Polyacrylamide production line

A technology of polyacrylamide and production line, which is applied in the direction of gravity filter, fixed filter element filter, dispersed particle filter, etc. It can solve the problems of short filter working time of dust collector, reduced dust removal efficiency of filter bag, fast dust retention speed and other problems , to achieve the effect of convenient and fast cutting and granulation, shortening unloading time, improving production capacity and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

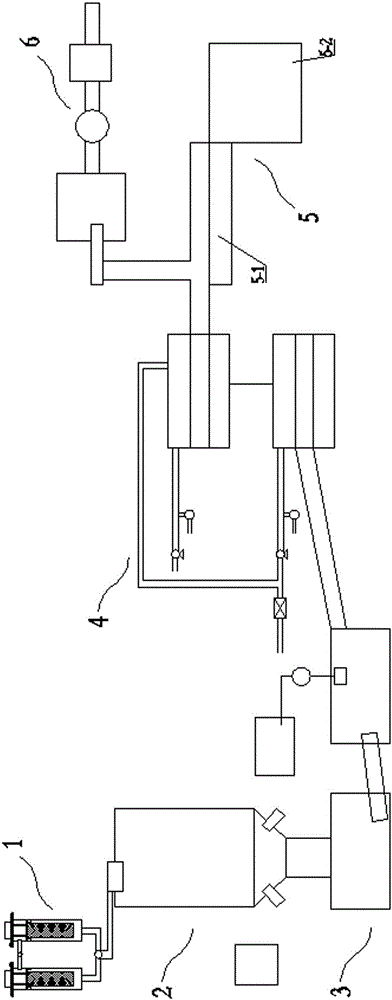

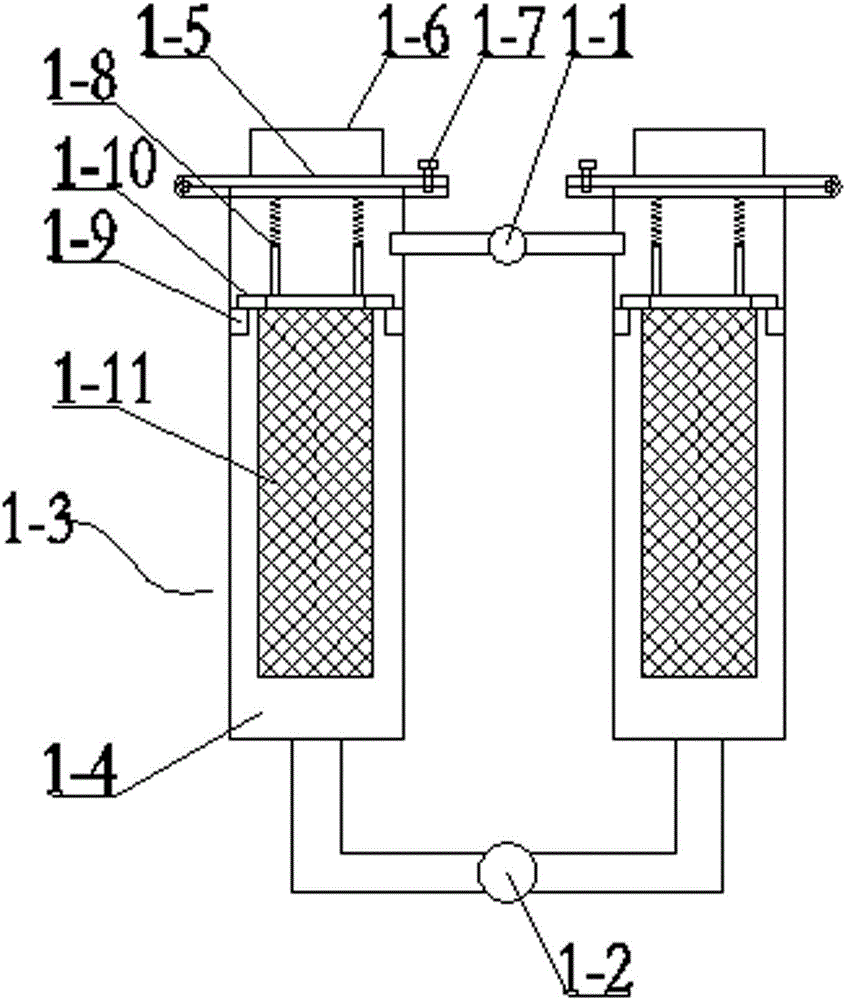

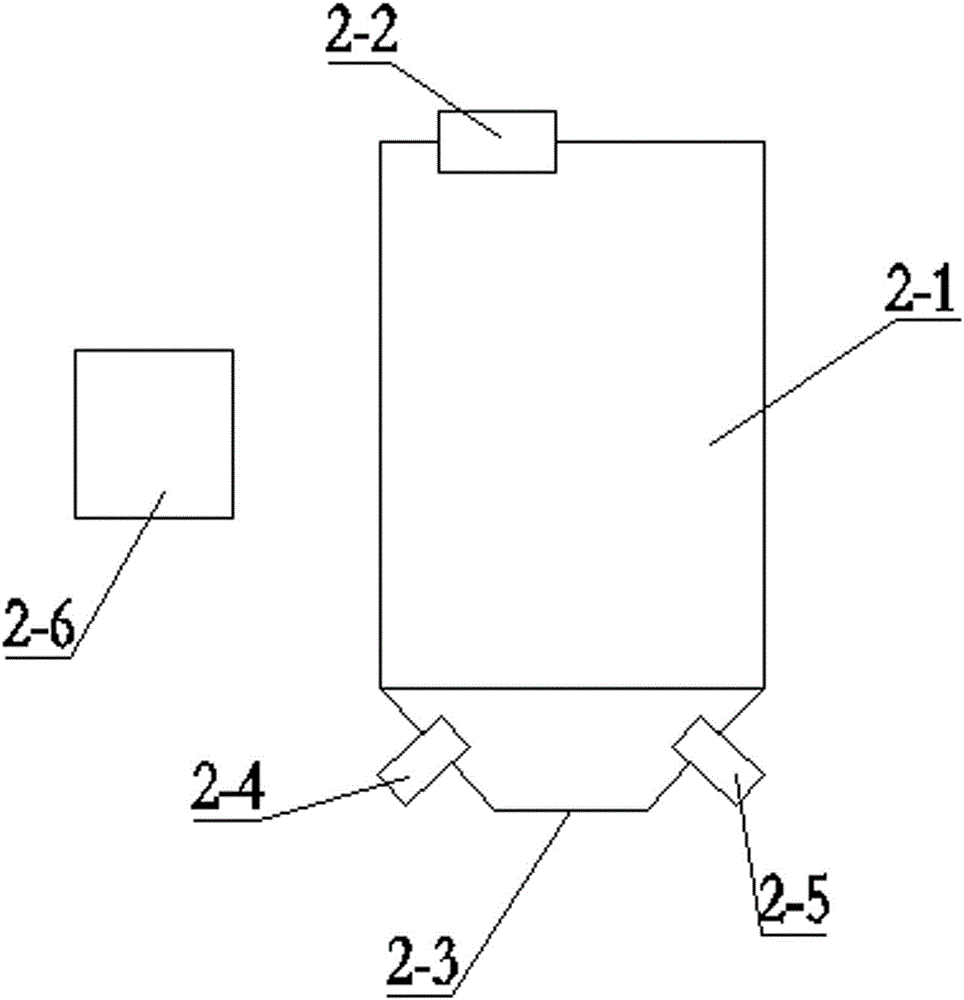

[0027] Figure 1-6Shown: a polyacrylamide production line, including a reactor pre-filter 1, an oil-feeding lubrication polymerization reactor 2, an oil-feeding lubrication crushing and granulating device 3, a polyacrylamide colloid drying production line 4, a screening and grinding device 5 and Pulse dust tail gas treatment device 6, reactor pre-filter 1, oil-inlet lubrication polymerization reactor 2, oil-inlet lubrication crushing and granulation device 3 and polyacrylamide colloid drying production line 4 are connected in sequence, and polyacrylamide colloid drying production line 4 is respectively The sieving and grinding device 5 and the pulse dust tail gas treatment device 6 are connected. The screening and grinding device 5 includes a screen 5-1 above one level and a roll grinder 5-2. The screen 5-1 above one level is correspondingly connected to the polyacrylamide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com