Cosmetic additive color foil and preparation method thereof

A cosmetic additive and color foil technology, applied in the field of cosmetic additives, can solve the problems of slow dissolution, poor film-forming property, and poor stability, and achieve the effect of good film-forming property, good stability, and easy subsequent drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

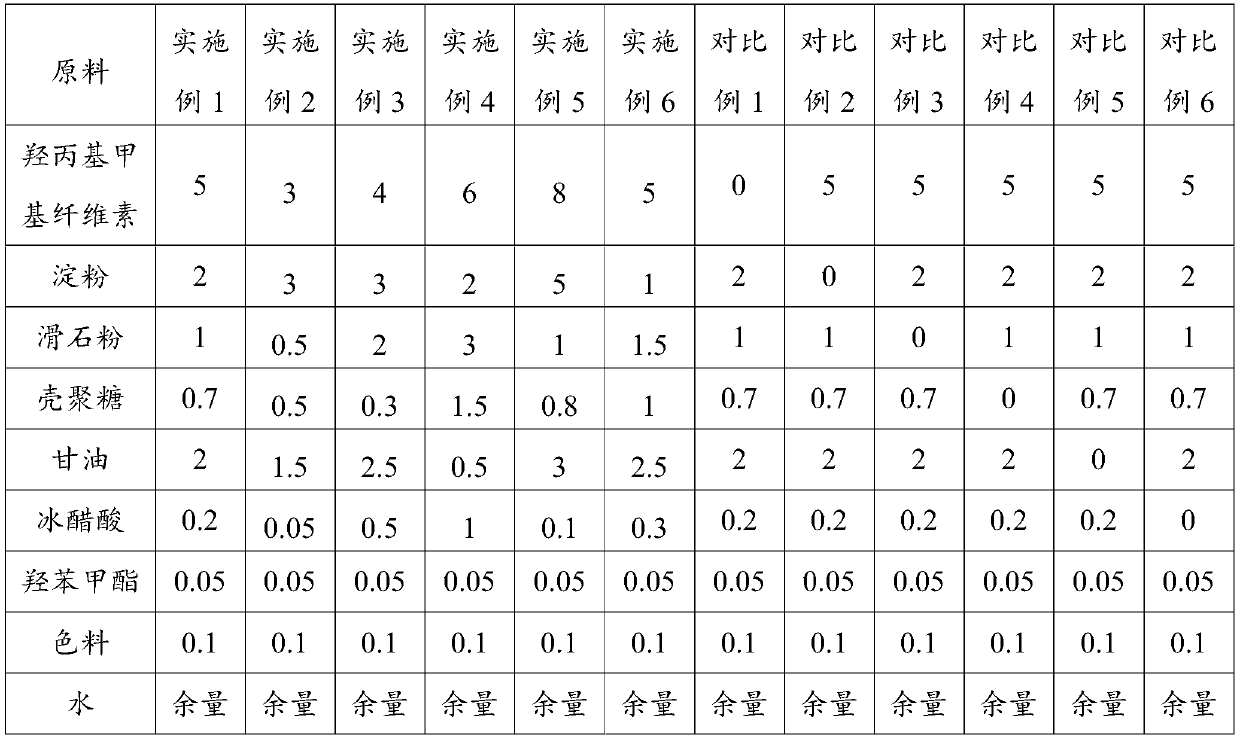

Embodiment 1~6 and comparative example 1~6

[0023] Examples 1 to 6 and Comparative Examples 1 to 6 are examples of the colored foils of the present invention. The raw material formulas of the colored foils of Examples 1 to 6 are shown in Table 1.

[0024] The preparation method of colored foil described in Examples 1 to 6 and Comparative Examples 1 to 6 includes the following steps:

[0025] (1) Add starch and 70% deionized water, gelatinize at 80°C, add hydroxypropyl methylcellulose and chitosan and mix well to obtain mixture A;

[0026] (2). Reduce mixture A to room temperature, add glacial acetic acid, stir for 3 to 5 minutes, add glycerin, and stir evenly to obtain mixture B;

[0027] (3) Add the filler and colorant to deionized water, ultrasonically disperse them uniformly, and add them to mixture B to obtain mixture C;

[0028] (4) Dissolve the preservative and deionized water and slowly add it to the mixture C, stir for 1 hour, vacuum to remove the foam in the mixture, and bake and dry on the casting machine, the drying te...

Embodiment 7

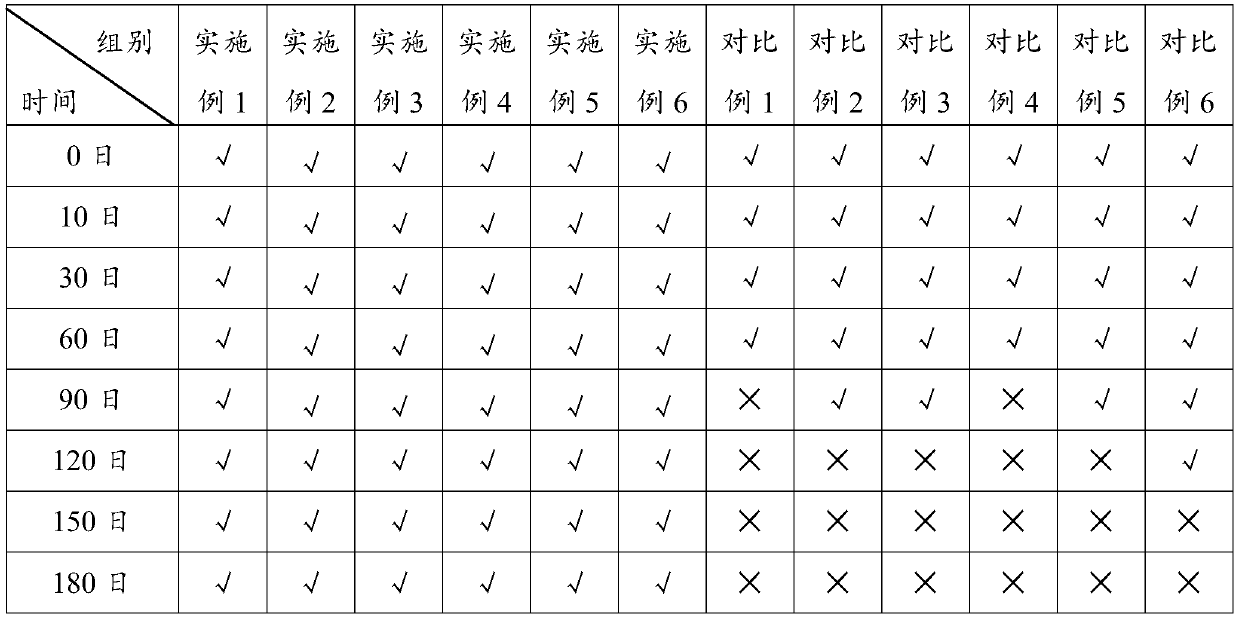

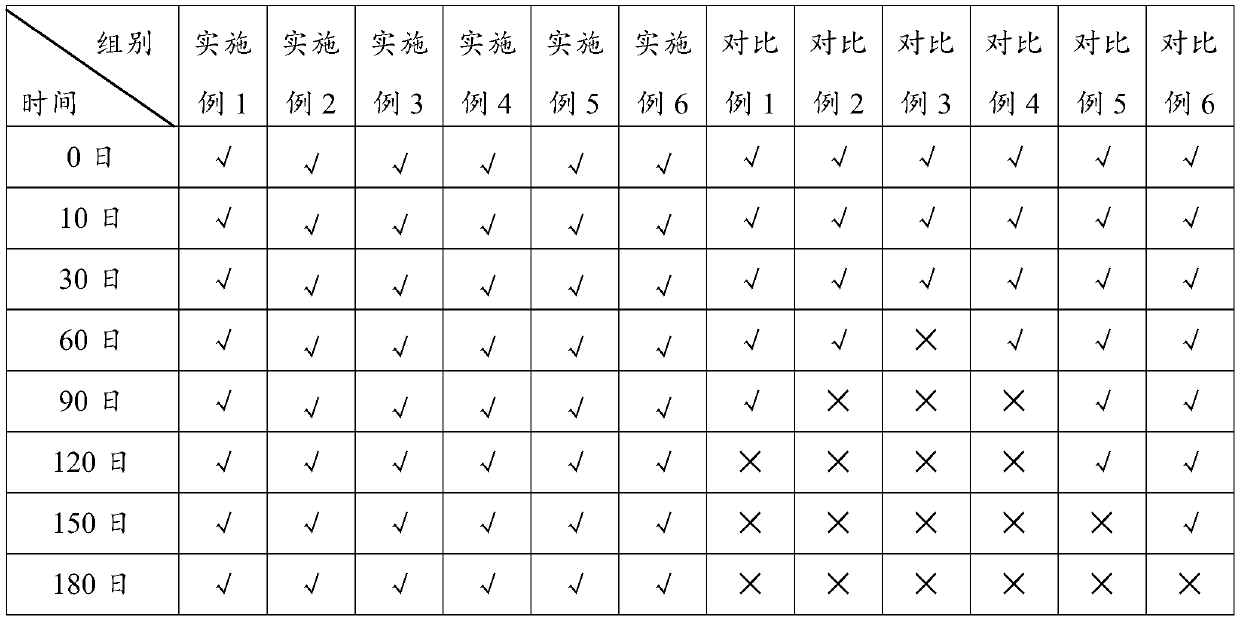

[0032] The color foils described in Examples 1 to 6 and Comparative Examples 1 to 6 were tested for stability performance, and the color foils were added to the gel and essence liquid, respectively, at 0 days, 30 days, 60 days, 90 days, 120 days and 150 days. After days, check whether the flakes are dissolved, disintegrated or discolored in the gel and essence stock solution. The test results are shown in Table 2 and Table 3.

[0033] Table 2 Stability test results of colored foil in gel

[0034]

[0035] Note: "√" means that the color foil did not dissolve, disintegrate or discolor in the gel; "×" means that the product dissolves, disintegrate or discolor in the gel.

[0036] Table 3 Stability test results of colored foil in essence liquid

[0037]

[0038] Note: "√" means that the color foil does not dissolve, disintegrate or discolor in the essence liquid; "×" means that the product dissolves, disintegrate or discolor in the essence liquid.

[0039] It can be seen from the stability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com