Preparation methods of illite/montmorillonite clay nanometer slurry and illite/montmorillonite clay nanometer powder

A technology of nano-powder and smectite, applied in the field of development and preparation of nano-materials, can solve problems such as inability to prepare, and achieve the effects of reducing agglomeration, good stability and high dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

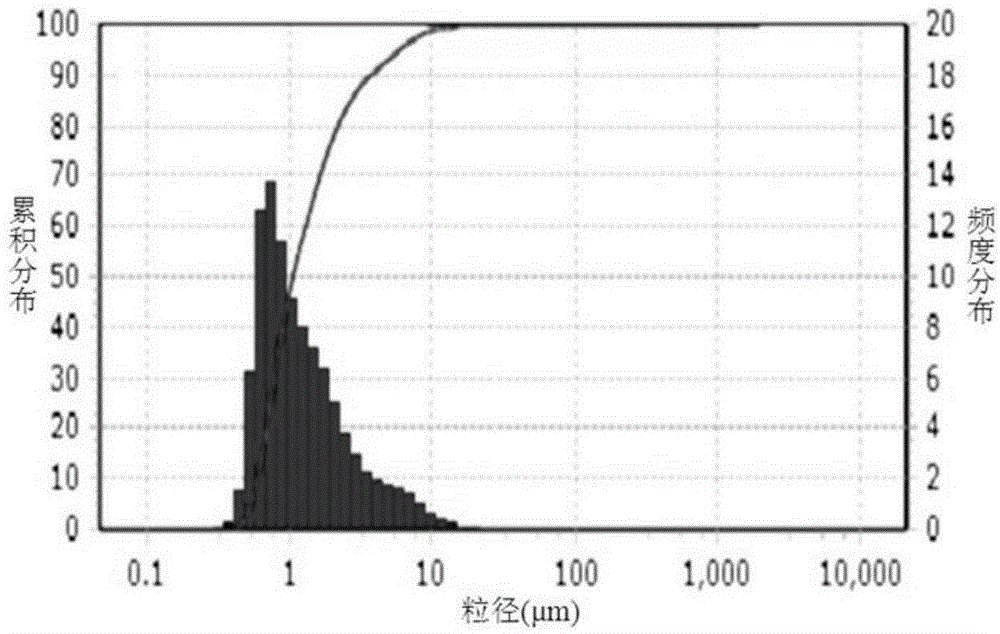

Embodiment 1

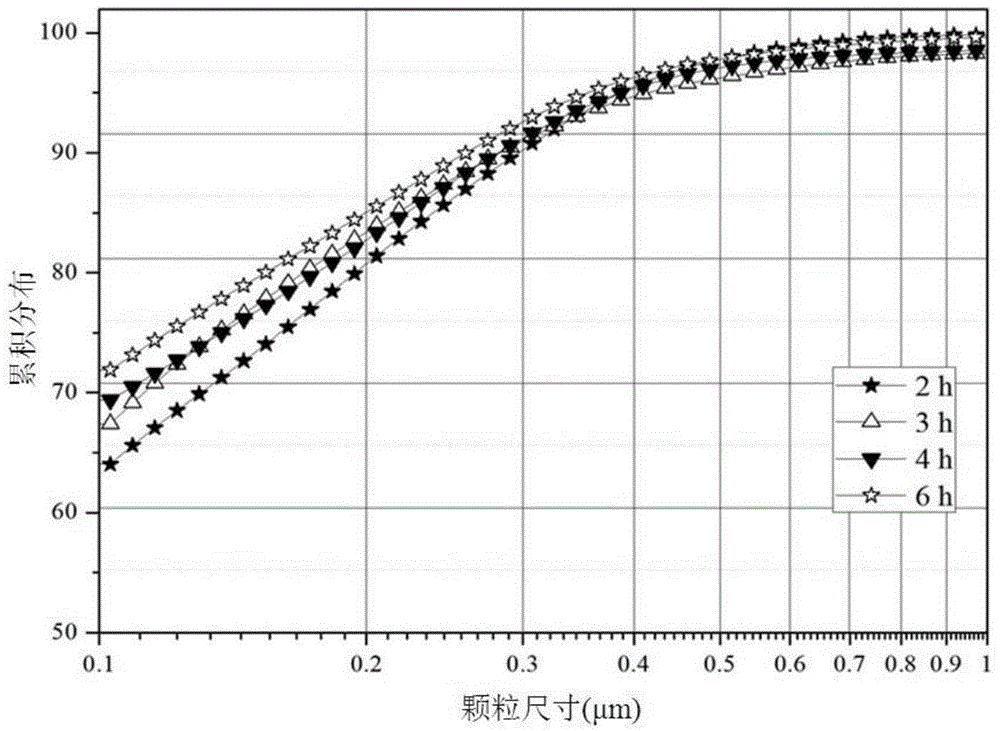

[0041] 1) Dry crushing: Mechanically crush natural Illuminate / Mongolian clay minerals into small pieces of Illuminate mixed layer clay minerals with a particle size of less than 5cm;

[0042] 2) Soaking: Soak the Ilmen-Mongolian mixed layer clay ore pieces obtained in step 1) with water for 12 hours to obtain Il / Mongolian clay slurry; the total mass of the slurry is 100%, wherein the solid content in the slurry is 45wt%;

[0043] 3) Pounding: Use 0.1mol / L NaOH solution to adjust the pH value of the Iraqi / Mongolian clay slurry to 8, add WF-211 dispersant, and use a sand mill disperser to disperse the slurry; among them, WF-211 disperses The addition of agent is 3wt% of solid content in the described slurry; The rotating speed of sand mill disperser is 1000rpm, and stirring time is 60min;

[0044] 4) Screening: pass the slurry after step 3) pounding and dispersion through a 500-mesh sieve to obtain the under-screen slurry;

[0045] 5) Iron removal: use a high gradient magnetic...

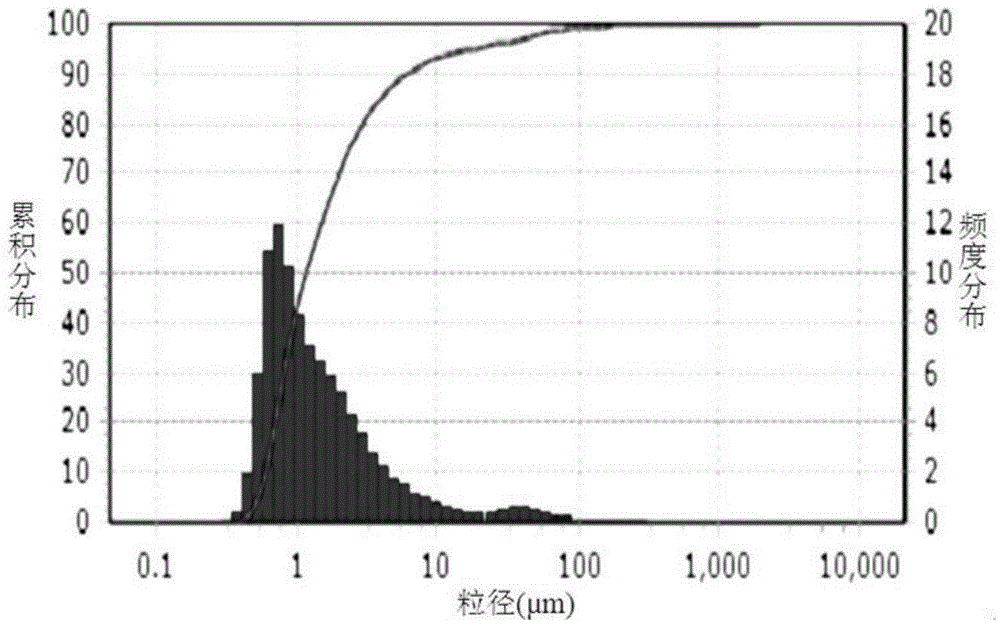

Embodiment 2

[0054] 1) Dry crushing: Mechanically crush natural Illuminate / Mongolian clay minerals into small pieces of Illuminate mixed layer clay minerals with a particle size of less than 5cm;

[0055] 2) Soaking: Soak the Ilmen-Mongolian mixed-layer clay ore pieces obtained in step 1) with water for 24 hours to obtain Il / Mongolian clay slurry; the total mass of the slurry is 100%, wherein the solid content in the slurry is 45wt%;

[0056] 3) Slurry: add 0.1mol / L NaOH solution to adjust the pH value of the Iraqi / Mongolian clay slurry to 10, add WF-211 dispersant, and use a sand mill disperser for slurry dispersion; among them, WF-211 dispersant The addition of agent is 1wt% of solid content in the described slurry; The rotating speed of sand mill disperser is 700rpm, and stirring time is 30min;

[0057] 4) Screening: pass the slurry after step 3) pounding and dispersion through a 500-mesh sieve to obtain the under-screen slurry;

[0058] 5) Iron removal: Use a high gradient magnetic s...

Embodiment 3

[0067] 1) Dry crushing: Mechanically crush natural Illuminate / Mongolian clay minerals into small pieces of Illuminate mixed layer clay minerals with a particle size of less than 5cm;

[0068] 2) Soaking: soak the block of Ilmen-Mongolian mixed-layer clay ore obtained in step 1) with water for 20 hours to obtain Il / Mongolian clay slurry; the total mass of the slurry is 100%, wherein the solid content in the slurry is 45wt%;

[0069] 3) Slurry: add 0.1mol / L NaOH solution to adjust the pH value of the Iraqi / Mongolian clay slurry to 9, add WF-211 dispersant, and use a sand mill disperser for slurry dispersion; among them, WF-211 dispersant The addition of agent is 2wt% of solid content in the described slurry; The rotating speed of sand mill disperser is 800rpm, and stirring time is 45min;

[0070] 4) Screening: pass the slurry after step 3) pounding and dispersion through a 500-mesh sieve to obtain the under-screen slurry;

[0071] 5) Iron removal: use a high gradient magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com