Equipment for rapidly compacting scraps generated in hardware machining process

A fast and hardware technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of poor compaction effect, time-consuming and laborious, and achieve the effect of simple structure and convenient control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

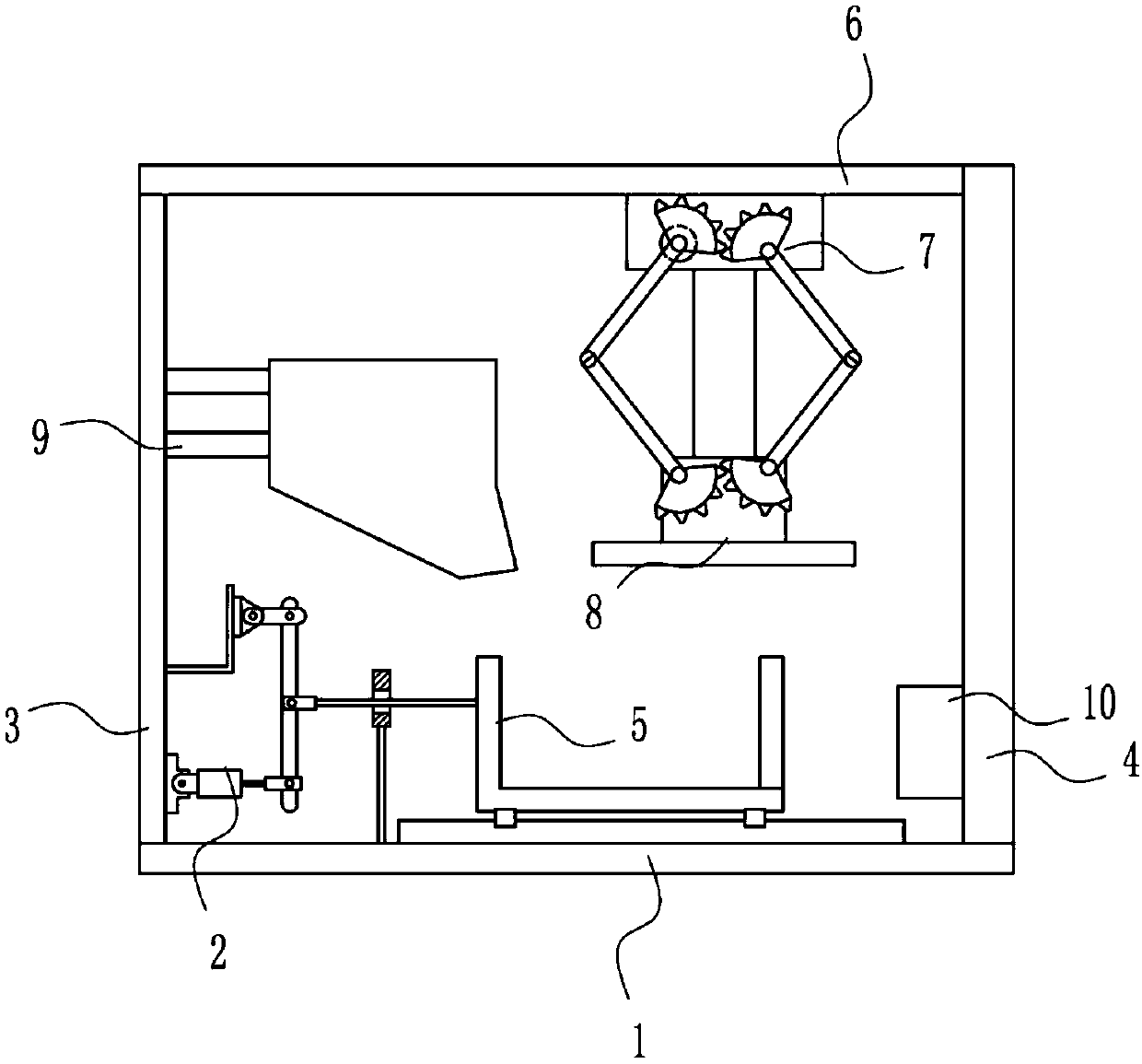

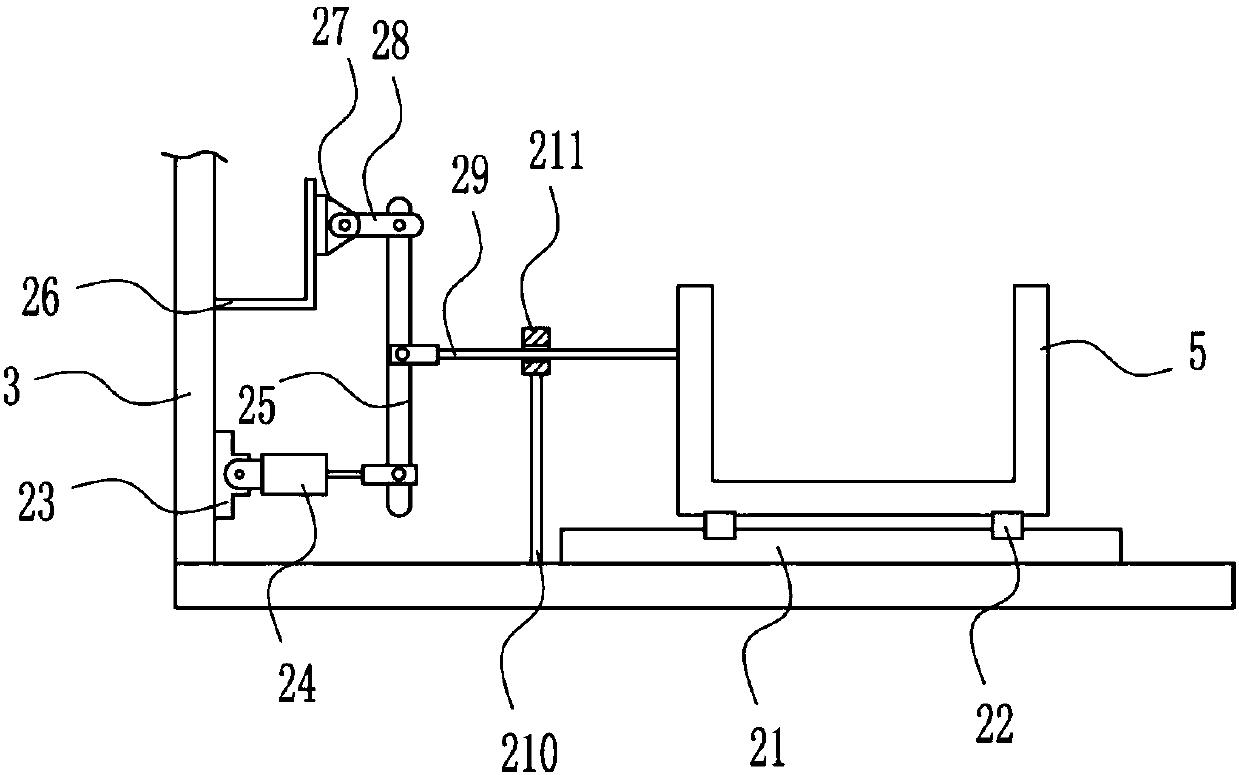

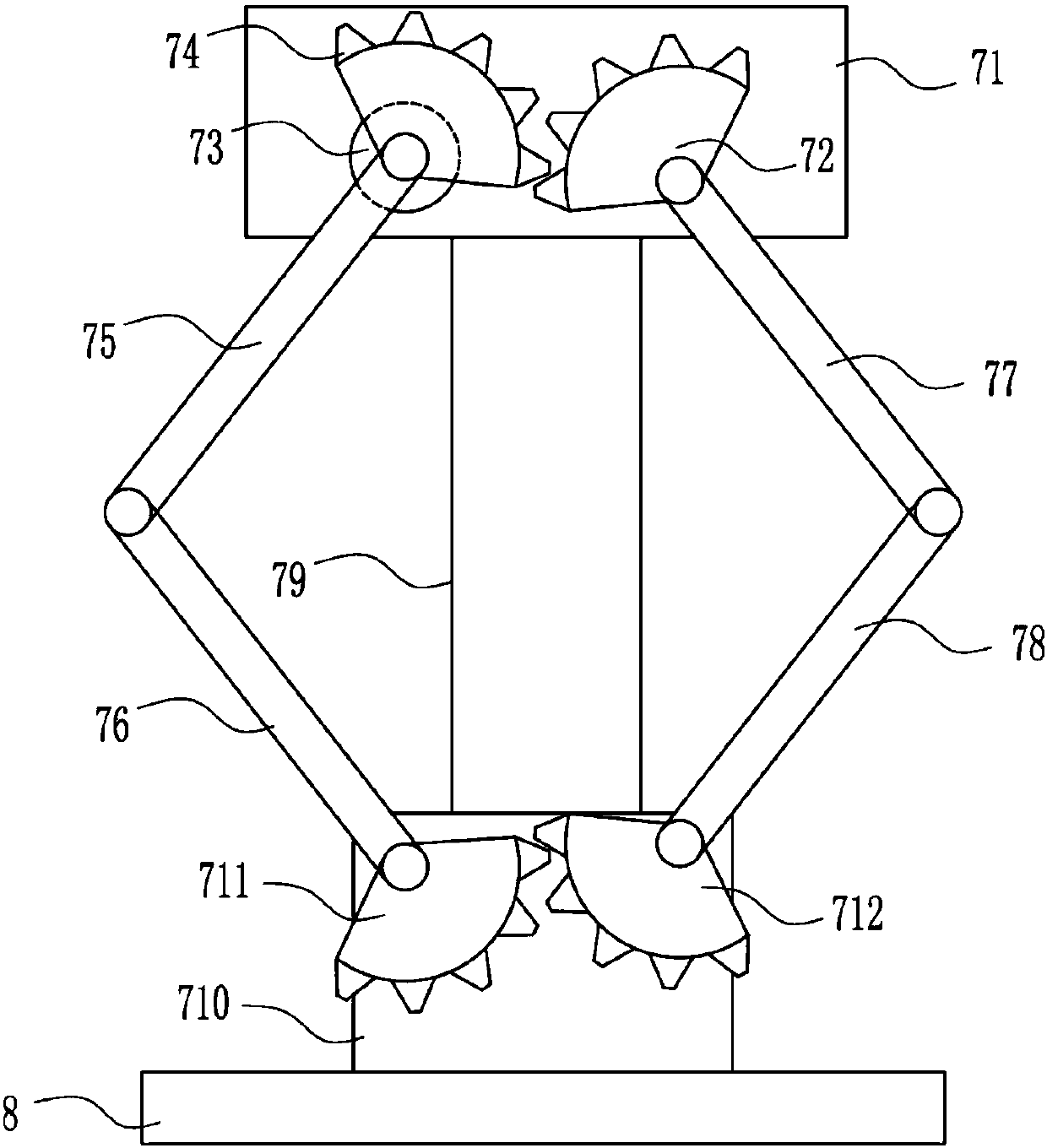

[0035] A rapid compaction equipment for metal processing waste, such as Figure 1-6 As shown, it includes a bottom plate 1, a moving device 2, a left frame 3, a right frame 4, a moving frame 5, a top plate 6, a lifting device 7, a pressure plate 8, a separating device 9 and a block 10, and the left side of the top of the bottom plate 1 is provided with a left Frame 3, the right frame 4 is provided on the top right side of the bottom plate 1, the mobile device 2 is provided on the left side of the left frame 3 and the top of the bottom plate 1, the mobile device 2 is provided with a mobile frame 5, and the top plate is provided on the top of the left frame 3 and the right frame 4 6. A lifting device 7 is provided on the right side of the bottom of the top plate 6, a pressure plate 8 is provided at the bottom of the lifting device 7, a separation device 9 is provided on the upper right side of the left frame 3, and a stopper 10 is provided on the lower left side of the right fram...

Embodiment 2

[0037] A rapid compaction equipment for metal processing waste, such as Figure 1-6 As shown, it includes a bottom plate 1, a moving device 2, a left frame 3, a right frame 4, a moving frame 5, a top plate 6, a lifting device 7, a pressure plate 8, a separating device 9 and a block 10, and the left side of the top of the bottom plate 1 is provided with a left Frame 3, the right frame 4 is provided on the top right side of the bottom plate 1, the mobile device 2 is provided on the left side of the left frame 3 and the top of the bottom plate 1, the mobile device 2 is provided with a mobile frame 5, and the top plate is provided on the top of the left frame 3 and the right frame 4 6. A lifting device 7 is provided on the right side of the bottom of the top plate 6, a pressure plate 8 is provided at the bottom of the lifting device 7, a separation device 9 is provided on the upper right side of the left frame 3, and a stopper 10 is provided on the lower left side of the right fram...

Embodiment 3

[0040] A rapid compaction equipment for metal processing waste, such as Figure 1-6 As shown, it includes a bottom plate 1, a moving device 2, a left frame 3, a right frame 4, a moving frame 5, a top plate 6, a lifting device 7, a pressure plate 8, a separating device 9 and a block 10, and the left side of the top of the bottom plate 1 is provided with a left Frame 3, the right frame 4 is provided on the top right side of the bottom plate 1, the mobile device 2 is provided on the left side of the left frame 3 and the top of the bottom plate 1, the mobile device 2 is provided with a mobile frame 5, and the top plate is provided on the top of the left frame 3 and the right frame 4 6. A lifting device 7 is provided on the right side of the bottom of the top plate 6, a pressure plate 8 is provided at the bottom of the lifting device 7, a separation device 9 is provided on the upper right side of the left frame 3, and a stopper 10 is provided on the lower left side of the right fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com