Multi-stage solid-liquid separation device

A solid-liquid separation and pre-separation tube technology, applied in transportation and packaging, solid waste removal, chemical instruments and methods, etc. Facilitate the separation and recycling of oil and water, facilitate transportation and treatment, and reduce the effect of water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

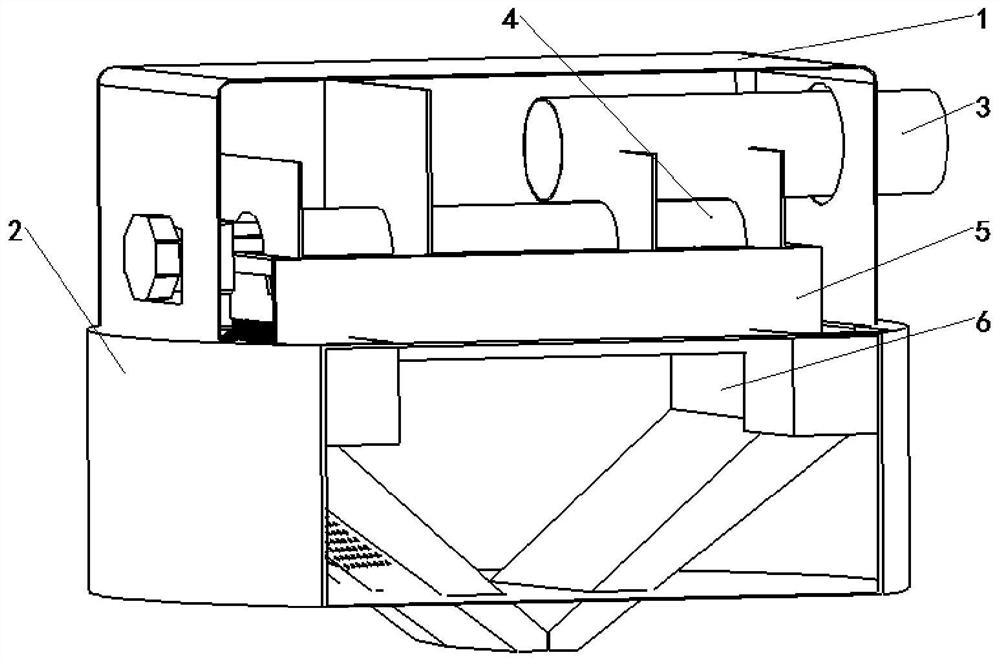

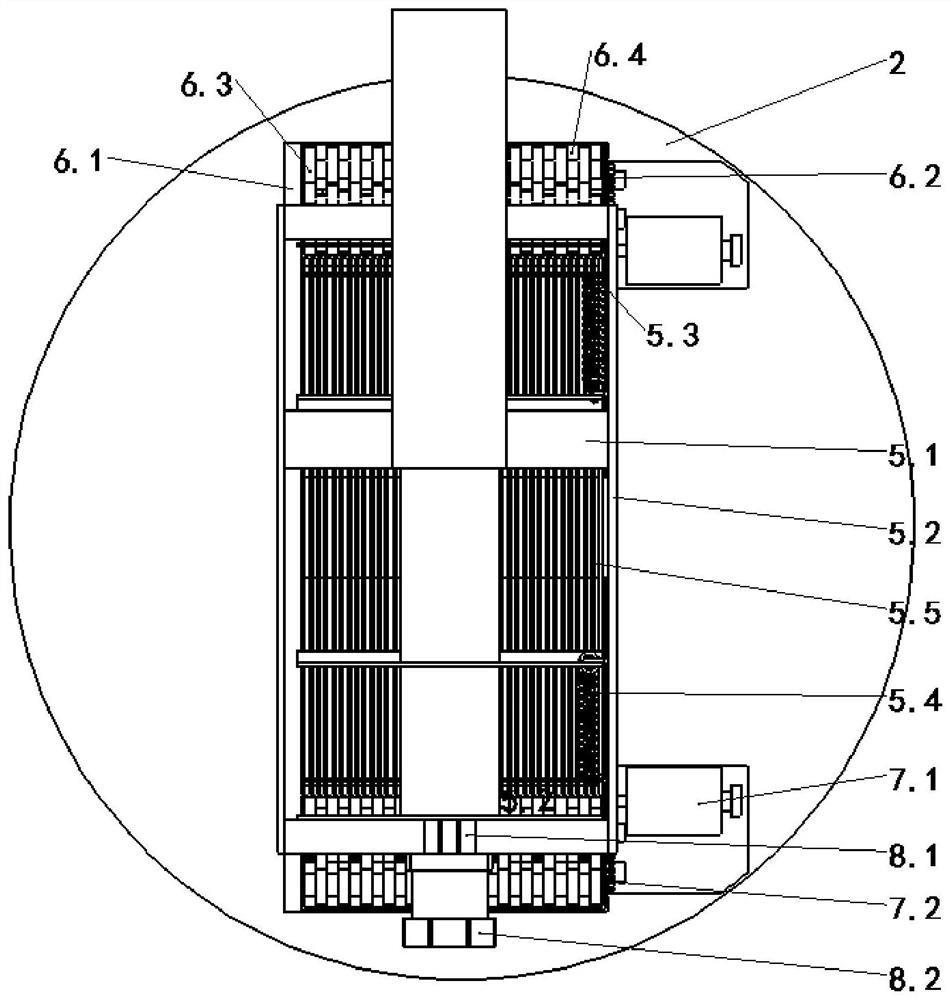

[0017] combine Figure 1-6 , the present invention is a multi-stage solid-liquid separation device, comprising: an upper box body 1, a lower box body 2, a feed pipe 3, a pre-separation pipe 4, a scraper slag remover 5, a crushing slag remover 6, a crusher Driving device 7, scraper driving device 8.

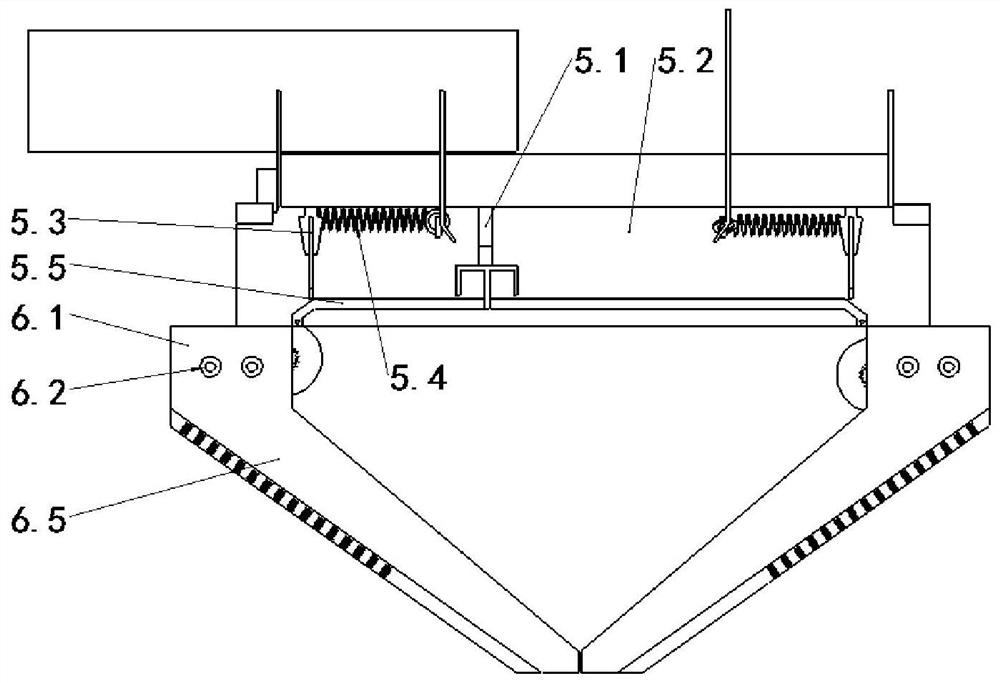

[0018] The upper box 1 of the multi-stage solid-liquid separation device of the present invention is rectangular, and the lower box 2 is cylindrical, including a feed pipe 3 and a pre-separation pipe 4 located on the upper box, and a scraper slag remover located below the pre-separation pipe 5 includes a scraper 5.1, a partition 5.2, a swing platen 5.3, a spring 5.4, and a filter grid 5.5. The crushing and slag removal machine located in the lower box 2 includes a hopper 6.1, a main shaft 6.2, a crushing blade 6.3, and a throwing blade 6.4. Tapered pipes 6.5. Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com