Patents

Literature

35results about How to "For subsequent drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation methods of illite/montmorillonite clay nanometer slurry and illite/montmorillonite clay nanometer powder

InactiveCN103588214AImprove stabilityGood anti-sedimentationMaterial nanotechnologySilicon compoundsDispersityHigh energy

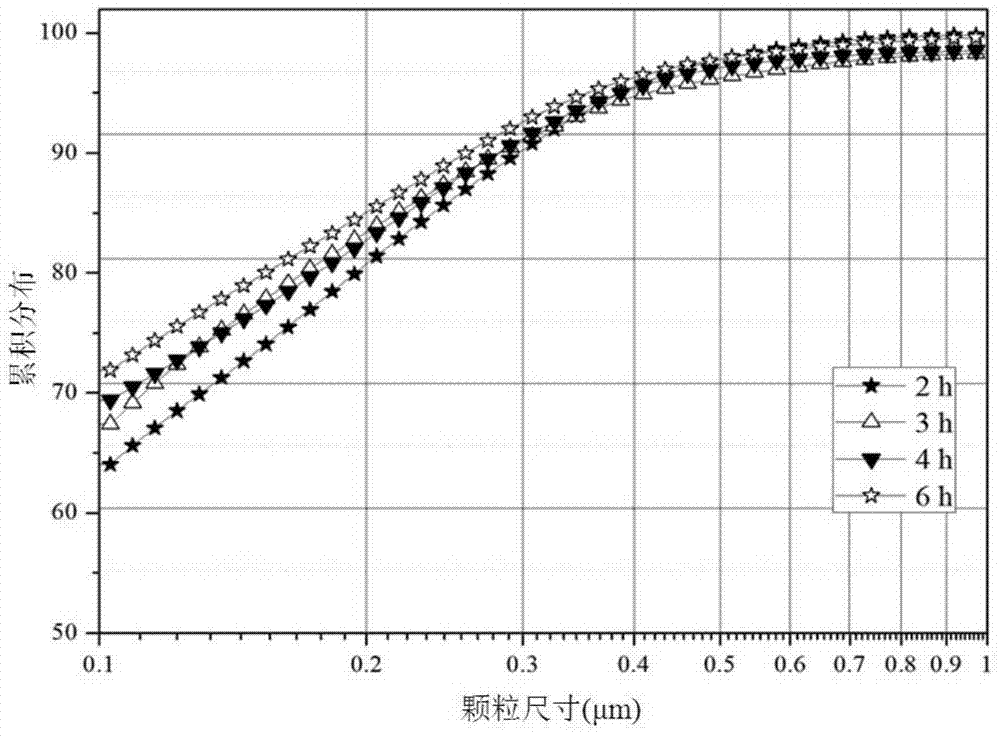

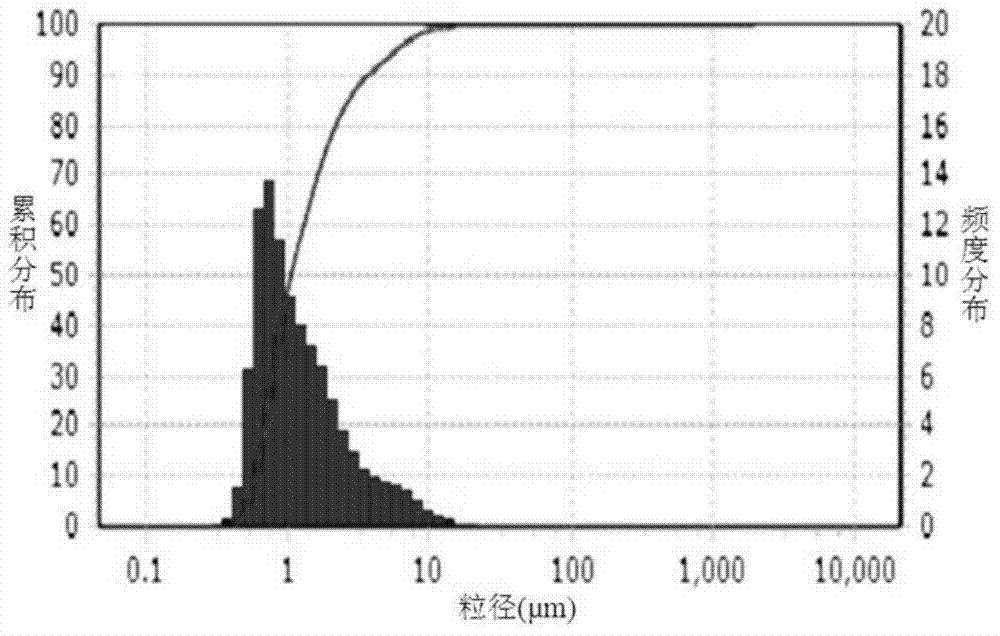

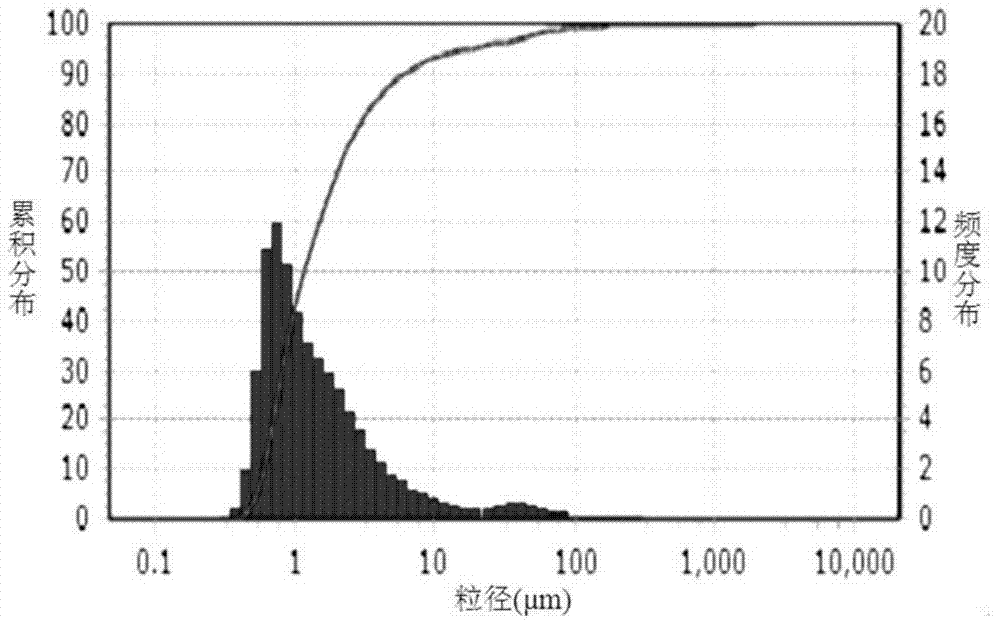

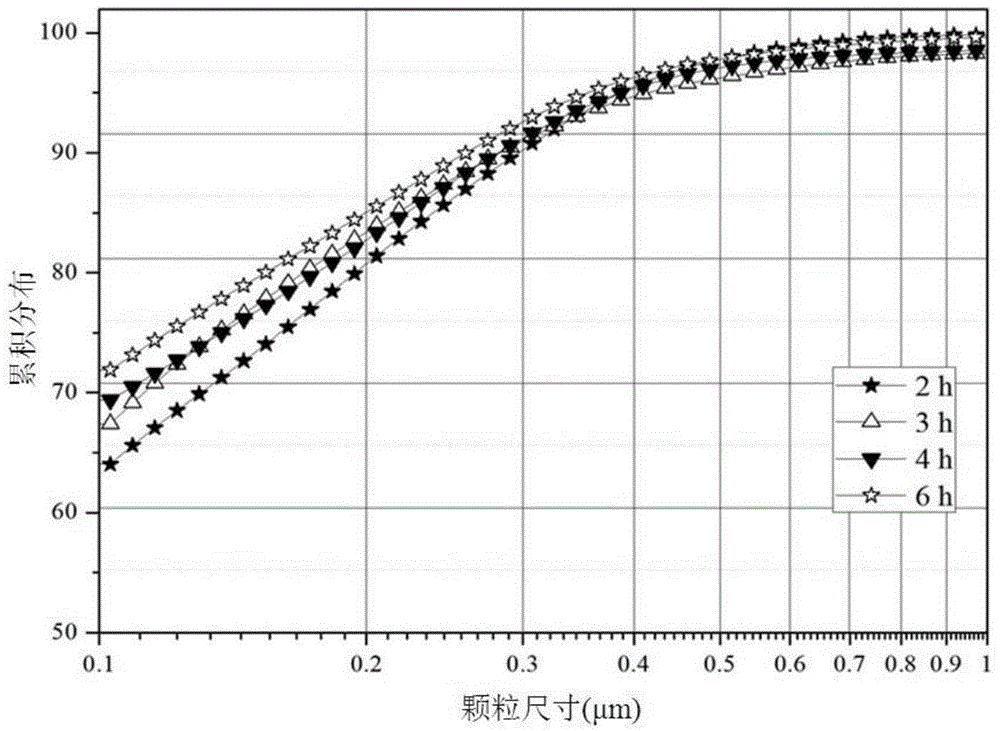

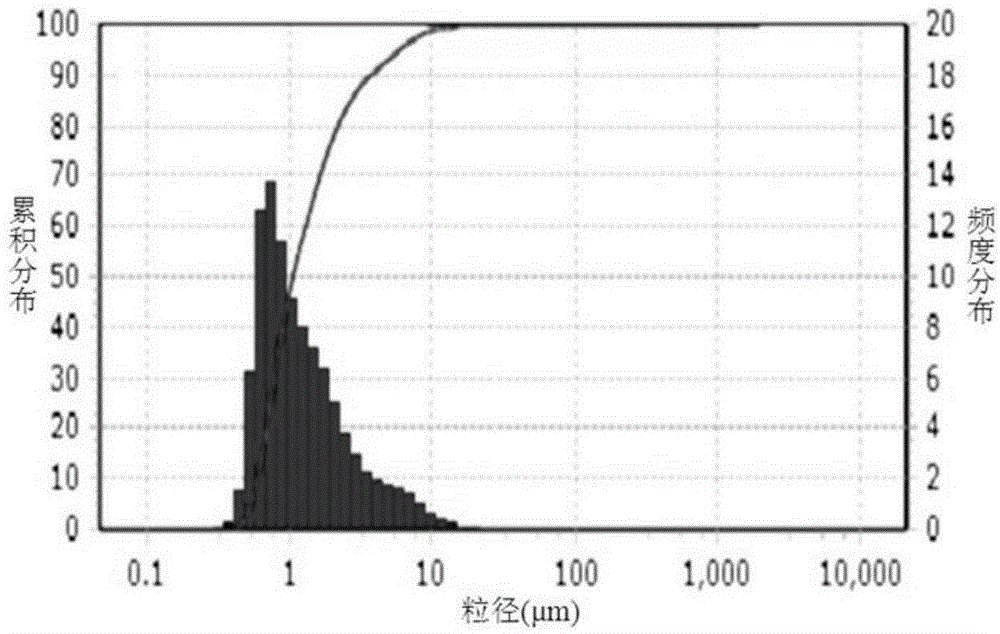

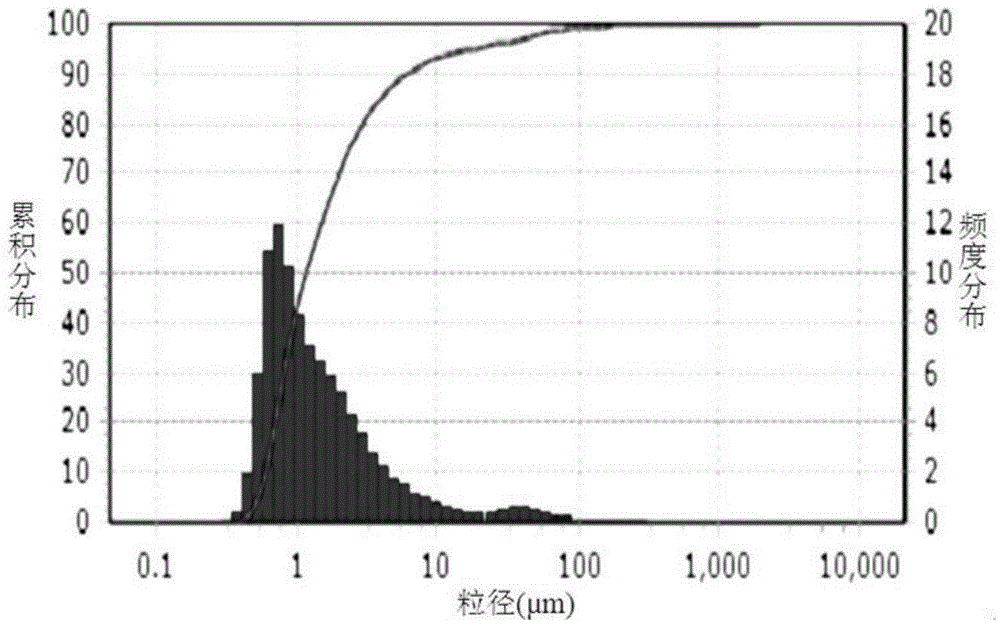

The invention discloses preparation methods of illite / montmorillonite clay nanometer slurry and illite / montmorillonite clay nanometer powder and belongs to the field of development and preparation of nanometer materials. The preparation method of the illite / montmorillonite clay nanometer powder comprises the following steps: (1) mechanically breaking natural illite / montmorillonite clay mineral; (2) soaking in water so as to obtain illite / montmorillonite clay slurry; (3) adjusting the pH value of the illite / montmorillonite clay slurry, puddling and dispersing; (4) sieving the puddled and dispersed slurry by using a 50-mesh sieve; (5) removing iron from the slurry; (6) chemically bleaching the slurry; (7) grinding the bleached slurry by adopting a high-energy density stirred mill so as to obtain nanometer slurry; (8) adding a dispersing agent to the nanometer slurry to carry out dispersing treatment; (9) adding a modifying agent to the slurry to carry out swelling treatment; (10) evaporating and drying; and (11) carrying out mechanical pulverization so as to obtain the illite / montmorillonite clay nanometer powder in the end. The illite / montmorillonite clay nanometer powder prepared by the method can reach the nanoscale and has good powder uniformity and dispersity.

Owner:SOUTH CHINA UNIV OF TECH +1

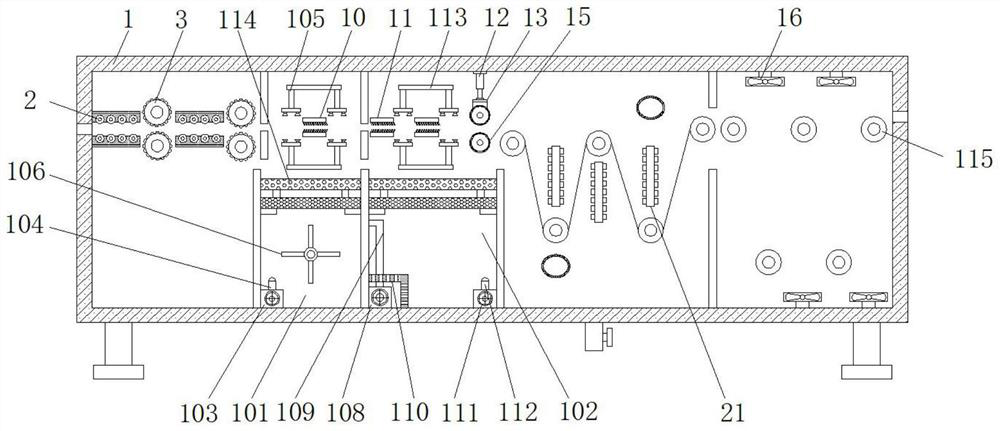

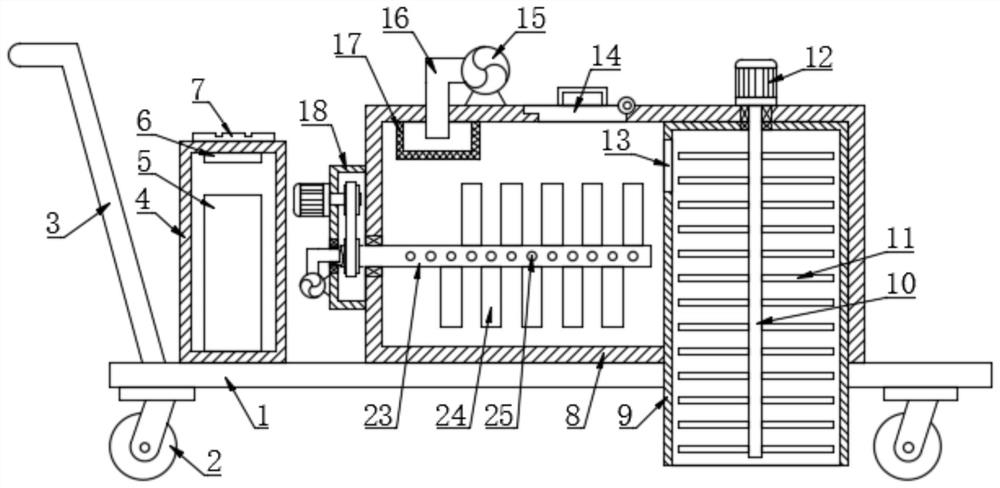

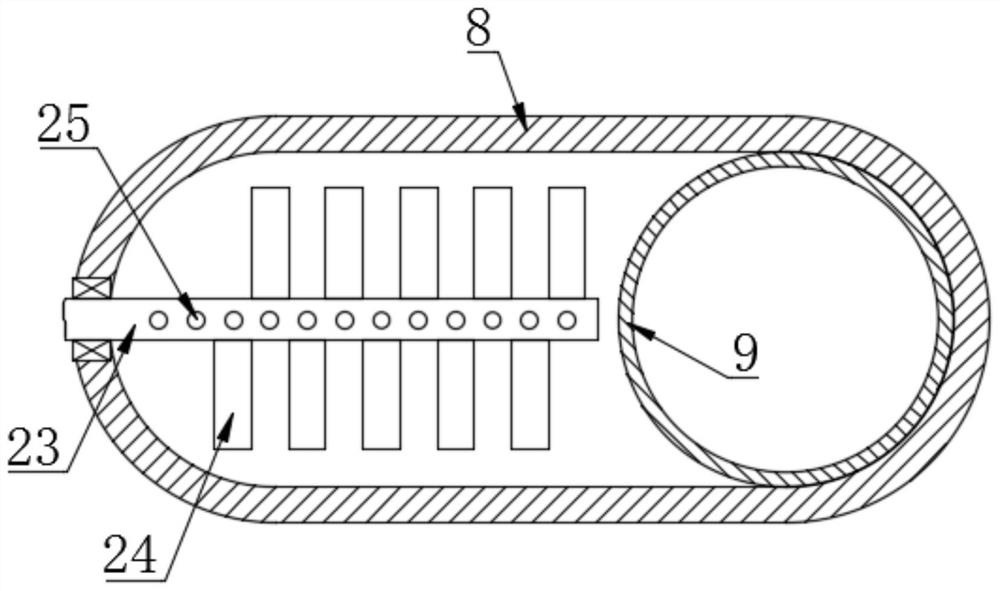

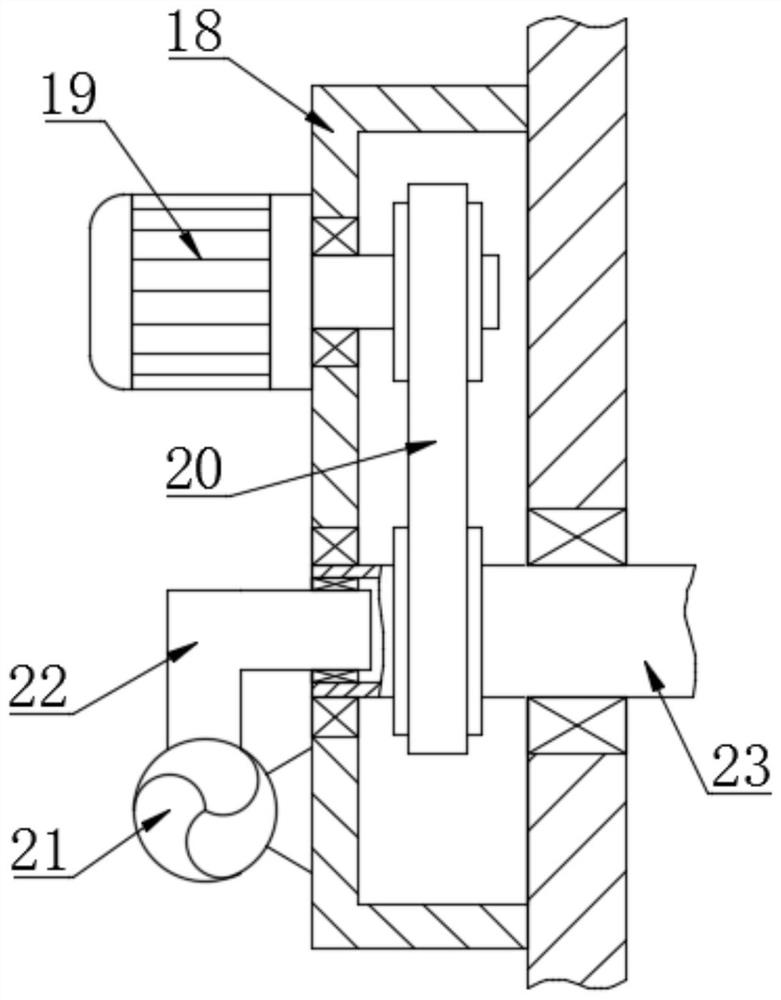

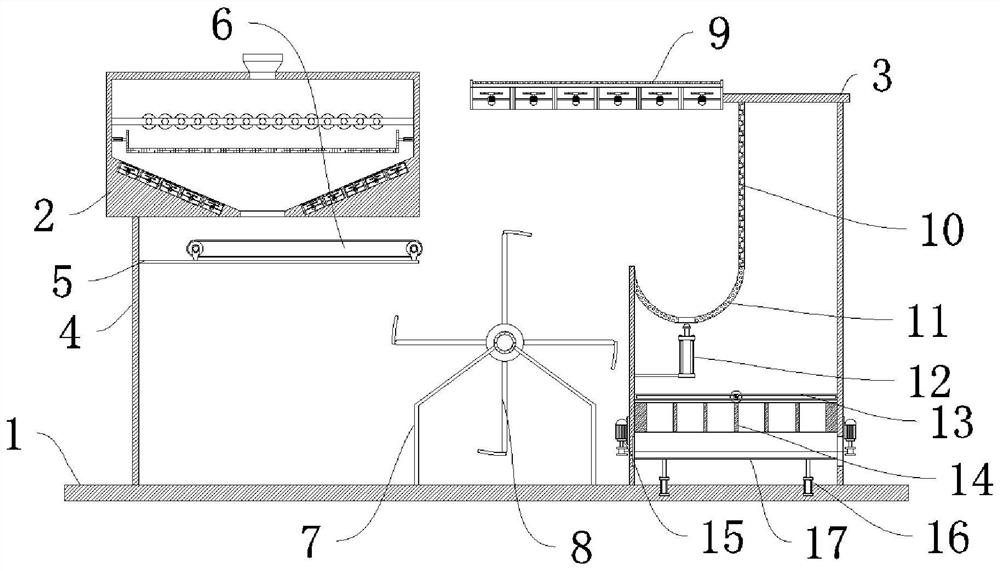

Cloth drying equipment for textile

PendingCN108759417AUniform moisture contentImprove drying efficiencyDrying solid materials without heatDrying gas arrangementsEngineeringMechanical engineering

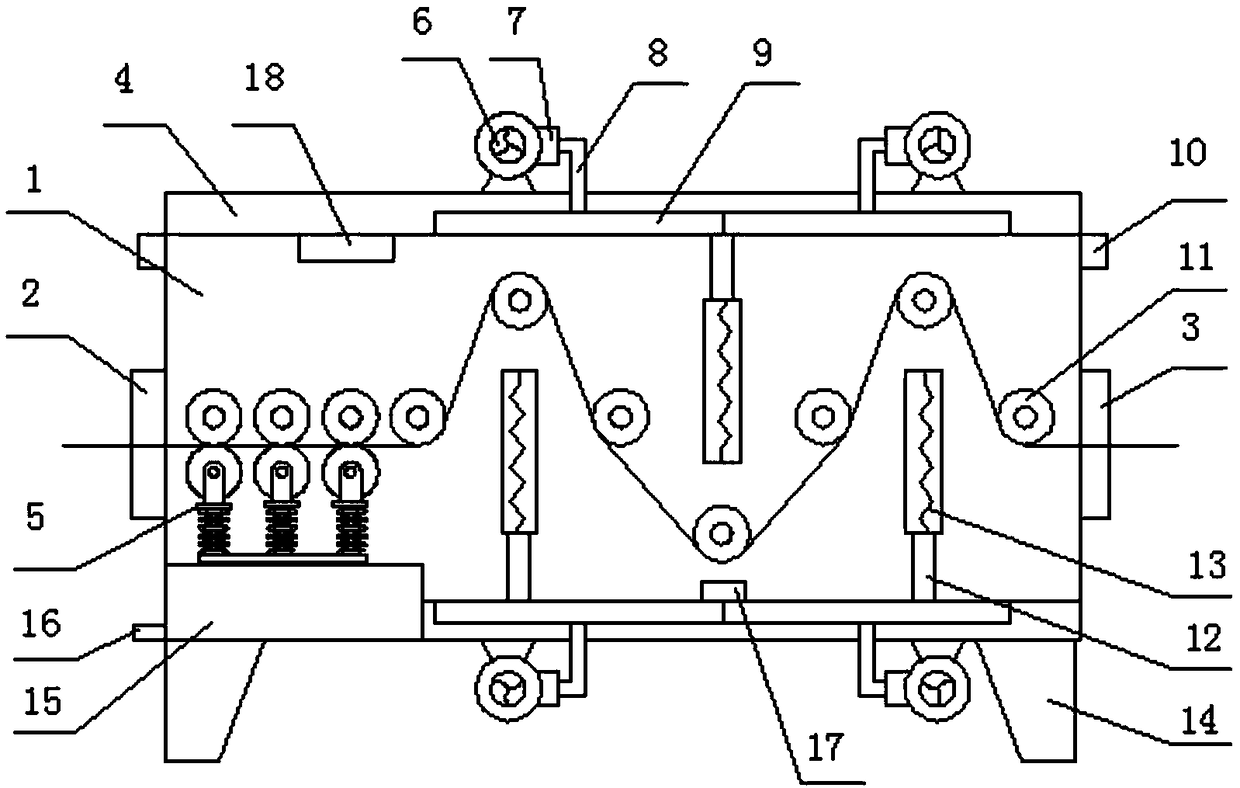

The invention discloses cloth drying equipment for textile. The cloth drying equipment comprises a drying shell, a water squeezing mechanism, blowers, air inlets, a conveying roller wheel, a drying lamp, a water collecting tank and a processor, wherein support legs are installed at both ends of the lower side of the drying shell, a feed opening and a discharge opening are respectively formed in the middles of both ends of the drying shell, the water squeezing mechanism is installed at the end, which is close to the feed opening, in the drying shell, the water squeezing mechanism is composed ofan upper water squeezing wheel and a lower water squeezing wheel, the conveying roller wheel is installed in the drying shell, the air inlets are formed in both sides of the upper side of the dryingshell, the blowers are installed on the top and the lower side of the drying shell, ventilating pipes and electric heaters are connected to one ends of the blowers, and one end of each ventilating pipe communicates with the corresponding air inlet. According to the cloth drying equipment for textile, the water squeezing mechanism is arranged so that cloth can be squeezed first, and the subsequentdrying treatment is facilitated.

Owner:德清兴昌利纺织品有限公司

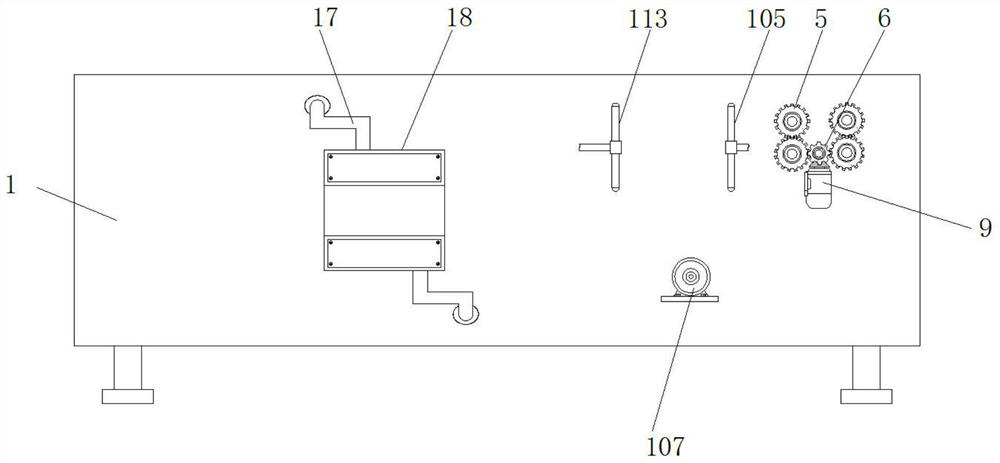

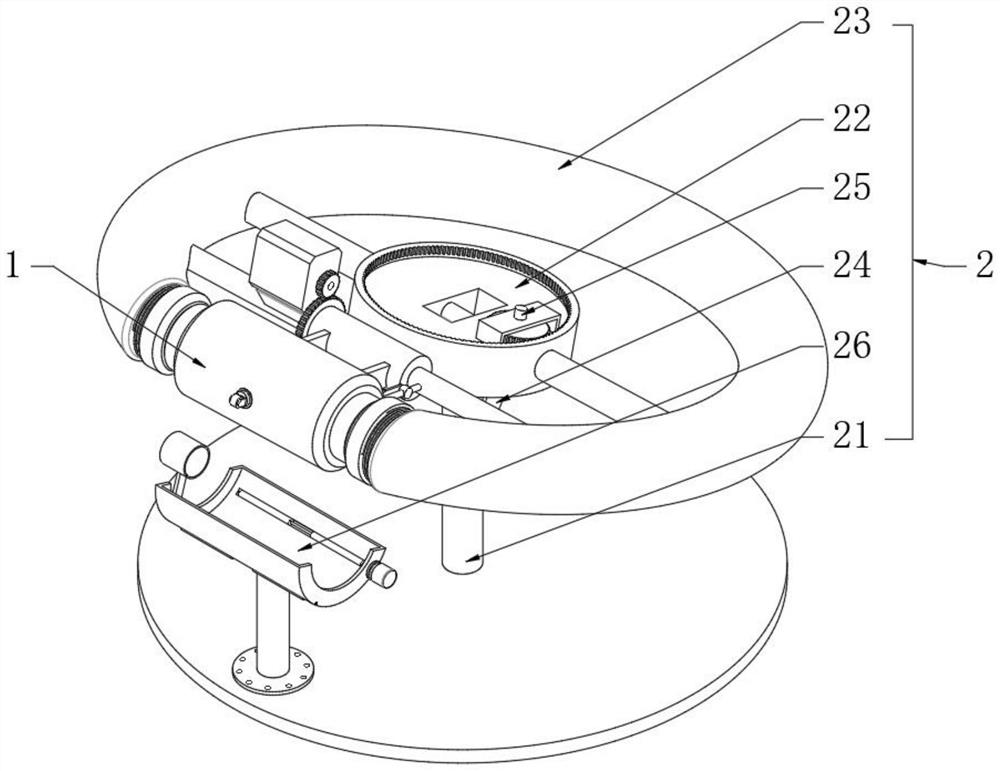

Medical apparatus cleaning and drying device

InactiveCN107755337AEasy to addGuaranteed cleaning effectDrying solid materials without heatDrying gas arrangementsSprayerWater diversion

The invention discloses a medical apparatus cleaning and drying device. The medical apparatus cleaning and drying device comprises a base, wherein a support plate is fixedly arranged on the base through a bracket; the top of the support plate is rotatably connected to a cleaning barrel through a ball; the bottom of the cleaning barrel is fixedly connected to a rotary shaft; the rotary shaft is hollow and penetrates through the support plate to be provided with a driven gear; a servo motor is arranged at the top of the base; a driving gear is mounted on a motor shaft at the top end of the servomotor and is engaged with the driven gear; a hollow water diversion disc is fixedly arranged at the bottom of the interior of the cleaning barrel; a plurality of water diversion pipes are uniformly connected to the side wall of the hollow water diversion disc; a plurality of high-pressure sprayers are arranged on the water diversion pipes; a high-pressure water pump is further arranged at the topof the base; the left end water outlet of the high-pressure water pump is connected to a high-pressure water pipe; and the water outlet end of the high-pressure water pipe penetrates through the rotary shaft and the cleaning barrel to be connected into the hollow water diversion disc. The high-pressure sprayers are uniformly arranged at the bottom and the side walls of the interior of the cleaning barrel for flushing, so that the medical apparatus cleaning and drying device is sufficiently wide in flushing range and better in cleaning effect and can spin-dry after cleaning.

Owner:李欢欢

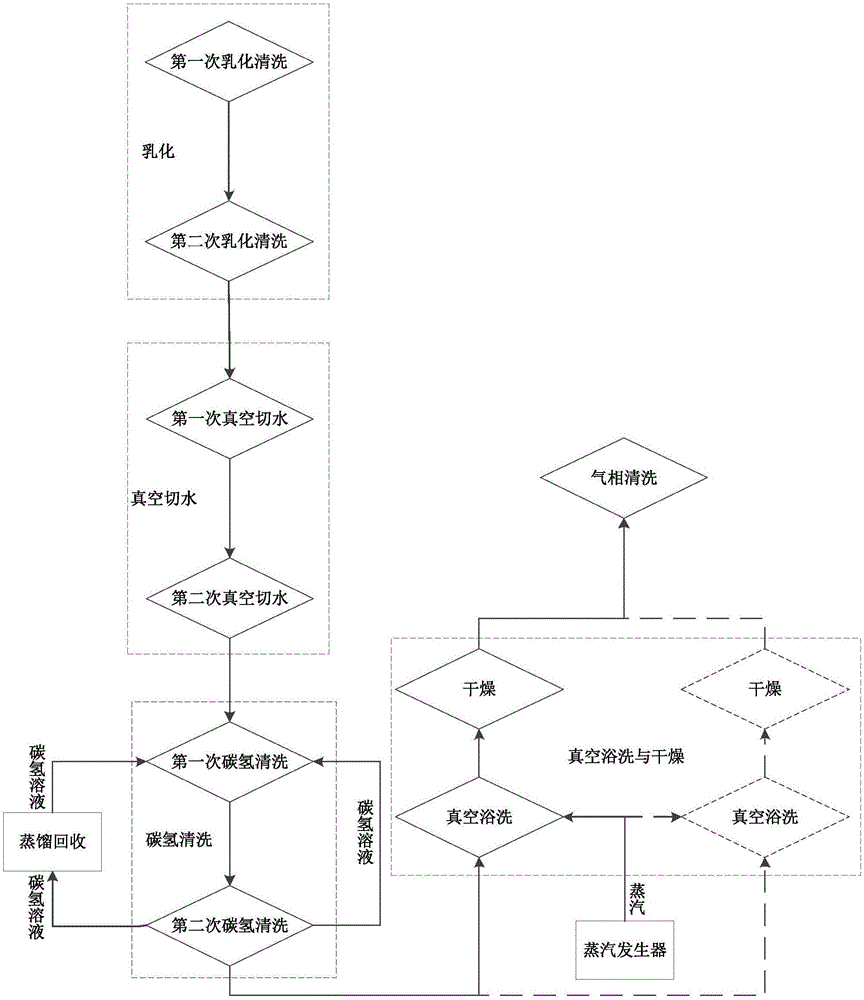

High-precision washing process for raw part of gold coin or silver coin

The invention discloses a high-precision washing process for a raw part of a gold coin or a silver coin and relates to the field of surface clearing of work pieces. The high-precision washing process comprises the following sequentially-set steps: emulsification, vacuum water shearing, hydrocarbon washing, vacuum bath-washing and gas-phase washing; therefore high-precision washing of the raw part of the gold coin or silver coin can be realized by means of control on vacuum degree, temperature of a detergent, ultrasonic wave frequency and washing time in each step. The high-precision washing process disclosed by the invention is complete in pollutant treatment, high in yield, high in automation degree in each step and capable of satisfying the environment protection requirements by adopting an environment-friendly detergent in each step.

Owner:SHENZHEN XINCHENGNUO ENVIRONMENTAL PROTECTION IND CO LTD

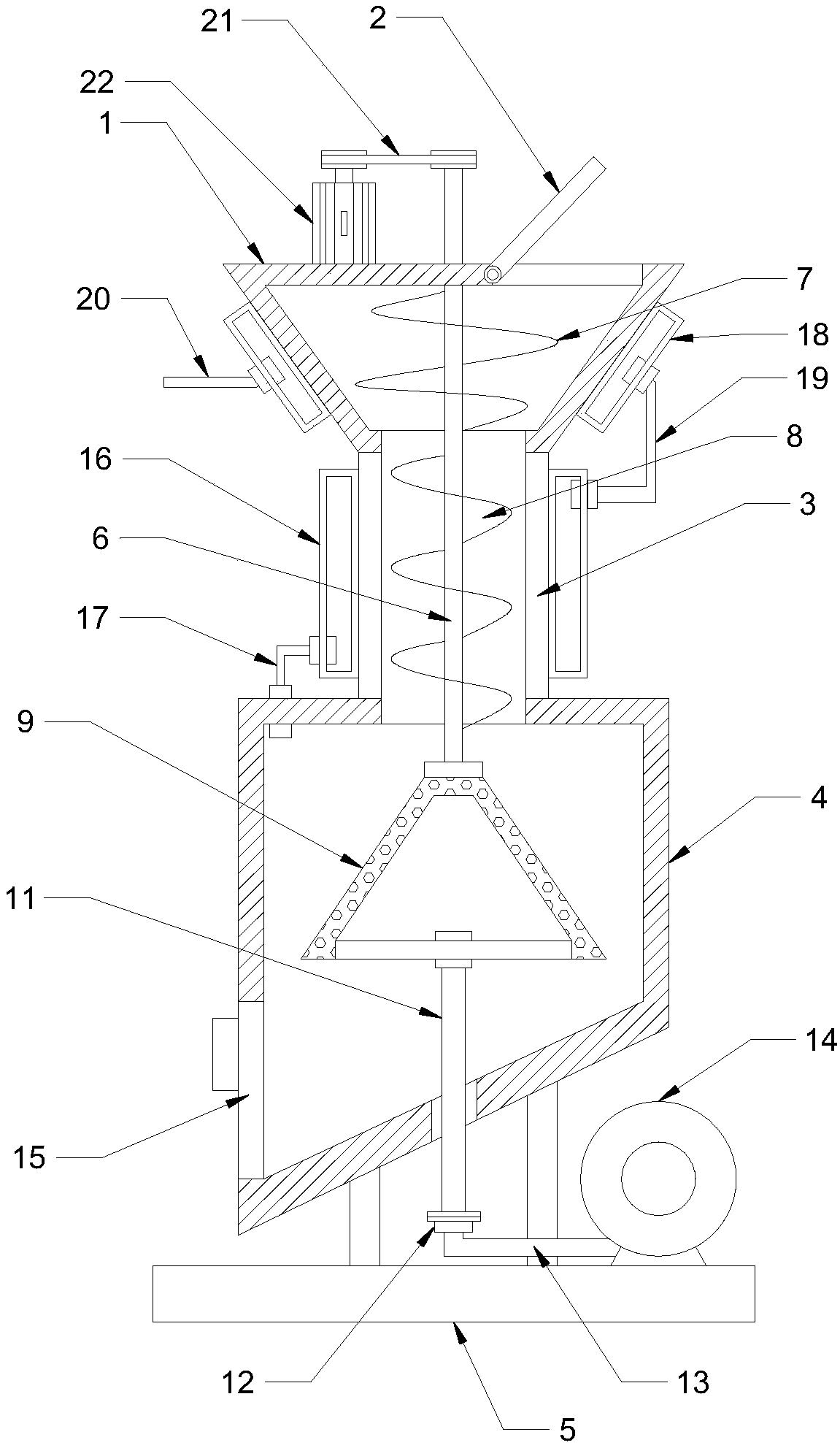

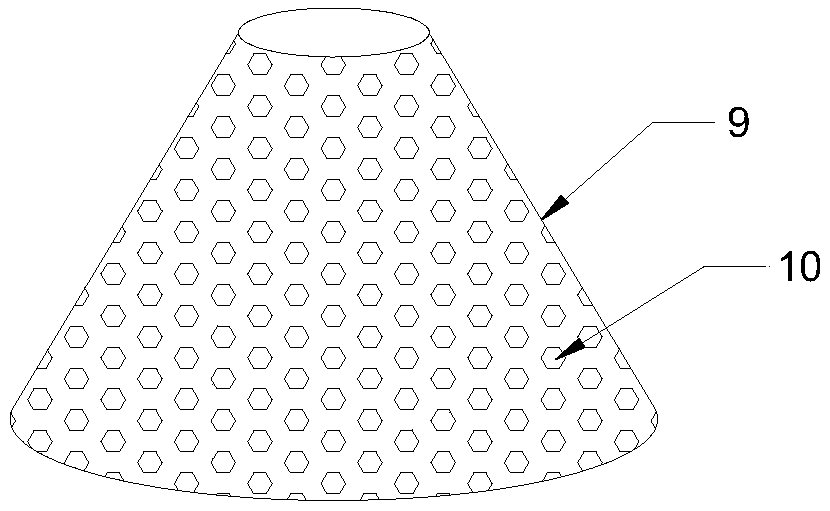

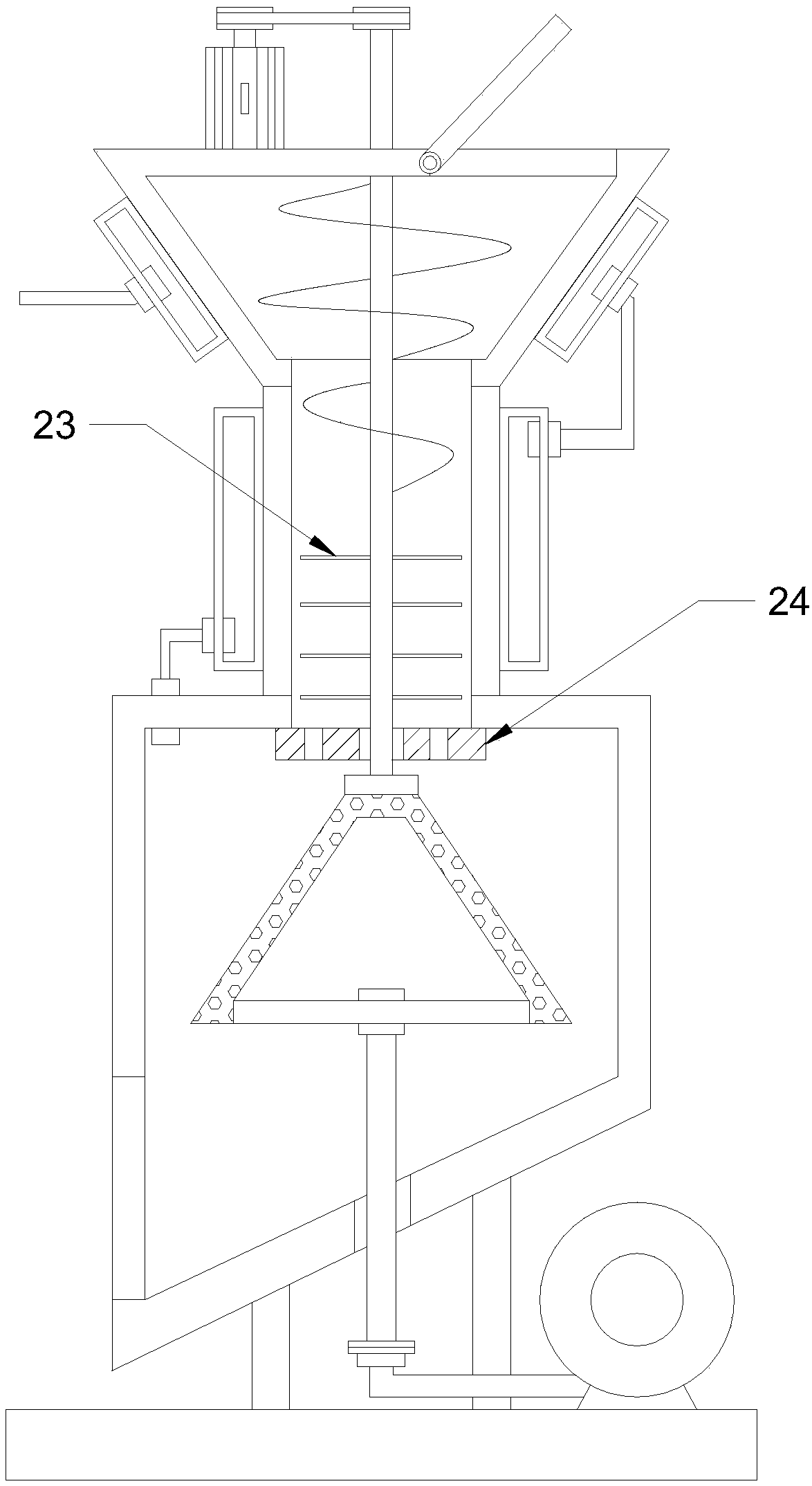

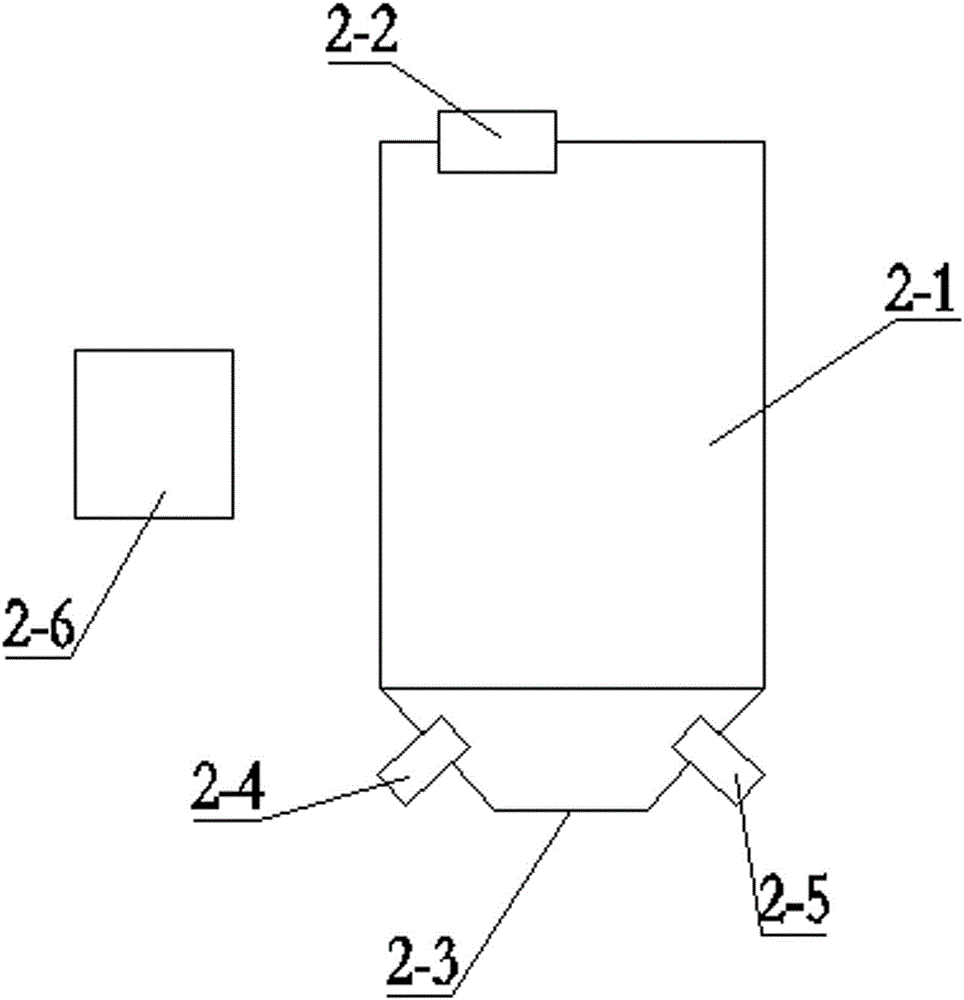

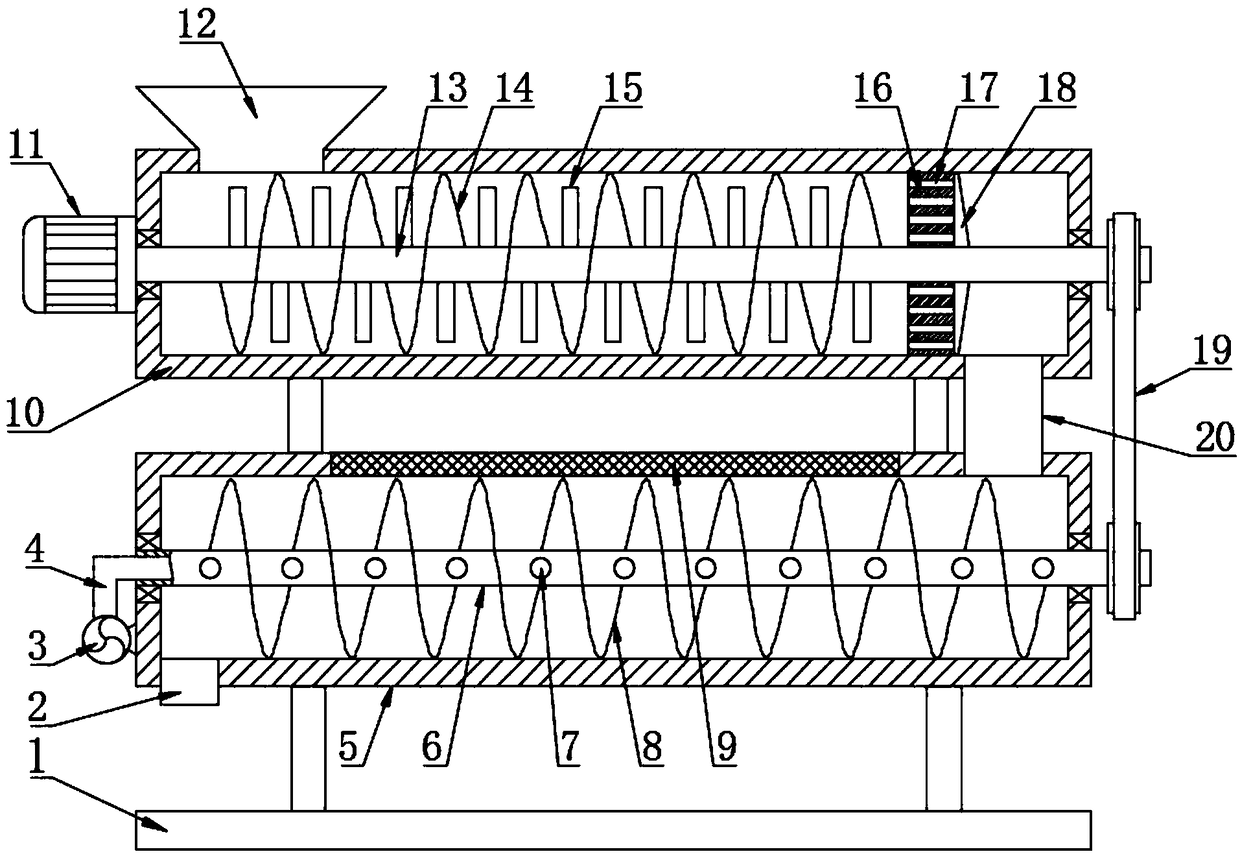

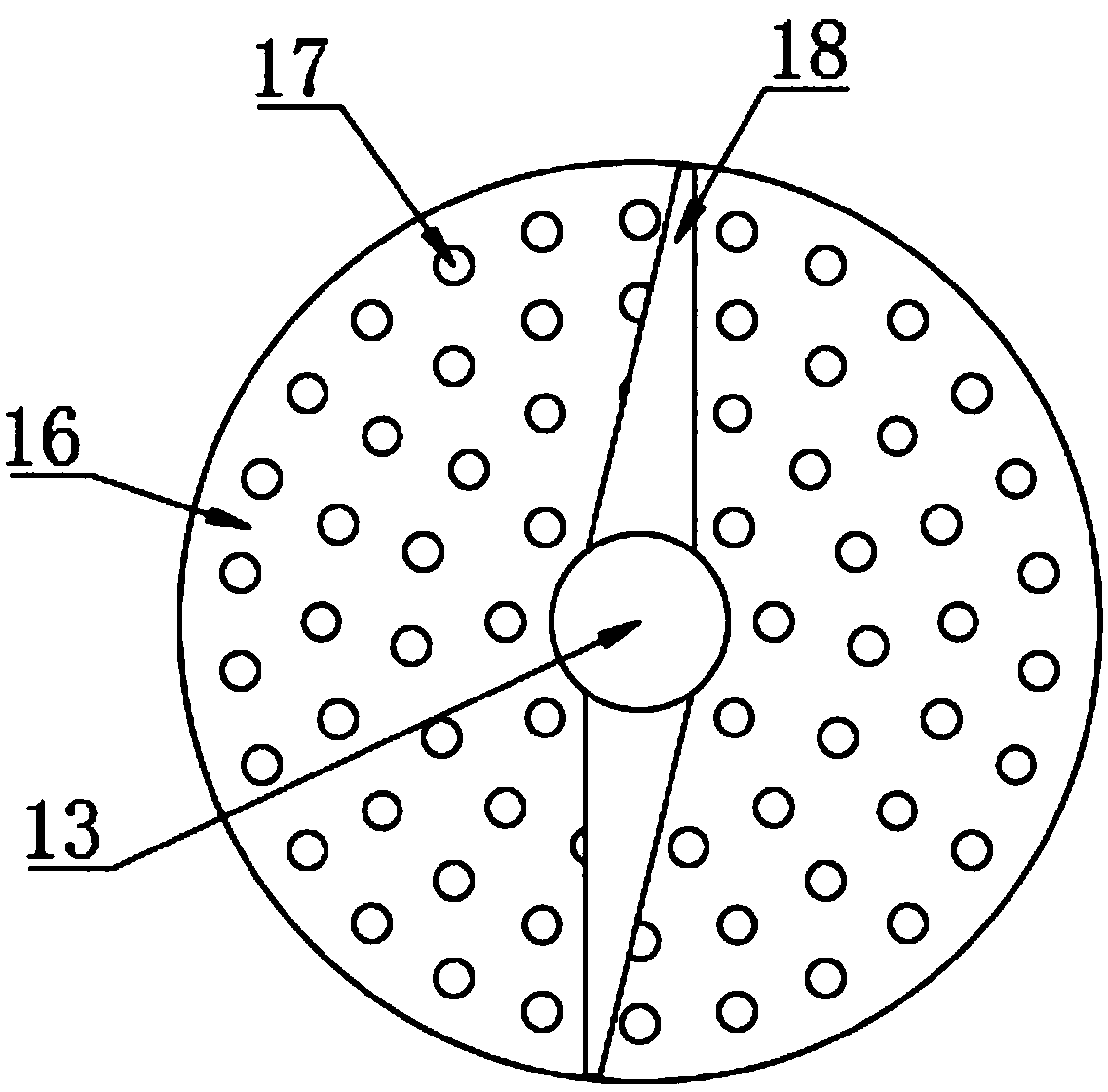

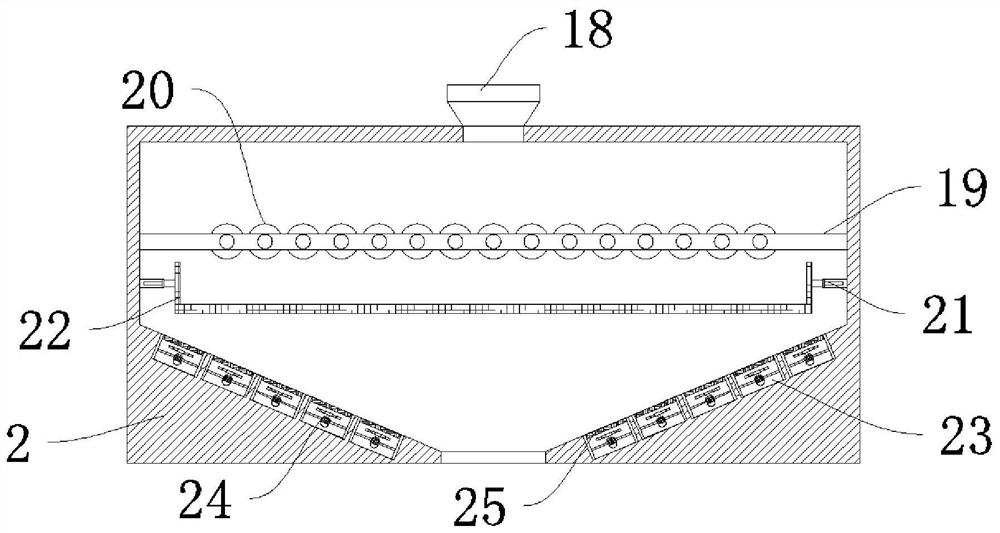

Energy-saving feed particle drying equipment

InactiveCN109631498ABlow evenlyEven and efficient dryingGranular material dryingDrying gas arrangementsEngineeringExhaust pipe

The invention discloses energy-saving feed particle drying equipment. The energy-saving feed particle drying equipment comprises a storage hopper, a feeding pipe and a drying box. The drying box communicates with the lower end of the storage hopper through the feeding pipe. A first preheating jacket sleeves the outer side of the feeding pipe, the first preheating jacket communicates with the innercavity of the drying box through a first communicating pipe. A second preheating jacket sleeves the outer side of the storage hopper, the second preheat jacket communicates with the first preheat jacket through a second communicating pipe, and the second preheating jacket communicates with an exhaust pipe. According to the energy-saving feed particle drying equipment, through a drying cylinder being a hollow cone, a drum, a rotating joint and an air heater, the uniform blowing of hot air from meshes of the drying cylinder is realized, feed particles spread and sliding down from the surface ofthe drying cylinder are evenly and efficiently dried, and the drying uniformity and the drying effect are improved; and the feed particles are preheated by arranging the first preheat jacket and thesecond preheat jacket, subsequent drying is facilitated, and meanwhile, heat is used fully.

Owner:柳良红

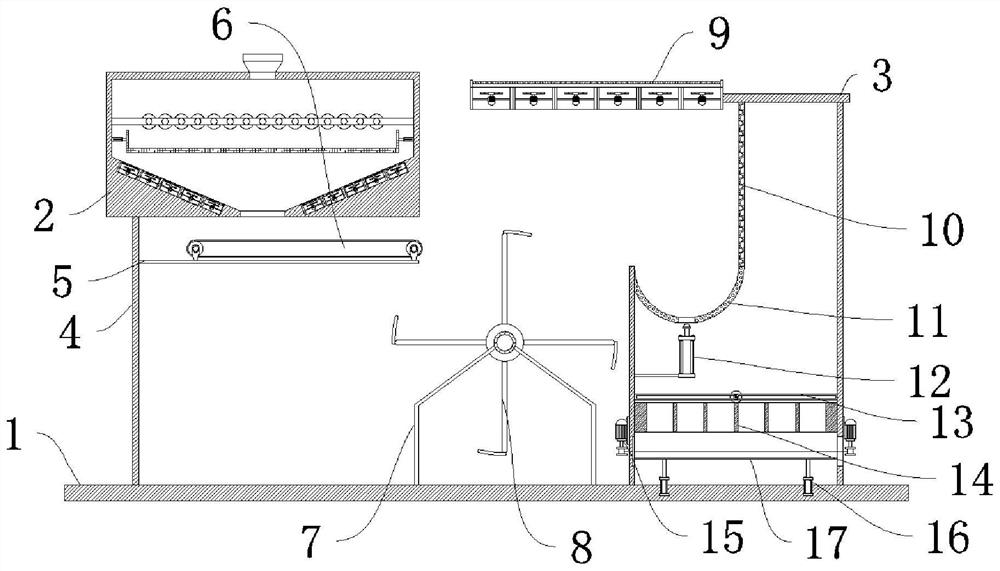

Traditional Chinese medicine residue drying and recycling device

InactiveCN108592531AReasonable structural designSolve environmental problemsDrying using combination processesDrying solid materials without heatWater collectionEnergy conservation

The invention provides a traditional Chinese medicine residue drying and recycling device. According to the specific technical scheme, the device is characterized by comprising a squeezing box, a water collection box, a smashing box, a drying device and a smell removal device. The squeezing box comprises a feeding hopper, a first squeezing device, a second squeezing device, a flow guide plate anda drainage port. A smashing device is arranged in the smashing box, the lower portion of the smashing device is provided with a second discharge hopper, the second discharge hopper is connected with the drying device through a flow guide pipe, the drying device comprises a supporting frame, a fixed outer barrel, an electric heating wire, a rotary net bucket and a driving device, and the smell removal device comprises a first gas guide pipe, a second gas guide pipe and a smell removal box. The traditional Chinese medicine residue drying and recycling device is reasonable in structural design, achieves medicine residue drying and recycling, avoids the environmental problem caused by direct discharge or burying of medicine residue, achieves energy conservation and emission reduction and is environmentally friendly.

Owner:山东万安药业股份有限公司

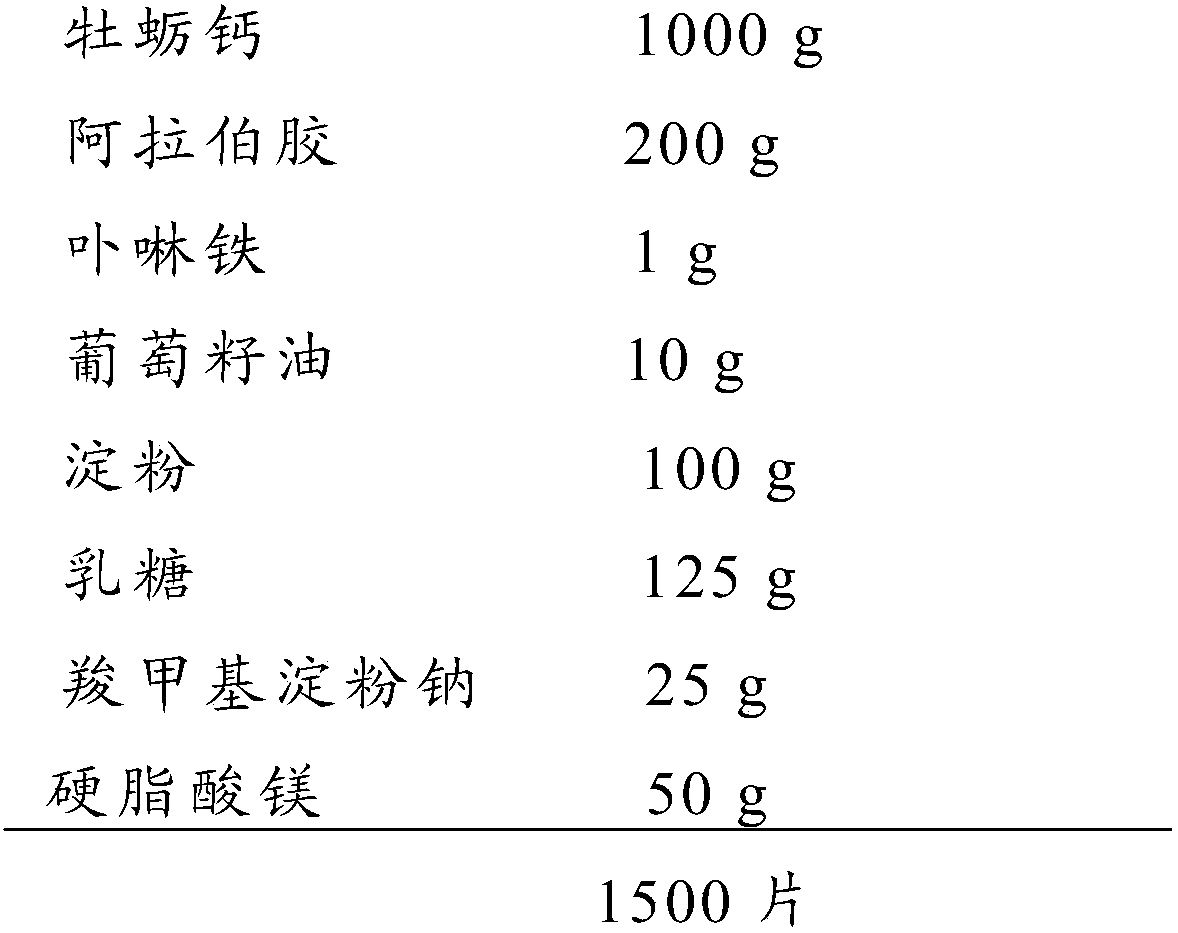

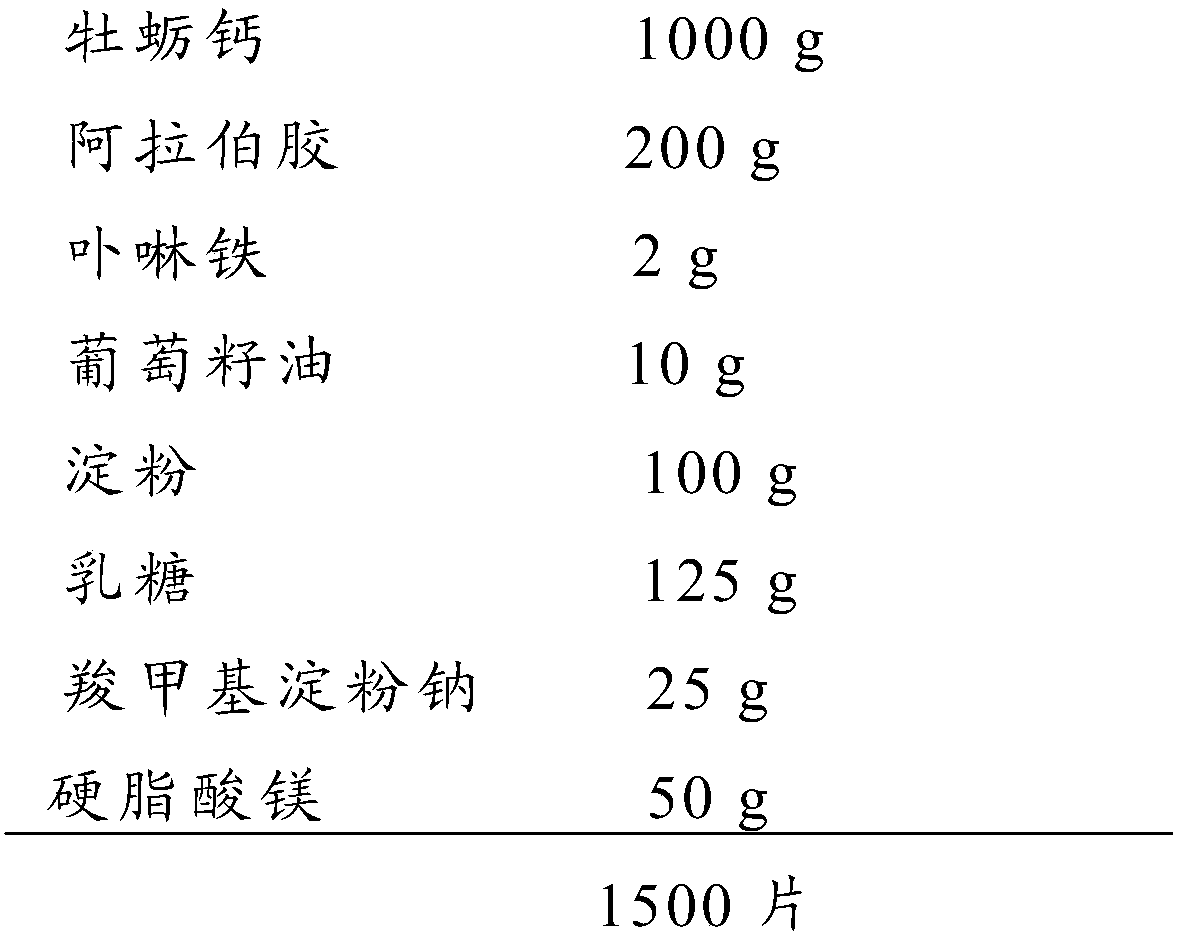

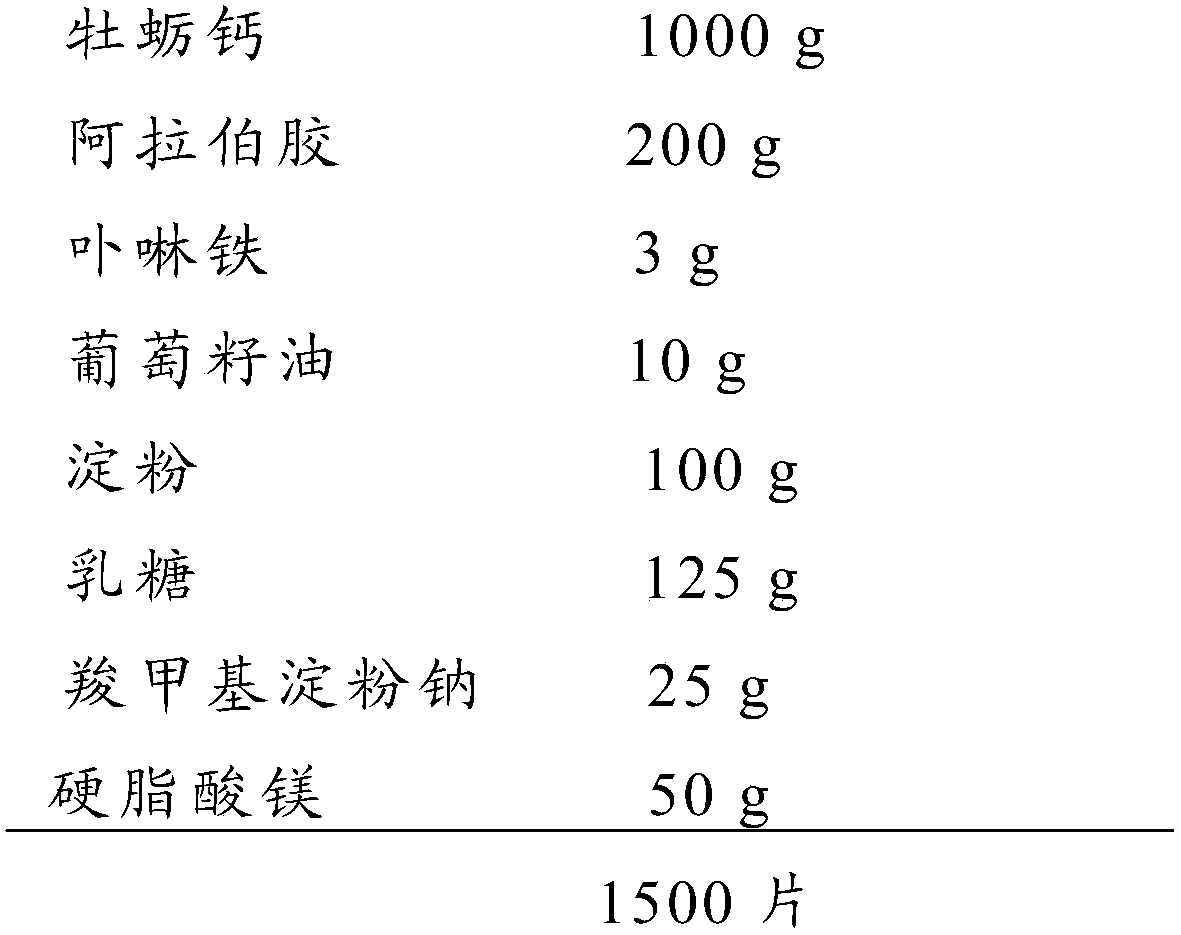

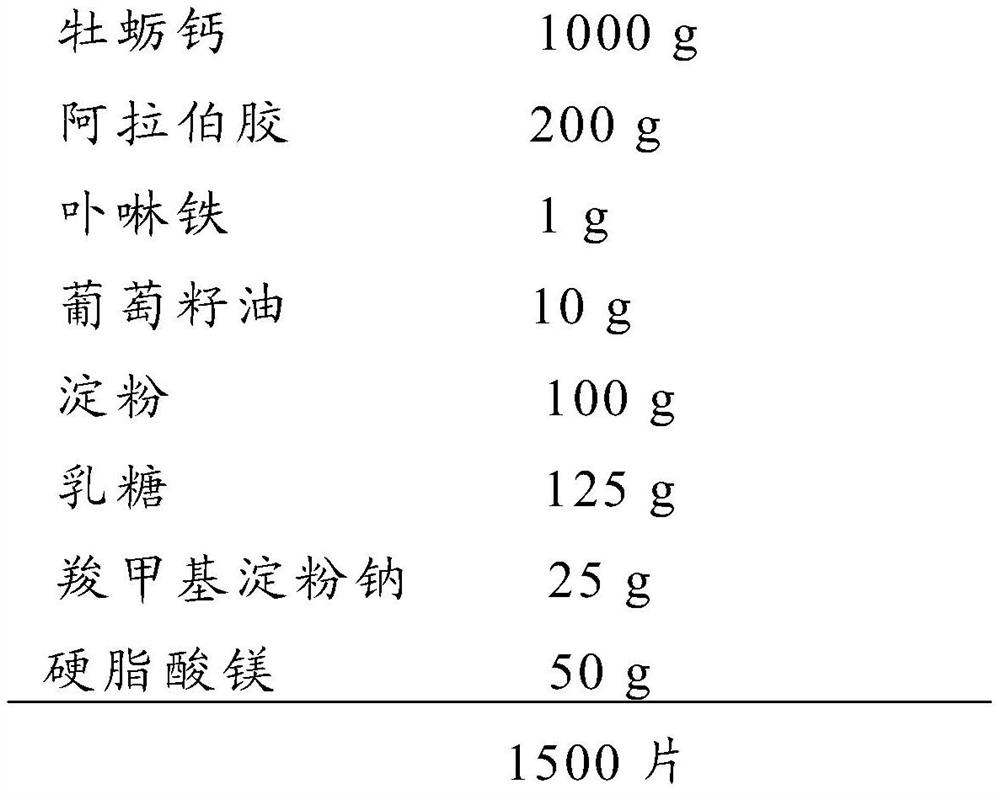

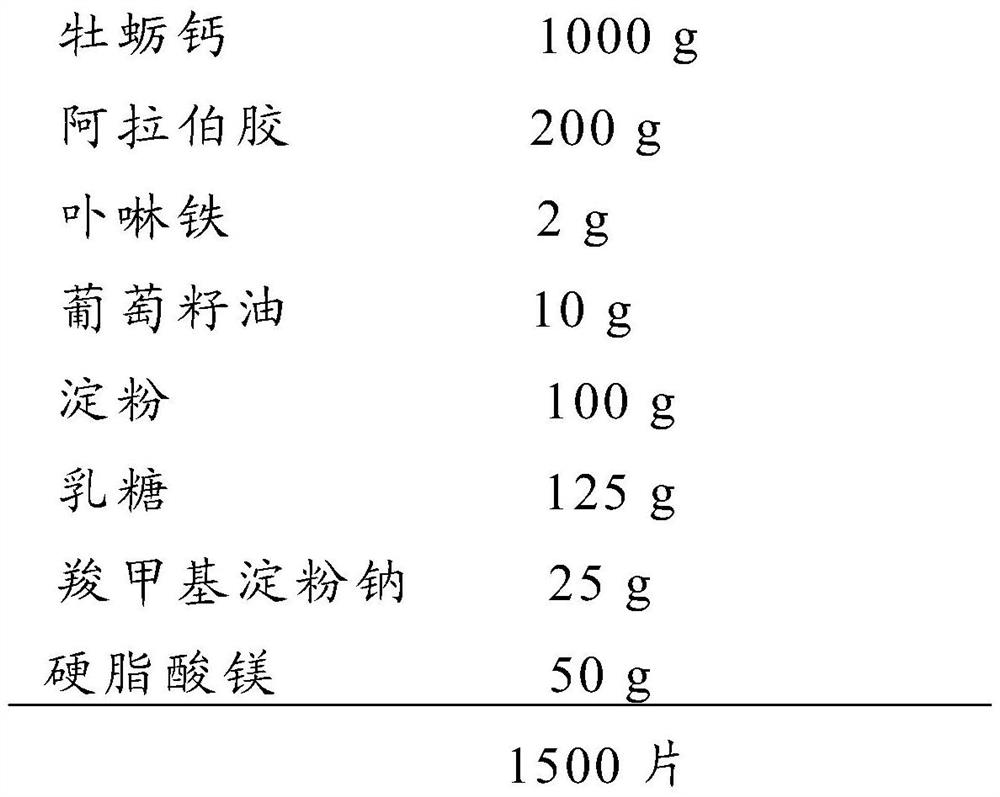

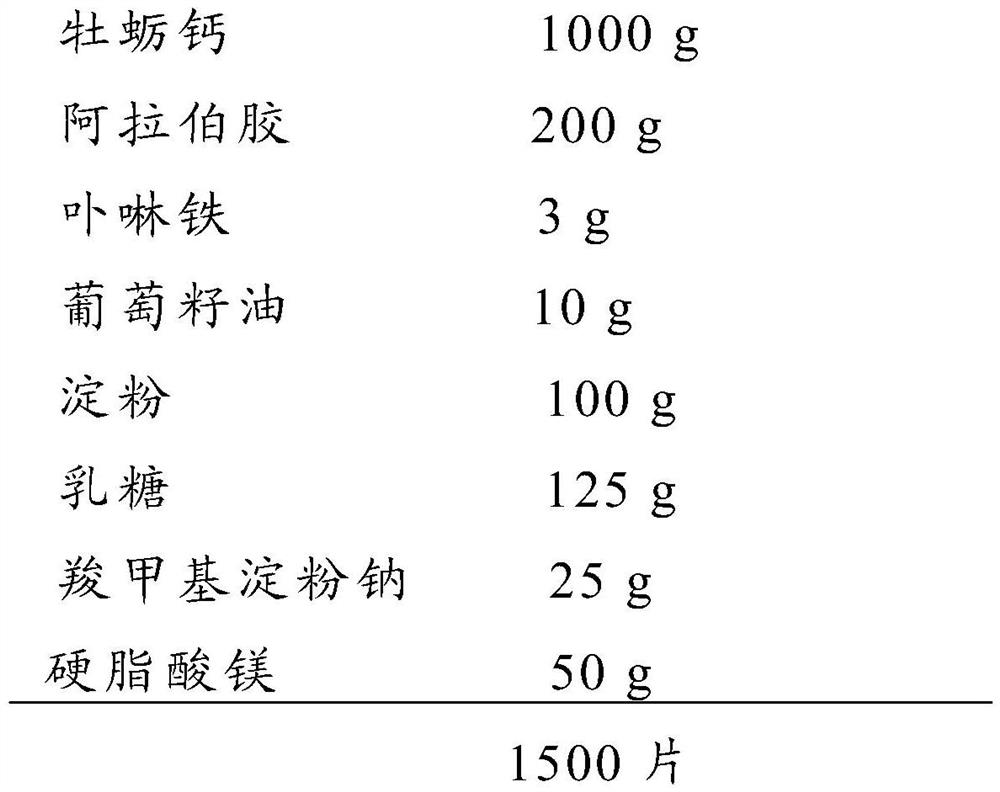

Natural oyster calcium carbonate preparation for prevention and treatment of calcium deficiency disease and preparing method thereof

ActiveCN107929313APromote absorptionPromote peristalsisOrganic active ingredientsMetabolism disorderDiseaseCarbonization

The invention discloses a natural oyster calcium preparation for prevention and treatment of calcium deficiency disease and a preparing method thereof for the first time. A natural oyster calcium compound with calcium carbonate as a main component is separated or extracted from oyster shells, and has the effect of preventing and treating calcium deficiency disease. The preparing method of the calcium preparation mainly comprises the steps of carrying out carbonization, activation, expansion, carbonization and drying of the oyster shells, and smashing and sieving an extract to extract the calcium compound with calcium carbonate as the main component, and the calcium compound belongs to the natural extract and can be used for supplementation of calcium for children, pregnant women and the elderly; compared with a technology for preparing calcium carbonate from raw material limestone, the technology process is equivalent, but the produced calcium carbonate compound has higher purity, is used for preparing granules and chewable tablets and has higher bioavailability.

Owner:SHANGHAI JINCHENG PHARMACEUTICAL CO LTD

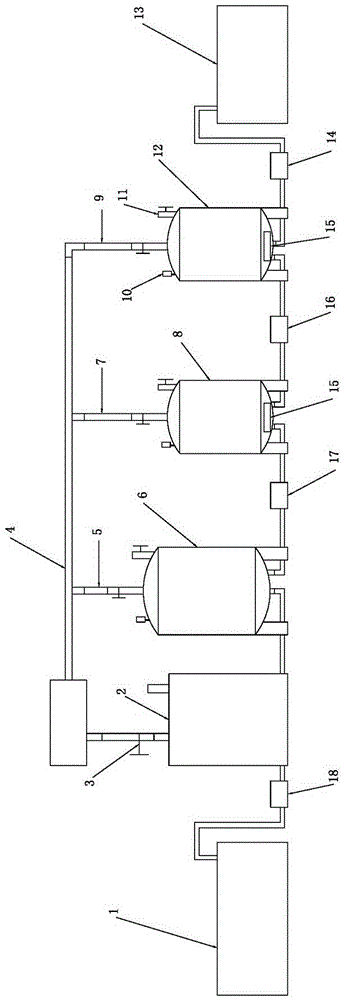

Polyacrylamide production line

ActiveCN105061646AFirmly connectedGuaranteed SolubilityDispersed particle filtrationGranulation by liquid drop formationProduction lineProcess engineering

The invention relates to a polyacrylamide production line. A reactor prefilter, an oil inlet lubrication polymerization reactor, an oil inlet lubrication smashing and pelleting device and a polyacrylamide colloid drying production line are connected in sequence, and the polyacrylamide colloid drying production line is respectively connected to a screening and grinding device and a pulse dust tail gas treatment device. The polyacrylamide production line is simple in structure, impurities in polyacrylamide production raw materials can be effectively filtered, the discharging time of a reactor is shortened, the amount of polymerization reactions is increased, colloid pelleting can be effectively lubricated, colloidal particles with the grain diameters of about 4 mm are obtained while the molecular weight of polyacrylamide is not reduced, required drying air quantity and energy consumption are reduced, the drying condition and standing time of materials are easily adjusted and controlled, the production capacity and product quality are improved, and the tail gas is effectively dedusted.

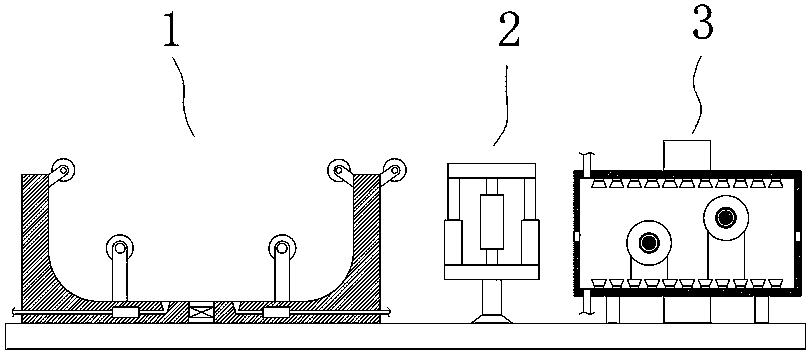

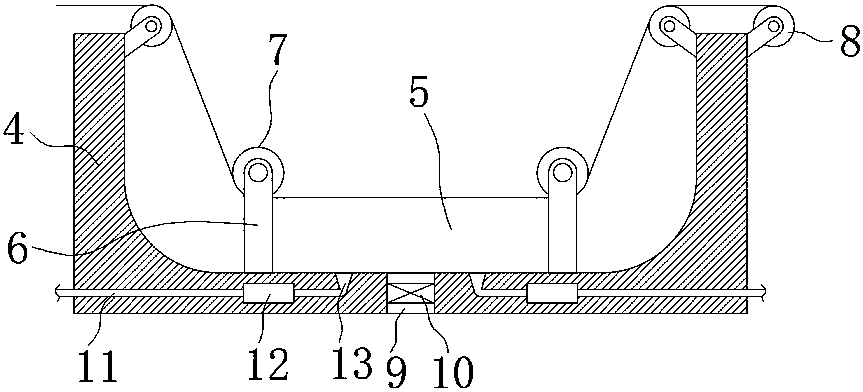

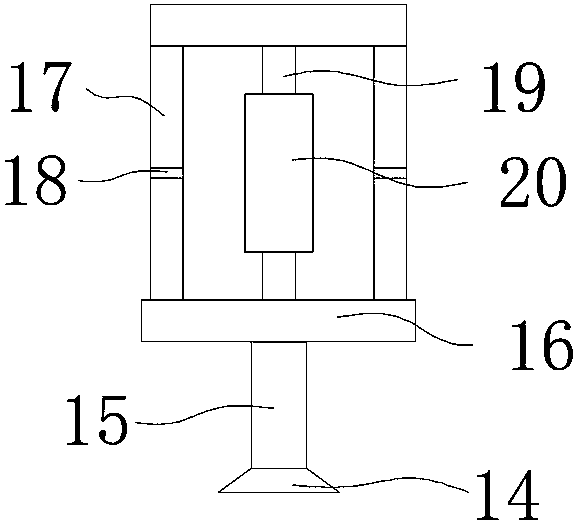

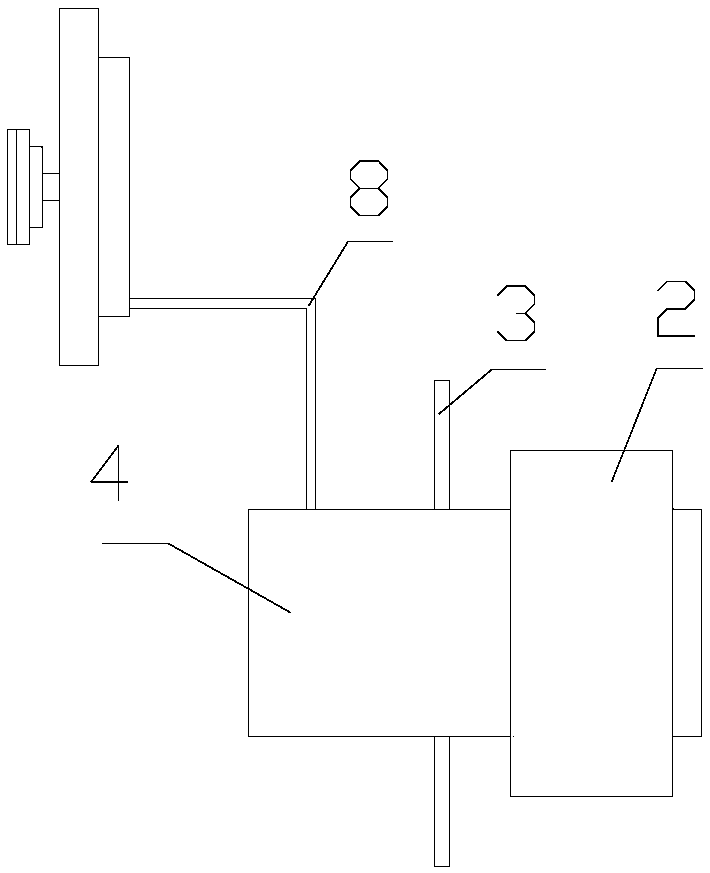

Device for conducting salt-free dyeing on cotton textiles without scouring and bleaching by adopting activated dye

InactiveCN109402907AEasy to dryPrevent precipitationTextile treatment containersLiquid/gas/vapor removal by squeezing rollersSalt freePulp and paper industry

The invention discloses a device for conducting salt-free dyeing on cotton textiles without scouring and bleaching by adopting activated dye. The device comprises a dip dyeing device, an extruding device and a drying device, the dip dyeing device, the extruding device and the drying device are successively arranged, and the dip dyeing device comprises a dyeing pond; a groove is formed in the dyeing pond, two fixed plates are fixedly and symmetrically connected to the side wall of the groove, and first guide rollers are rotatably connected to the ends, away from one end of the bottom side wallof the groove, of the two fixed plates. Through mutual effect of the first guide rollers and second guide rollers, a woven fabric passes through the inside of the dyeing pond to be subjected to dip dyeing, through extruding of two extruding rollers, excess water of the fabric after dip dyeing is extruded out, the woven fabric enters into a shell body through an inlet and is wound on a heating roller to be ironed, and therefore wrinkles generated from extruding of the fabric are ironed flat, and the fabric is more attractive; through a draught fan and a fan cover, the upper and lower sides of the fabric are blown by air, so that the fabric is dried.

Owner:宁建阳

Fodder mixing and pelleting device with drying function

The invention discloses a fodder mixing and pelleting device with a drying function. The fodder mixing and pelleting device comprises a base. A drying barrel is fixedly arranged on the upper side of the base through a support. A mixing and pelleting barrel is fixedly arranged at the top of the drying barrel through a support. A rotating shaft is arranged at the inner axis of the mixing and pelleting barrel. A speed reducing motor is fixedly arranged on the left wall of the mixing and pelleting barrel. A right motor shaft of the speed reducing motor is connected with the rotating shaft. An electric heating disc is arranged on the right side in the mixing and pelleting barrel fixedly. The rotating shaft penetrates the electric heating disc to be connected with the electric heating disc rotationally. A plurality of pelleting holes penetrating leftwards and rightwards are formed in the electric heating disc evenly. A cutter is fixedly connected with the side wall of the rotating shaft, andis attached to the right end faces of the pelleting holes. A second spiral blade is fixedly connected with the side wall of the rotating shaft. The fodder mixing and pelleting device has the advantages that the pelleting holes are formed in the electric heating disc, the electric heating disc can serve as a pelleting disc and can also heat and dry fodder initially during pelleting, the surface ofthe fodder is dried and solidified, and accordingly, scattering of the folder after pelleting is avoided.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

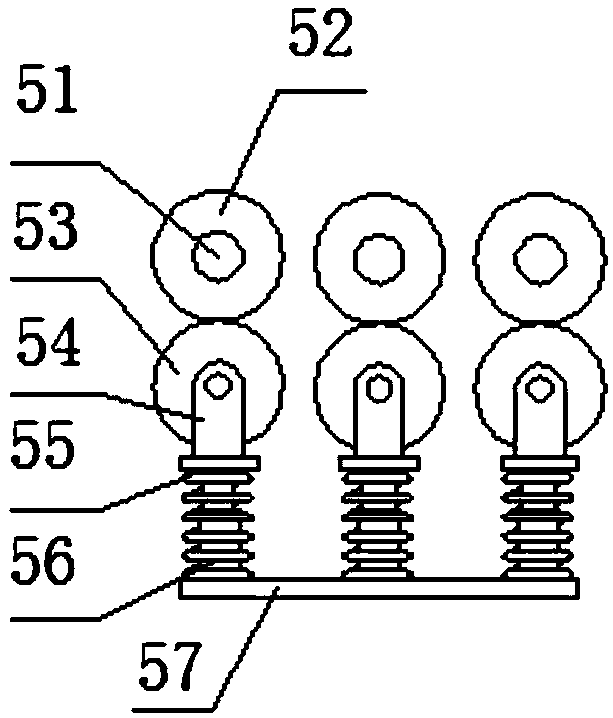

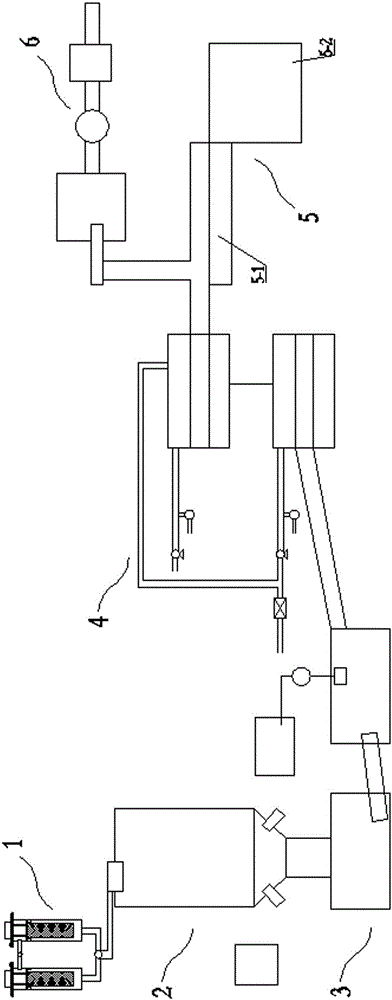

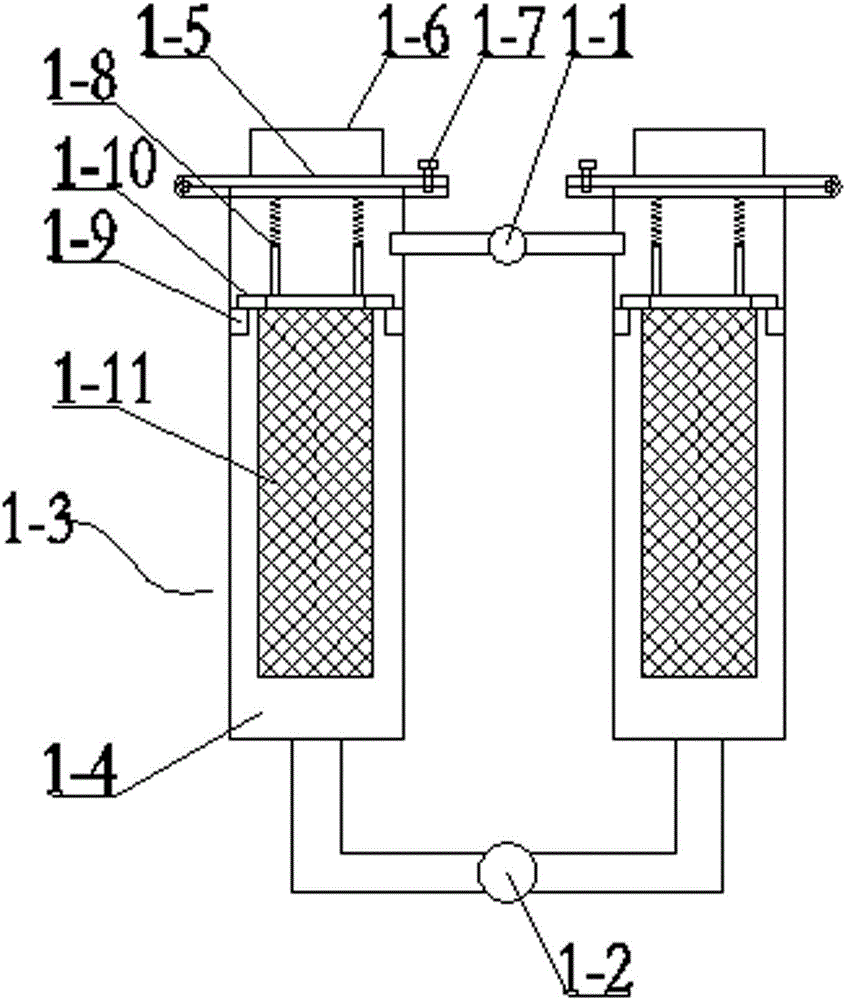

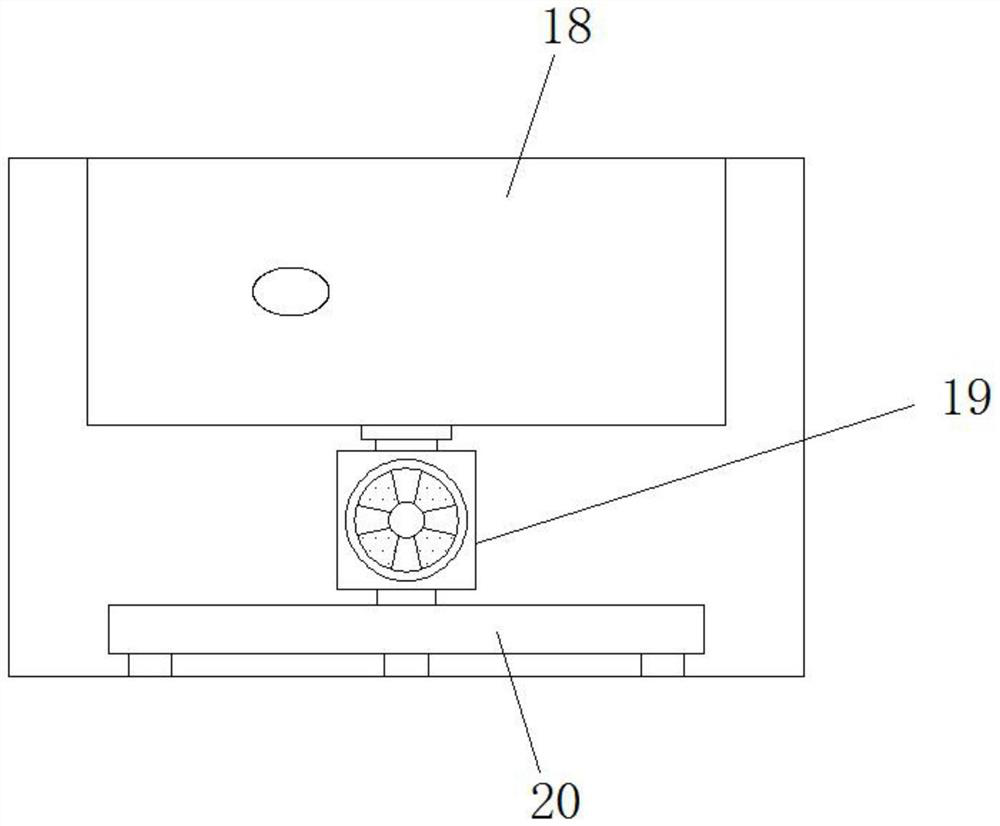

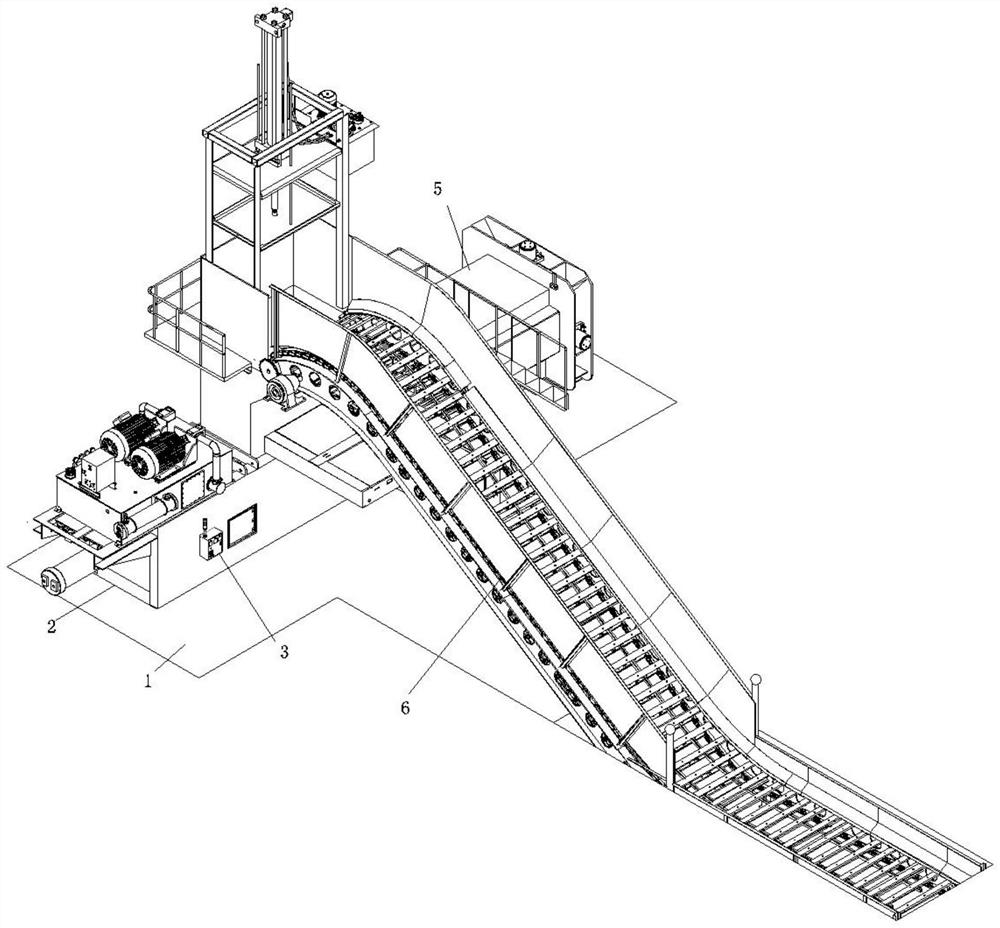

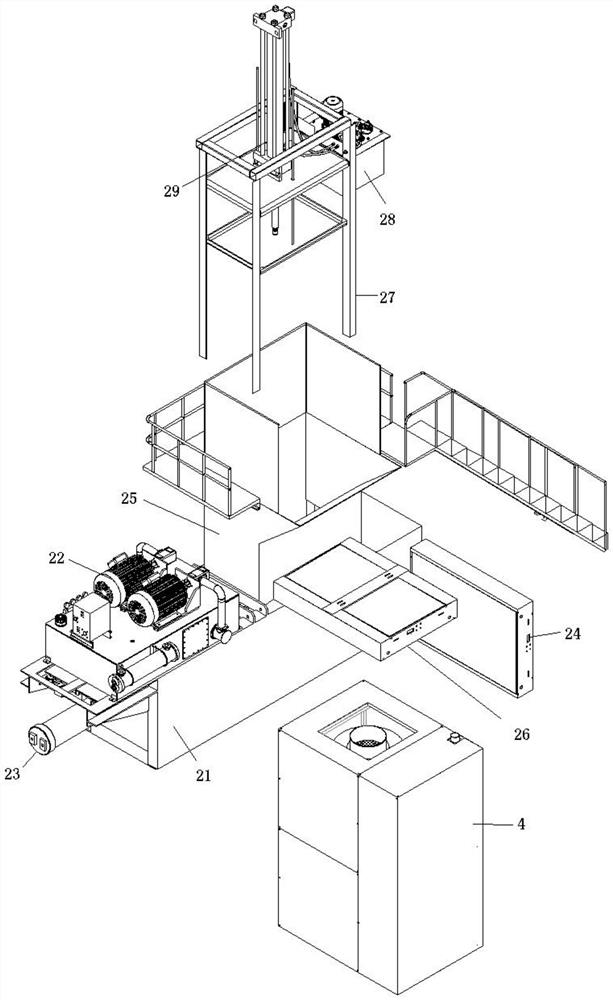

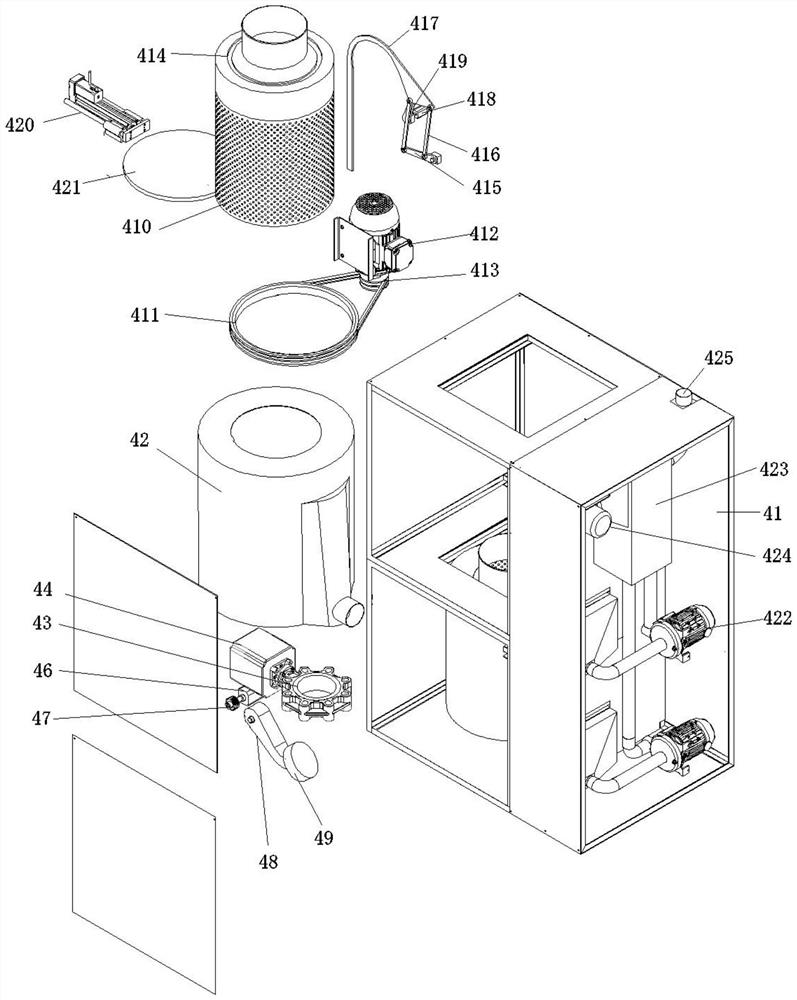

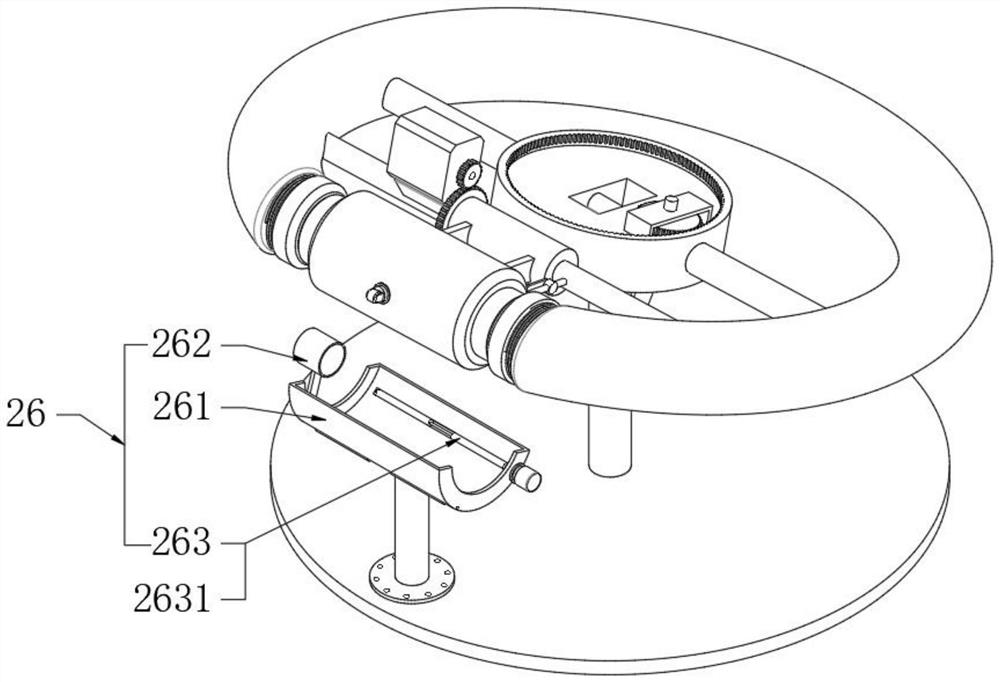

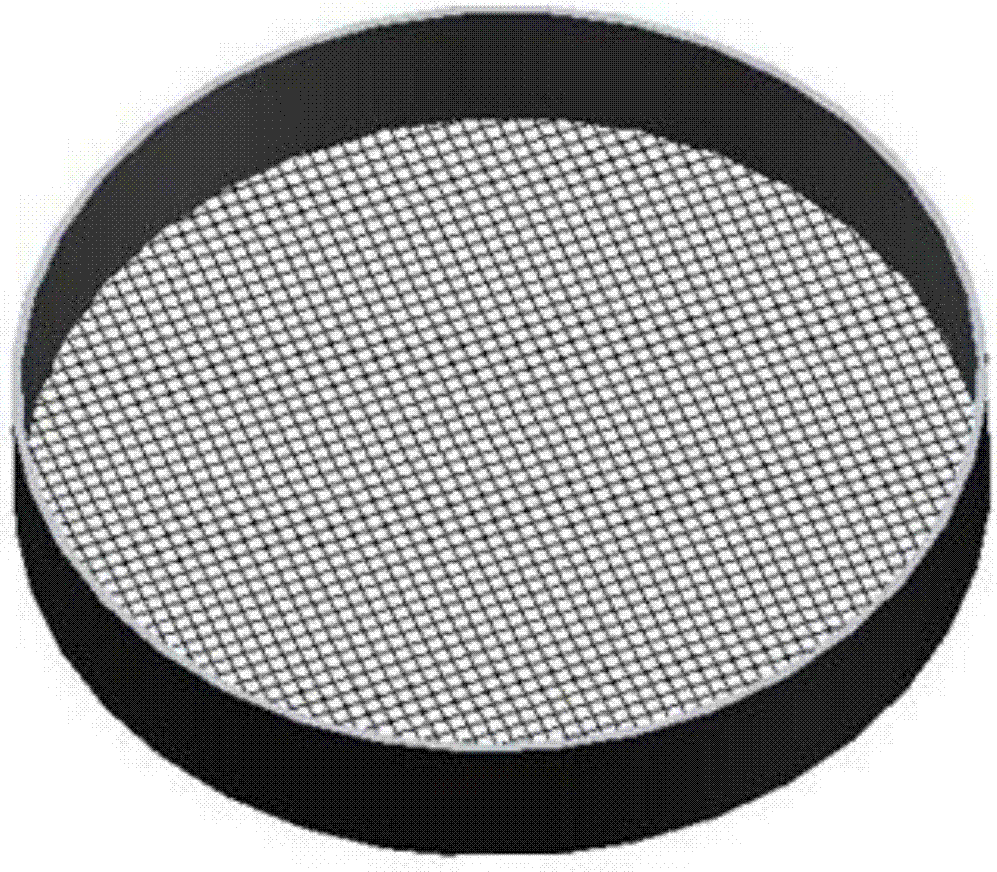

Rare earth waste drying device for rare earth waste recovery

ActiveCN112404105AFor subsequent dryingLimit flyawayDispersed particle filtrationTransportation and packagingThermodynamicsElectric machine

The invention discloses a rare earth waste drying device for rare earth waste recovery, and relates to the technical field of rare earth waste treatment. The rare earth waste drying device comprises afixed base, a pretreatment box and a storage box, a micro motor in the pretreatment box drives a grinding cylinder to rotate to achieve material grinding, and a second air cylinder drives a vibrationfiltering net to shake, materials fall off after being well separated, and subsequent drying is convenient; a second motor drives a rotary drum to rotate, the rotary drum drives a connecting plate and an arc-shaped baffle to rotate, and the second motor is controlled to move in a pause mode in actual use, so that it is guaranteed that the materials can be conveyed into the storage box, and further heating can be conducted; harmful gas generated during material drying is sucked in through a gas suction fan in a gas suction box; the filtering and adsorbing effects are achieved through the filtering net; and the dried materials can be pressed into blocks and then pushed out through cooperation of a pressing assembly, a forming base and a pushing assembly, and subsequent transportation treatment is facilitated.

Owner:萍乡鑫森新材料有限责任公司

Environment-friendly weeding and recycling device

The invention discloses an environment-friendly weeding and recycling device. The device comprises a base; a storage box is fixedly arranged at the top of the base; a crushing barrel matched with thestorage box is fixedly arranged on the right side of the storage box; the bottom of the crushing barrel is open, and the bottom of the crushing barrel penetrates through the bottom wall of the storagebox and the base and extends to the lower part of the base; the top part, right on the top center of the crushing barrel, of the storage box is fixedly provided with a motor; a motor shaft at the bottom end of the motor penetrates through the storage box and the top wall of the crushing barrel and is fixedly connected with a rotating shaft; a plurality of crushing blades are fixedly connected tothe side wall of the rotating shaft; the upper left side of the crushing barrel is provided with a material passing opening; and an exhaust fan is fixedly arranged on the left side of the top of the storage box; an air inlet end of the exhaust fan is fixedly connected with an air exhaust pipe; and the air exhaust pipe penetrates through the top wall of the material storage box and is connected tothe upper left side of the storage box. According to the invention, the crushing blades rotate to remove grass, and meanwhile air is exhausted through the exhaust fan, so that weeds can move upwards in the crushing barrel and enter the storage tank in a crushing process, the weeds can move upwards in the crushing barrel and are fully crushed, and subsequent drying can be facilitated.

Owner:深圳市宝晨物业管理有限公司

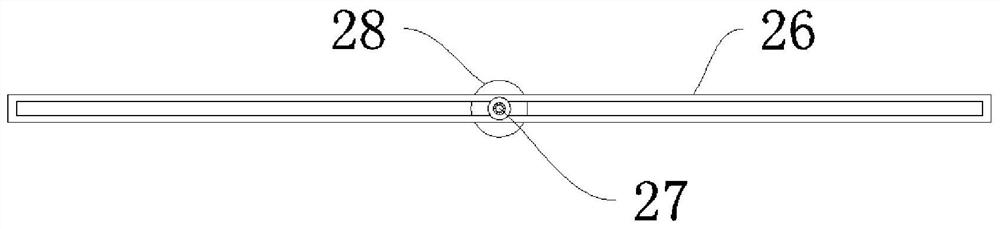

Novel cleaning and drying device for textile fabric before dyeing

PendingCN113668158ADifficult to clean upImprove surface cleanlinessMechanical cleaningPressure cleaningSurface cleaningBevel gear

The invention discloses a novel cleaning and drying device for a textile fabric before dyeing. The novel cleaning and drying device for the textile fabric before dyeing comprises a device body, a first scrubbing brush and a suction pipe, wherein a textile static elimination rod is arranged in the device body; the inner wall of the device body is rotatably connected with a cleaning roller; the rear end of the cleaning roller penetrates through the device body and is connected with first transmission shafts; first gears are arranged on the first transmission shafts in a penetrating mode, and meanwhile, the upper first transmission shaft and the lower first transmission shaft are in meshed connection through the first gears; and a second transmission shaft is rotationally connected to the rear side face of the device body and connected with a first electric motor through a bevel gear set. According to the novel cleaning and drying device for the textile fabric before dyeing, under the action of a first liquid conveying pump, cleaning liquid in a cleaning chamber is sprayed out through a first spraying pipe to preliminarily clean the textile fabric, the surface of the cleaned textile fabric is cleaned through the first scrubbing brush, and flushing water in a flushing chamber is sprayed out through a second spraying pipe through a third liquid conveying pump to flush the cleaned textile fabric again, so that the surface cleanliness of the textile fabric is improved.

Owner:大丰园丁纺织有限公司

Flame-retarded elastic textile fabric and processing method thereof

InactiveCN111560690AAntistaticIncrease elasticityElectroconductive/antistatic filament manufactureWool fibre washing/scouringElastomerPolymer science

The invention discloses a flame-retarded elastic textile fabric and a processing method thereof. The fabric is formed by weaving warp with weft. The warp comprises, by weight, 35-55 parts of chinlon,20-30 parts of acrylic fibers, 5-10 parts of conductive fibers, 5-10 parts of performance additive, and 1-5 parts of elastomers, wherein the performance additive comprises, by weight, 30-45 parts of sodium alginate, 25-35 parts of poly-diphthalate, 15-25 parts of chitosan and 5-10 parts of casein-soybean glue. According to the textile fabric, a two-layer flame retarding mode is adopted, the flameretarding effect is good, the reaction speed between available chlorine and wool can be controlled, severe damage to the wool is small, softening treatment is conducted to wool fibers subjected to enzymolysis, the softness of the wool fibers is improved, meanwhile, the wool fibers can be washed rapidly through a designed washing device, moisture inside the wool fibers can be squeezed out, and subsequent drying is facilitated.

Owner:杭州悦仕达新材料科技有限公司

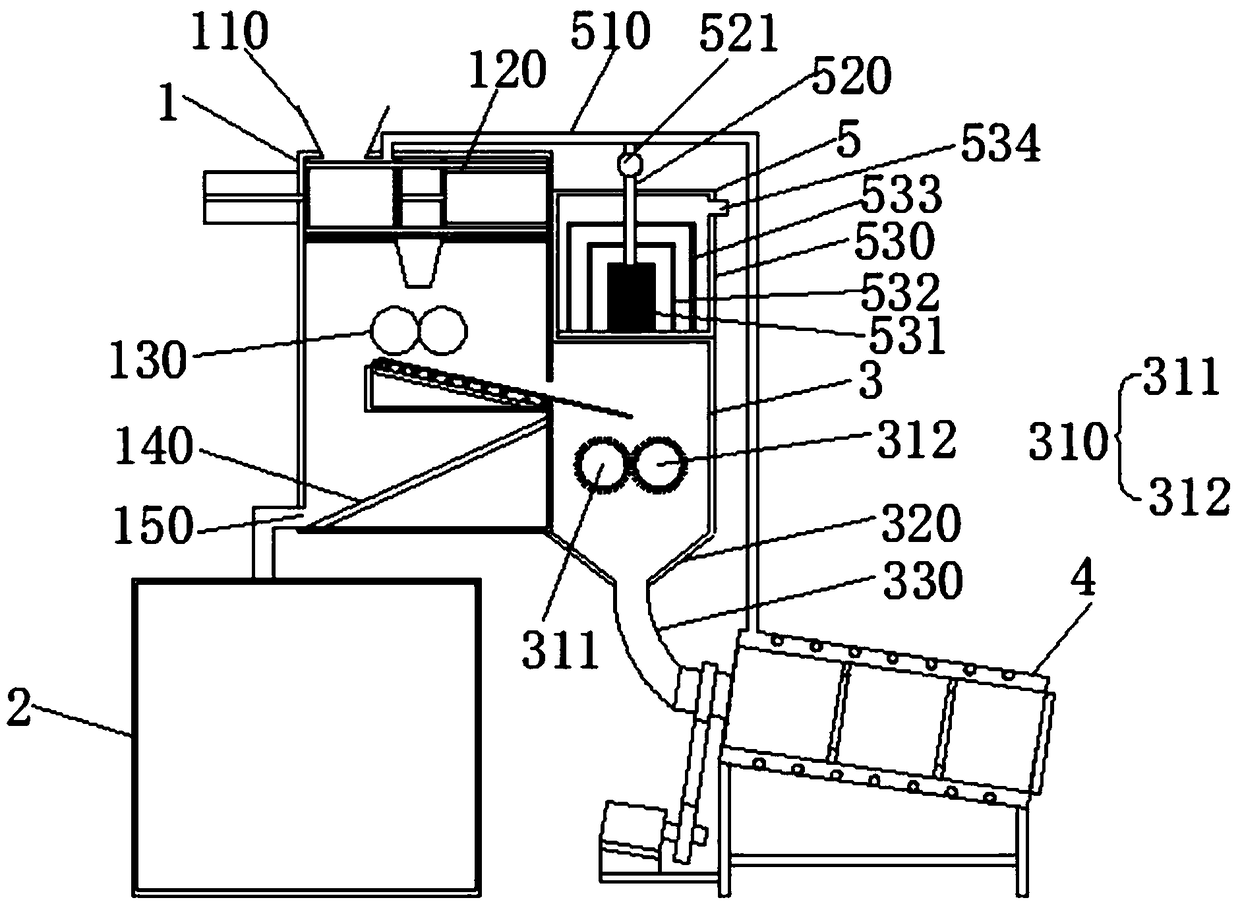

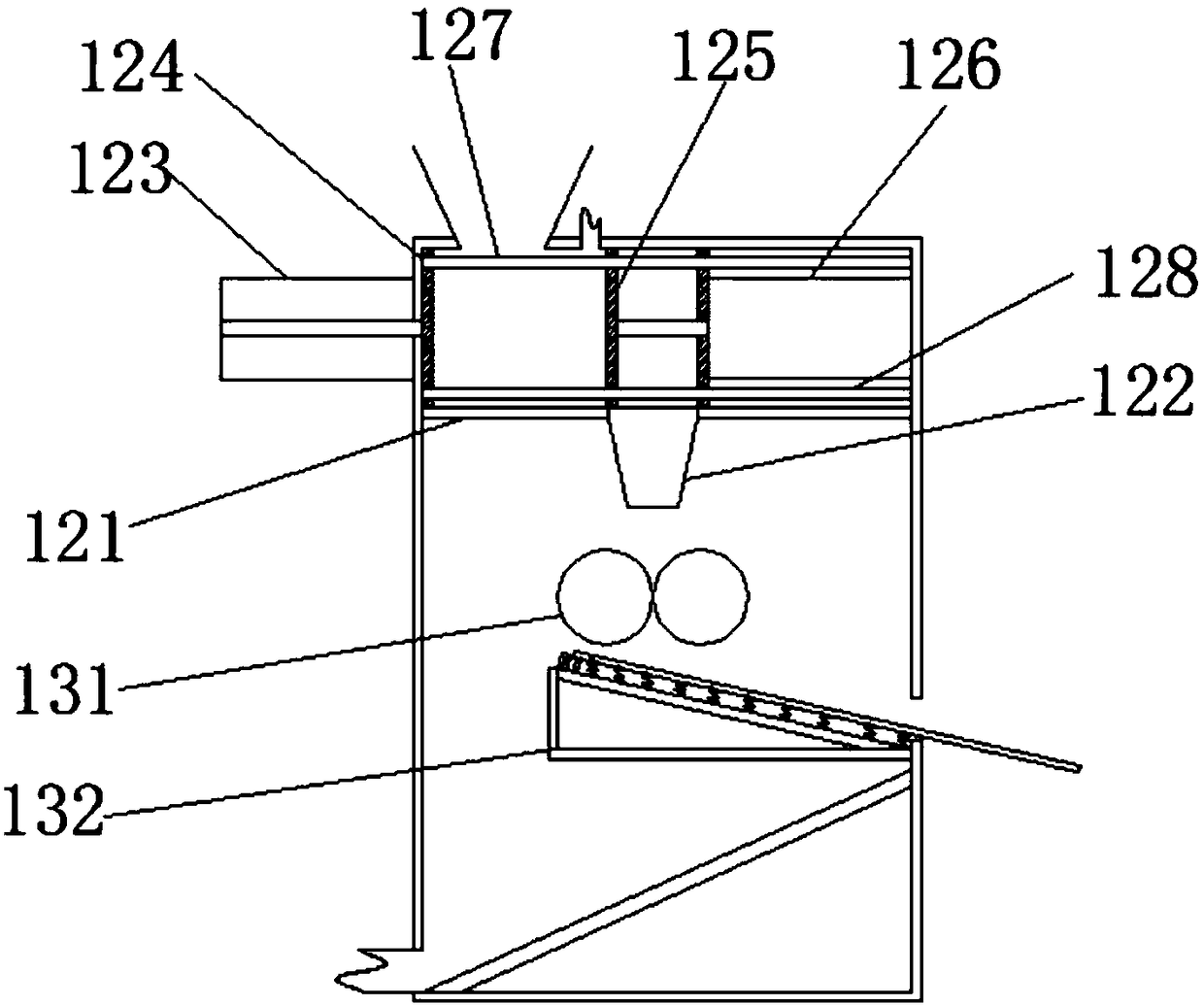

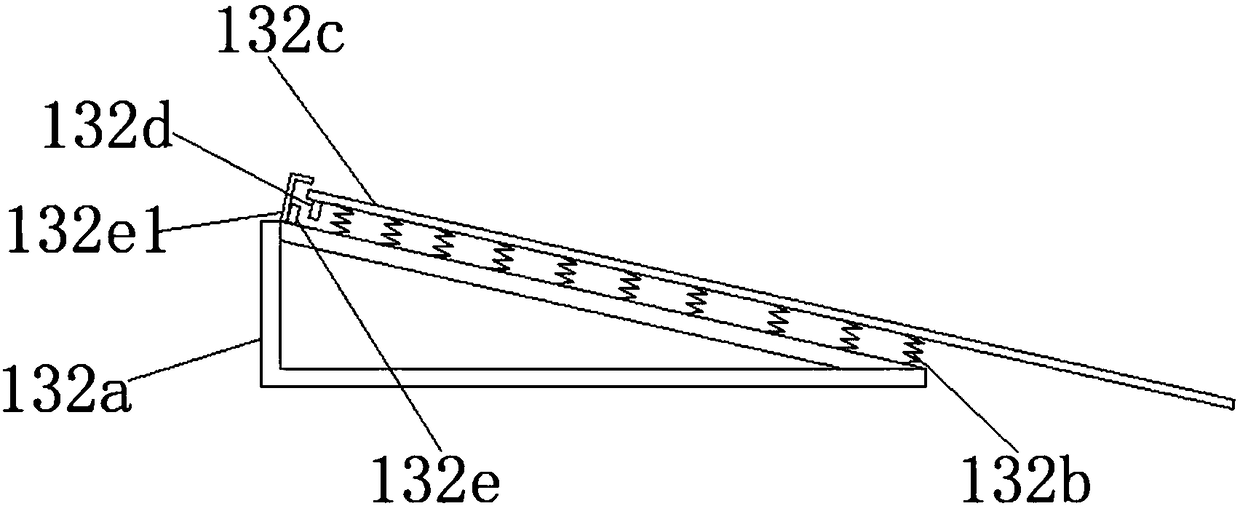

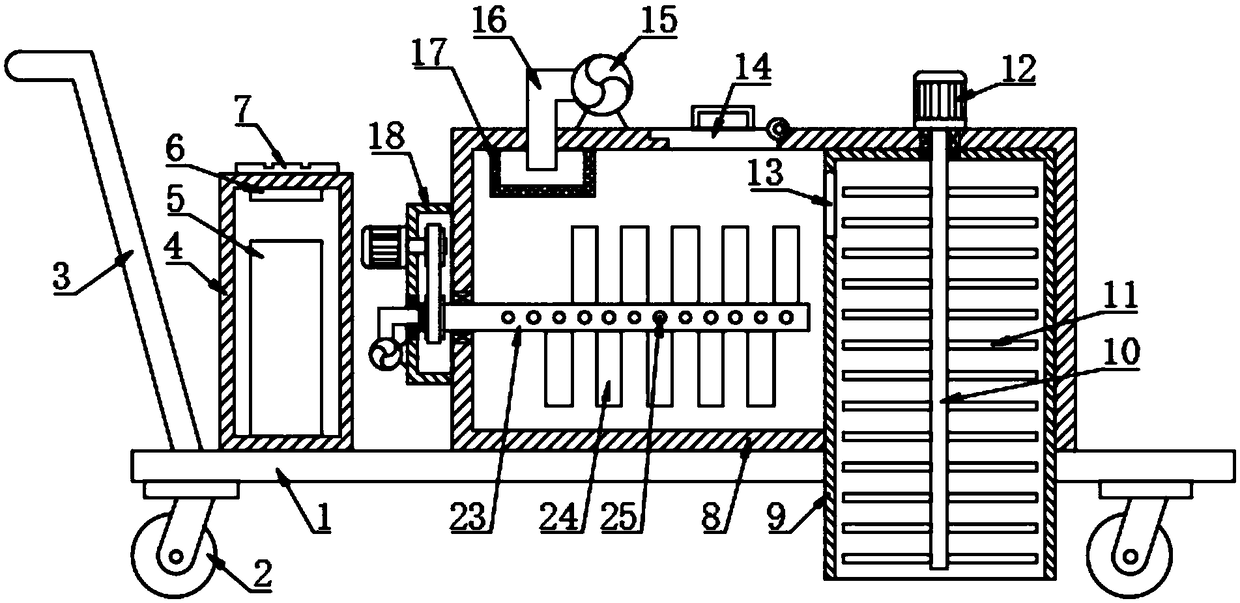

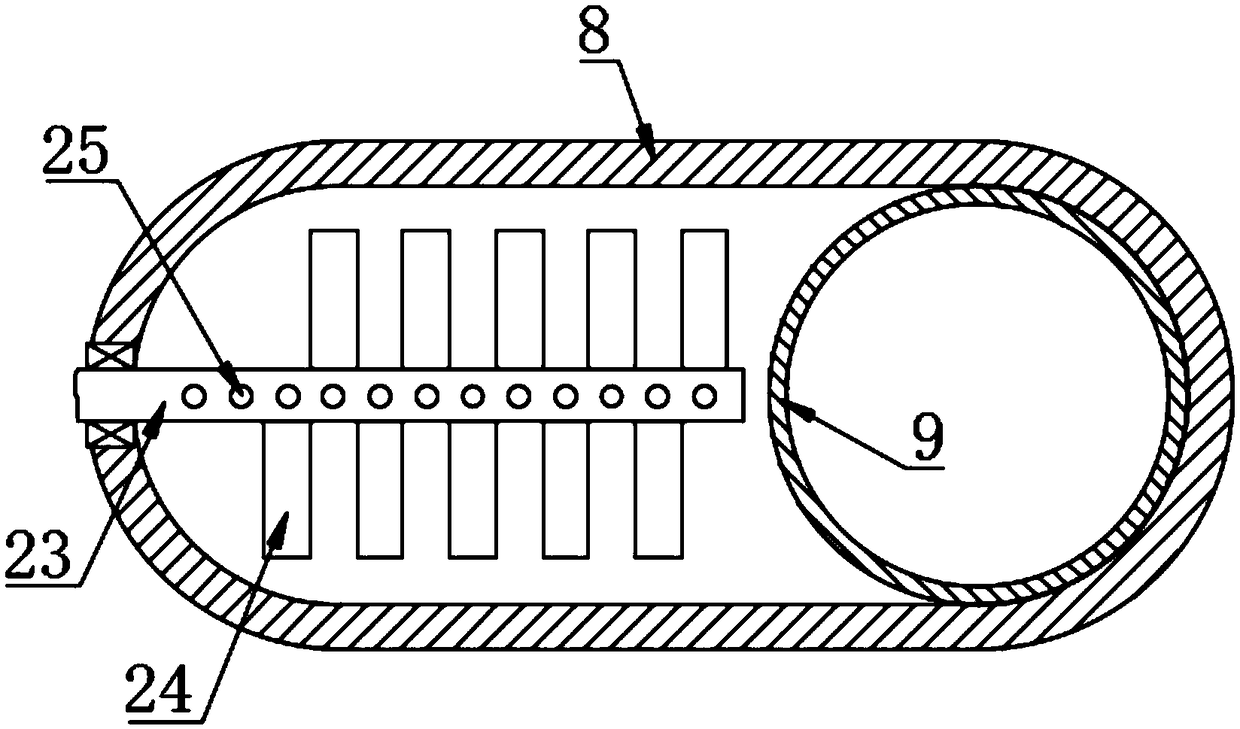

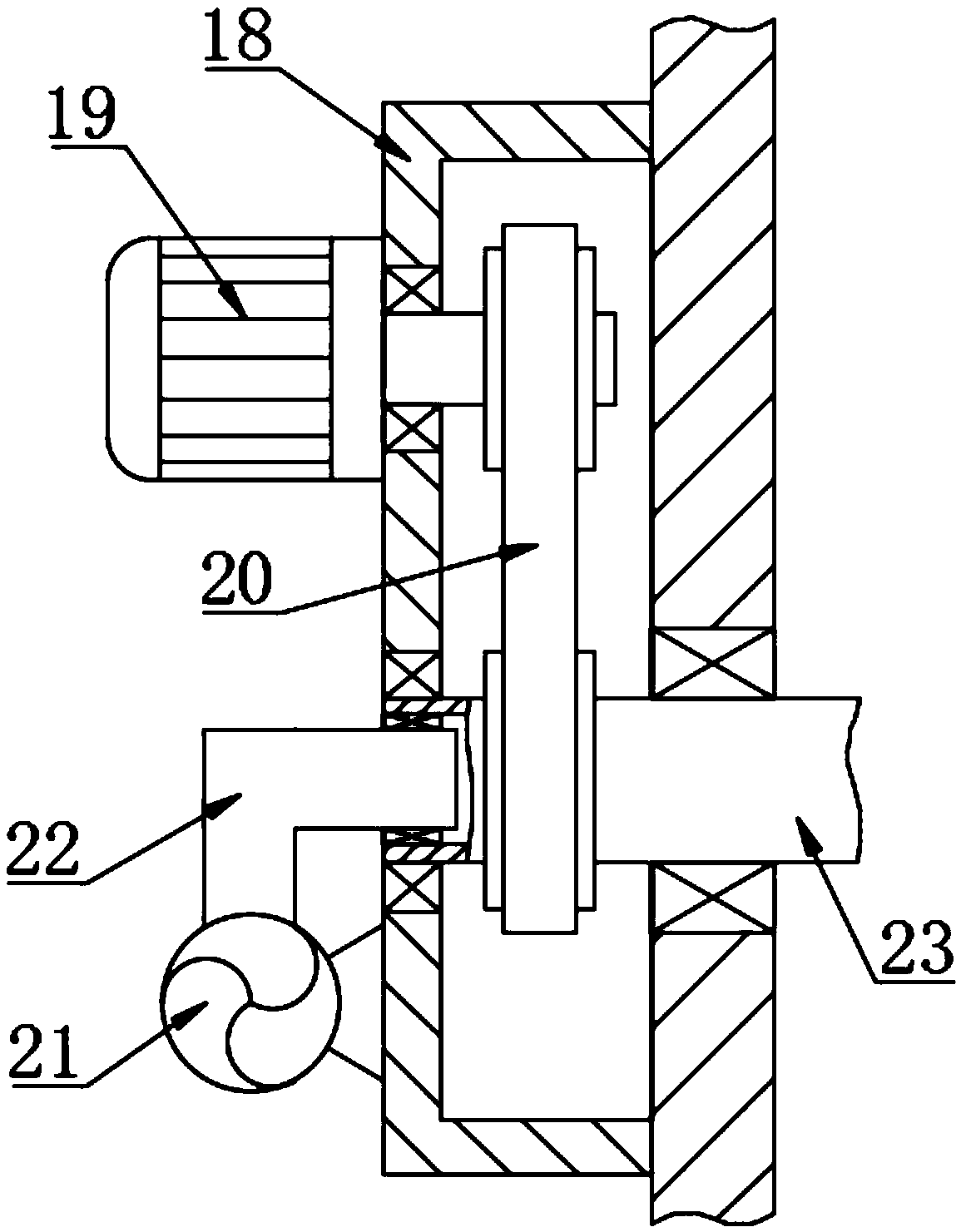

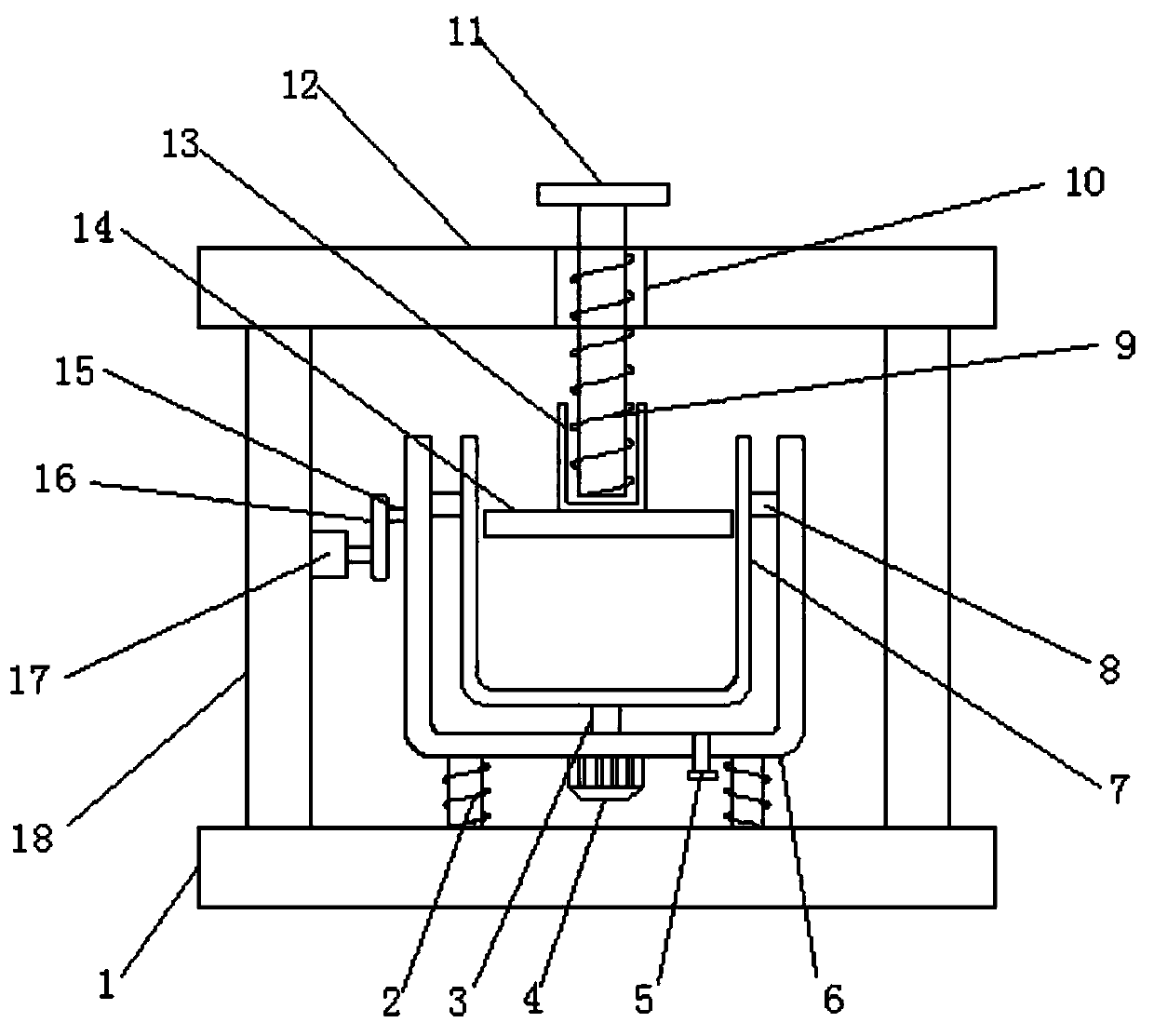

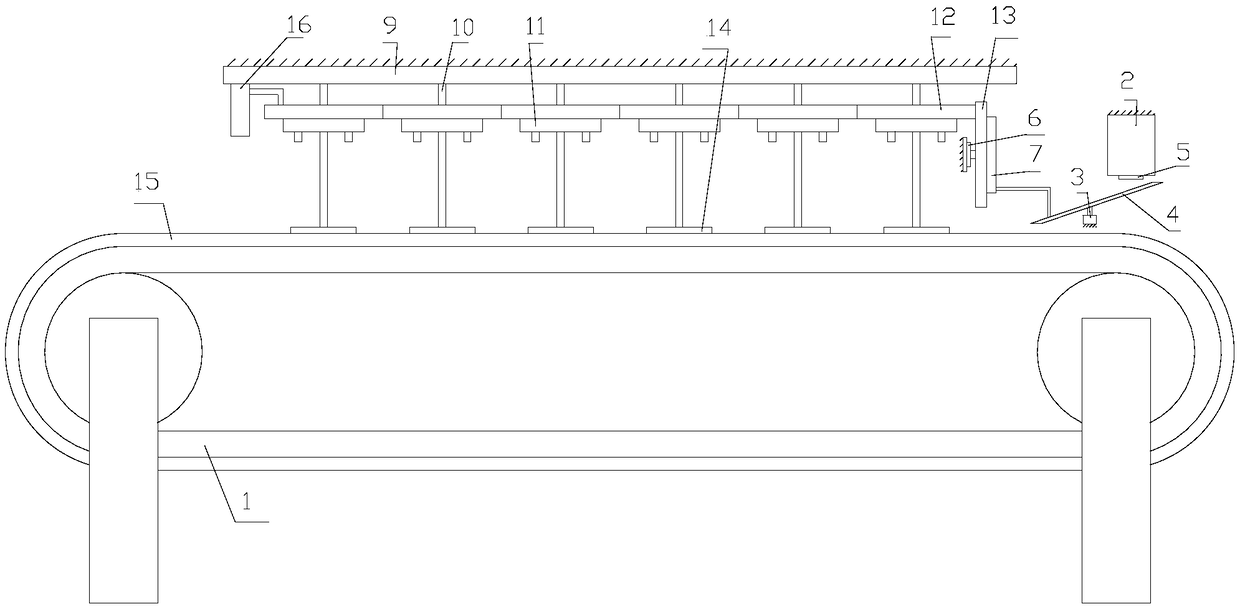

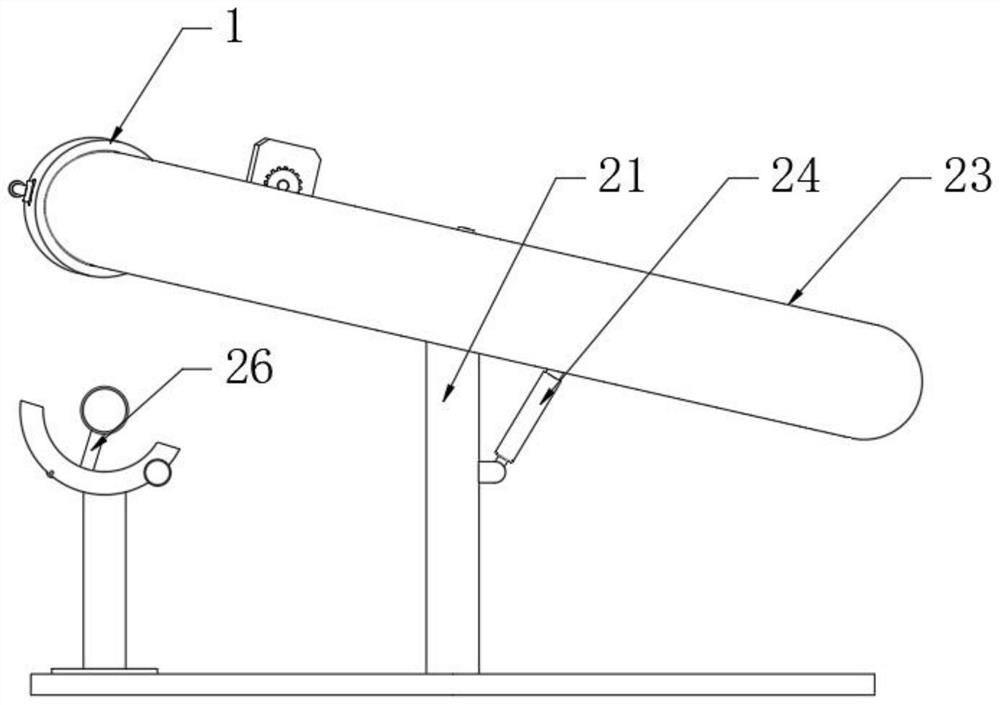

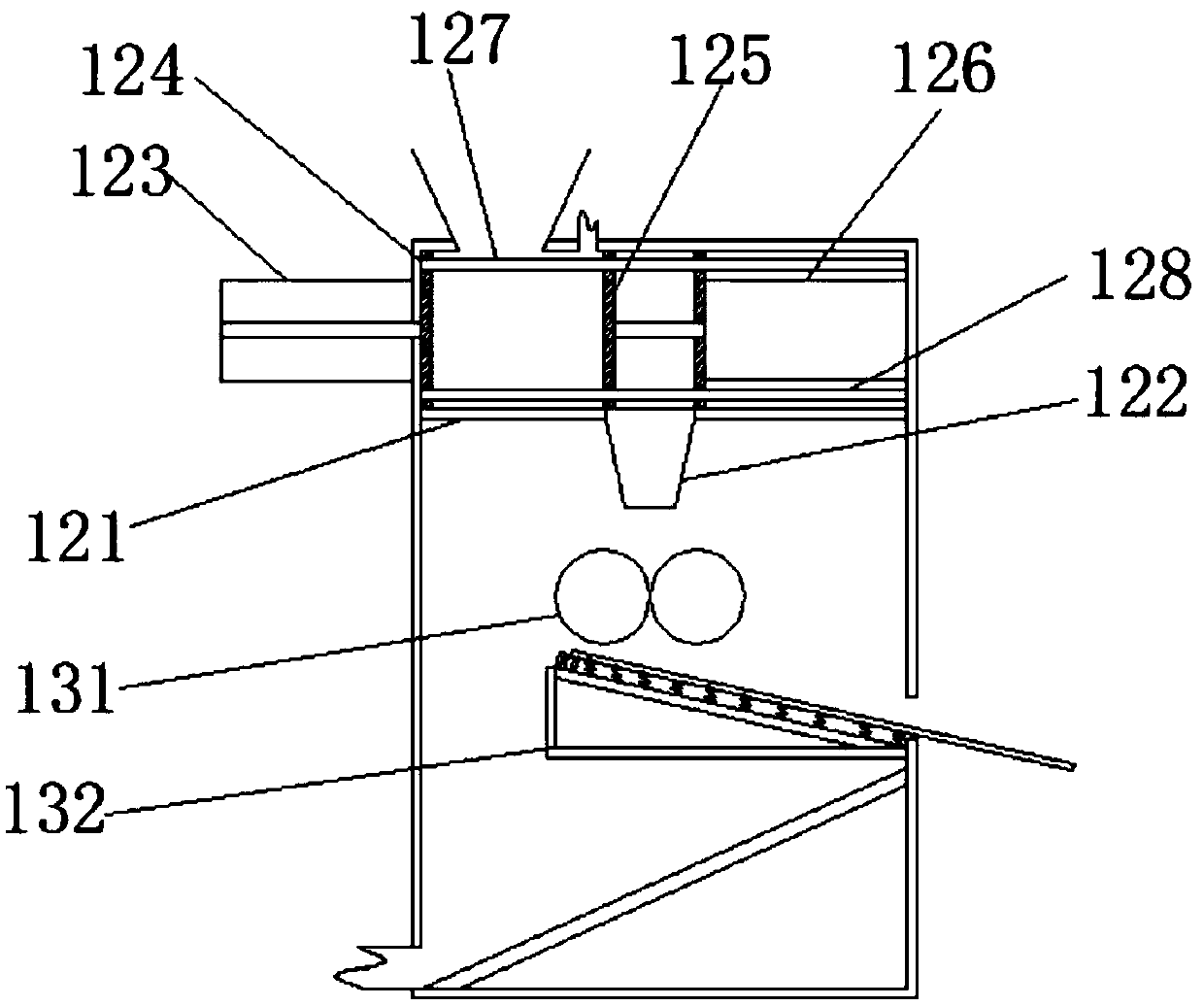

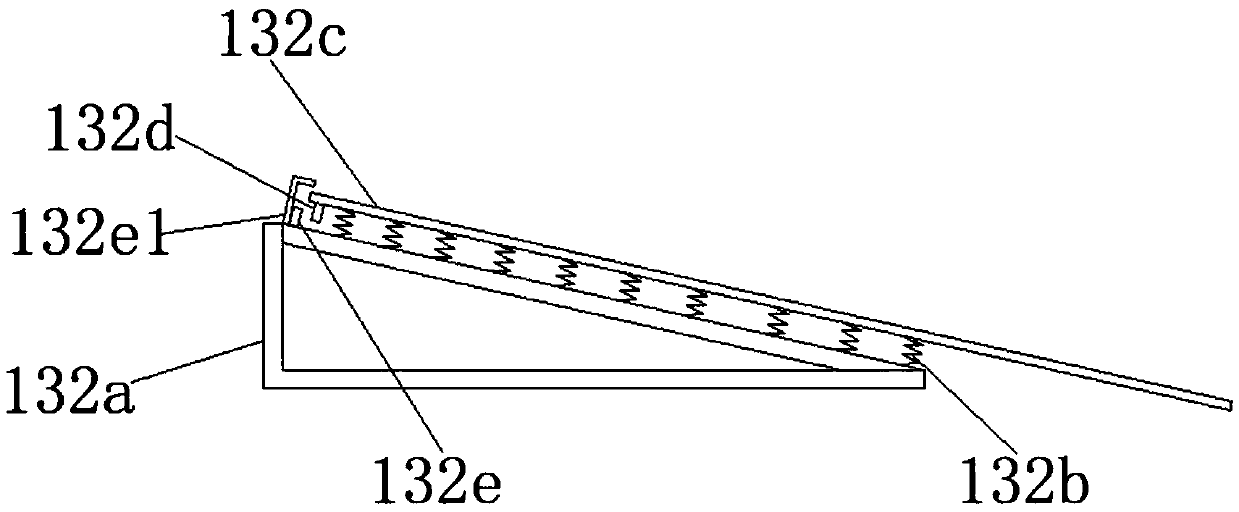

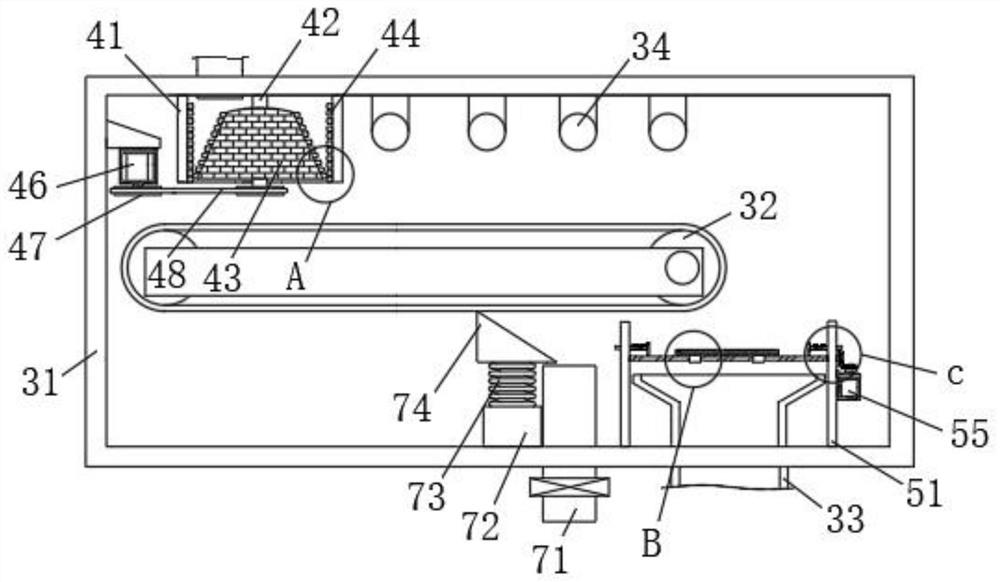

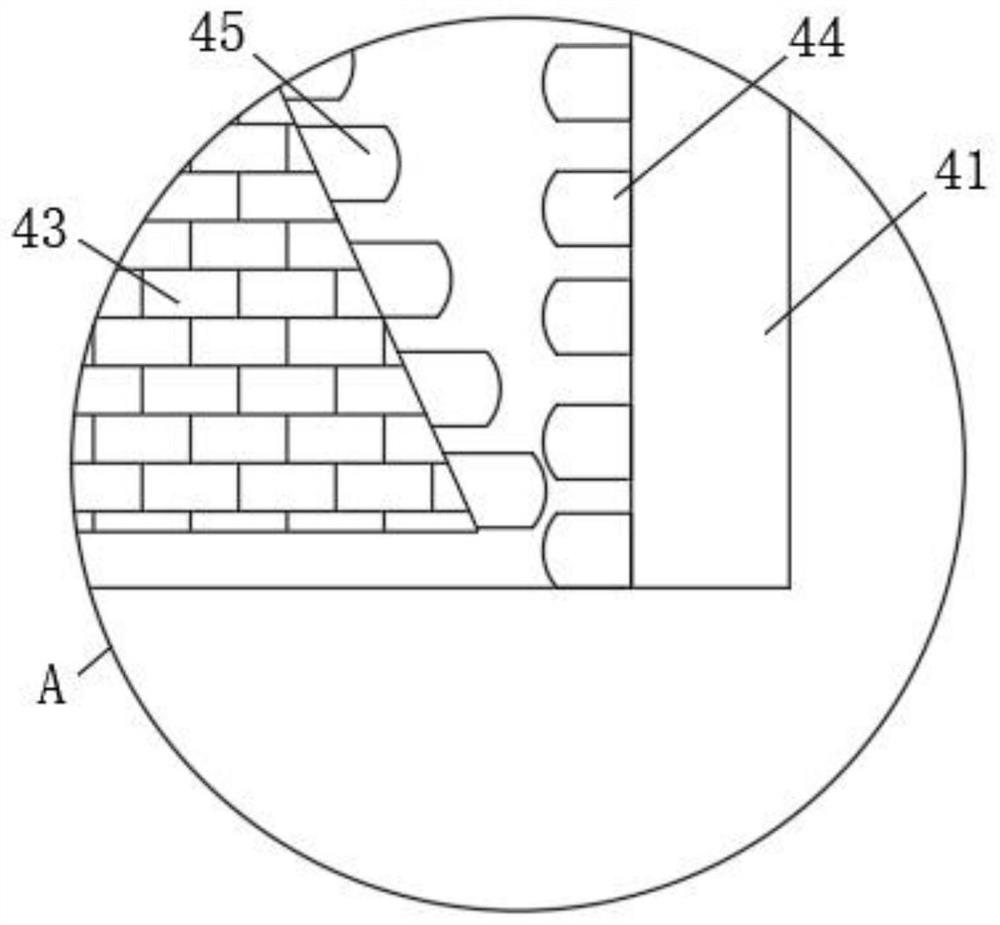

Device used for drying medicinal materials

InactiveCN109458825AEvenly distributedFor subsequent dryingDrying machines with progressive movementsDrying solid materialsEngineeringMechanical engineering

The invention discloses a device used for drying medicinal materials. The device comprises a conveying belt, a material box, a sliding bar, a guide plate, a moving mechanism and a drying part. A discharging hole is formed in the bottom end of the material box. The sliding bar is located above the conveying belt. The sliding rod is arranged in the width direction of the conveying belt. The guide plate is connected with the sliding rod in a sliding manner. The guide plate is obliquely arranged. The higher end of the guide plate is located below the discharging hole, and the lower end of the guide plate is located above the conveying belt. The moving mechanism is in transmission connection with the guide plate, and the drying part is used for drying medicinal materials.

Owner:安徽山里货农业股份有限公司

Method for retreating wastewater after pueraria starch processing

InactiveCN106477659AFor subsequent dryingEasy to crushOrganic chemistryWater/sewage treatment by heatingWastewaterPuerarin

The invention provides a method for retreating wastewater after pueraria starch processing. The method particularly includes: collecting wastewater after pueraria starch extraction; adopting a concentration unit to heat for concentration and water volatilization to obtain puerarin size of 30-40% in water content; lyophilizing, and smashing to obtain puerarin. The concentration unit is adopted to heat for concentration and water volatilization, so that the wastewater after pueraria starch processing can be concentrated into the puerarin size of 30-40% in water content in one step, and convenience is brought to subsequently drying and smashing the puerarin size to obtain puerarin.

Owner:十堰市绿田生物科技有限公司

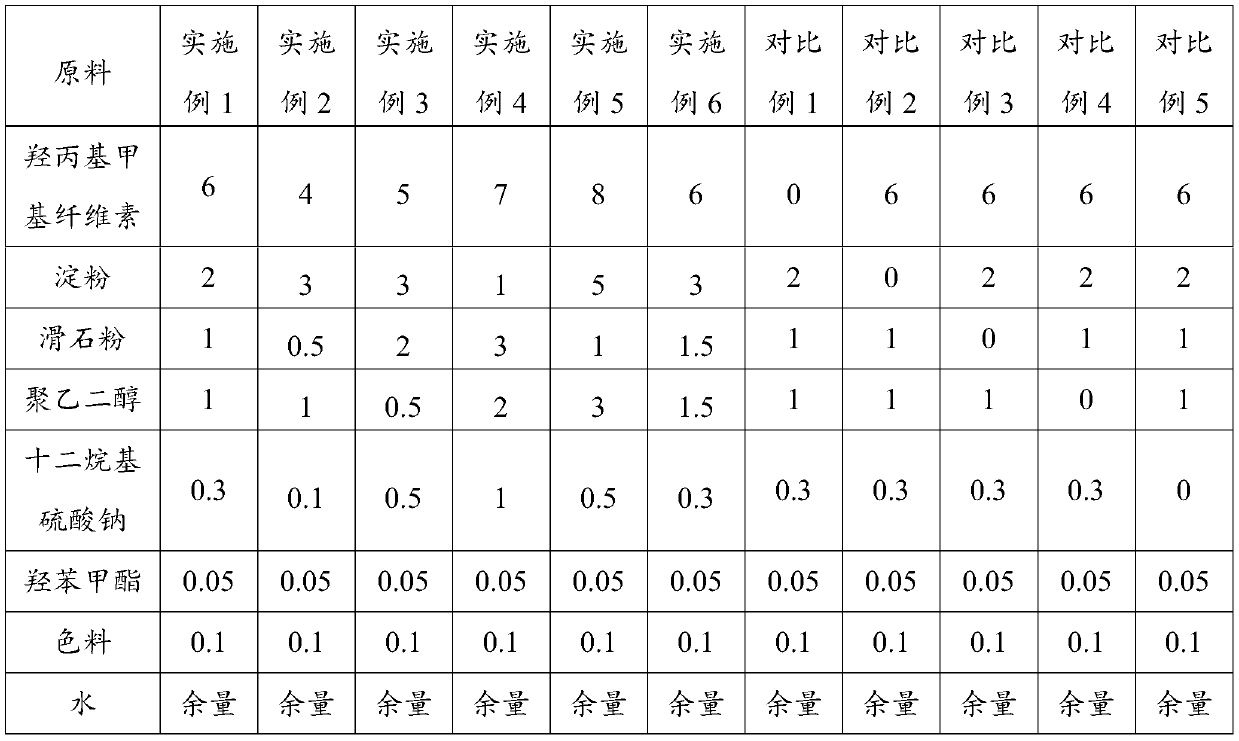

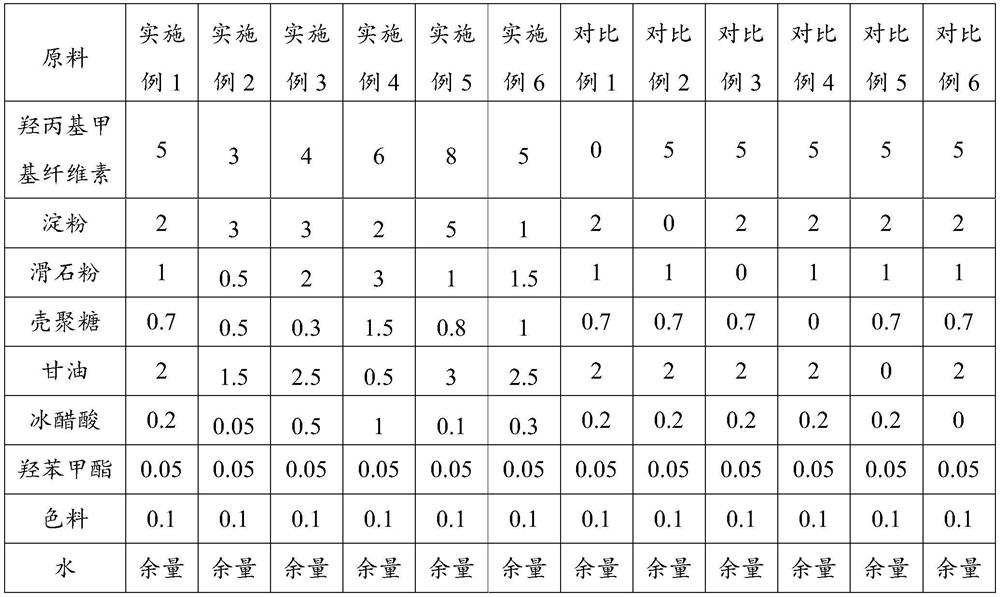

Novel flake toothpaste additive and preparation method thereof

ActiveCN109846749APlay a role in enhancing beauty and efficiencyGood film formingCosmetic preparationsToilet preparationsSolubilityToothpaste Product

The invention discloses a flake toothpaste additive, which comprises the following components by weight: 4-8 parts of hydroxypropyl methylcellulose, 1-5 parts of starch, 0.5-3 parts of filler, 0.5-3 parts of plasticizer and 0.1-1 part of a cosolvent. The flake toothpaste additive of the invention is a water-soluble additive, and has the following advantages: 1, the additive has the function of cleaning teeth and protecting teeth; 2, the raw materials are reasonably matched, and can be uniformly fused together; 3, the obtained additive has good film forming property, is easy to follow-up drying; 4, the flake has good stability after being added to the toothpaste product; 5, the flake has good solubility, and when the toothpaste is used, the flake can be dissolved by an external force; and 6, the flake toothpaste additive plays a role in increasing beauty and synergism. The invention also discloses a preparation method of the novel flake toothpaste additive.

Owner:广州常青藤化妆品有限公司 +1

Preparation methods of illite/montmorillonite clay nanometer slurry and illite/montmorillonite clay nanometer powder

InactiveCN103588214BImprove stabilityGood anti-sedimentationMaterial nanotechnologySilicon compoundsDispersityHigh energy

The invention discloses preparation methods of illite / montmorillonite clay nanometer slurry and illite / montmorillonite clay nanometer powder and belongs to the field of development and preparation of nanometer materials. The preparation method of the illite / montmorillonite clay nanometer powder comprises the following steps: (1) mechanically breaking natural illite / montmorillonite clay mineral; (2) soaking in water so as to obtain illite / montmorillonite clay slurry; (3) adjusting the pH value of the illite / montmorillonite clay slurry, puddling and dispersing; (4) sieving the puddled and dispersed slurry by using a 50-mesh sieve; (5) removing iron from the slurry; (6) chemically bleaching the slurry; (7) grinding the bleached slurry by adopting a high-energy density stirred mill so as to obtain nanometer slurry; (8) adding a dispersing agent to the nanometer slurry to carry out dispersing treatment; (9) adding a modifying agent to the slurry to carry out swelling treatment; (10) evaporating and drying; and (11) carrying out mechanical pulverization so as to obtain the illite / montmorillonite clay nanometer powder in the end. The illite / montmorillonite clay nanometer powder prepared by the method can reach the nanoscale and has good powder uniformity and dispersity.

Owner:SOUTH CHINA UNIV OF TECH +1

Compaction equipment in plastic film cleaning and recycling production line

The invention relates to the technical field of plastic film recycling, and discloses a compacting device in a plastic film cleaning and recycling production line, which comprises a base, a water squeezing mechanism, a controller, a smashing mechanism and a conveying belt, the water squeezing mechanism is arranged on the left side of the top end of the base in the front-back direction. The controller is mounted on the outer side of the water squeezing mechanism; the smashing mechanism is arranged at the top end of the base in the front-back direction and located on the rear side of the water squeezing mechanism. The conveying belt is arranged on the right side of the top end of the base. According to the compaction equipment in the plastic film cleaning and recycling production line, the water squeezing effect on plastic film particles and the scattering effect after water squeezing can be improved, the dehydration performance of the cleaned plastic film particles is improved, and the subsequent drying operation efficiency is indirectly improved; and fine plastic film particles in waste water discharged after extrusion and dehydration can be recycled, pollution caused by the discharged waste water is avoided, the recycling effect of the plastic film is improved, and the device is more environmentally friendly.

Owner:郭懒懒

Wax oil mixture obtained by extracting fat-soluble components of traditional Chinese medicine

ActiveCN104352530BFor subsequent dryingGood for crushing processCapsule deliveryOil/fats/waxes non-active ingredientsAlcoholAdditive ingredient

Owner:山西黄河中医药研究所(有限公司)

A kind of cosmetic additive color foil and preparation method thereof

ActiveCN109833225BPlay a role in enhancing beauty and efficiencyGood film formingCosmetic preparationsToilet preparationsCelluloseAcetic acid

The invention discloses a cosmetic additive color foil, which comprises the following components in parts by weight: 3-7 parts of hydroxypropyl methylcellulose, 1-5 parts of starch, 0.5-3 parts of filler, and 0.3-1.5 parts of chitosan 0.5-3 parts of plasticizer and 0.05-1 part of glacial acetic acid. The cosmetic additive color foil described in the present invention is a non-water-soluble additive and has the following advantages: 1. Each component complies with the raw materials permitted for cosmetics, and each raw material is reasonably matched and can be evenly fused together; 2. The prepared additive forms a film Good stability, easy to follow-up drying; 3. The color foil has good stability when added to cosmetics, can maintain the shape of the sheet, and the color remains unchanged; 4. When using it, it is slightly affected by external force (such as the force when it is pressed out through the nozzle or the force when smearing). It can be broken into tiny particles invisible to the naked eye; 5. It can enhance the beauty and synergy of cosmetics. The invention also provides a preparation method of the cosmetic additive color foil.

Owner:广州常青藤化妆品有限公司 +1

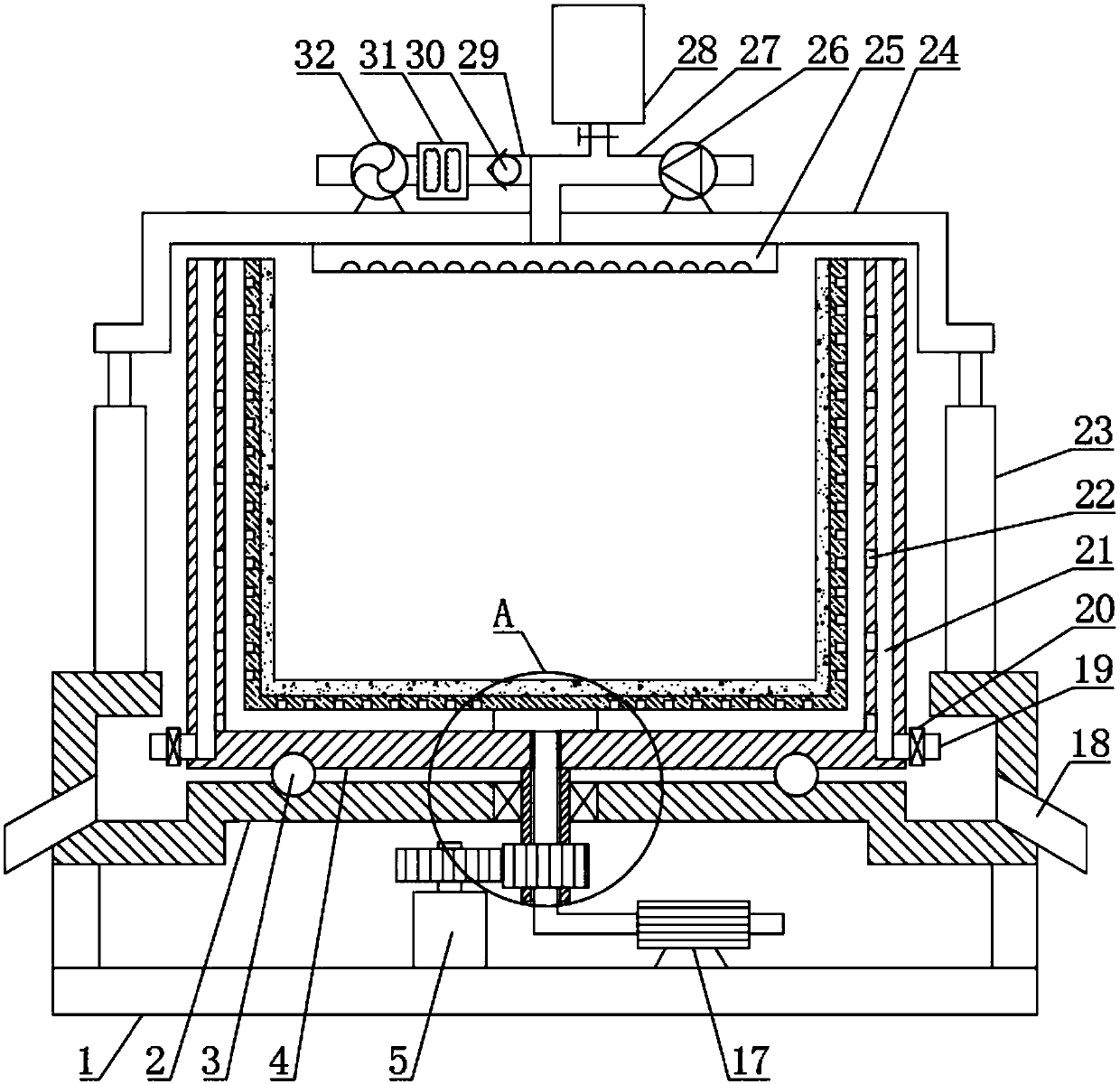

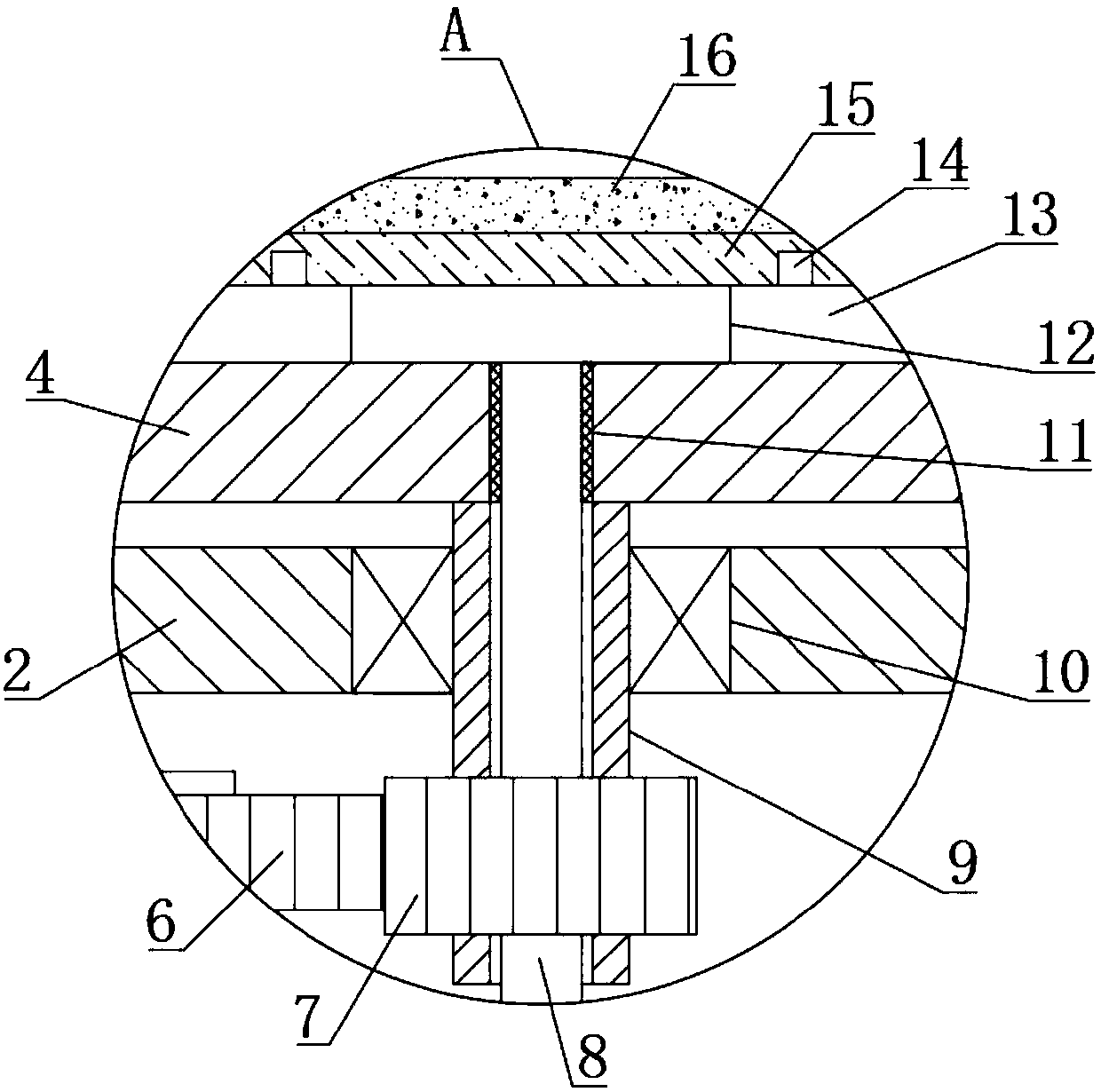

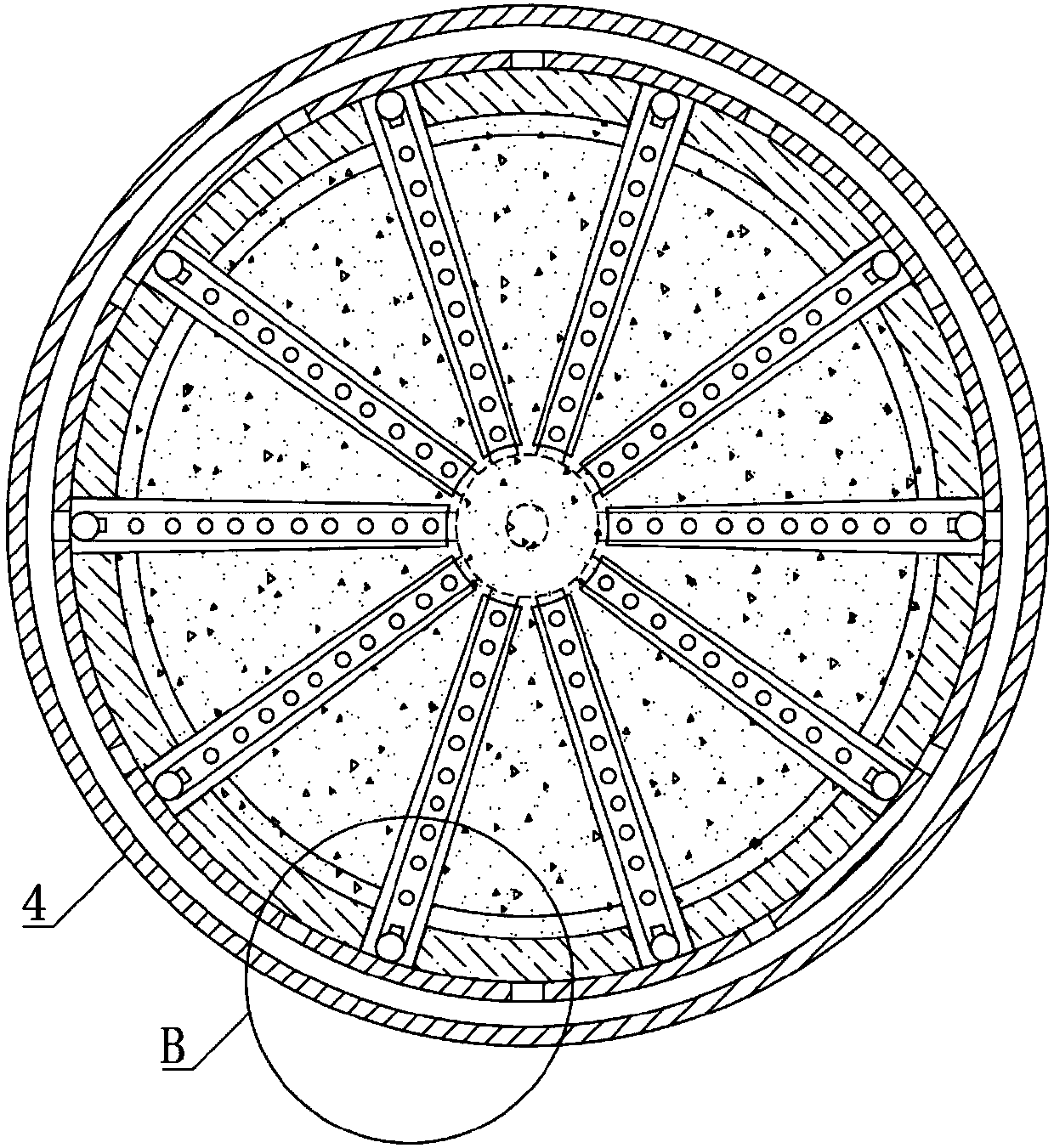

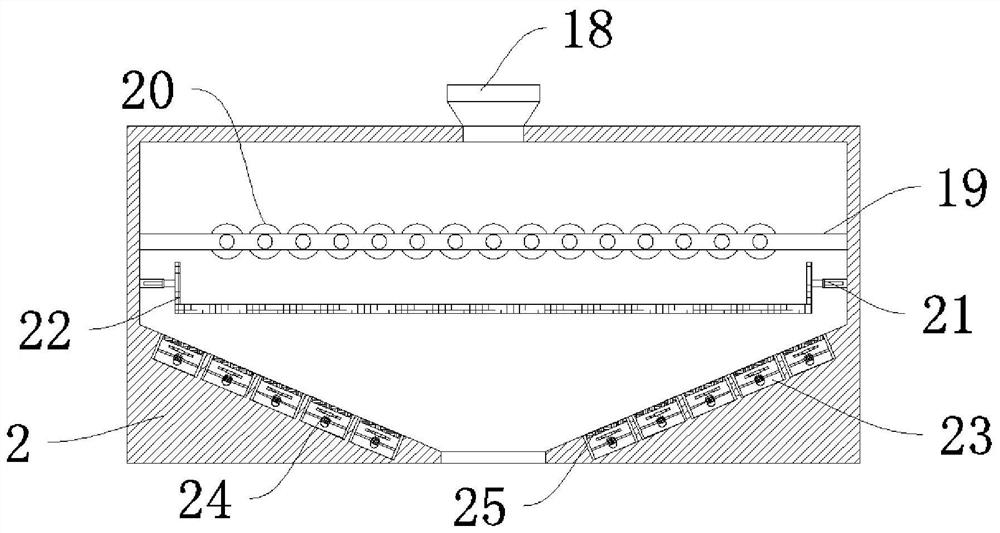

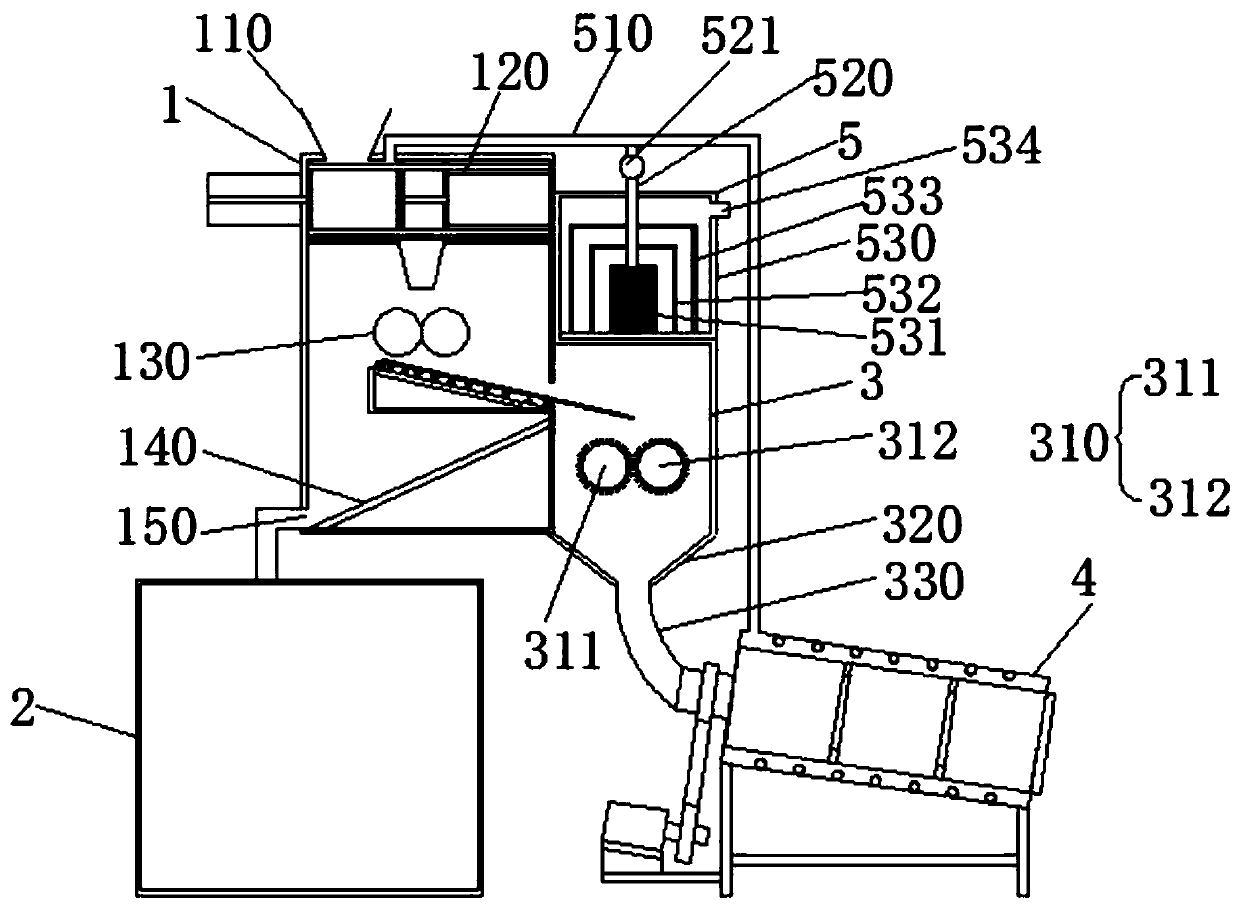

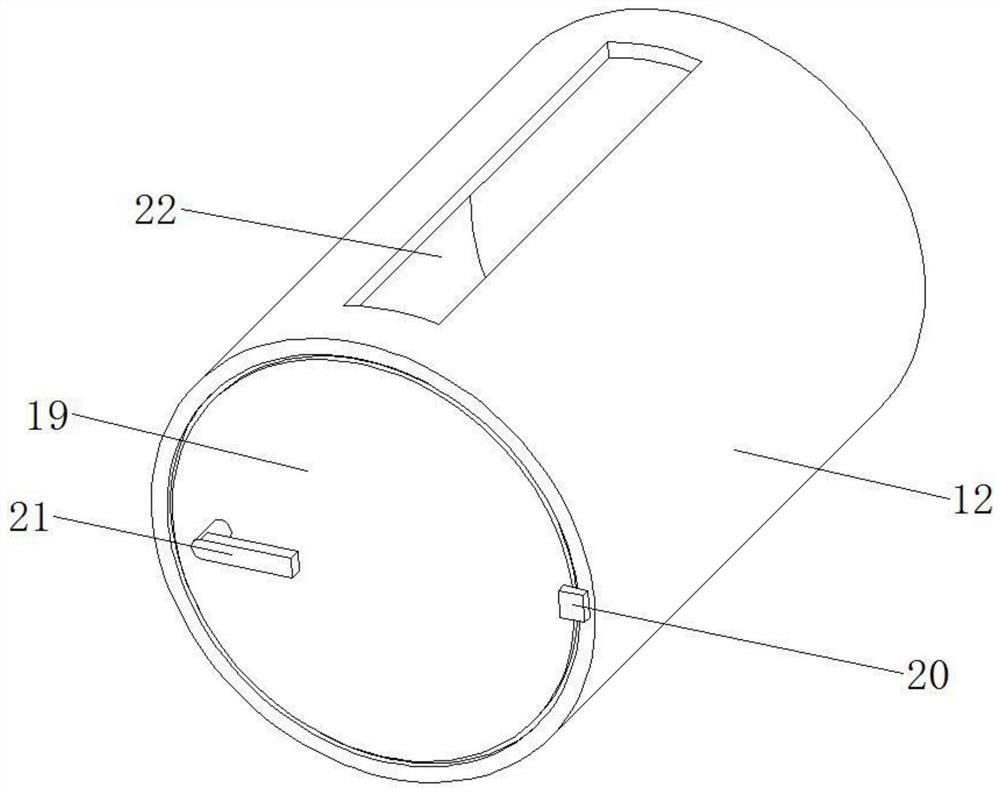

Cleaning device with pre-drying function for traditional Chinese medicine decoction piece processing

ActiveCN113877880AReduce humidityRinse thoroughlyDrying gas arrangementsDrying chambers/containersProcess engineeringMechanical engineering

The invention discloses a cleaning device with a pre-drying function for traditional Chinese medicine decoction piece processing. The cleaning device comprises a decoction piece cylinder and a cleaning part. According to the cleaning device, the decoction piece cylinder and the cleaning part are arranged, a C-shaped cleaning pipe is arranged on the cleaning part and can rotate and swing up and down, the open end of the C-shaped cleaning pipe is detachably connected with the decoction piece cylinder, a closed cleaning channel is formed in the C-shaped cleaning pipe and the decoction piece cylinder after the C-shaped cleaning pipe and the decoction piece cylinder are in butt joint, when the C-shaped cleaning pipe inclines and the decoction piece cylinder is located at the highest point, the decoction piece cylinder can be in butt joint with or detached from the C-shaped cleaning pipe, traditional Chinese medicine decoction pieces in the C-shaped cleaning pipe can be comprehensively flushed when the C-shaped cleaning pipe rotates in a horizontal state or an inclined state, flushing is more thorough, feeding and discharging operation is facilitated, meanwhile, a drying combination is arranged on the cleaning part, the decoction pieces in the decoction piece cylinder can be pre-dried through the drying combination, the humidity of the decoction pieces is greatly reduced, and subsequent drying or airing treatment is facilitated.

Owner:安国市深豪药业有限公司

Natural oyster calcium carbonate preparation for preventing and treating calcium deficiency and preparation method thereof

ActiveCN107929313BPromote absorptionFast absorptionOrganic active ingredientsMetabolism disorderBiotechnologyCarbonization

The invention discloses a natural oyster calcium preparation for prevention and treatment of calcium deficiency disease and a preparing method thereof for the first time. A natural oyster calcium compound with calcium carbonate as a main component is separated or extracted from oyster shells, and has the effect of preventing and treating calcium deficiency disease. The preparing method of the calcium preparation mainly comprises the steps of carrying out carbonization, activation, expansion, carbonization and drying of the oyster shells, and smashing and sieving an extract to extract the calcium compound with calcium carbonate as the main component, and the calcium compound belongs to the natural extract and can be used for supplementation of calcium for children, pregnant women and the elderly; compared with a technology for preparing calcium carbonate from raw material limestone, the technology process is equivalent, but the produced calcium carbonate compound has higher purity, is used for preparing granules and chewable tablets and has higher bioavailability.

Owner:SHANGHAI JINCHENG PHARMACEUTICAL CO LTD

An environmentally friendly weeding and recycling device

The invention discloses an environment-friendly weeding and recycling device, which comprises a base, a material storage box is fixedly arranged on the top of the base, and a crushing bucket matched with it is fixedly arranged on the right side of the inside of the storage box. The bottom wall of the material box and the base extend to the bottom of the base; the top of the material storage box is located directly above the center of the top of the crushing bucket, and a motor is fixedly installed. A number of crushing blades are connected; the upper left side of the crushing barrel is provided with a feed opening, and an exhaust fan is fixed on the left side of the top of the storage box. Attaches to the upper left side inside the storage box. The invention weeds through the rotation of the crushing blade, and at the same time draws air through the exhaust fan, so that the weeds move upwards in the crushing barrel and enter the storage box during the crushing process; the weeds move upwards in the crushing barrel and are fully crushed, which is convenient for subsequent drying.

Owner:深圳市宝晨物业管理有限公司

A device for drying and recovering traditional Chinese medicine dregs

InactiveCN108592531BReasonable structural designSolve environmental problemsDrying using combination processesDrying solid materials without heatWater collectionChinese drug

The invention provides a traditional Chinese medicine residue drying and recycling device. According to the specific technical scheme, the device is characterized by comprising a squeezing box, a water collection box, a smashing box, a drying device and a smell removal device. The squeezing box comprises a feeding hopper, a first squeezing device, a second squeezing device, a flow guide plate anda drainage port. A smashing device is arranged in the smashing box, the lower portion of the smashing device is provided with a second discharge hopper, the second discharge hopper is connected with the drying device through a flow guide pipe, the drying device comprises a supporting frame, a fixed outer barrel, an electric heating wire, a rotary net bucket and a driving device, and the smell removal device comprises a first gas guide pipe, a second gas guide pipe and a smell removal box. The traditional Chinese medicine residue drying and recycling device is reasonable in structural design, achieves medicine residue drying and recycling, avoids the environmental problem caused by direct discharge or burying of medicine residue, achieves energy conservation and emission reduction and is environmentally friendly.

Owner:山东万安药业股份有限公司

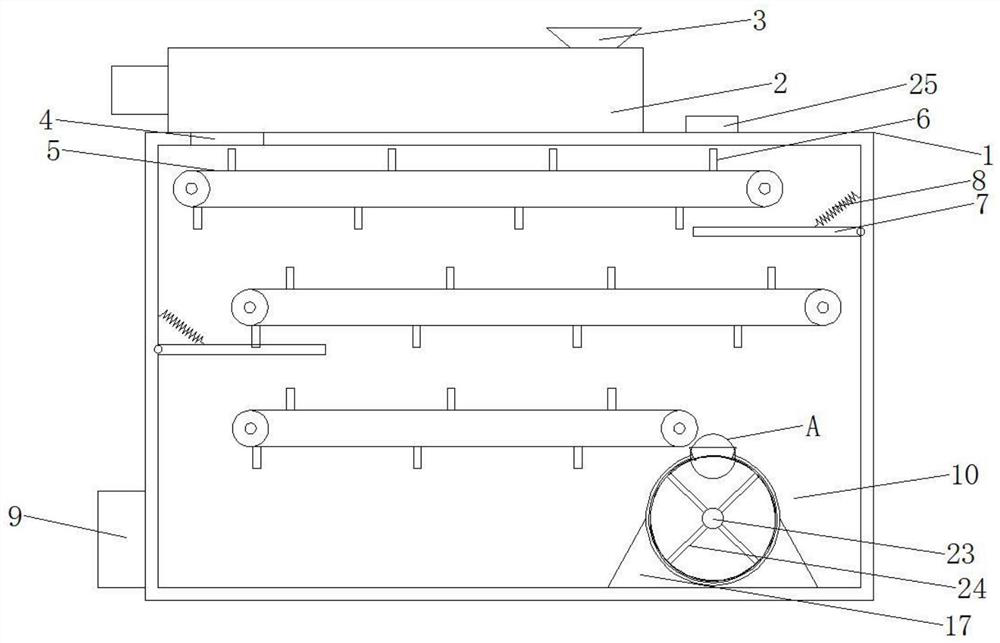

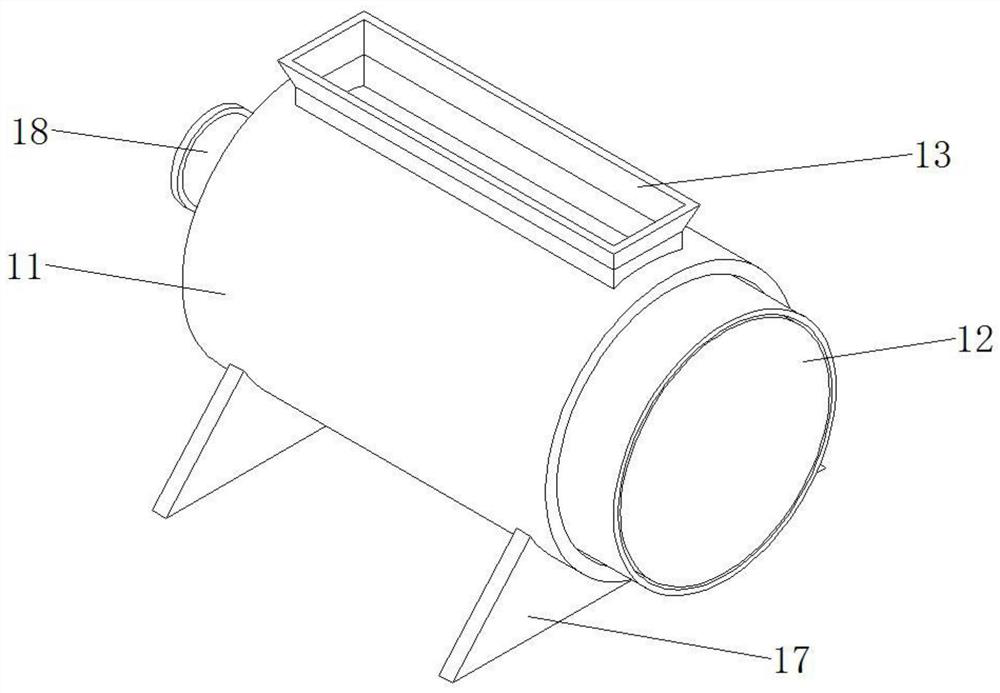

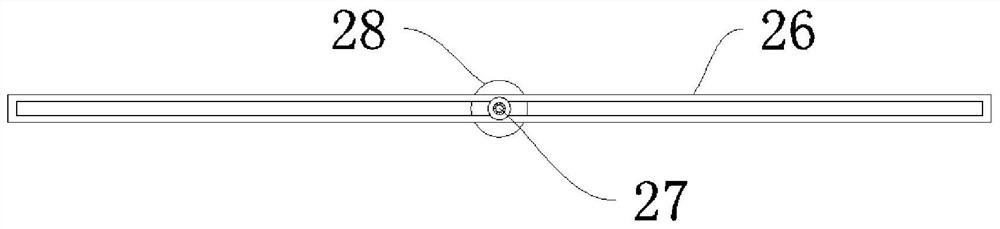

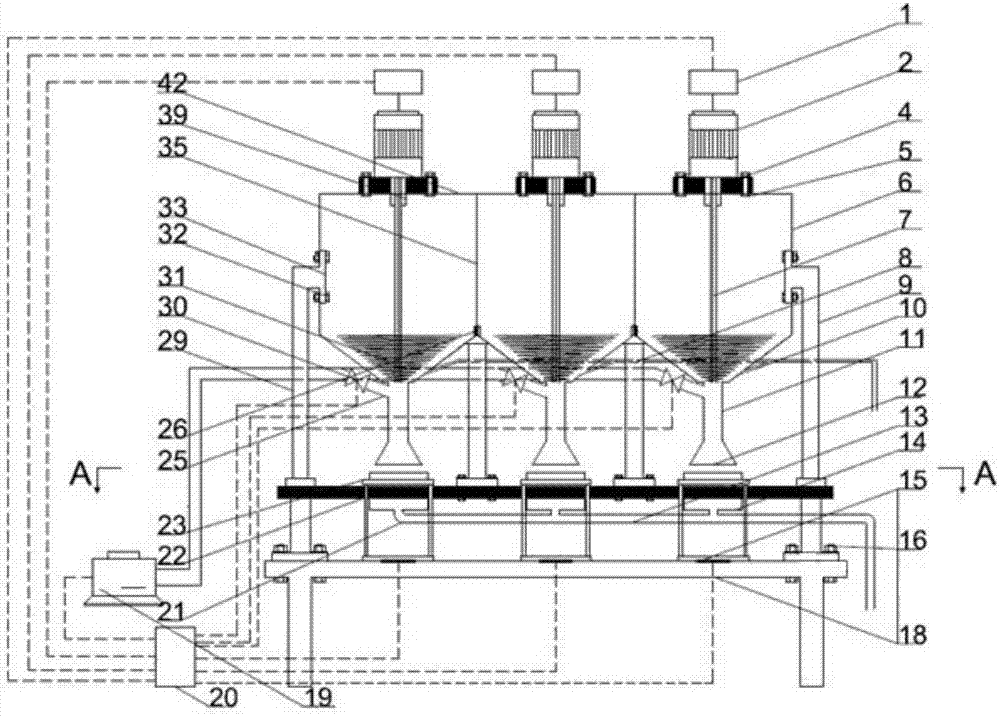

An agricultural seed drying device with rotary stirring

InactiveCN110388810BIncrease temperatureExtended storage timeDrying machine combinationsDrying gas arrangementsAgricultural scienceAgricultural engineering

The invention relates to the field of agriculture, and particularly discloses an agricultural seed drying device with a rotary stirring function. The agricultural seed drying device comprises a shell,a feed heating barrel, a feed hopper, a feeding port and conveyor belts; the bottom of the left end of the feed heating barrel communicates with the interior of the shell through the feeing port, andthe shell is internally provided with a plurality of horizontal conveyor belts; a rotary stirring mechanism is arranged below the discharging end of the lowest conveyor belt, and comprises a heatingouter barrel, a rotating inner barrel, a collecting bucket and a support frame; the arc-shaped side wall of the rotating inner barrel is provided with a discharging port in parallel with a center shaft; and the discharging port is rotatably connected with an inner barrel opening and closing baffle through a hinge pin, and the inner barrel opening and closing baffle can be rotated toward the interior of the rotating inner barrel. The multiple conveyor belts are arranged so that the contact time between seeds and hot air internally is long, and the seeds are in full contact with the air; the drying effect is improved; and through the rotary stirring mechanism arranged at the bottom, the seeds are continuously collected and turned over inside finally, and moisture of the remaining seeds whichare not dried is removed thoroughly.

Owner:陈堪 +2

A rare earth waste drying device for rare earth waste recovery

ActiveCN112404105BFor subsequent dryingLimit flyawayDispersed particle filtrationTransportation and packagingElectric machineEnvironmental engineering

Owner:萍乡鑫森新材料有限责任公司

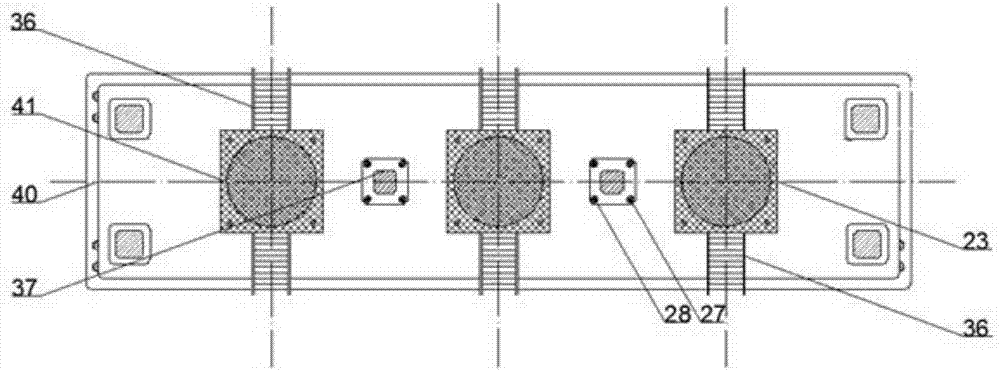

A round cake laver dehydration weighing automatic blanking forming device and forming method thereof

ActiveCN105996091BReduce moisture contentHighly consistent weightFood shapingRotation - actionEngineering

The invention discloses an automatic blanking forming device for round cake laver dehydration and weighing, which comprises a driving device, a blanking assembly, a material receiving assembly and a weighing device. The weighing device is arranged on a frame, and the connecting device The material assembly is set on the weighing device, the blanking assembly is correspondingly set above the material receiving assembly, the driving device is set on the material receiving assembly, and rotates relative to the material receiving assembly to extrude the material. . The invention can realize molding automation and has strong ability to adapt to load changes. The weight of laver in the material receiving assembly is uniform, and the dehydration process is omitted, which is safe and efficient.

Owner:SOUTHEAST UNIV

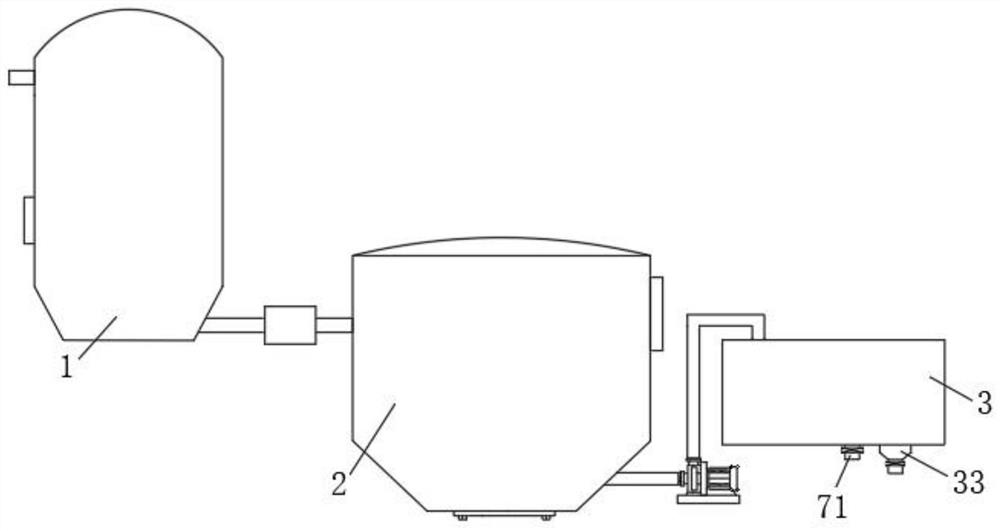

Edible salt production and processing technology and device

PendingCN113798012ARealize multi-stage continuous crushingImprove qualitySievingScreeningProcess engineeringFood science

The invention belongs to the technical field of edible salt production, and discloses an edible salt production device. The edible salt production device comprises an evaporator, a crystal cultivation device, a drying device and a grinding mechanism, wherein the evaporator, the crystal cultivation device and the drying device are sequentially connected through pipelines, the drying device comprises a drying box, a drying assembly and a discharging pipe fixed to the drying box, the drying assembly is installed in the drying box and comprises a conveying belt and a heating pipe. and the grinding mechanism is installed in the drying box. According to the edible salt production and processing technology and device, through cooperation of structures such as a fixing cylinder, a grinding cylinder, a rotating rod and a first grinding block, the edible salt crystal grains entering the drying box can be subjected to rolling treatment, the edible salt crystal grains continuously fall from top to bottom so that multi-stage continuous crushing can be achieved, and therefore, the edible salt grains can be gradually ground into fine particles from large particles, the product quality is greatly improved, subsequent drying treatment is facilitated, and the use effect is extremely good.

Owner:重庆合川盐化工业有限公司

Wax oil mixture obtained by extracting fat-soluble ingredients from traditional Chinese medicines

ActiveCN104352530AReduce dosageFor subsequent dryingCapsule deliveryOil/fats/waxes non-active ingredientsBiotechnologyOrganic chemistry

The invention relates to the technical field of extraction and purification of traditional Chinese medicines, and particularly relates to a wax oil mixture obtained by extracting fat-soluble ingredients from traditional Chinese medicines. The wax oil mixture is prepared by the following method: heating and melting bee wax; adding the melted bee wax into an alcohol extraction liquid of which the temperature is 65 to 75 DEG C and the relative density is 1.08-1.20; fully stirring and uniformly mixing; cooling and standing for 12-24 hours; taking the liquid at the upper part, filtering and separating to obtain the wax oil mixture. Meanwhile, technical problems that certain loss of volatile ingredients and fat-soluble ingredients is caused by the alcohol extraction liquid during subsequent concentration, drying and crushing, and difficult drying and difficult crushing are caused by fatty oil and the like, are solved.

Owner:山西黄河中医药研究所(有限公司)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com