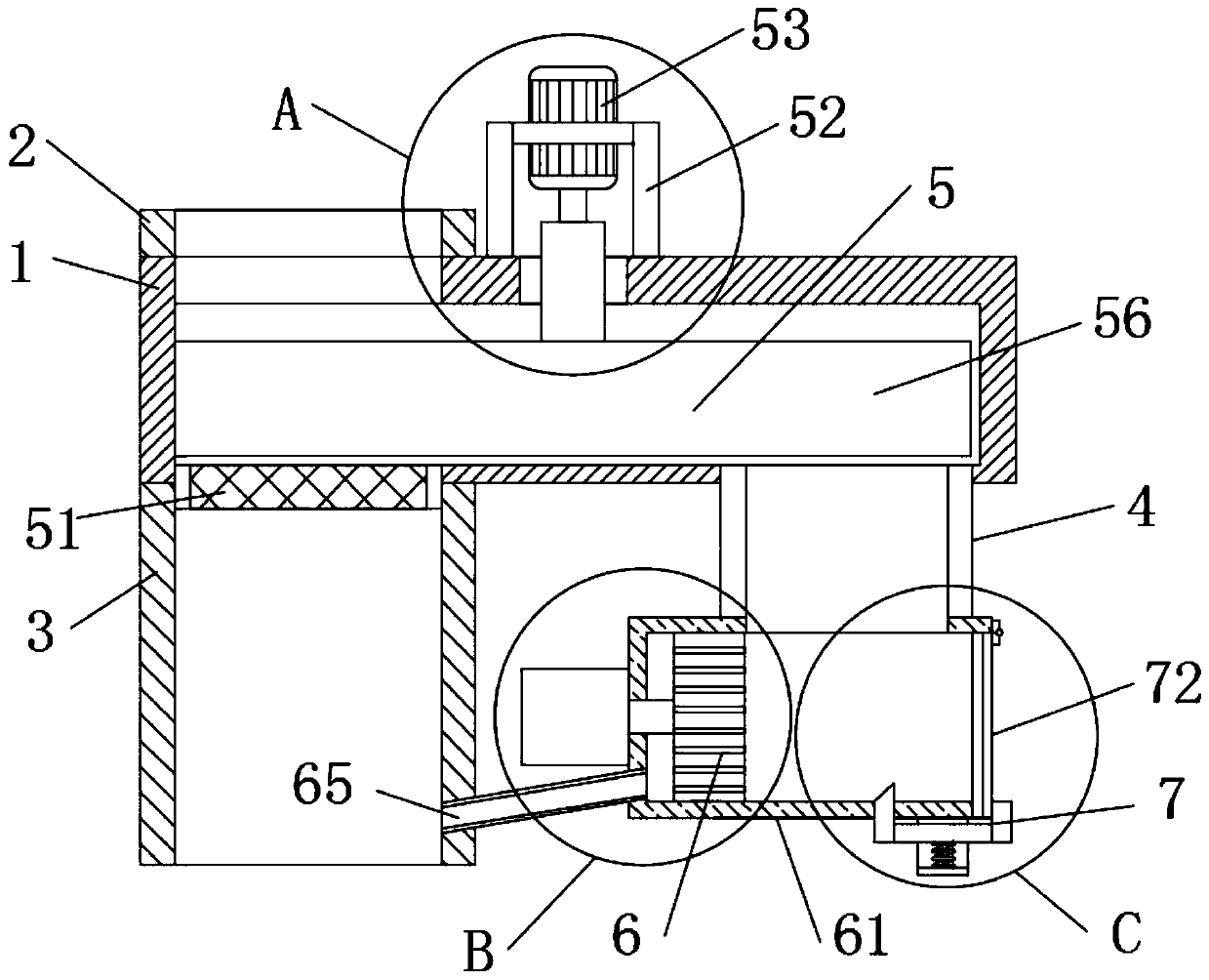

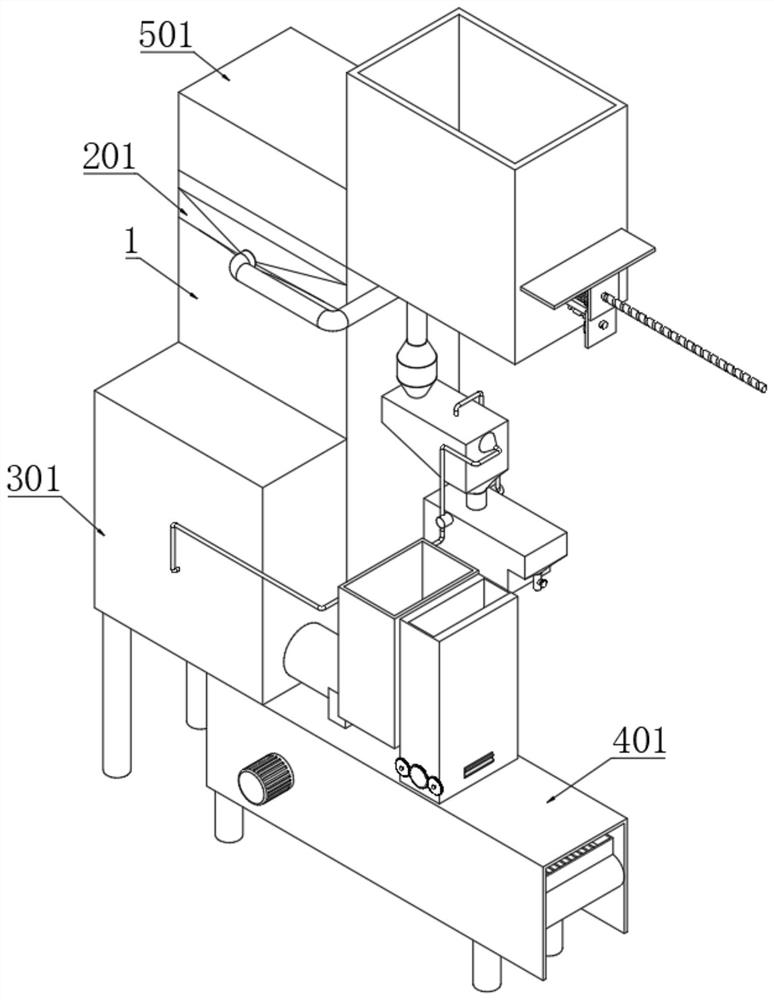

Crushing equipment for recycling building waste materials

InactiveCN111644252AReduce pollutionEasy handling for transportDispersed particle filtrationGrain treatmentsElectric machineryActivated carbon

The invention belongs to the technical field of buildings, and particularly relates to crushing equipment for recycling building waste materials. The crushing equipment comprises a crushing box, wherein a box body and a suction pump are fixedly connected to the left side of the crushing box; the suction pump is arranged above the box body; the air outlet end of the suction pump communicates with the box body through a first connecting pipe; and the other end of the suction pump communicates with the crushing box through a second connecting pipe. According to the crushing equipment, through thearrangement of the suction pump, the box body, an activated carbon adsorption net layer, a sponge net plate and a filter screen plate, dust in the crushing box is sucked through the suction pump, thedust is preliminarily filtered by the filter screen plate, the dust is filtered again by the sponge net plate, dust particles are adsorbed and purified by the activated carbon adsorption net layer, and the pollution of the dust to the air is reduced; and furthermore, through the arrangement of a motor, a rotating shaft and crushing slurry, the motor works to drive the rotating shaft and the crushing slurry to rotate, the building waste materials are subjected to crushing treatment when the crushing slurry rotates, and the later transportation is facilitated.

Owner:深圳市兰锋科技有限公司

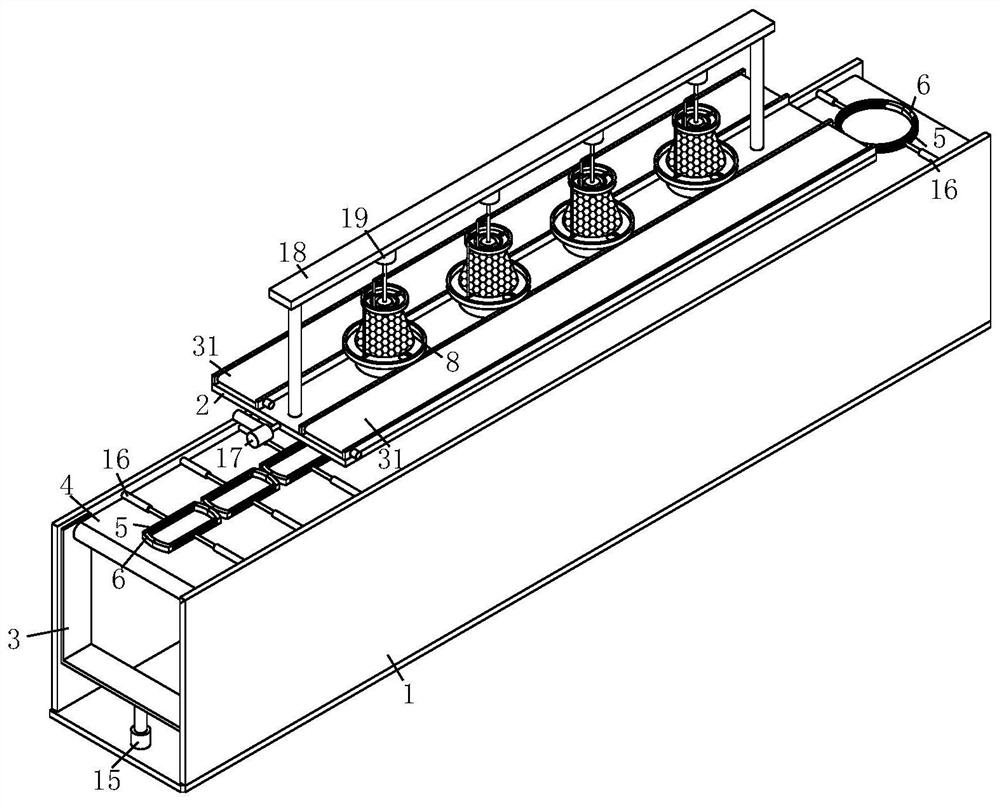

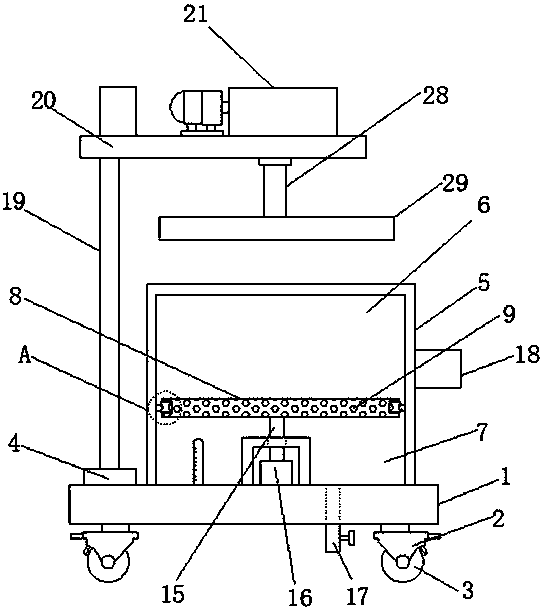

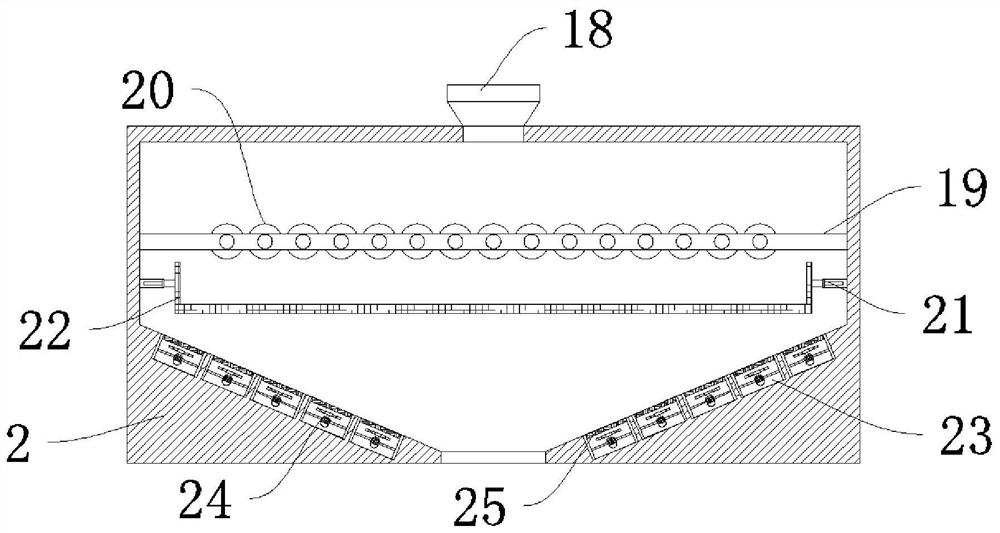

Underground coal gangue separation equipment

ActiveCN113019651AEasy to adjust the positionAdjustable positionGrain treatmentsGradingMining engineeringRubber sheet

The invention discloses underground coal gangue separation equipment. The underground coal gangue separation equipment comprises a base and an overturning plate arranged above the base; and a movable plate is connected into the base in a lifting manner, a material conveying belt is arranged on the movable plate, soft rubber plates are symmetrically and movably connected to the material conveying belt, fixing blocks are fixedly connected to the two ends of each soft rubber plate, and the fixing blocks are matched with each other. A cylinder is fixedly connected to the overturning plate, the upper end of the cylinder penetrates through the overturning plate and is fixedly connected with a conical cylinder, a rotating rod is fixedly connected into the cylinder, a spiral material pushing plate is fixedly connected to the rotating rod and matched with the inner side wall of the cylinder, and a rotating block is fixedly connected to the upper end of the rotating rod. According to the underground coal gangue separation equipment, coal scraps and coal gangue in coal raw materials can be conveniently sorted out for transportation treatment, and convenience is brought to workers.

Owner:ANHUI UNIV OF SCI & TECH

Packaging equipment for compressible waste recycling

ActiveCN113387022ATightly boundSmall footprintWeb rotation wrappingElectric machineProcess engineering

The invention discloses packaging equipment for compressible waste recycling. The packaging equipment comprises a machine box, a pretreatment mechanism and an auxiliary mechanism are installed in the machine box, the pretreatment mechanism comprises a conveying pipe fixedly connected to the inner wall of the machine box through a supporting column, a first sliding block is slidably connected into the conveying pipe, connecting pipes are symmetrically and fixedly connected to the side wall of the conveying pipe in a penetrating mode, a second sliding block is slidably connected into each connecting pipe, rotating rods are symmetrically and rotationally connected to the inner wall of the machine box, a connecting plate is fixedly connected to the side walls of the rotating rods, a motor is installed on the bottom wall of the machine box, a rotating shaft is coaxially fixed to the output end of the motor, and the rotating shaft penetrates through the inner wall of the machine box and then is fixedly connected with a rod shaped like a Chinese character' ji '. According to the packaging equipment for compressible waste recycling, a circular ring body slides on the side wall of the supporting plate, so that a packaging roller is driven to move synchronously, a packaging belt is wound around the packaging roller, and therefore the packaging roller drives the packaging belt to carry out winding type packaging on compressible waste after extrusion forming, and conveying is automatically carried out on the compressible waste.

Owner:南通市通州区茂润包装制品有限公司

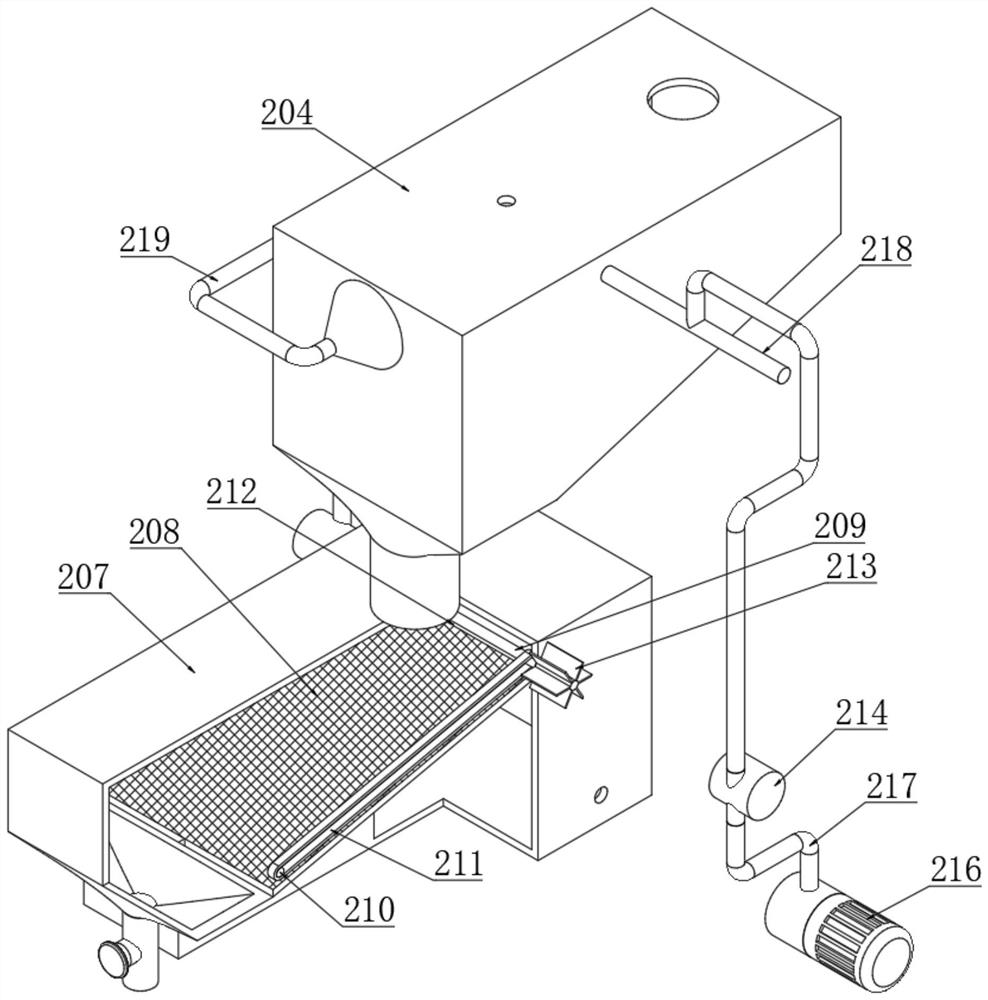

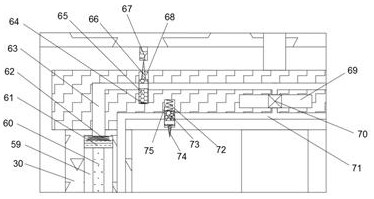

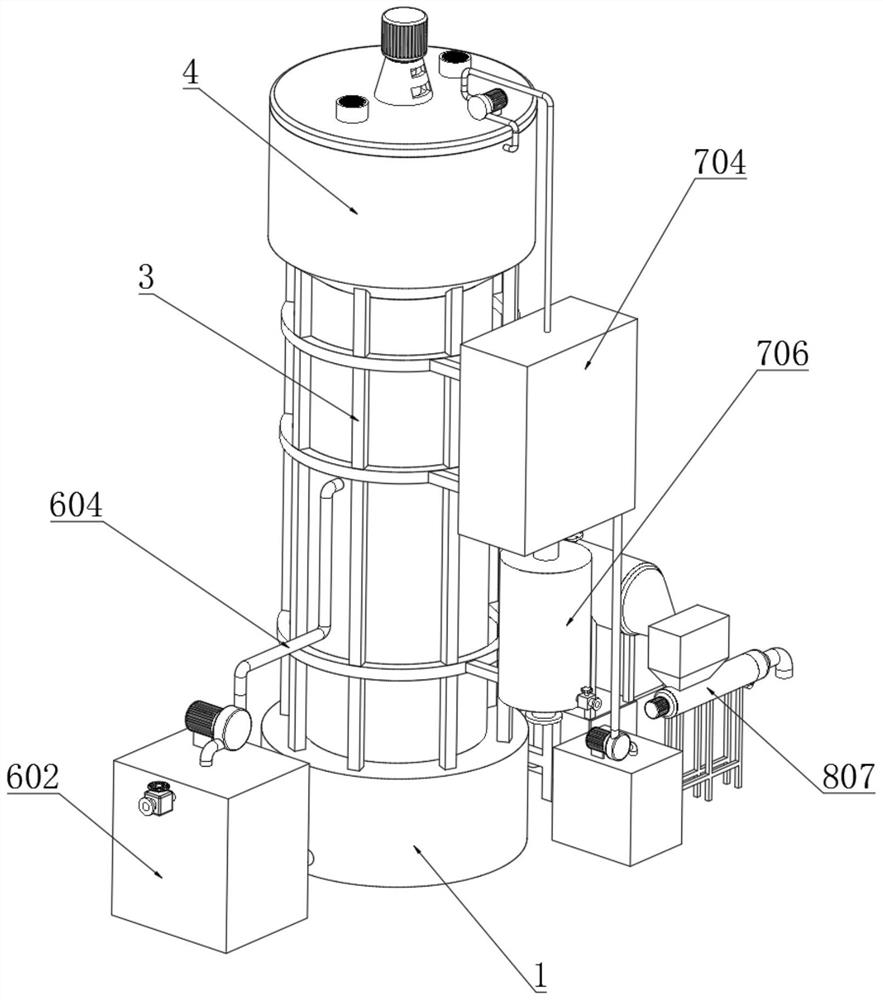

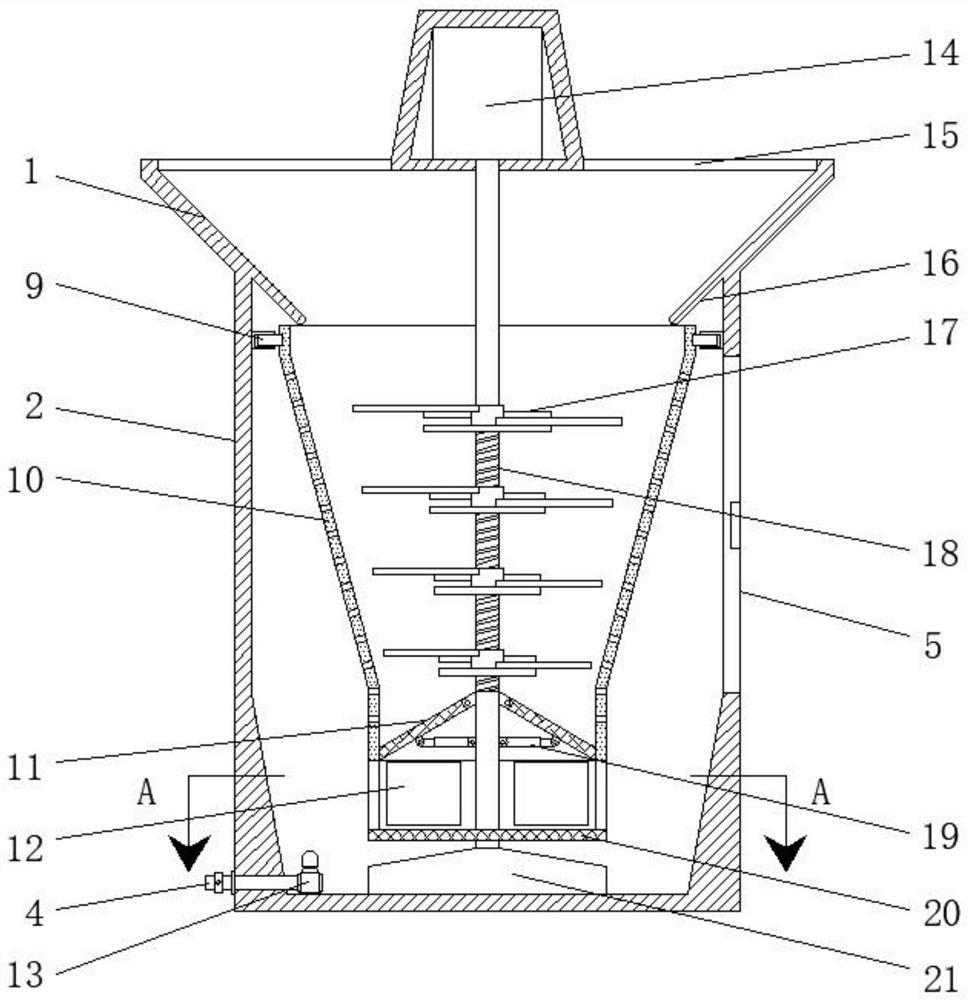

Sludge dewatering and curing treatment device of drainage pipeline for drainage facility

ActiveCN111333297AReduce weightEasy handling for transportFixation/solidifcation sludge treatmentElectric machineryDrainage tubes

The invention discloses a sludge dewatering and curing treatment device of a drainage pipeline for a drainage facility. The device comprises a separation cylinder, one side of the upper surface of theseparation cylinder fixedly communicates with a first drainage pipe, the lower surface of the separation cylinder is fixedly communicated with a second drainage pipe matched with the first drainage pipe, a conveying pipe fixedly communicates with the side, away from the second drainage pipe, of the lower surface of the separation cylinder, a separation mechanism is arranged in the separation cylinder, and the lower end of the conveying pipe is fixedly connected with a dewatering mechanism. The device achieves the following beneficial effects: the separation mechanism utilizes a motor to drivea rotating shaft to rotate so as to drive a scraper plate to rotate, sludge on a filter plate is scraped into the conveying pipe through the obliquely-arranged scraper plate, a push block is pushed by an air cylinder through the arranged dewatering mechanism, the push block extrudes the sludge falling into the dewatering cylinder, water in the sludge is extruded out through dewatering holes, andthen most of the water in the sludge is extruded out, so the weight of the sludge is greatly reduced.

Owner:武汉一念元环境科技有限公司

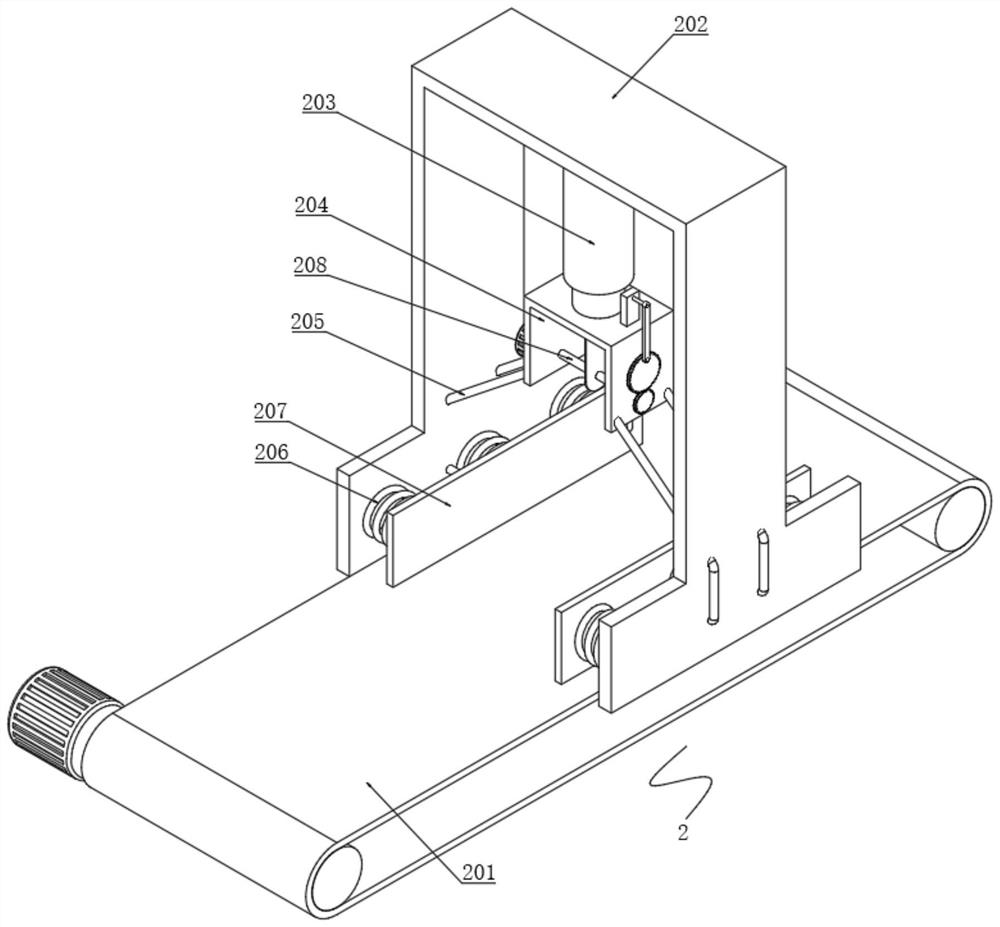

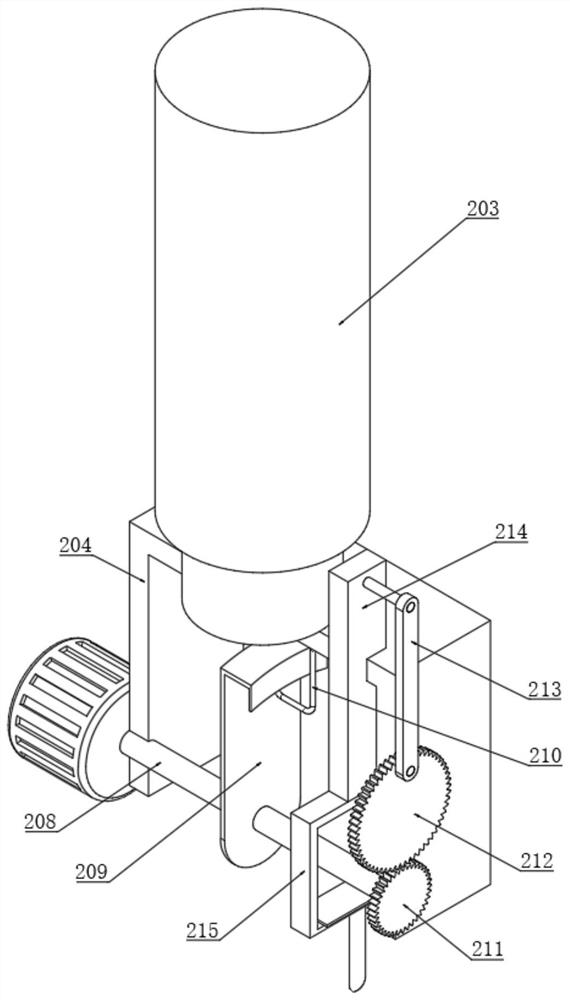

Continuous product detection device and method convenient for sampling

PendingCN114112486AEasy to move simultaneouslyFacilitate multi-style sampling processingWeighing by removing componentTransportation and packagingGear wheelControl engineering

The invention discloses a continuous product detection device and method convenient for sampling, and the device comprises a fixed seat, and an automatic clamping and sampling assembly is fixedly installed at the edge of the top end of the fixed seat. The automatic clamping and sampling assembly is mainly formed by combining an electric rotating shaft, a sampling driving gear, a sampling driven gear, a sampling connecting rod, a sampling sliding rod and a sampling connecting frame, the electric rotating shaft has the function of taking materials from a cutting knife, and the sampling driving gear, the sampling driven gear, the sampling connecting rod, the sampling sliding rod and the sampling connecting frame have the function of synchronously taking materials from a needle cylinder; through cooperation of the automatic clamping and sampling assembly and the rotary buffering and collecting assembly, a worker can conveniently carry out positioning and sampling treatment on materials, the material sampling process of the worker is optimized, the stability of the material sampling process is guaranteed, meanwhile, the worker can conveniently carry out storage treatment on sampled waste materials, and the working efficiency is improved. And the pollution to the external environment caused by peculiar smell generated by placing the waste materials everywhere is avoided.

Owner:刘萍

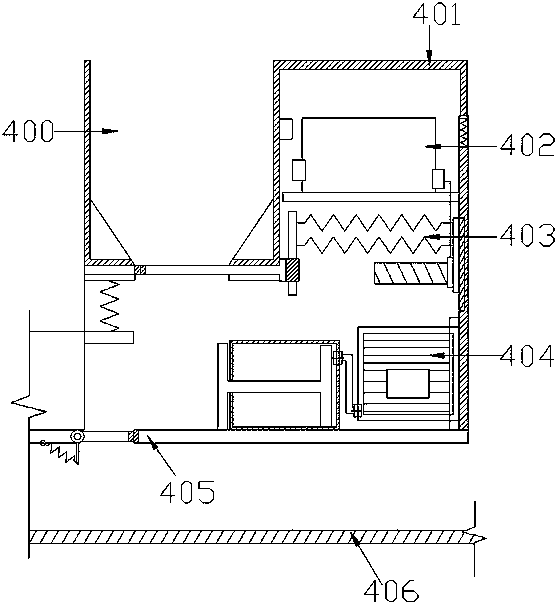

Multi-stage solid-liquid separation device

PendingCN113058974AReduce moisture contentEasy handling for transportSolid waste disposalTransportation and packagingSlagProcess engineering

The invention aims to provide a multi-stage solid-liquid separation device. An upper box body is located above a lower box body, a feeding pipe extends into the upper box body, the feeding pipe communicates with a pre-separation pipe, the pre-separation pipe is located above a scraper slag remover, the scraper slag remover is located in the upper box body, and a crushing slag remover is located in the lower box body. A pre-separation device, the scraper slag remover and the crushing slag remover are adopted for solid-liquid separation, the water content of kitchen waste is greatly reduced, the effect of separating and discharging waste water and residues is achieved, transportation treatment of the residues is facilitated, and further oil-water separation and recycling of the waste water are facilitated.

Owner:HARBIN ENG UNIV

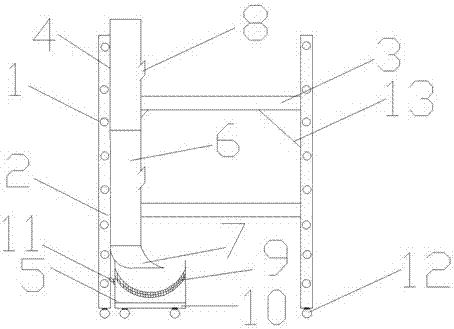

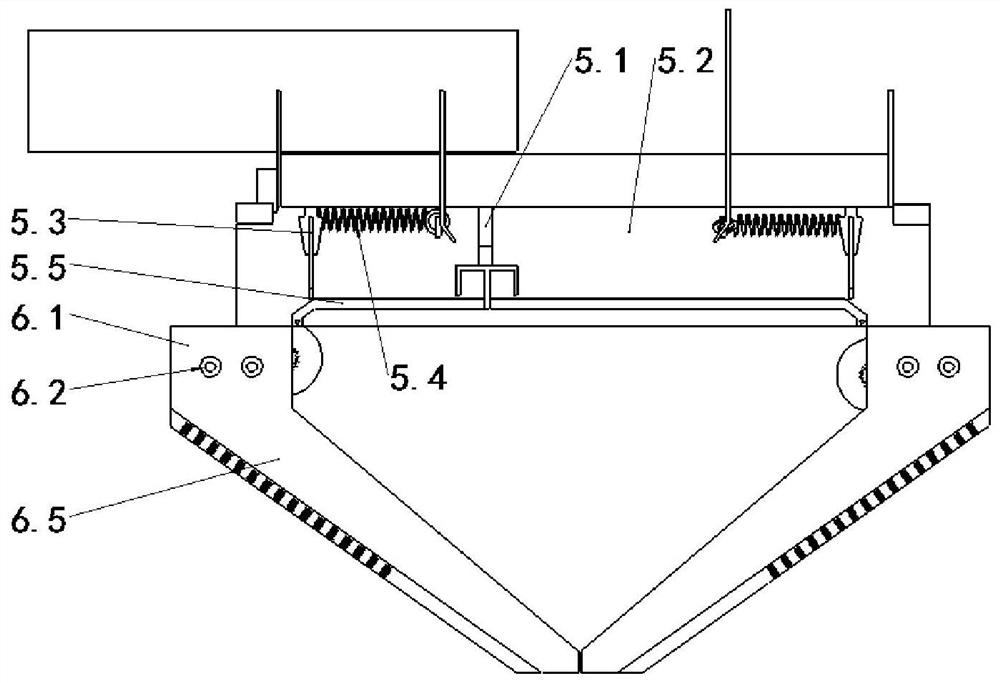

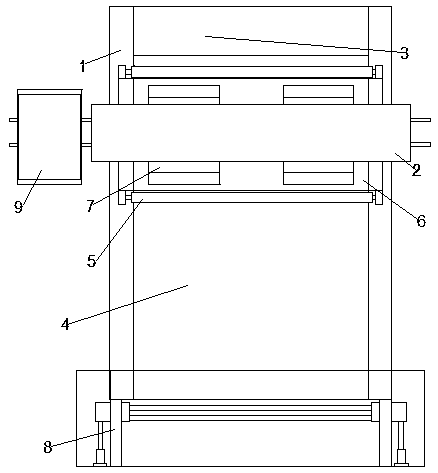

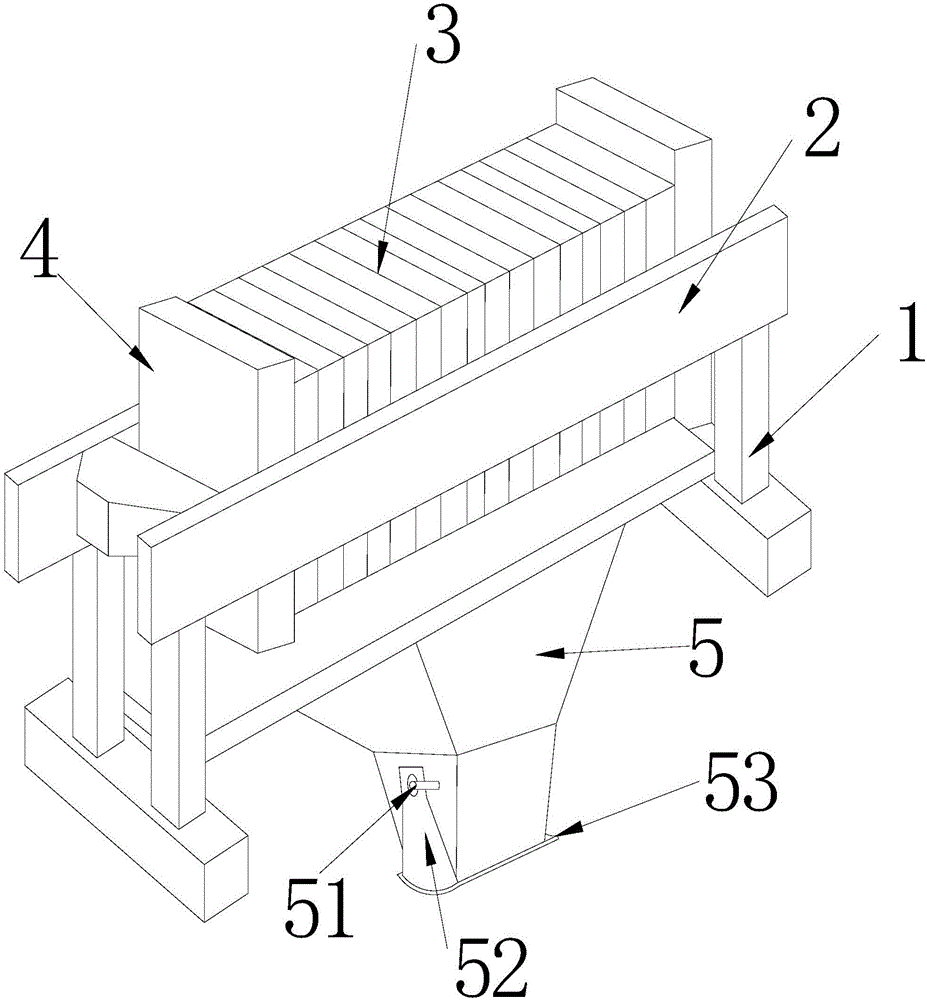

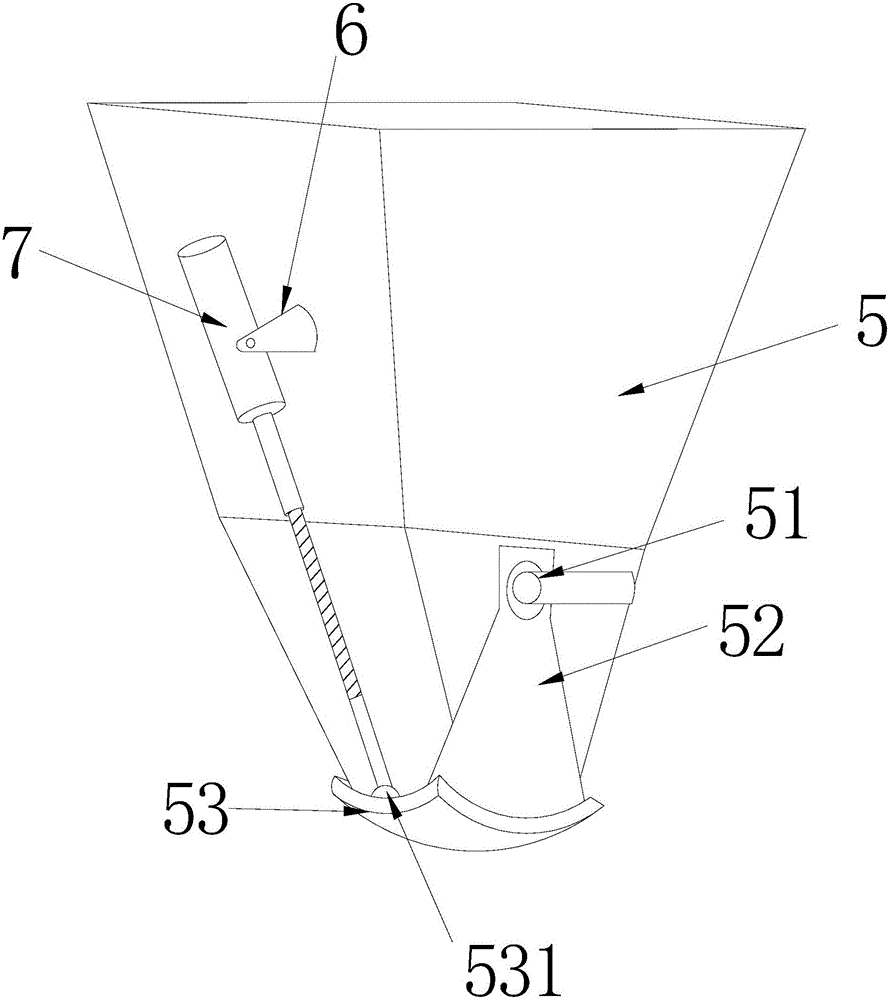

Filter residue collection and storehouse inventory integrating device

InactiveCN105964027AEasy handling for transportMake full use of storage capacityFiltration separationWaste management

The invention discloses a filter residue collection and storehouse inventory integrating device, and belongs to filter residue collection devices. The filter residue collection and storehouse inventory integrating device mainly comprises a machine base, a compressing plate installed on the machine base, main beams connected to the two ends of the machine base, a filter plate installed on the inner side of the compressing plate. A filter residue hopper is installed at the portion, below the filter plate, of the bottom end of the machine base. An arc material stopping cover is installed at the bottom of the filter residue hopper. An electric hydraulic rod is installed on the back of the filter residue hopper through a hinge base. A shell at the upper end of the electric hydraulic rod is hinged to the hinge base and can rotate around the hinge base by a certain angle. The filter residue collection and storehouse inventory integrating device has the advantages that the large-volume filter residue hopper is designed, and the filter residue hopper is provided with the arc material stopping cover, so that the storage volume of the filter residue hopper can be sufficiently utilized, timed adoption and concentrated collection performed only when a filter frame is disassembled are avoided, meanwhile, the arc material stopping cover is controlled by an electric hydraulic rod, filter residues can be conveniently conveyed and processed by automatically opening and closing the filter residue hoppers, and the production efficiency is improved.

Owner:ANQING HONGTAI NEW MATERIAL

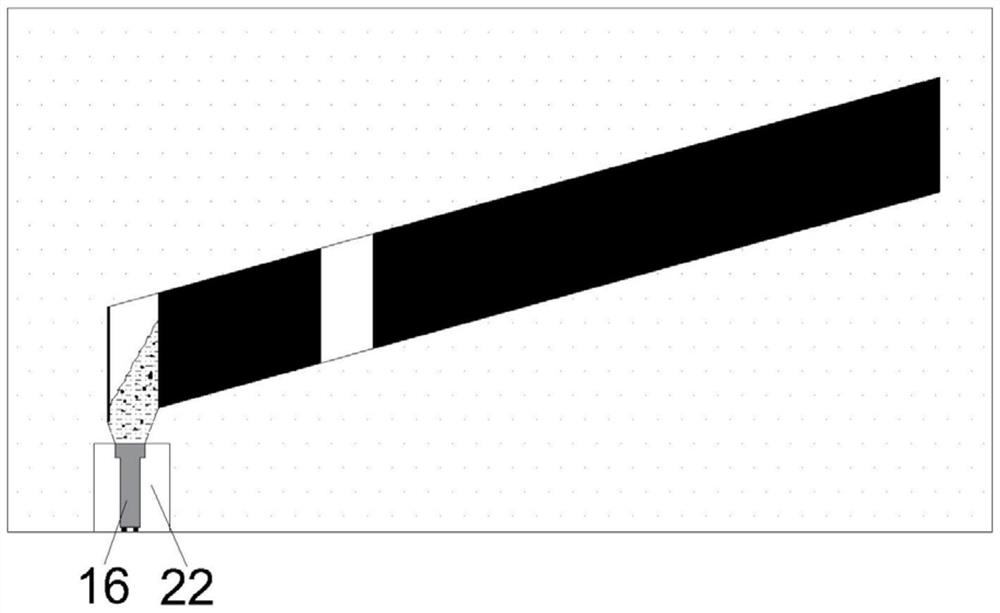

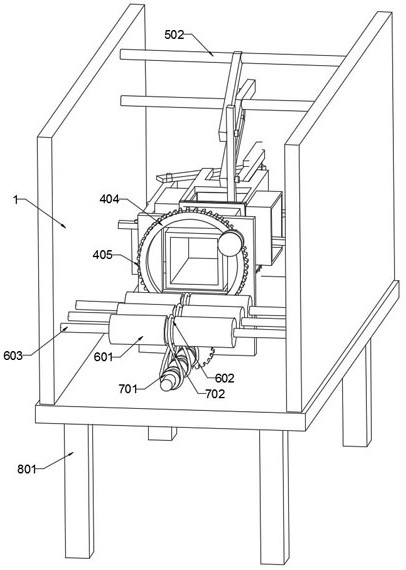

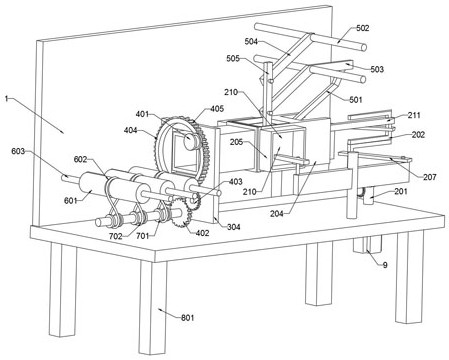

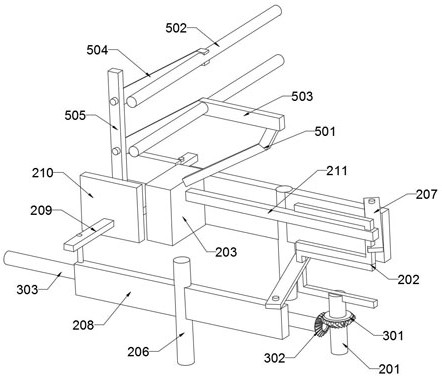

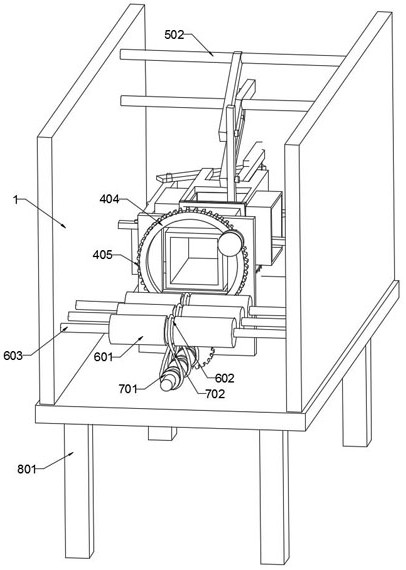

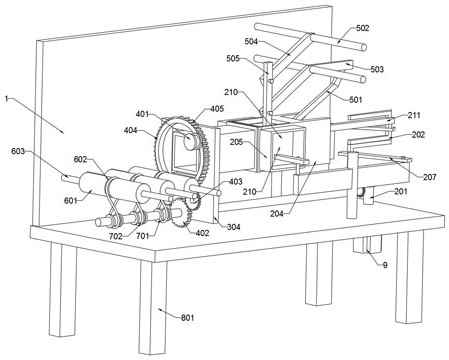

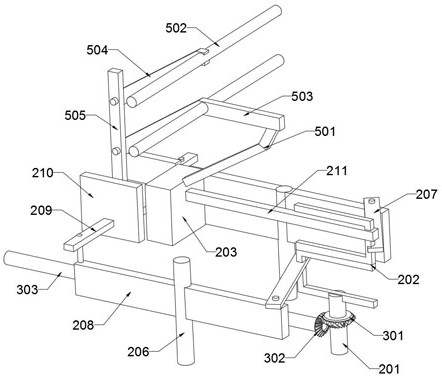

Automatic material receiving cutting machine of optical fiber mat

PendingCN109014614ASave human effortEasy handling for transportLaser beam welding apparatusEngineeringLaser cutting

The invention discloses an automatic material receiving cutting machine of an optical fiber mat. The machine comprises a rack, a cutting frame is arranged on the rack, a laser cutting device is arranged on the cutting frame, a feeding conveying area, a chemical fiber mat cutting collecting area and a waste material conveying area are arranged on the rack, conveying rollers are arranged at the front end and the rear end of the chemical fiber mat cutting collecting area, a cutting supporting frame with chemical fiber mat collection openings is arranged in the chemical fiber mat cutting collecting area, fixing grooves are formed in the cutting supporting frame, moving plates capable of sealing the chemical fiber mat collection openings is arranged in the fixing grooves, the positions, on thefront side and the rear side of each chemical fiber mat collection opening, of the lower end of the cutting supporting frame are each provided with a front side mounting plate and a rear side mountingplate which extend downwards, a chemical fiber mat collection frame moves along the rail on the ground, and a waste swing stacking device is arranged at the rear end of the waste material conveying area. The machine is simple in structure and reasonable in design, cut chemical fiber mats can be stacked in order, waste can be stacked and collected, and work efficiency is improved.

Owner:HAIAN ZHONGSHAN SYNTHETIC FIBER

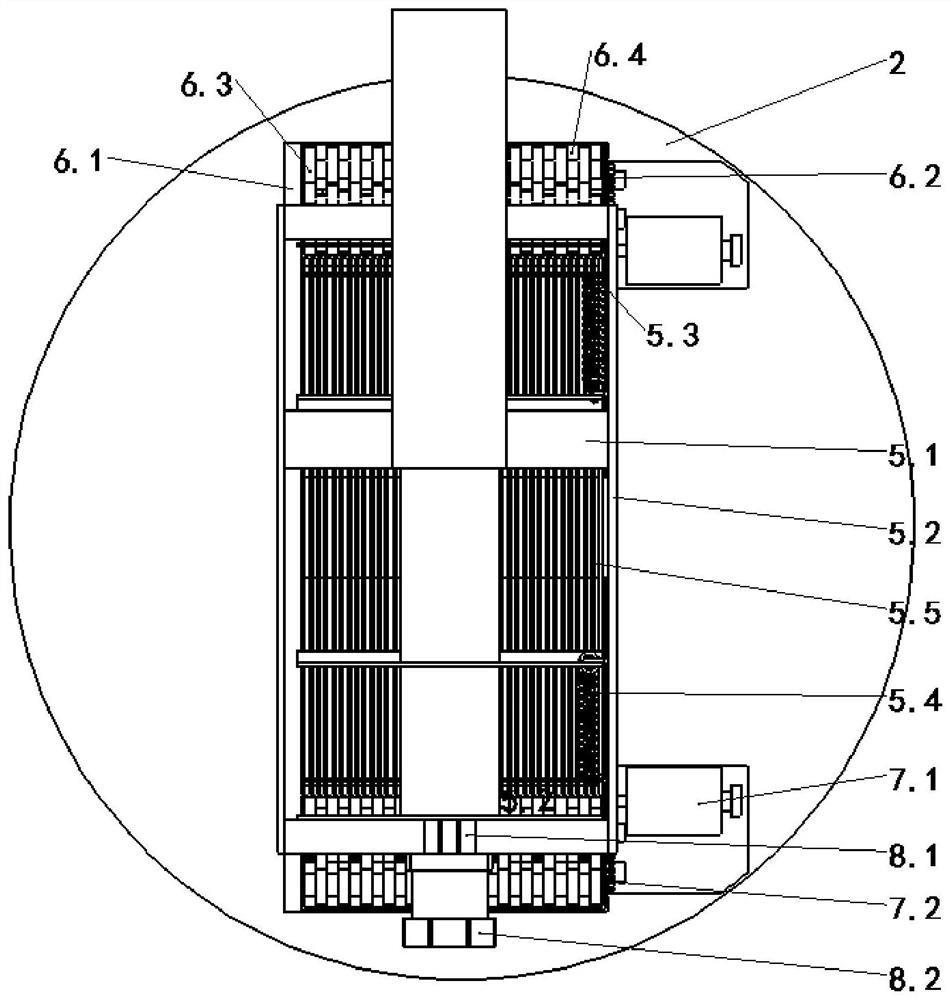

Device for filter residue collection and automatic bin cleaning of filter press

The invention discloses a device for filter residue collection and automatic bin cleaning of a filter press and belongs to a filter residue collection device. The device mainly comprises a machine base, pressing plates mounted on the machine base, girders for connecting two ends of the machine base as well as filter plates mounted on inner sides of the pressing plates, wherein a filter residue hopper is mounted at the bottom end of the machine base and below the filter plates, an arc-shaped blocking cover is mounted at the bottom of the filter residue hopper, a sector-shaped fixed plate is fixed at each of two ends of the arc-shaped blocking cover, and the sector-shaped fixed plates are fixed on two sides of a bottom port of the filter residue hopper by the aid of positioning pins. The device has the advantages as follows: the large-volume filter residue hopper is designed and is provided with the arc-shaped blocking cover, so that the storage volume of the filter residue hopper can be fully utilized, and timed taking and centralized collection during disassembly of a filter frame are avoided; meanwhile, the arc-shaped blocking cover is controlled by an electric hydraulic rod, the filter residue hopper can be automatically opened and closed to facilitate transportation treatment of filter residues, and the production efficiency is improved.

Owner:ANQING HONGTAI NEW MATERIAL

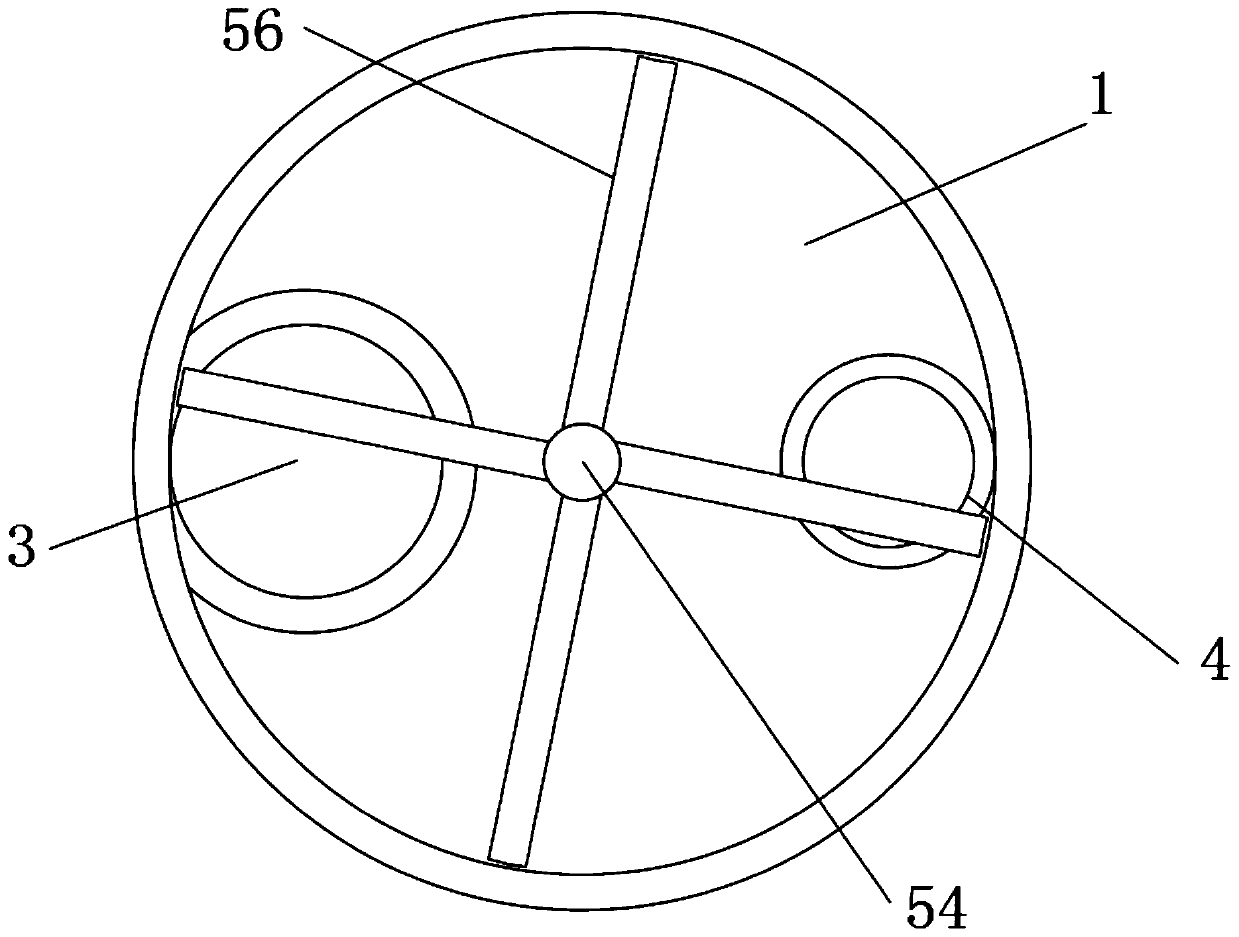

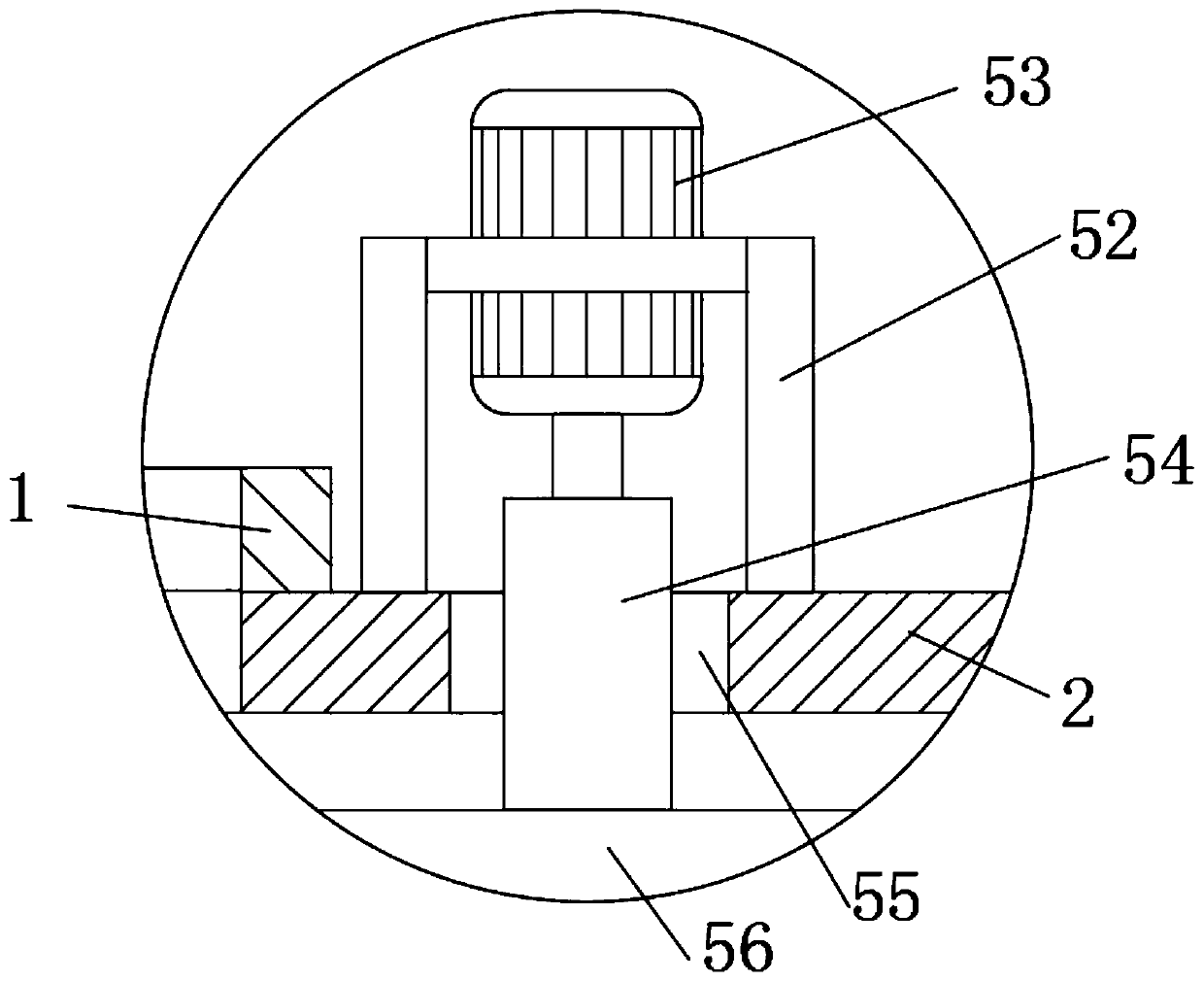

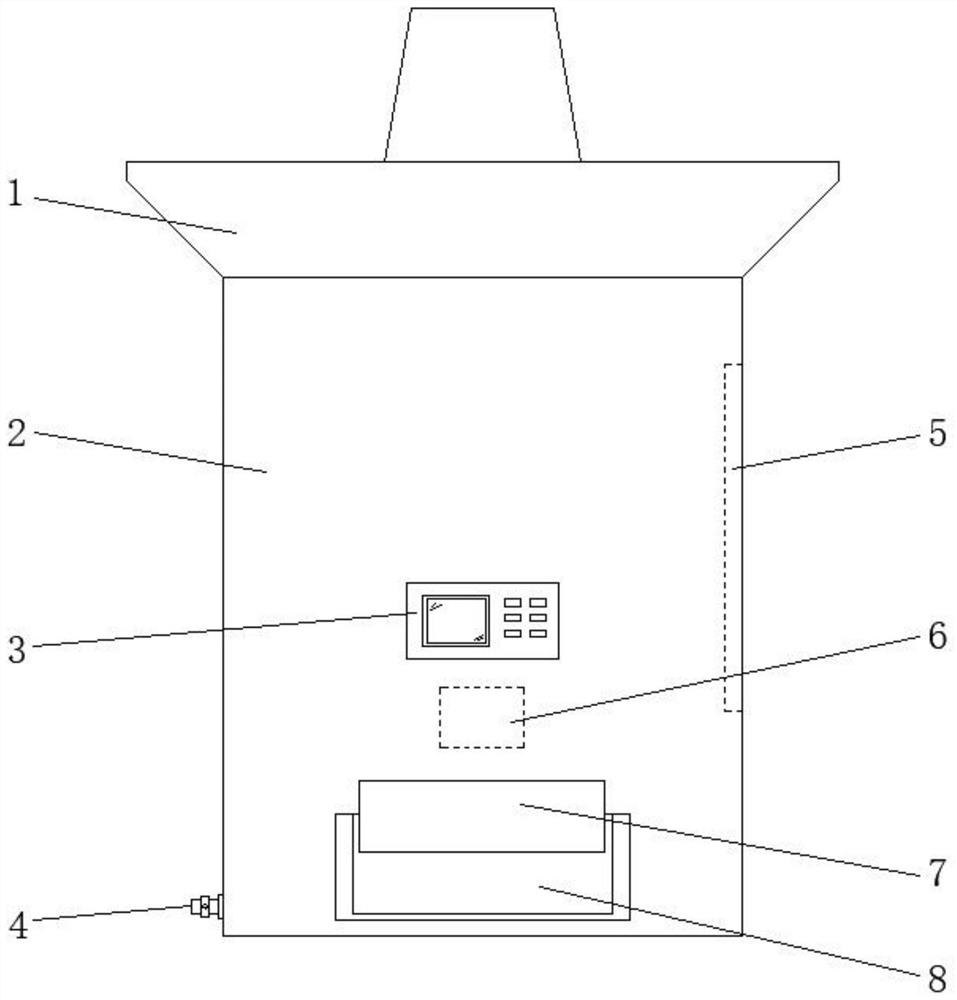

Medical infusion bottle processing device

The invention discloses a medical infusion bottle processing device comprising a support base. The medical infusion bottle processing device is characterized in that a plurality of mounting bases internally sleeved with universal wheels are arranged on the bottom end of the support base; a fixed seat and a box body are disposed on the top end of the support base; the box body with the top providedwith a processing room is a cylindrical cavity structure with the top end open; a discharge outlet is arranged on one side, far from the fixed seat, of the bottom of the processing room; a liquid storage chamber is arranged at the bottom of the box body; the processing room and the liquid storage chamber are separated through a turntable; a plurality of through holes are opened on the turntable;a ring groove internally provided with multiple fixed shafts is also arranged on the turntable; runners are evenly respectively arranged on the fixed shafts. The medical infusion bottle processing device has the advantages of having a simple and reasonable overall design, not only saving occupation space of an infusion bottle in the treatment of the infusion bottle but also being easy for transportation processing after processing, having high processing efficiency, and saving labor by manual processing.

Owner:ANHUI AIKEER PHARMA CO LTD

Prefabricated concrete preparation device for constructional engineering

InactiveCN113927701AAvoid cloggingLabor savingCombination devicesFeeding arrangmentsWater filterArchitectural engineering

The invention discloses a prefabricated concrete preparation device for constructional engineering. The prefabricated concrete preparation device comprises a fixing box, the top of one side of the fixing box is fixedly provided with a dust falling, filtering and anti-blocking collecting assembly, the bottom of one side of the fixing box is fixedly provided with a multi-stage crushing and mixing assembly, a filler compacting and automatic stripping assembly is fixedly installed at the edge part of the bottom end of the multi-stage crushing and mixing assembly, a quantitative adding and excess preventing assembly is fixedly installed at the top end of the fixing box, and the dust falling, filtering and anti-blocking collecting assembly comprises a water filtering net fixedly installed in the middle of the inner side of a water filtering box. According to the prefabricated concrete preparation device, through the dust falling, filtering and anti-blocking collecting assembly, a worker can conveniently utilize kinetic energy generated during flowing of gas and water, so that blockage of the water filter net caused by adhesion of impurities is avoided, the worker does not need to clean the water filter net in the later period, the labor force of the worker for using the preparation device is reduced, and the automatic dust filtering, falling and recycling functions of the preparation device on the impurities are achieved.

Owner:郝文涛

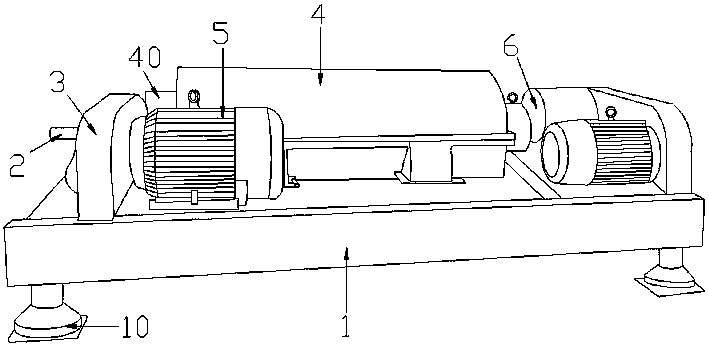

Dewatering device for papermaking

The invention discloses a dewatering device for papermaking. The dewatering device structurally comprises a fixing base, a connection center shaft, two stabilizing support bases, a dewatering body, two motors and a connection pipeline. The stabilizing support bases are arranged on the upper side of the fixing base through bolts, and are located on two sides of the dewatering body. The connection center shaft is inserted and connected into the stabilizing support bases to be connected with the dewatering body. The dewatering body is arranged on the upper surface of the fixing base through bolts. The motors are arranged on the same plane and on the upper surface of the fixing base through bolts. The connection pipeline is arranged on the upper surface of the right side of the fixing base. The fixing base is provided with fixing support legs. The dewatering device has the advantages that the dewatering device can compress papermaking residues timely during use, so that space waste duringtreatment is avoided, convenience is brought to later transportation and the like, the residues are prevented from forming flying dust effectively, and environment protection is benefited.

Owner:何敬亮 +2

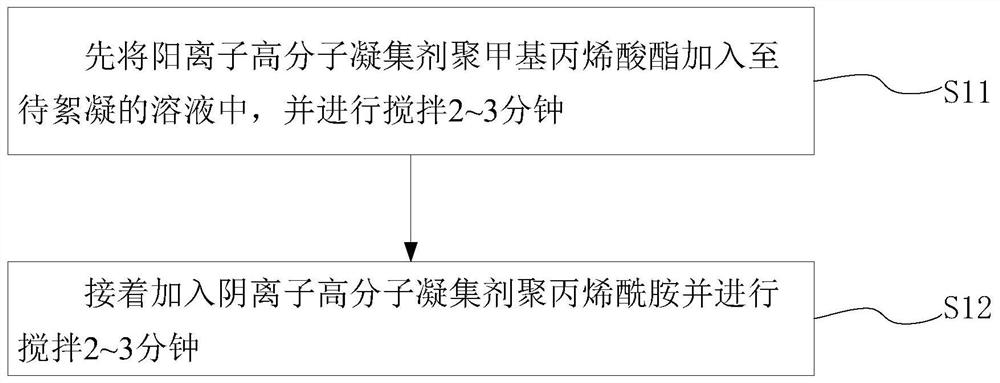

A new type of waste mud mud-water separation material with high solid phase content and its preparation method

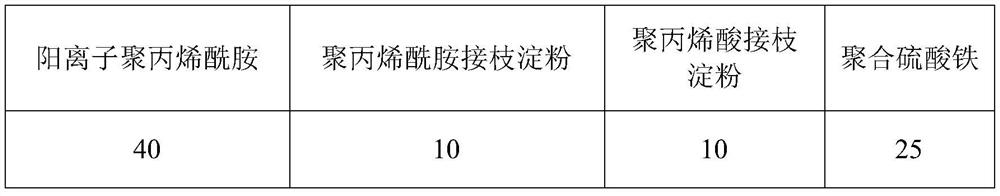

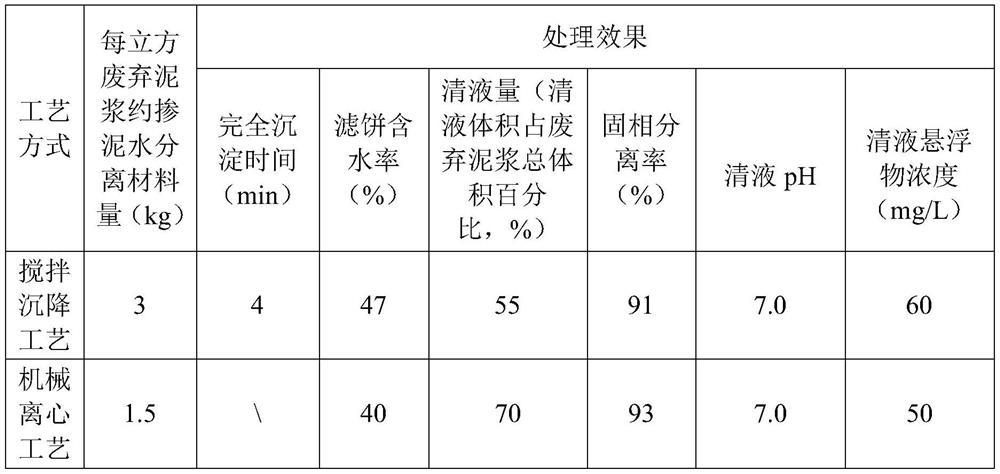

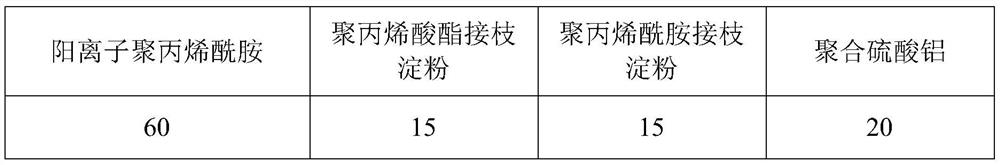

ActiveCN107265826BImprove solid phase separation rateQuick reunionSludge treatment by de-watering/drying/thickeningSlurryPolyacrylamide

The invention discloses a novel mud-water separation material for high-solid-content waste slurry and a preparation method of the novel mud-water separation material. The novel mud-water separation material is prepared from, by weight, 40-60 parts of polyacrylamide, 20-30 parts of modified starch and 20-30 parts of inorganic flocculant by compounding. By the novel mud-water separation material, synchronous quick flocculation of more than 90% of solid-phase particles (larger than 200-mesh in particle size) in waste slurry can be completed in 5min, and the novel mud-water separation material has advantages of high flocculation speed, high particle separation rate, excellent extremely fine particle separation effects, low application mixing amount, environmental friendliness, excellent performances and the like; clear liquid obtained after separation meets requirements of municipal sewage discharge standards. The novel mud-water separation material can be used as a flocculating agent for treatment processes of mechanical centrifugal separation and stirring standing separation and is applicable to mud-water separation of high-solid-content waste slurry generated in building construction.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD +1

Suspended garbage channel for building construction

InactiveCN111350327AEasy dischargeSteady down toBuilding material handlingGrain treatmentsArchitectural engineeringPipe

The invention discloses a suspended garbage channel for building construction. The suspended garbage channel aims at the problem that garbage is inconvenient to transport and blocking is likely to happen. According to the following scheme, the suspended garbage channel comprises a first conveying pipe, a bent pipe and a second conveying pipe. One end of the bent pipe is inserted into one end of the first conveying pipe, and the other end of the bent pipe is inserted into one end of the second conveying pipe. A conveying groove is welded to the end, away from the bent pipe, of the first conveying pipe, and a guide plate is welded to the inner wall of one side of the conveying groove. A conveying mechanism is arranged on the inner wall of the first conveying pipe, and the surface of the conveying mechanism and the surface of the guide plate are located on the same straight line. The two sides of the circumferential inner wall of the second conveying pipe are fixedly connected with alternately distributed rubber plates. According to the suspended garbage channel for building construction, falling materials can be blocked properly, and the falling speed of the falling materials is reduced; cutting tooth sheets are arranged at the bottom of an annular belt, the bottoms of the cutting tooth sheets are closed, and the falling materials are blocked by the cutting tooth sheets in the falling process; and under the gravity of the falling materials, the cutting tooth sheets can be opened, then discharging is carried out, and buffering is achieved again.

Owner:葛飞月

Concrete preparation and pouring all-in-one machine for municipal construction

InactiveCN112459491AConvenient discharge and transportationEasy pouringDischarging apparatusBuilding material handlingAugerThreaded pipe

The invention relates to the field of municipal administration, in particular to a concrete preparation and pouring all-in-one machine for municipal construction. The machine comprises a conveying cavity, a conveying shaft is arranged in the middle of the conveying cavity, a conveying auger is arranged on the conveying shaft, a first bevel gear is installed on the conveying shaft, a second bevel gear is meshed with the upper end of the first bevel gear, and a first rotating shaft is arranged at the upper end of the second bevel gear. The upper end of the first rotating shaft is connected witha first threaded rod through a belt, a sliding block is connected to the first threaded rod, a first connecting pipe is arranged on the outer side of the sliding block, a pouring nozzle is installed at the outer end of the first connecting pipe, a sealing cavity is formed in the conveying cavity, a third bevel gear is installed in the sealing cavity, and a fourth bevel gear is meshed with the upper end of the third bevel gear. A second threaded rod is arranged at the upper end of the fourth bevel gear, the upper end of the second threaded rod is arranged in the stirring cavity, the upper end of the second threaded rod is connected with a threaded pipe, and stirring rods are installed at the two ends of the threaded pipe.

Owner:徐天元

Packing equipment for compressible waste recycling

The invention discloses a packing device for recovering compressible waste, which includes a case, and a pretreatment mechanism and an auxiliary mechanism are installed inside the case; the pretreatment mechanism includes a delivery pipe fixedly connected to the inner wall of the case through a pillar, A first slider is slidably connected to the delivery pipe, a connecting pipe is fixedly connected through the side wall of the delivery pipe symmetrically, a second slider is slidably connected to each of the connecting pipes, and a rotating rod is connected to the inner wall of the cabinet for symmetrical rotation. , the side wall of the rotating rod is fixedly connected with a connecting plate, the bottom wall of the case is equipped with a motor, the output end of the motor is coaxially fixed with a rotating shaft, and the rotating shaft penetrates through the inner wall of the case and is fixedly connected with a zigzag rod. The annular body in the present invention slides on the side wall of the support plate, thereby driving the packing roller to move synchronously, and the packing belt is wound around the packing roller, so that the packing roller drives the packing belt to wrap the compressible waste after extrusion molding , and the compressible waste is automatically conveyed.

Owner:南通市通州区茂润包装制品有限公司

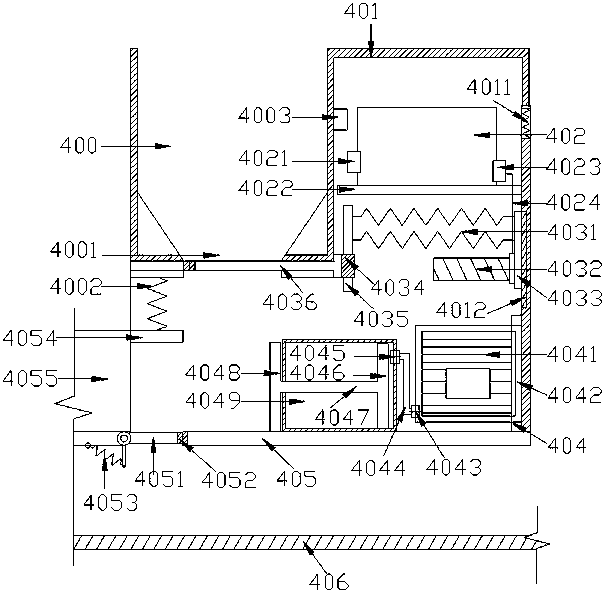

Rare earth slag curing forming system

InactiveCN113058969AEasy to launchEasy handling for transportSolid waste disposalTransportation and packagingSlagEngineering

The invention discloses a rare earth slag curing forming system. The system comprises a machine shell, wherein a driving cavity is formed in the machine shell, a stirring cavity is formed in the upper end wall of the driving cavity, a driving cavity is formed in the upper end wall of the stirring cavity, a liquid inlet cavity communicated with the outside is formed in the upper end wall of the stirring cavity, a feeding cavity is formed in the machine shell, a transmission cavity is formed in the right end wall of the feeding cavity, a rotating cavity is formed in the lower end wall of the transmission cavity, a working cavity is formed in the lower end wall of the transmission cavity, a cavity is formed in the lower end wall of the working cavity, a conical column is arranged in the feeding cavity, rare earth slag can be ground after the conical column is matched with the end wall of the feeding cavity, a mold is arranged in the working cavity and can be used for manufacturing rare earth slag blocks, a feeding plate is arranged in the driving cavity, a liquid discharging fan is arranged in the liquid inlet cavity, and the liquid discharging fan can discharge a coagulant into a stirring cavity according to rotation of a feeding plate.

Owner:永康市孙虎科技有限公司

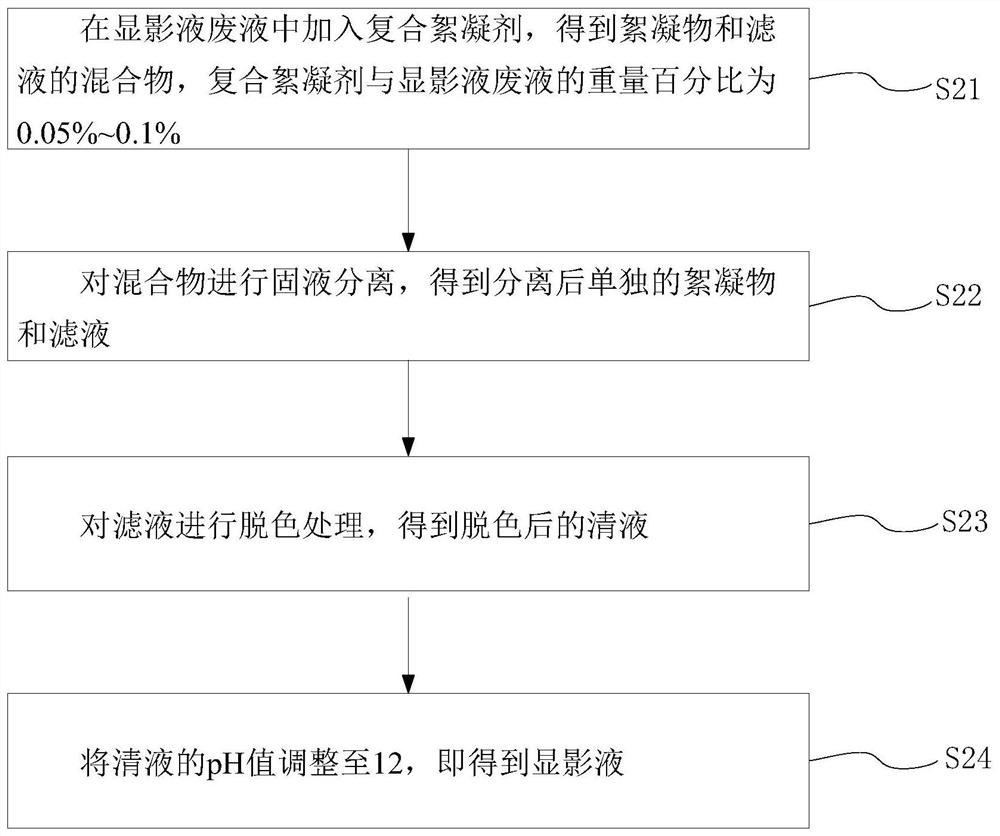

Composite flocculant and its flocculation method, recycling method and system

ActiveCN110015735BLarge particle sizeReduce moisture contentTreatment involving filtrationMultistage water/sewage treatmentFlocculationPolymer science

Owner:SHENZHEN CYPRESS IND DEV CO LTD

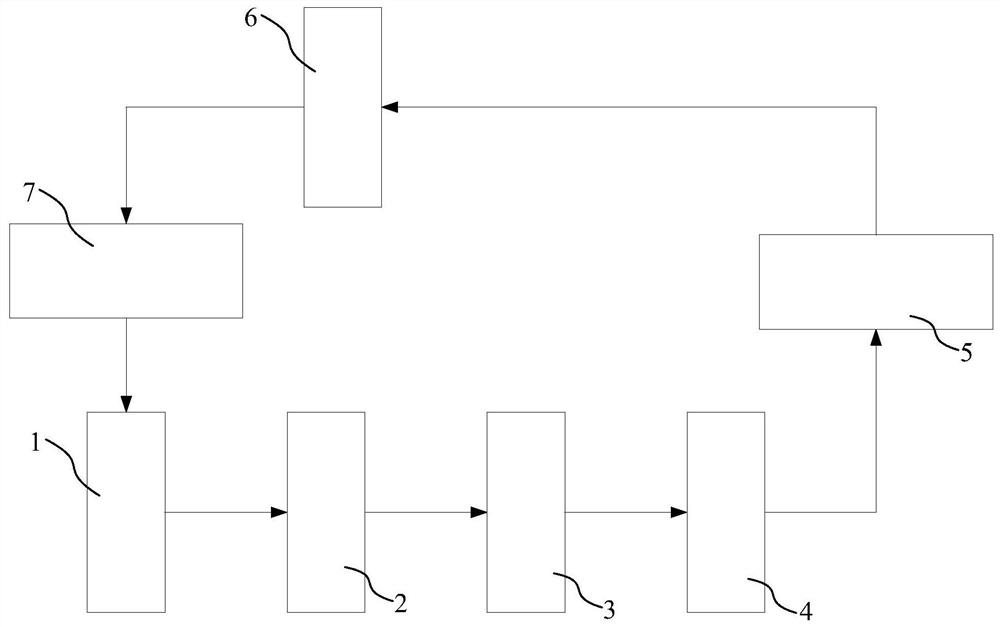

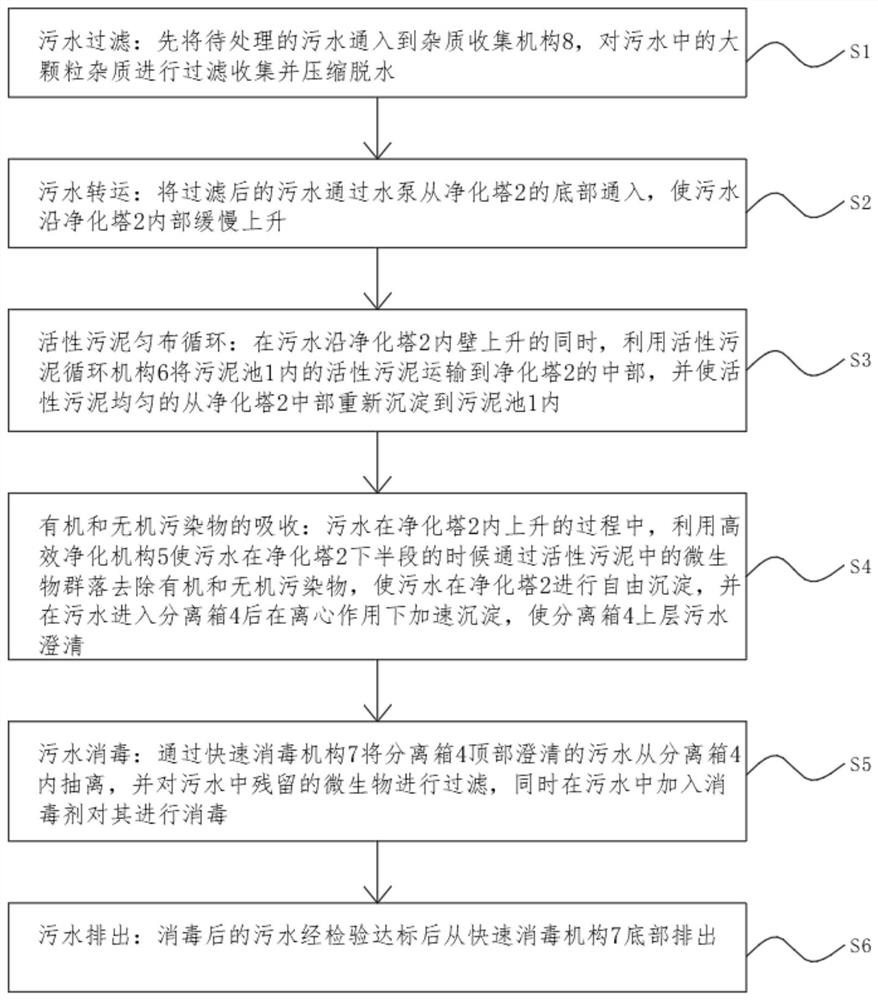

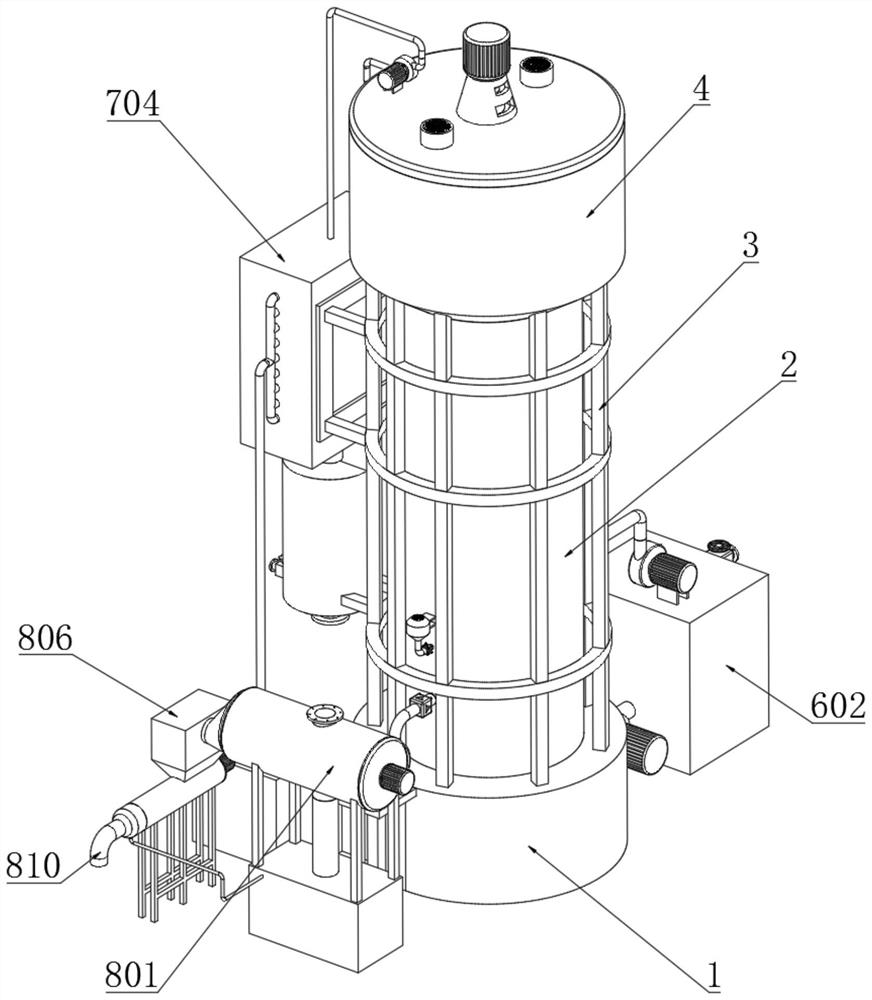

Environment-friendly method for treating sewage by utilizing microorganisms

ActiveCN111718075AImprove purification efficiencyLow input costWater/sewage treatment by centrifugal separationTreatment involving filtrationActivated sludgeMicroorganism

The invention discloses an environment-friendly method for treating sewage by utilizing microorganisms. Sewage treatment equipment needs to be used in the process of sewage treatment. The sewage treatment equipment comprises a sludge tank, wherein the top end of the sludge tank is fixedly connected with a purification tower; the top end of the purification tower is fixedly connected with a separation box; an efficient purification mechanism is arranged in the separation box; an activated sludge circulating mechanism is arranged at the bottom end of one side of the sludge tank; and a rapid disinfection mechanism is arranged on the inner side of the separation box. According to the invention, a vertical distribution structure of an efficient purification mechanism effectively reduces the occupied area of the sewage purification equipment, so decentralized construction of the sewage treatment equipment is facilitated, the mode of centralized treatment of sewage in a large area in traditional sewage treatment is changed, implementation of special treatment of sewage in a small area is facilitated, adjustment of the types of total microbial communities of activated sludge according to the types of pollutants in the sewage in the area is facilitated, and sewage treatment effect is improved.

Owner:福建洋屿环保科技股份有限公司

Salvage auxiliary device used for ecological restoration and capable of solving problem of inconvenient garbage treatment

PendingCN113309052AReduce size and weightIncrease profitWater cleaningPressesAnimal scienceEngineering

The invention relates to the technical field of ecological restoration, and discloses a salvage auxiliary device used for ecological restoration and capable of solving the problem of inconvenient garbage treatment. The salvage auxiliary device comprises a shell, and a material containing box is fixedly connected in the shell. Through the combined action of the material containing box, a left pressing tool, a right pressing tool, a connecting rod, a cone pulley, a first rotating plate, a first movable plate and a second rotating plate, salvaged and contained garbage is automatically compressed, redundant water in the garbage is squeezed out, the size and weight of the garbage are reduced, the space utilization rate is increased, convenience is provided for subsequent transportation treatment, the treatment cost is effectively reduced, a the actual use requirement is met, the opening and closing state of a discharging port is controlled, support is provided for garbage compression operation, extruded sewage is discharged through water leakage holes of a baffle, after compression operation is completed, the discharging port is not shielded any more, garbage blocks are transferred under the action of the garbage blocks, space is vacated for subsequent garbage compression operation, and the garbage treatment operation is orderly carried out.

Owner:郑文海

High-speed AB sheet box pasting machine

InactiveCN113733664AEasy to operatePracticalPaper-makingBox making operationsCartonElectric machinery

The invention discloses a high-speed AB sheet box pasting machine, and relates to the technical field of box pasting machines. The high-speed AB sheet box pasting machine comprises a working plate, wherein a double-shaft motor is fixedly connected to the middle of the right side of the top of the working plate through a connecting block, a moving structure is installed at the bottom of the working plate, and a storage tank is fixedly connected to the left side of the working plate. The high-speed AB sheet box pasting machine is easy to operate and high in practicability, a double-shaft motor provides power support, the device is convenient to move through telescopic supporting rods, universal wheels, a vehicle plate, a vehicle wheel body, a conveying vehicle belt, a storage tank box and a pushing handle body, and meanwhile, paper boxes are convenient to transport and treat; through the use of a transmission rod, a transmission cylinder, a thick conveying belt, a thin conveying belt, a left supporting plate, a right supporting plate, a rear transmission rod, a rear conveying belt, a double-telescopic plate, a telescopic body, an adjusting plate, a pressing body, a transverse plate, a telescopic adjusting rod, a telescopic control rod, a glue spraying body, a glue box, a lower concave body, an upper concave body, telescopic pressing bodies, creasing plates and glue pressing plates, and box pasting can be achieved conveniently.

Owner:温州力跃机械有限公司

A rare earth waste drying device for rare earth waste recovery

ActiveCN112404105BFor subsequent dryingLimit flyawayDispersed particle filtrationTransportation and packagingElectric machineEnvironmental engineering

Owner:萍乡鑫森新材料有限责任公司

A leachate treatment device for a garbage transfer station

ActiveCN110328212BEfficient collectionEasy to collectTransportation and packagingSolid waste disposalEnvironmental engineeringMechanical engineering

Owner:ANHUI LANDING ENVIRONMENTAL PROTECTION ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com