Novel flake toothpaste additive and preparation method thereof

A technology of additives and flakes, which is applied in the field of toothpaste additives, can solve the problems of poor film formation, poor stability, and slow dissolution rate, etc., and achieve the effect of good film formation, good stability, and easy subsequent drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~5

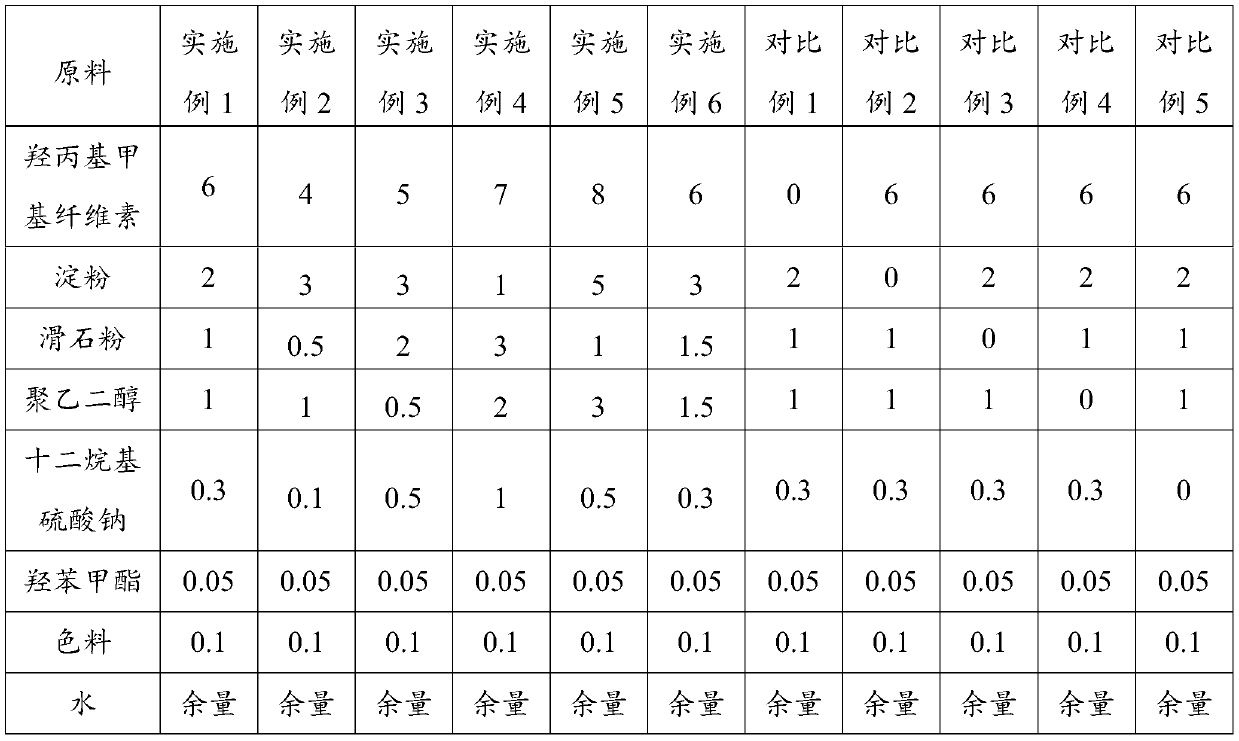

[0024] See Table 1 for the raw material formulations of the flake toothpaste additives described in Examples 1-6 and Comparative Examples 1-5.

[0025] The preparation method of the flake toothpaste additive described in Examples 1-6 and Comparative Examples 1-5 comprises the following steps:

[0026] (1), add starch and 70% deionized water, gelatinize at 80°C, add hydroxypropyl methylcellulose and stir evenly to obtain mixture A;

[0027] (2), the mixture A is lowered to room temperature, polyethylene glycol is added, and the mixture is evenly stirred to obtain the mixture B;

[0028] (3), add talcum powder and colorant to part of the deionized water, ultrasonically disperse evenly, add to mixture B to obtain mixture C;

[0029] (4), after dissolving sodium lauryl sulfate and preservative plus deionized water, slowly add in mixture C, stir for 1h, vacuumize to remove the foam in the mixture, bake and dry on the tape casting machine, the drying temperature is lower than Slic...

Embodiment 7

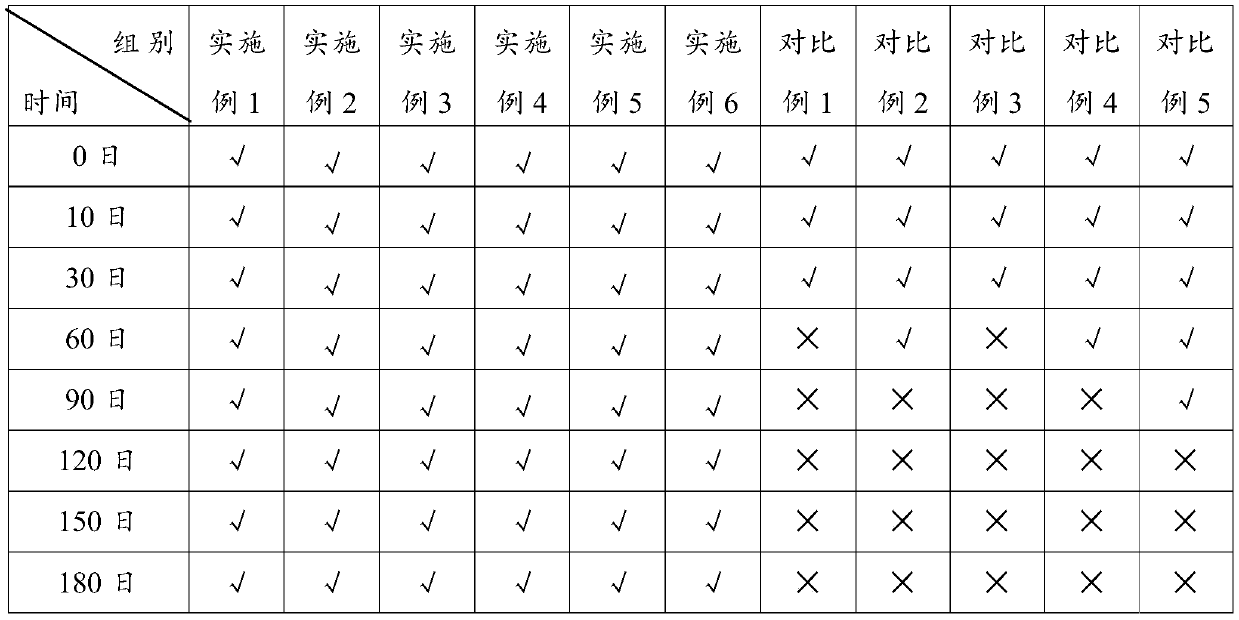

[0033] The flake toothpaste additives described in Examples 1 to 6 and Comparative Examples 1 to 5 were tested for stability, and the flake toothpaste additives were added to the toothpaste, and checked after 0 days, 30 days, 60 days, 90 days, 120 days and 150 days See Table 2 for the test results whether there is dissolution, disintegration or discoloration of the flakes in the toothpaste.

[0034] Table 2 Stability test results

[0035]

[0036] Note: "√" indicates that the flake toothpaste additive did not dissolve, disintegrate and decolorize in the paste; "×" indicates that the product dissolved, disintegrated or decolorized in the paste.

[0037] As can be seen from the stability test results in Table 2, the flake toothpaste additive described in Examples 1 to 6 can maintain good stability after 180 days, and there is no dissolution, disintegration and decolorization in the toothpaste paste; and The flake toothpaste additive described in Comparative Examples 1 to 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com