Flame-retarded elastic textile fabric and processing method thereof

A technology of textile fabrics and processing methods, applied in the field of textile fabrics, can solve the problems of wool with large strength damage, easy combustion, rough elasticity, etc., and achieve the effects of small strength damage, improved flame retardancy, and reduced addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

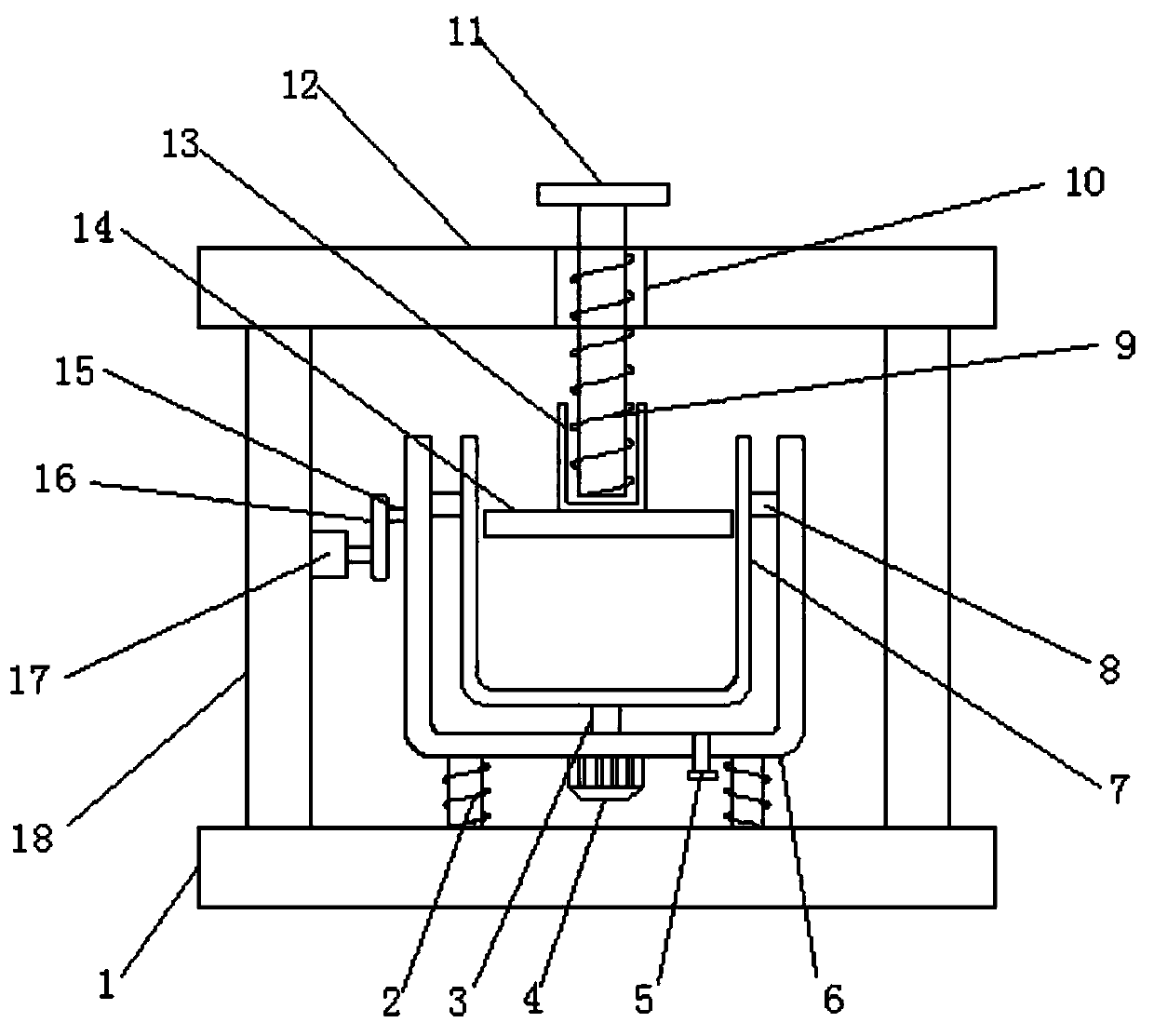

Image

Examples

Embodiment 1

[0040] A flame-retardant elastic textile fabric, the fabric is woven from warp threads and weft threads, and the warp threads include 35-55 parts by weight of nylon, 20-30 parts of acrylic fiber, 5-10 parts of conductive fiber, 5-10 parts of Modification aid, 1-5 parts of elastomer, wherein said modification aid includes 30-45 parts of sodium alginate, 25-35 parts of polyethylene terephthalate, 15-25 parts of chitosan, 5 parts by weight -10 parts of soybean protein glue, the elastomer weight parts include 1-5 parts of coupling agent, 55-65 parts of polypropylene, 20-30 parts of polyolefin elastomer, and 10-20 parts of styrene-based thermoplastic elastomer;

[0041] The weft is composed of spandex and modified wool fibers coated on the outside of the spandex, wherein the weight ratio of spandex and modified wool fibers is 85-90 parts of spandex and 10-15 parts of modified wool fibers;

[0042] The preparation method of the modified wool fiber comprises the following steps;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com