Energy-saving feed particle drying equipment

A technology for drying equipment and feed pellets, applied in drying, dryer, granular material drying and other directions, can solve the problems of high drying energy consumption, increased processing cost of extruded feed, clogging of screen (mesh) holes, etc. Improve drying efficiency, improve drying uniformity and drying effect, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

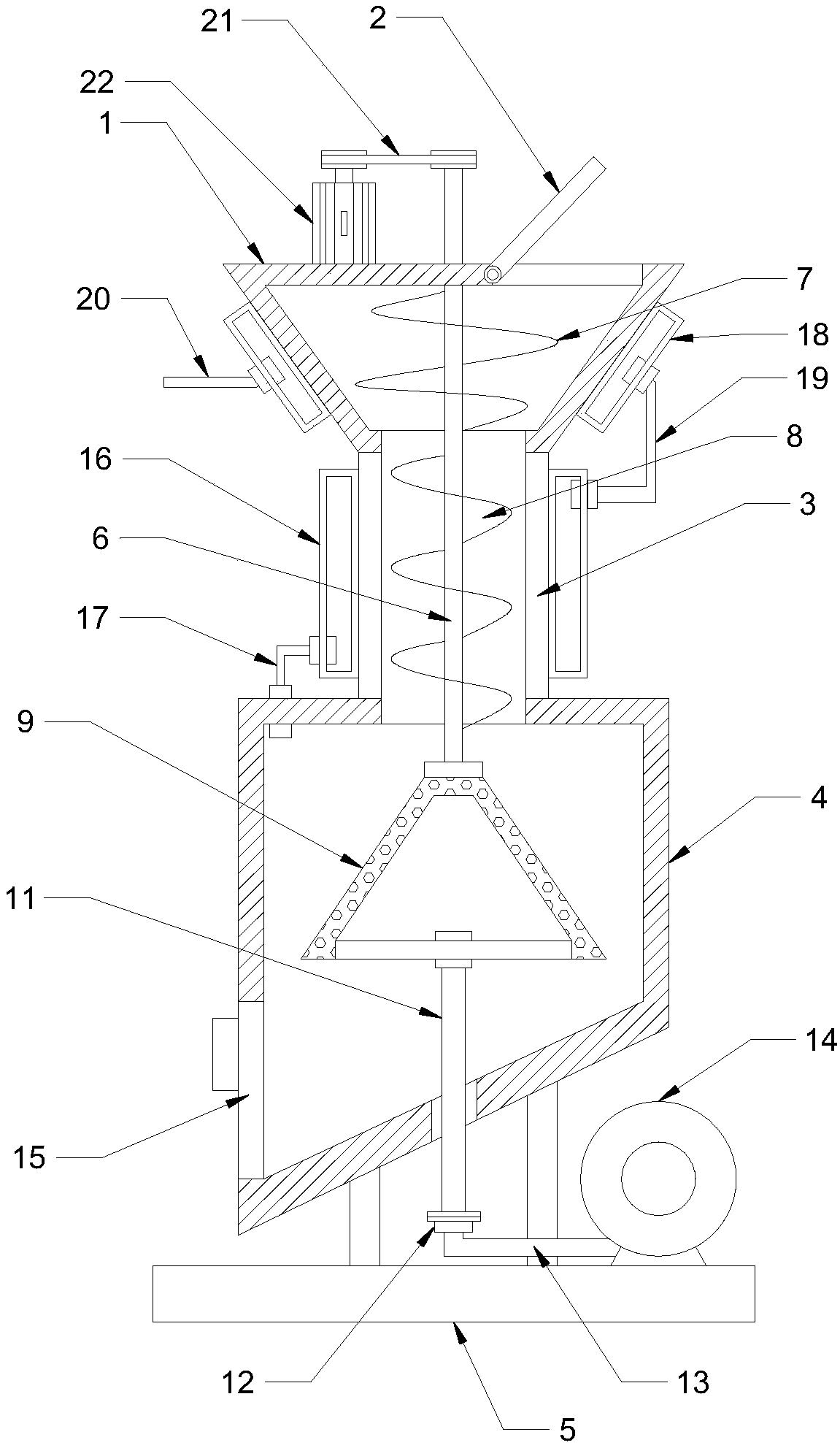

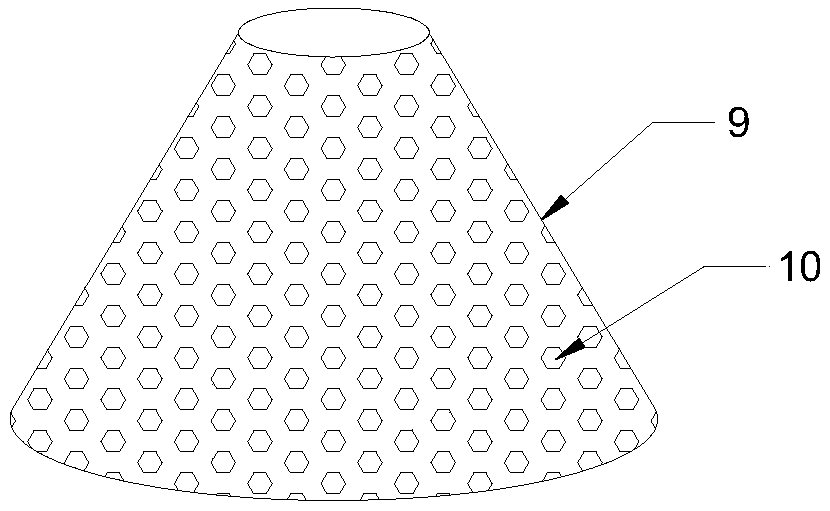

[0021] see Figure 1~2 , in the embodiment of the present invention, an energy-saving feed pellet drying equipment includes a storage hopper 1, a feeding pipe 3 and a drying box 4; the upper end of the storage hopper 1 is hinged with a feeding plate 2, which is opened to feed the storage Coarse feed particles are added in the hopper 1; the lower end of the storage hopper 1 is connected with a drying box 4 through the feeding pipe 3, the storage hopper 1 is provided with a first helical blade 7, and the feeding pipe 3 is provided with a second helical blade 8 The first helical blade 7 and the second helical blade 8 are fixedly connected with a through shaft 6, the through shaft 6 extends above the storage hopper 1 and is connected to the output shaft of the driving motor 22 through the transmission belt 21, and the driving motor 22 is fixed by bolts It is fixedly connected with the storage hopper 1, and the drive motor 22 is electrically connected with the external power supply...

Embodiment 2

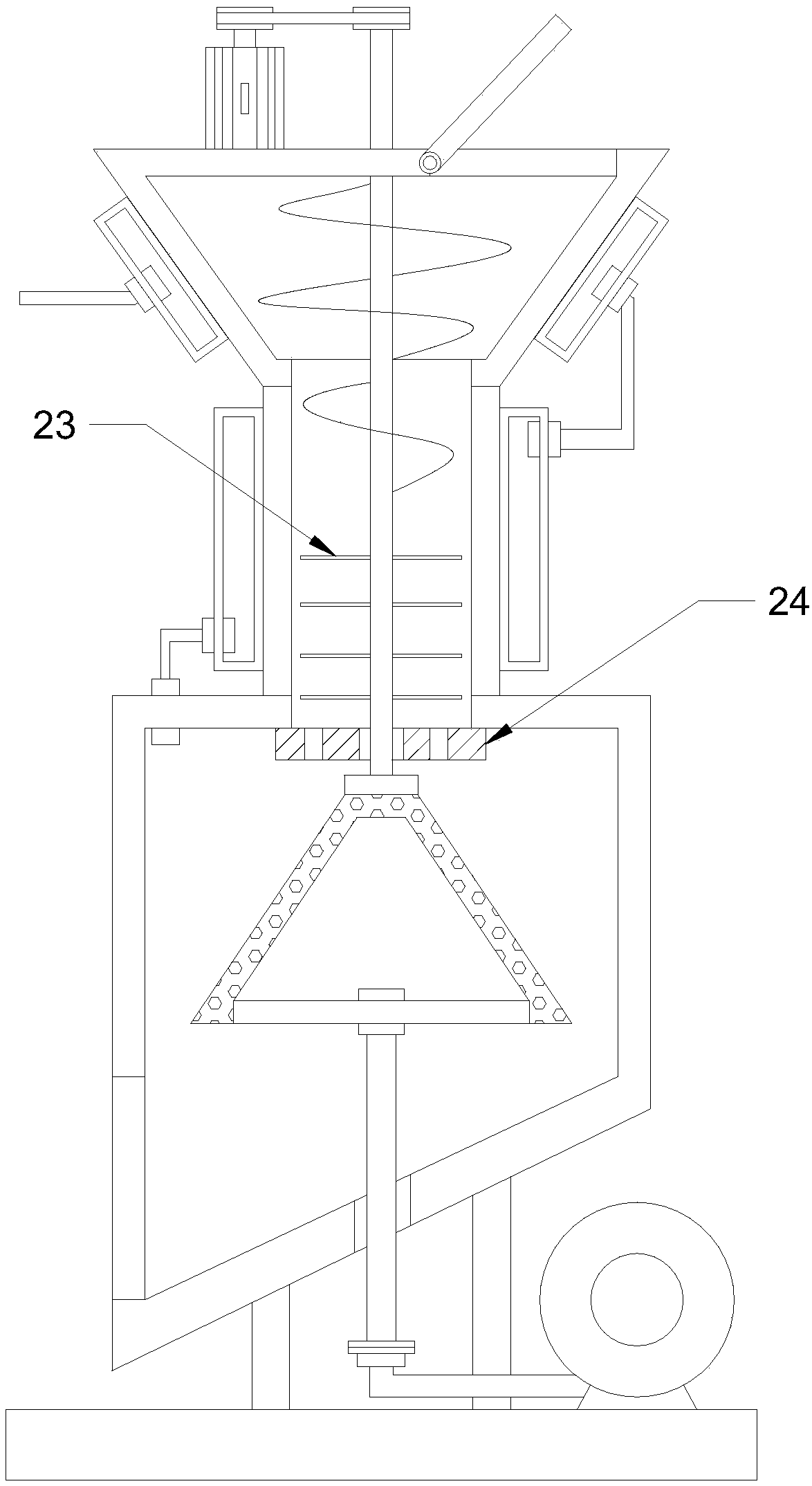

[0025] see image 3 , the difference between this embodiment and embodiment 1 is that a crushing knife 23 is provided in the feeding pipe 3, and the crushing knife 23 is fixedly connected with the through shaft 6 to crush the feed particles, so that the subsequent feed particles and the drying cylinder 9 Full contact, more efficient drying, a sieve plate 24 is provided at the connection between the feeding pipe 3 and the drying box 4 to ensure the crushing quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com