Method for preparing super-hydrophobic high-intensity thin ceramic glaze layer based on 3D printing and surface micron/ nanoparticles coating

A surface coating and nano-particle technology, applied in the field of ceramics, can solve the problems of poor surface hydrophobicity and waste of raw materials, and achieve the effect of increasing hydrophobicity, improving roughness, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

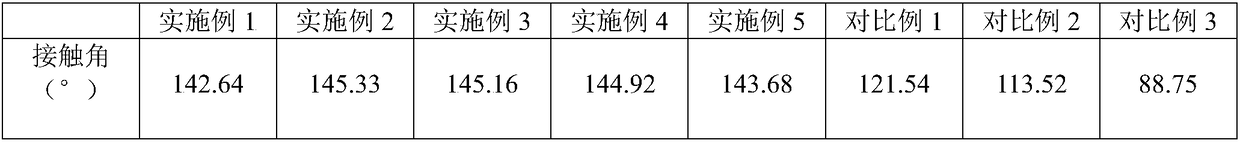

Examples

Embodiment 1

[0034] A method for preparing a superhydrophobic high-strength ceramic glaze thin layer based on 3D printing and surface coating micro / nano particles, comprising the following steps:

[0035] (1) Modeling: Use a 3D scanner to scan the outer contour shape of the molded ceramic body to obtain 3D point cloud data, input the 3D point cloud data into the computer to obtain a ceramic body model, and then print on the outer surface of the ceramic body model Construct a 3D thin-layer model of ceramic glaze, and then decompose the 3D thin-layer model of ceramic glaze into a series of two-dimensional models with a thickness of 200 μm;

[0036](2) Glazing: Input the ceramic glaze 3D thin-layer model data in step (1) into the 3D printer supporting equipment, set the printing program, and then add the ceramic glaze slurry to the 3D printer, and the 3D printer nozzle sprays on the surface of the ceramic body Ceramic glaze ink, which accumulates on the surface of ceramic glaze to form a thin...

Embodiment 2

[0048] A method for preparing a superhydrophobic high-strength ceramic glaze thin layer based on 3D printing and surface coating micro / nano particles, comprising the following steps:

[0049] (1) Modeling: Use a 3D scanner to scan the outer contour shape of the molded ceramic body to obtain 3D point cloud data, input the 3D point cloud data into the computer to obtain a ceramic body model, and then print on the outer surface of the ceramic body model Construct a 3D thin-layer model of ceramic glaze, and then decompose the 3D thin-layer model of ceramic glaze into a series of two-dimensional models with a thickness of 220 μm;

[0050] (2) Glazing: Input the ceramic glaze 3D thin-layer model data in step (1) into the 3D printer supporting equipment, set the printing program, and then add the ceramic glaze slurry to the 3D printer, and the 3D printer nozzle sprays on the surface of the ceramic body Ceramic glaze ink, which accumulates on the surface of ceramic glaze to form a thi...

Embodiment 3

[0062] A method for preparing a superhydrophobic high-strength ceramic glaze thin layer based on 3D printing and surface coating micro / nano particles, comprising the following steps:

[0063] (1) Modeling: Use a 3D scanner to scan the outer contour shape of the molded ceramic body to obtain 3D point cloud data, input the 3D point cloud data into the computer to obtain a ceramic body model, and then print on the outer surface of the ceramic body model Construct a 3D thin-layer model of ceramic glaze, and then decompose the 3D thin-layer model of ceramic glaze into a series of two-dimensional models with a thickness of 250 μm;

[0064] (2) Glazing: Input the ceramic glaze 3D thin-layer model data in step (1) into the 3D printer supporting equipment, set the printing program, and then add the ceramic glaze slurry to the 3D printer, and the 3D printer nozzle sprays on the surface of the ceramic body Ceramic glaze ink, which accumulates on the surface of ceramic glaze to form a thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com