Patents

Literature

36results about How to "Easy to move simultaneously" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

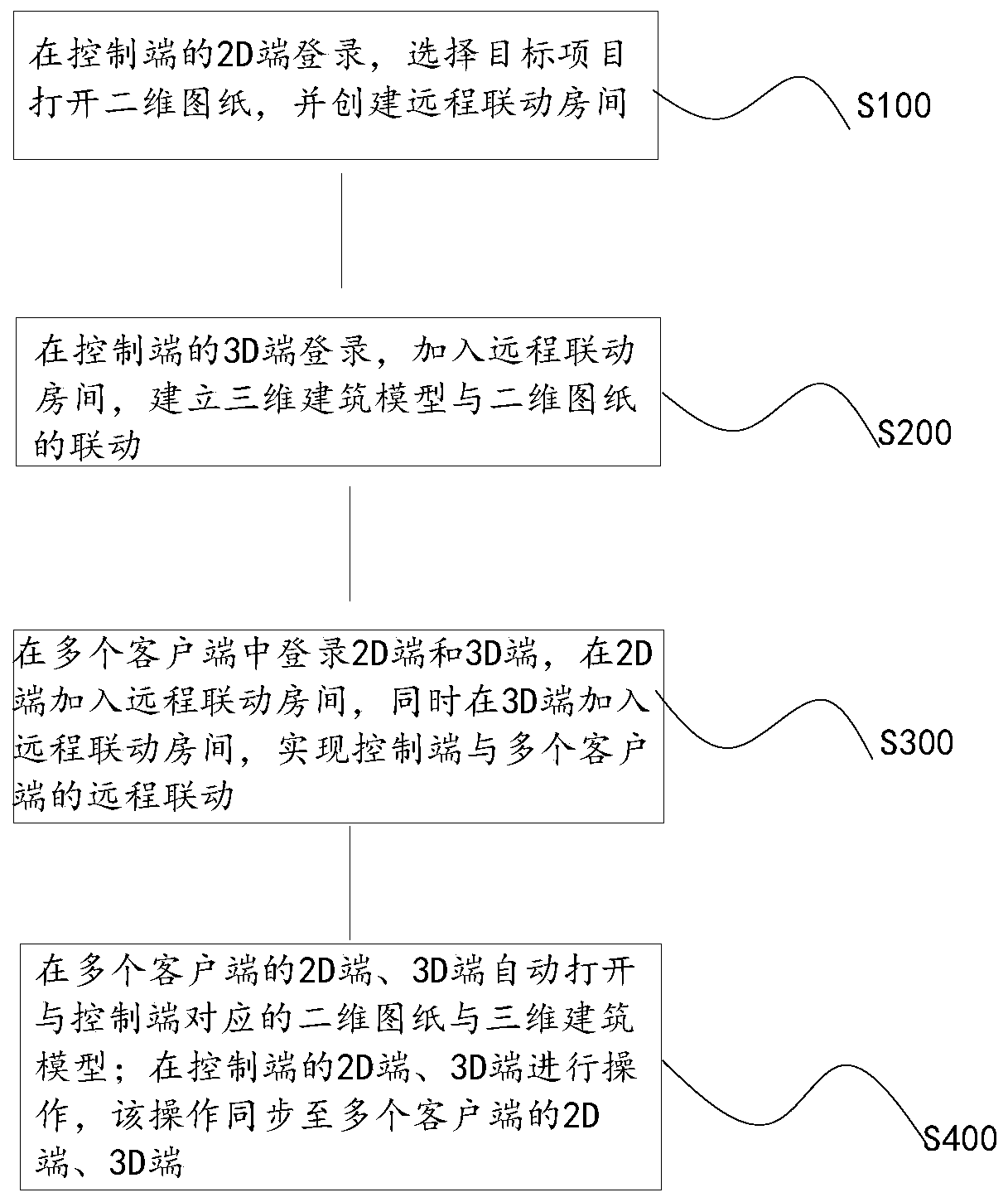

Linkage method and system for three-dimensional building model and two-dimensional drawing

ActiveCN110554901AEasy to viewFacilitate communicationExecution for user interfacesTotal factory controlEngineeringBuilding model

The invention discloses a linkage method and system for a three-dimensional building model and a two-dimensional drawing, and the method comprises the steps: logging in at a 2D end of a control end, selecting a target project to open the two-dimensional drawing, and creating a remote linkage room; logging in at a 3D end of the control end, adding a remote linkage room, and establishing linkage between the three-dimensional building model and the two-dimensional drawing; logging in a 2D end and a 3D end in the plurality of clients, adding a remote linkage room at the 2D end, and adding a remotelinkage room at the 3D end at the same time to realize remote linkage between the control end and the plurality of clients; automatically opening a two-dimensional drawing and a three-dimensional building model corresponding to the control end at the 2D ends and the 3D ends of the plurality of clients; and performing operation at the 2D end and the 3D end of the control end, wherein the operationis synchronized to the 2D ends and the 3D ends of the plurality of clients. On the basis of realizing linkage of the two-dimensional drawing and the three-dimensional building model, remote synchronous linkage operation of multiple users can be realized.

Owner:深圳前海贾维斯数据咨询有限公司

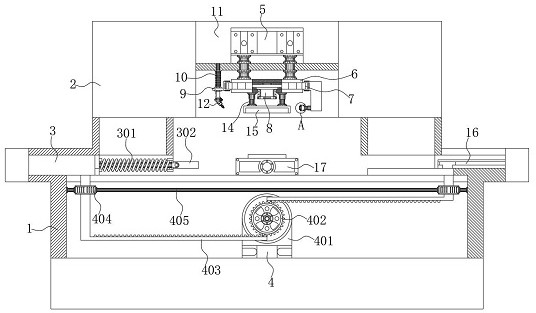

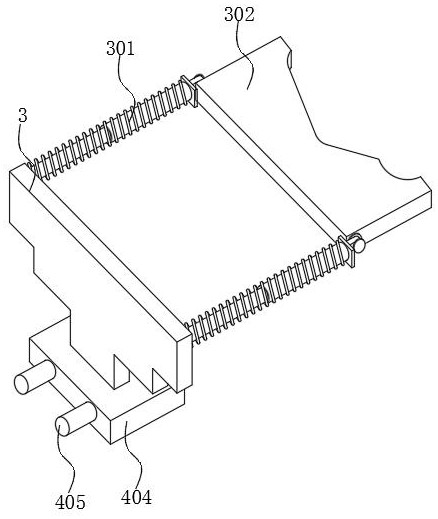

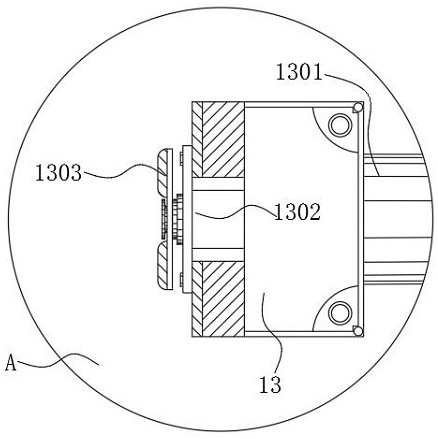

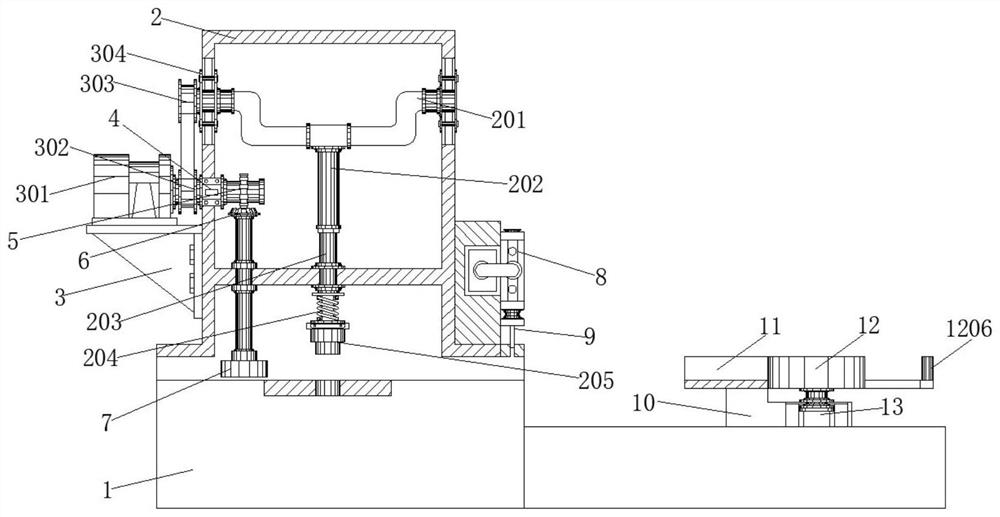

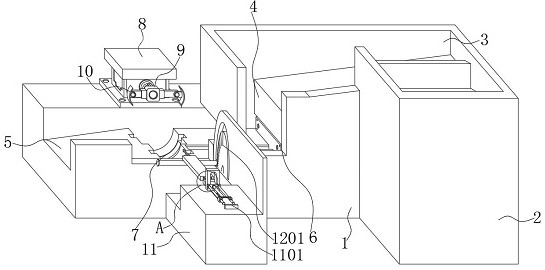

Retro robot pendant mechanical arm welding spot grinding and machining production device

InactiveCN112518324AEasy to passEasy to weldEdge grinding machinesWelding/cutting auxillary devicesMachineWelding

The invention discloses a retro robot pendant mechanism arm welding spot grinding and machining production device. The retro robot pendant mechanical arm welding spot grinding and machining productiondevice comprises a welding machine box, feeding boxes are symmetrically arranged on the two sides of the top of an inner cavity of the welding machine box, a parallel sliding assembly is arranged atthe bottom of the machine box inner cavity of the welding machine box, a welding head is fixedly installed at the bottom of a support in a bolt clamping mode, a grinding assembly is arranged at the bottom of the right side of a rotary disc, and a second feeding block is arranged at the bottom of the feeding box on the right side of the inner cavity of the welding machine box. A first feeding blockand the second feeding block are symmetrically arranged at the bottom of the feeding box, the parallel sliding assembly is arranged, the first feeding block and the second feeding block can be conveniently driven to transfer a mechanical arm to the bottom of a positioning block, meanwhile, the welding head and the grinding assembly are arranged on the two sides of the rotary disc, so that weldingmarks on the surface of the mechanical arm can be conveniently ground while the mechanical arm is welded, infirmness of gluing and unattractiveness of the surface during welding are avoided, and therefore, the assembly production of the mechanical arm is facilitated.

Owner:重庆优云迪科技有限公司

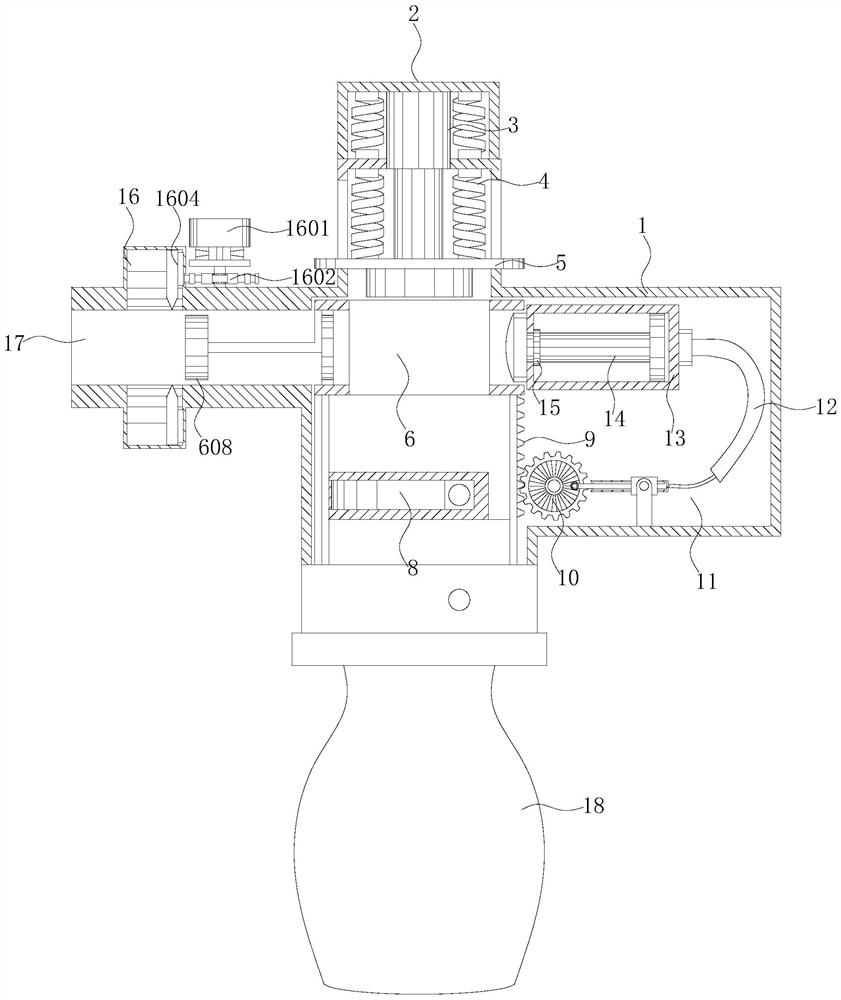

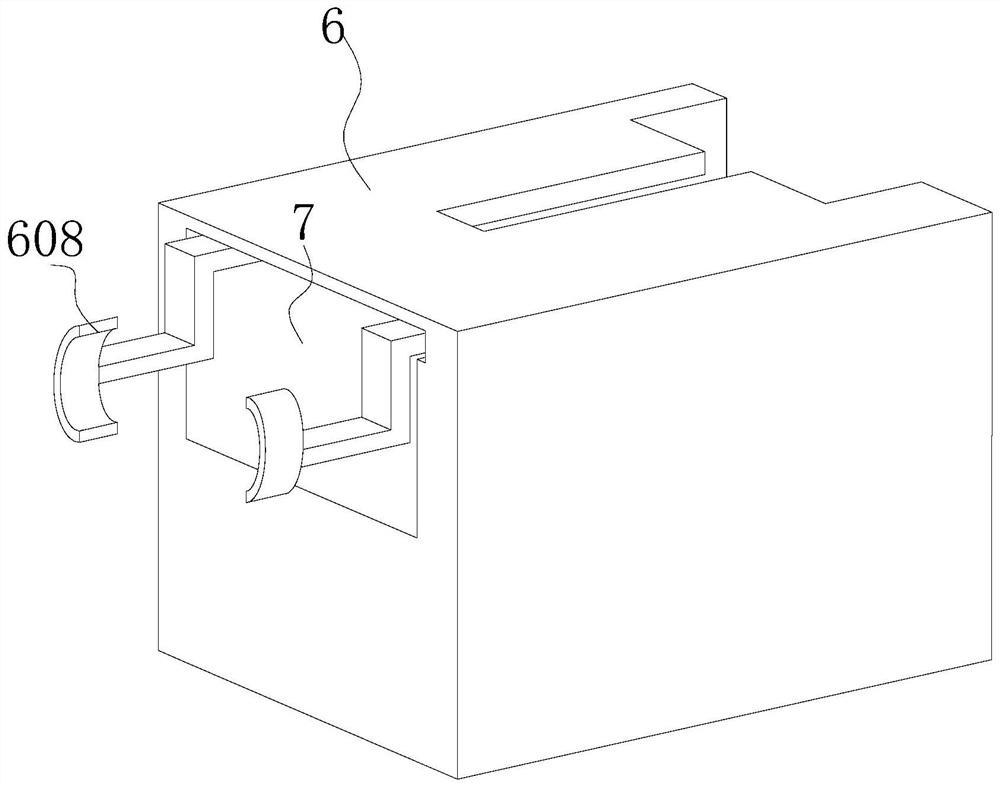

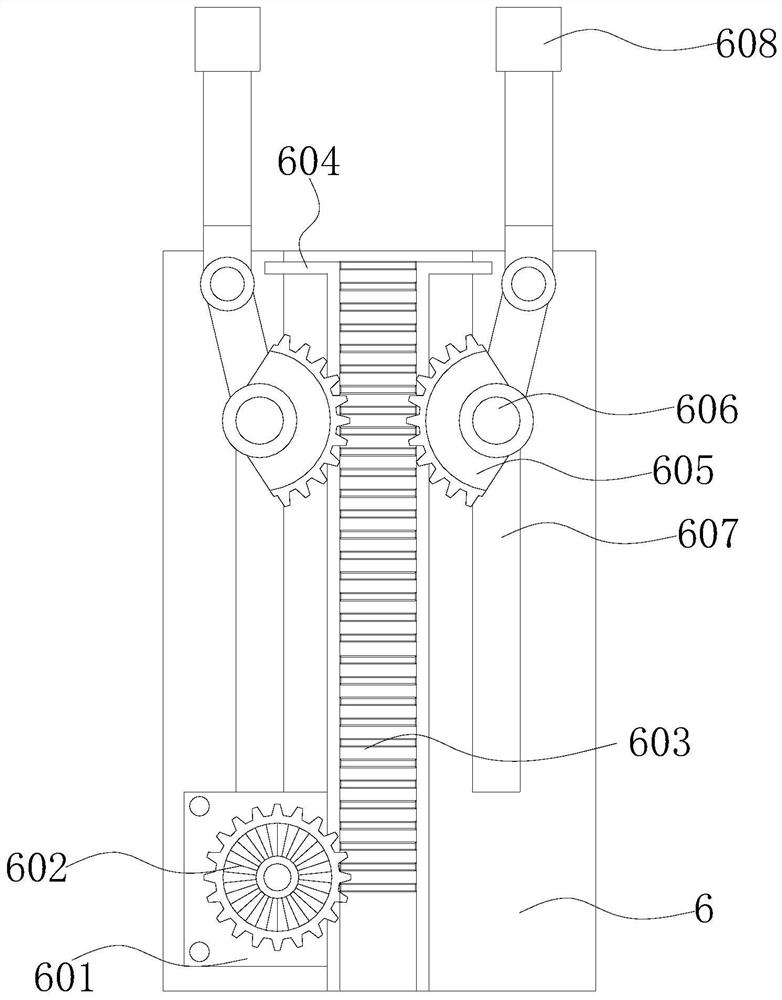

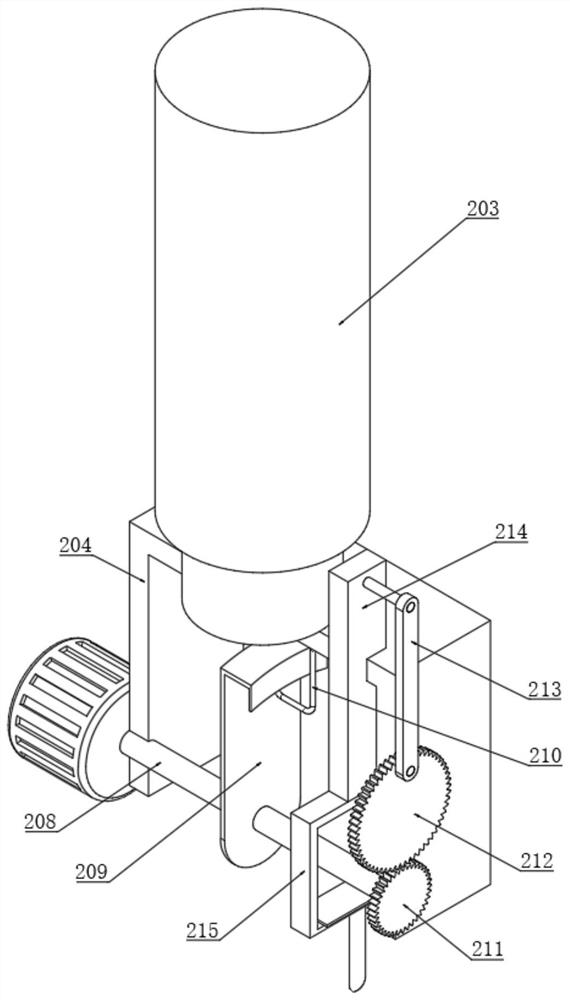

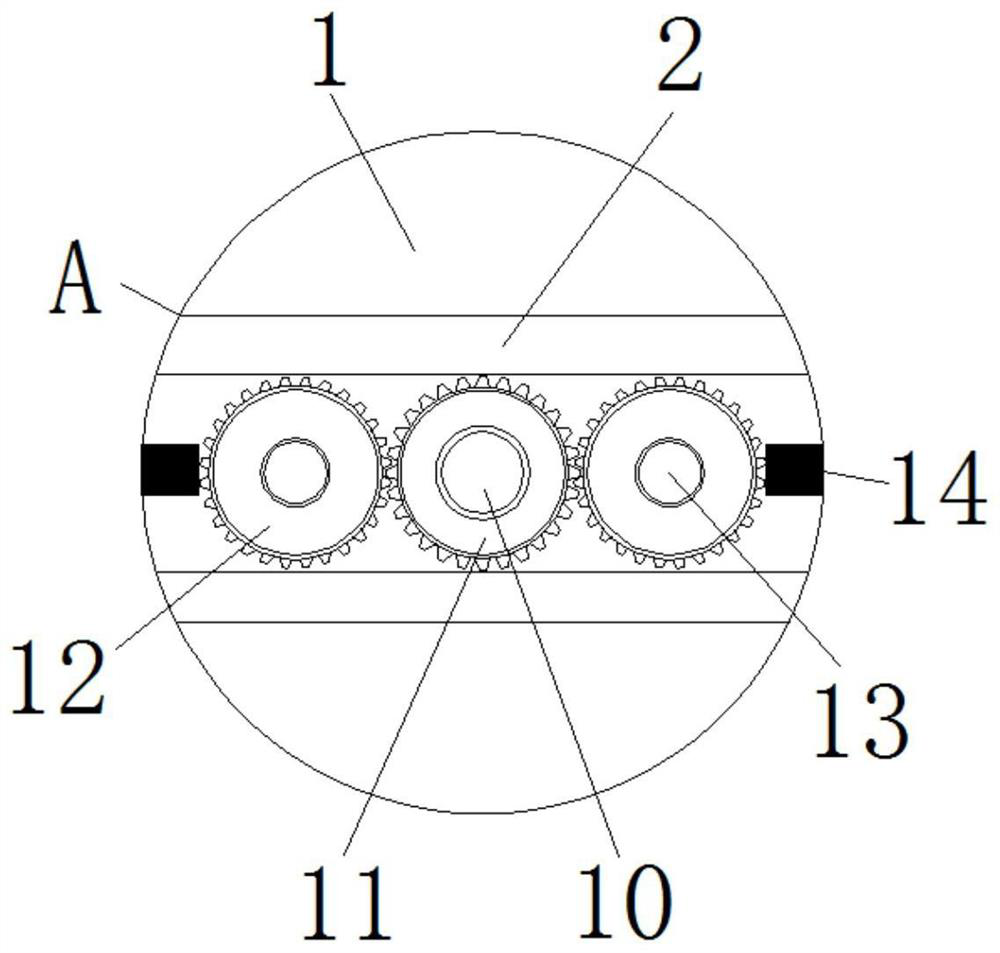

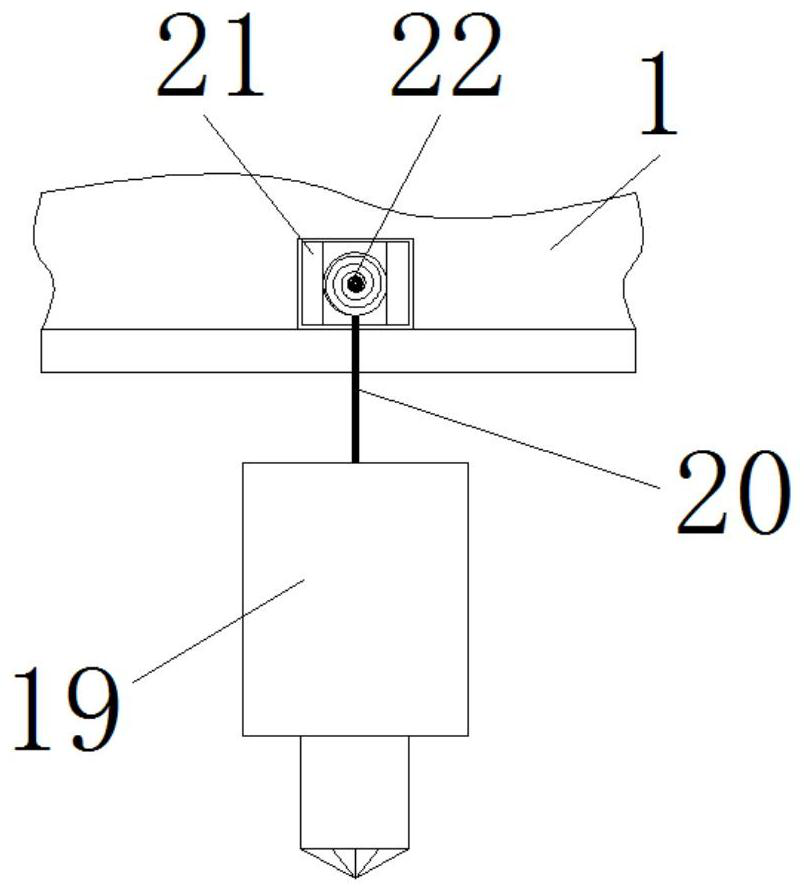

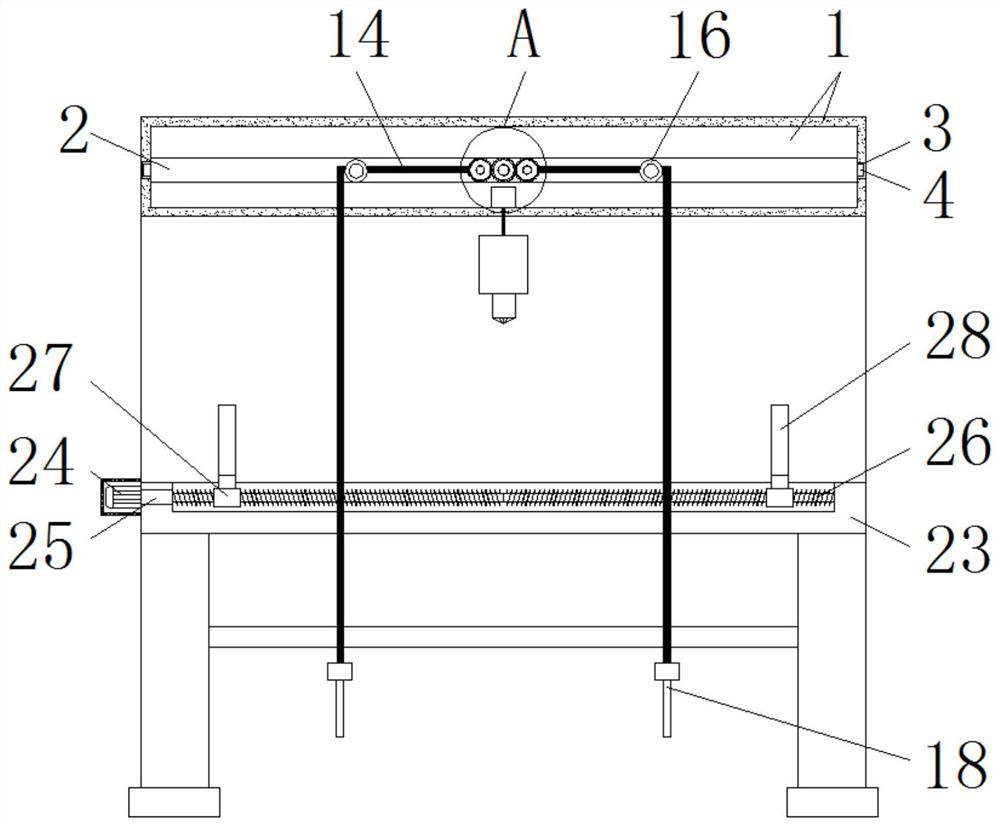

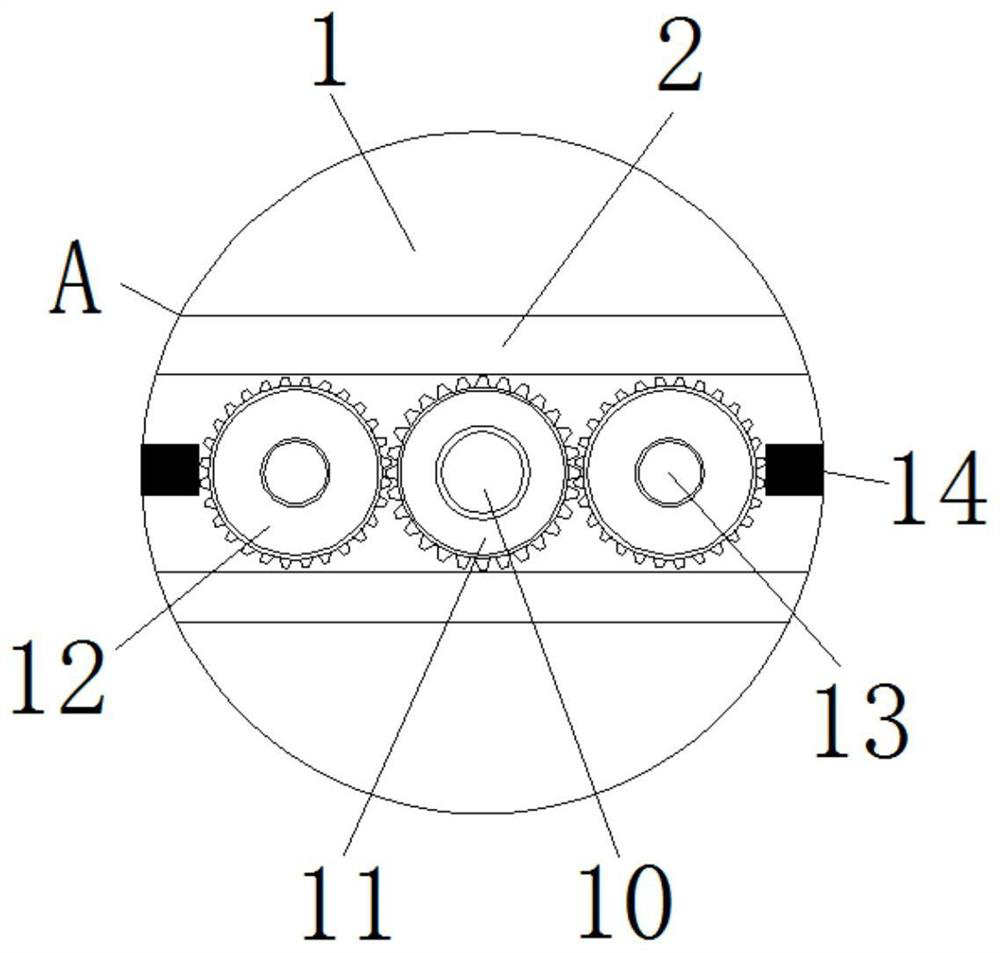

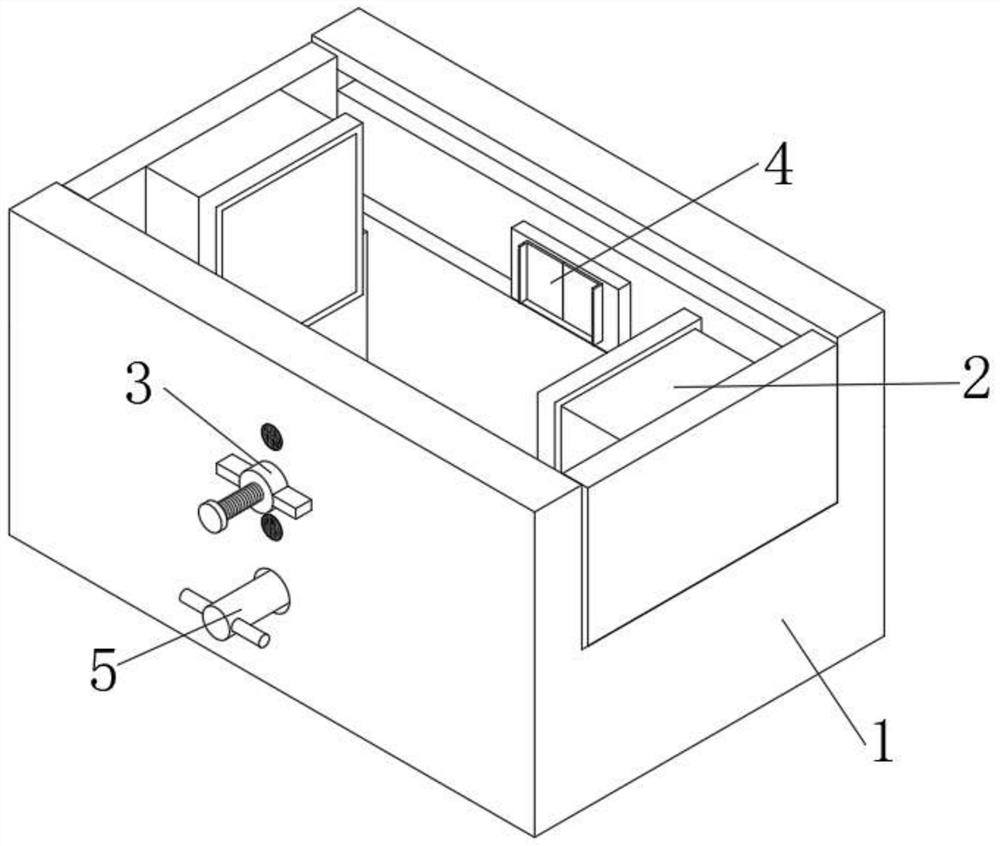

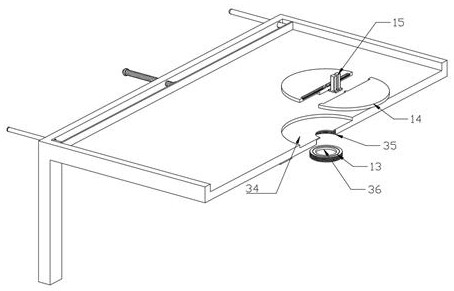

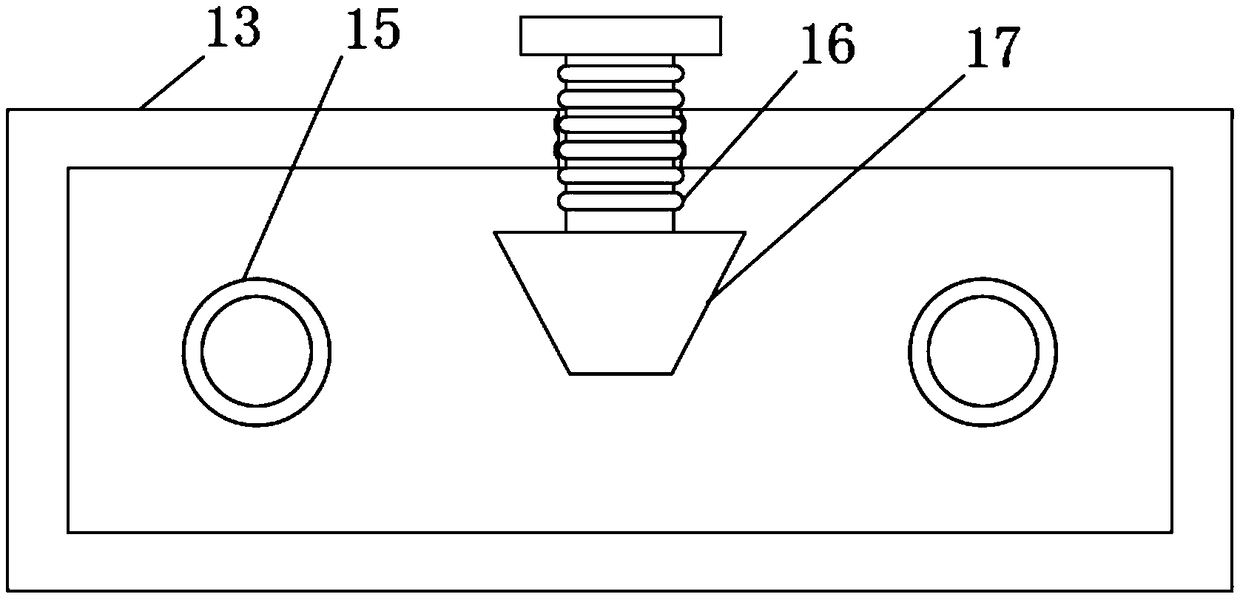

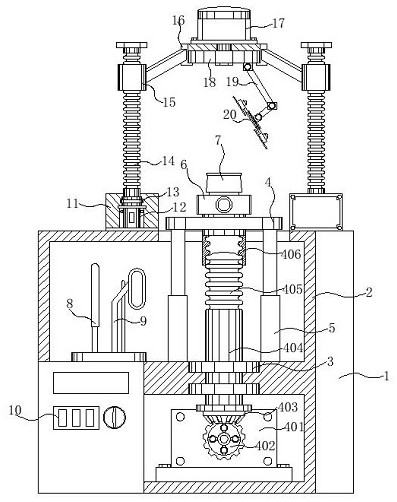

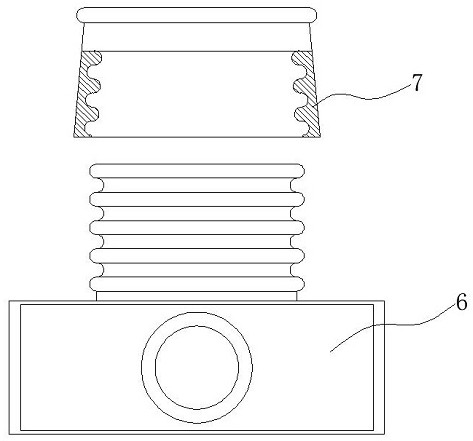

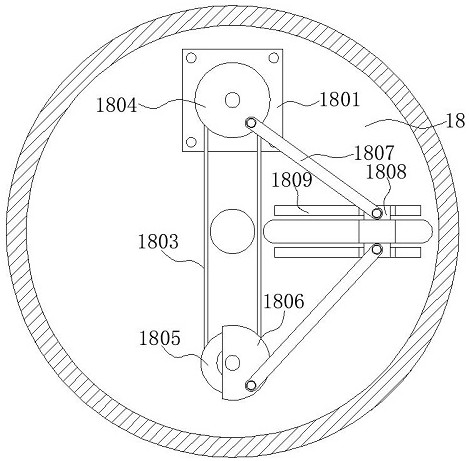

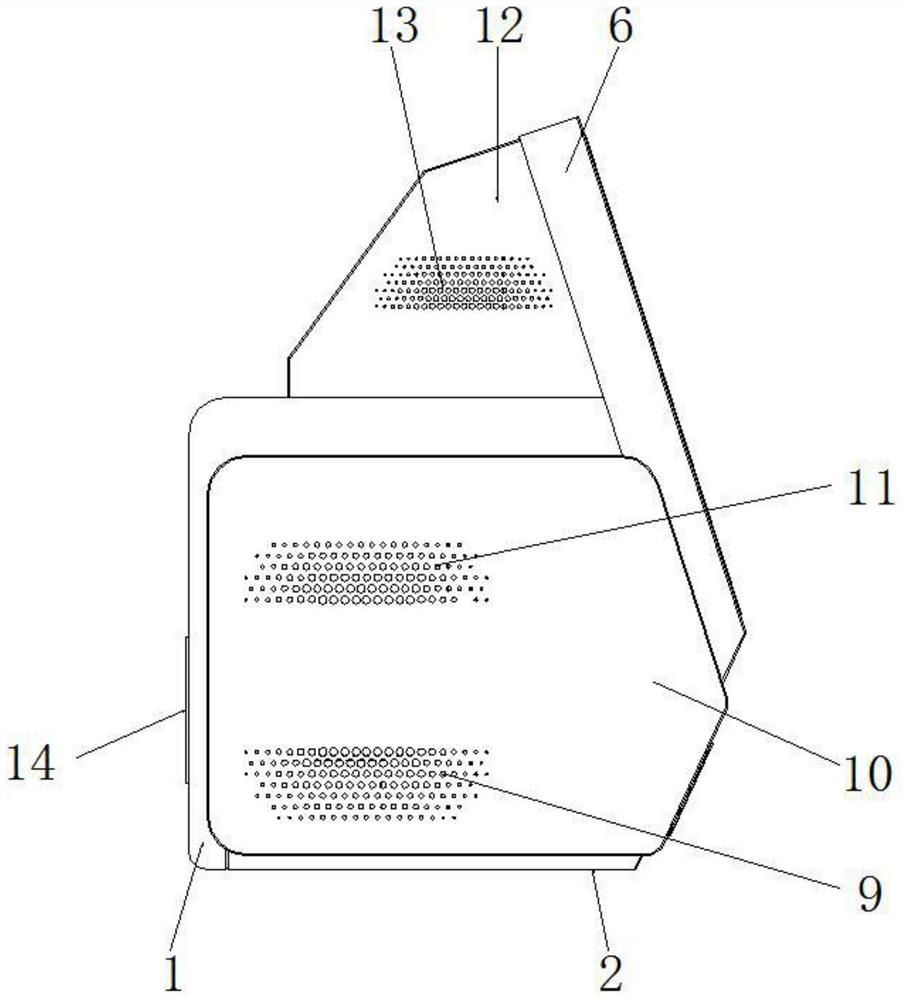

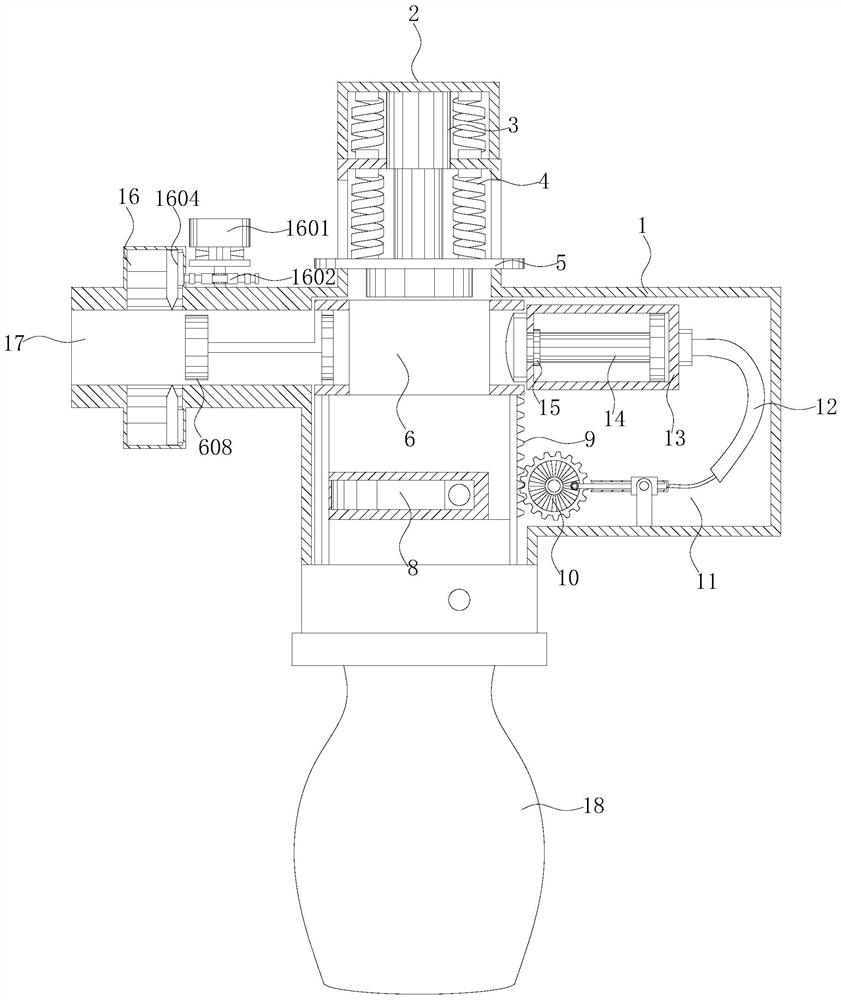

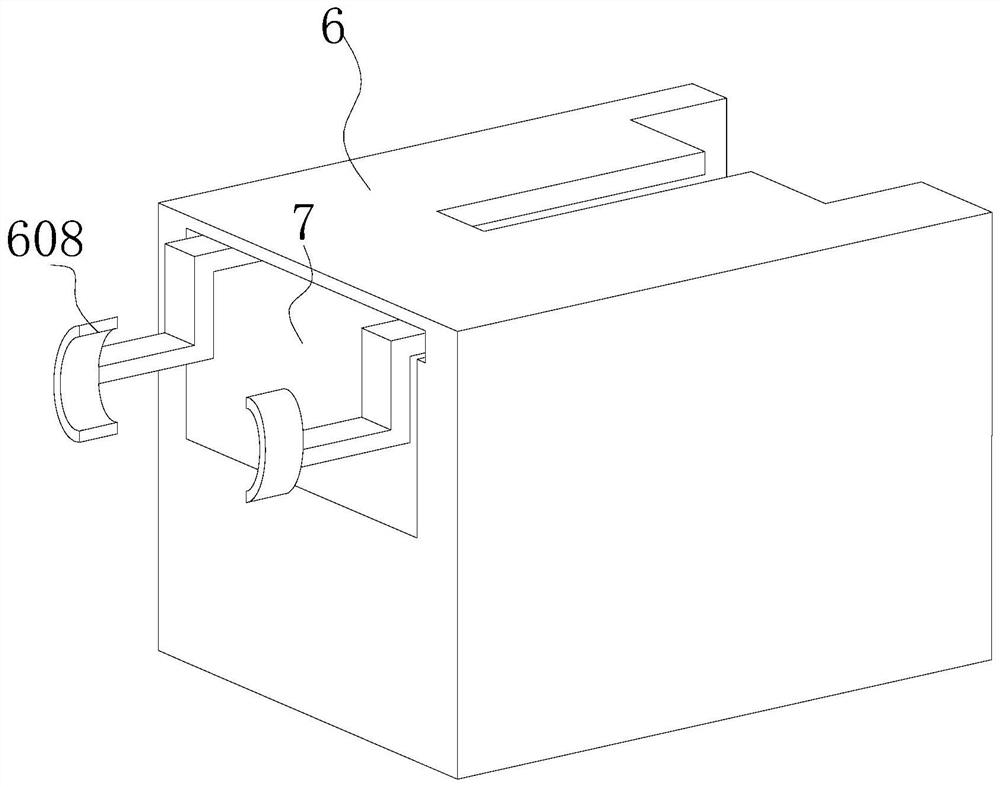

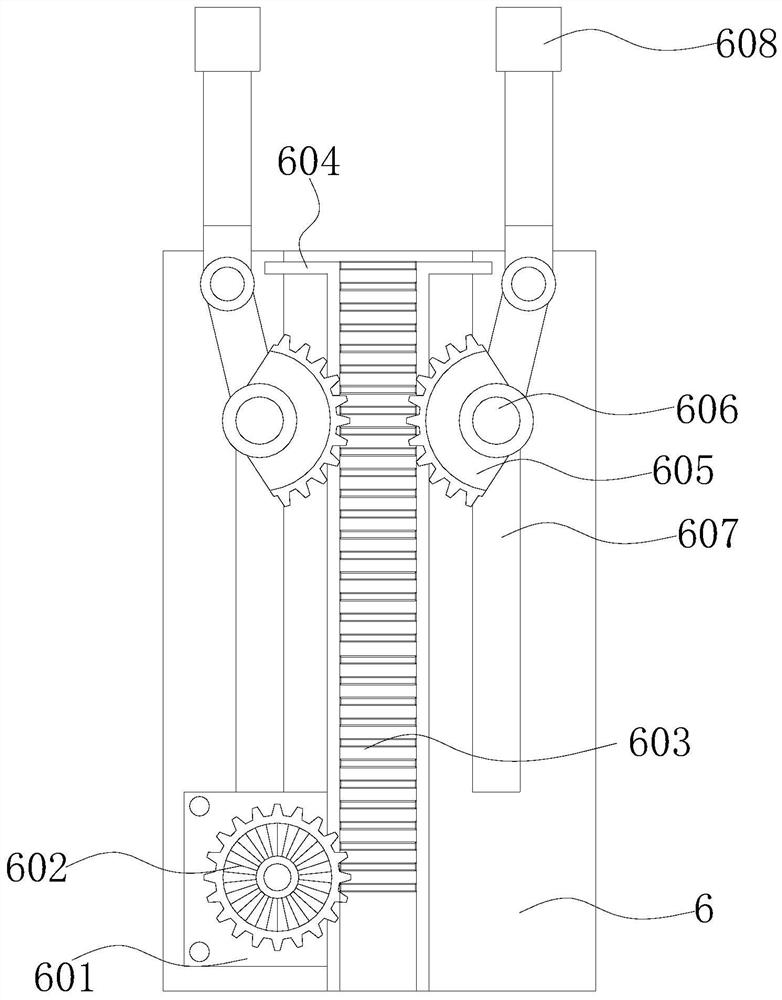

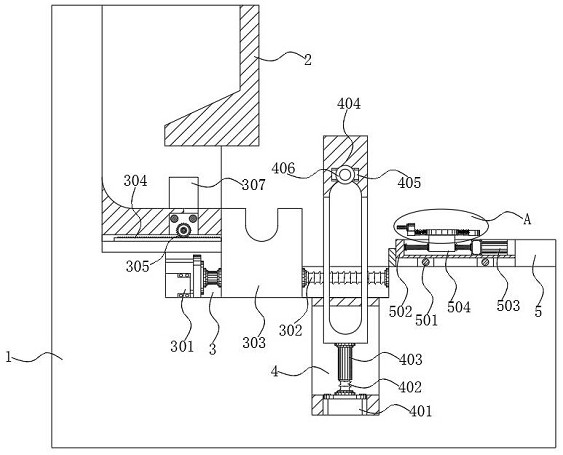

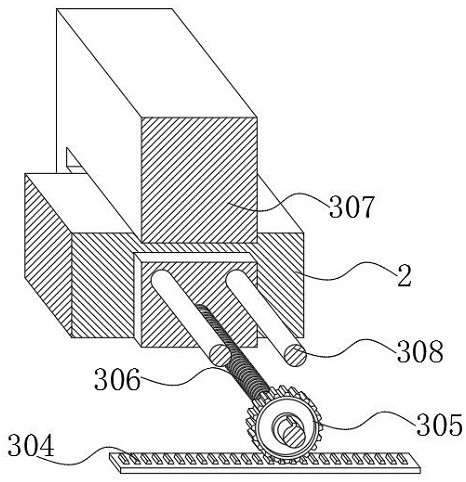

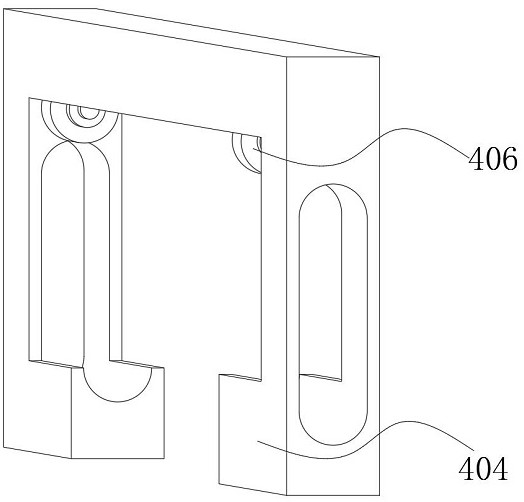

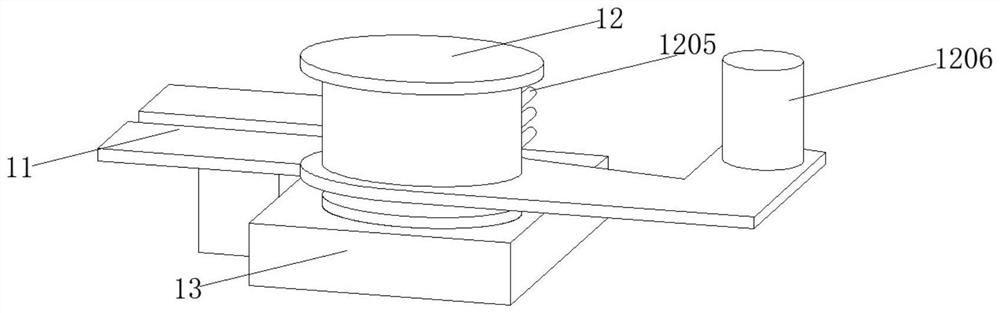

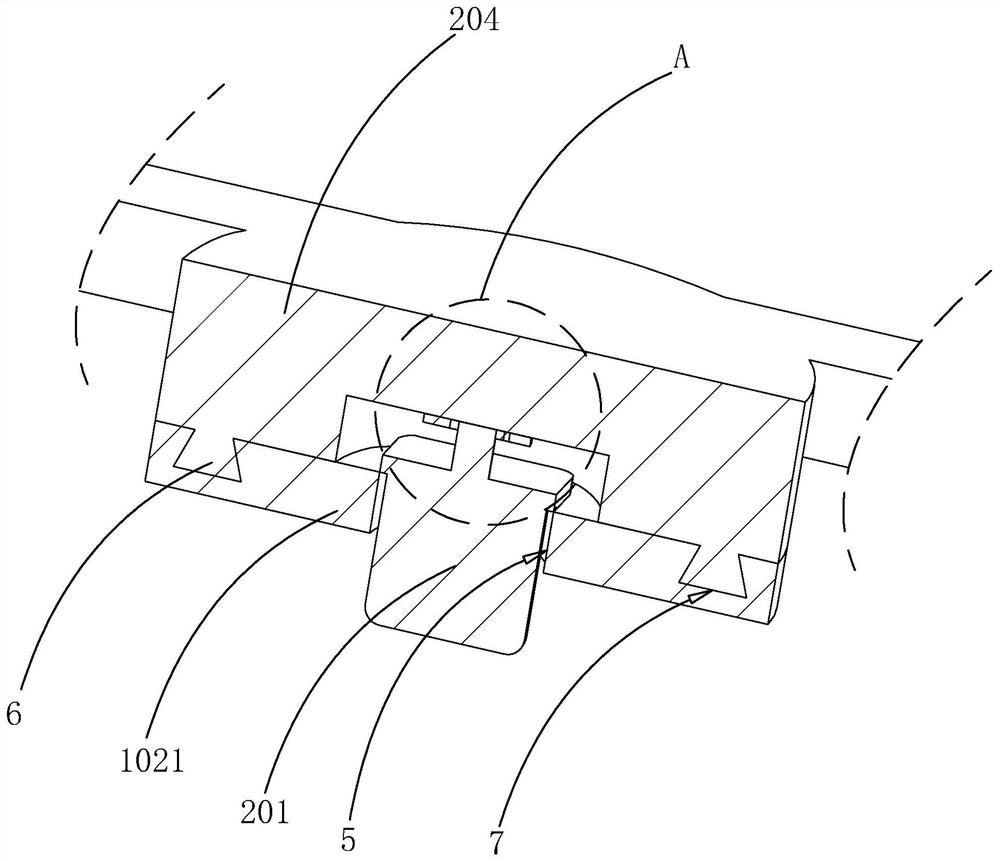

Highland barley paper pasting device applied to batteries

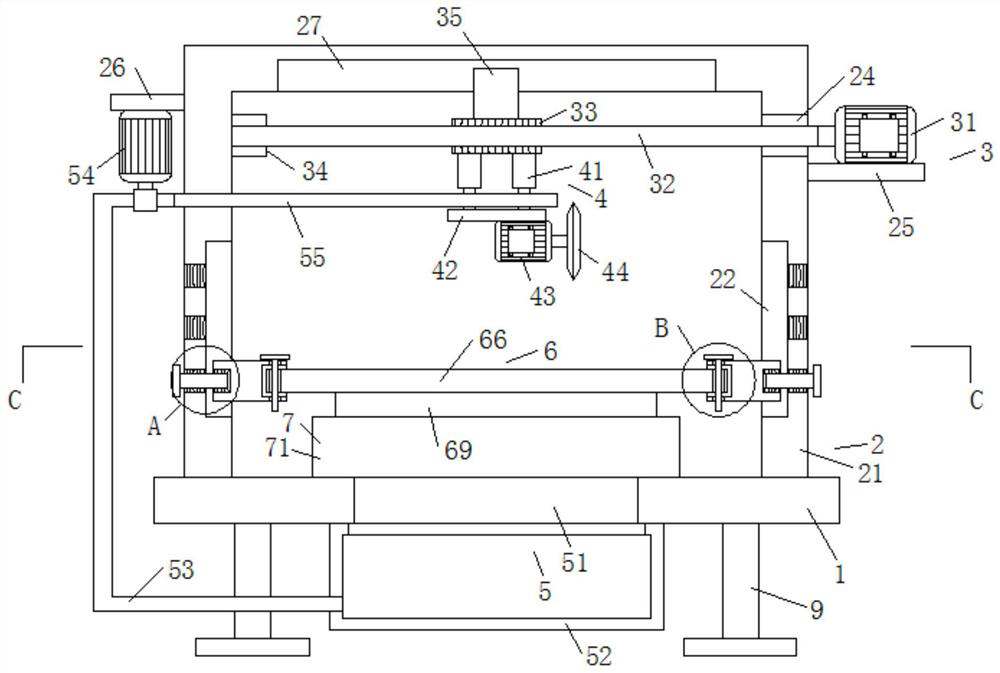

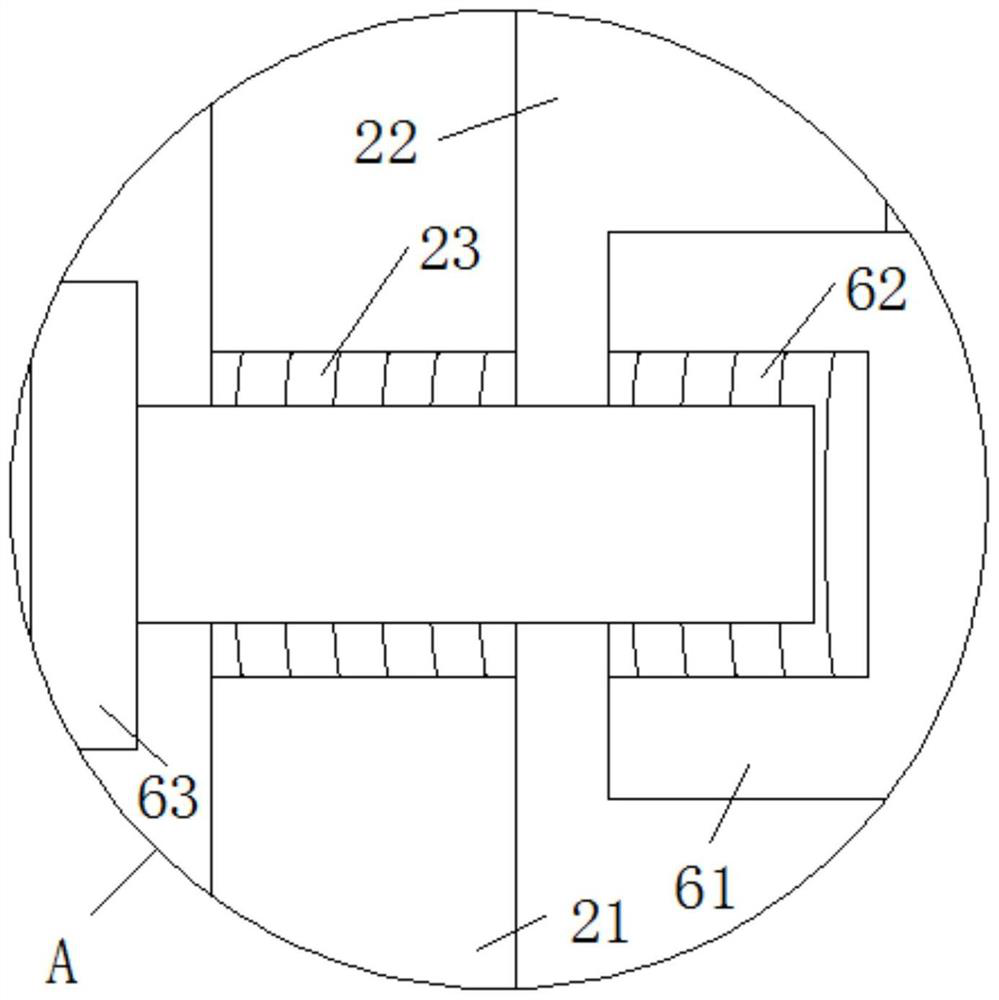

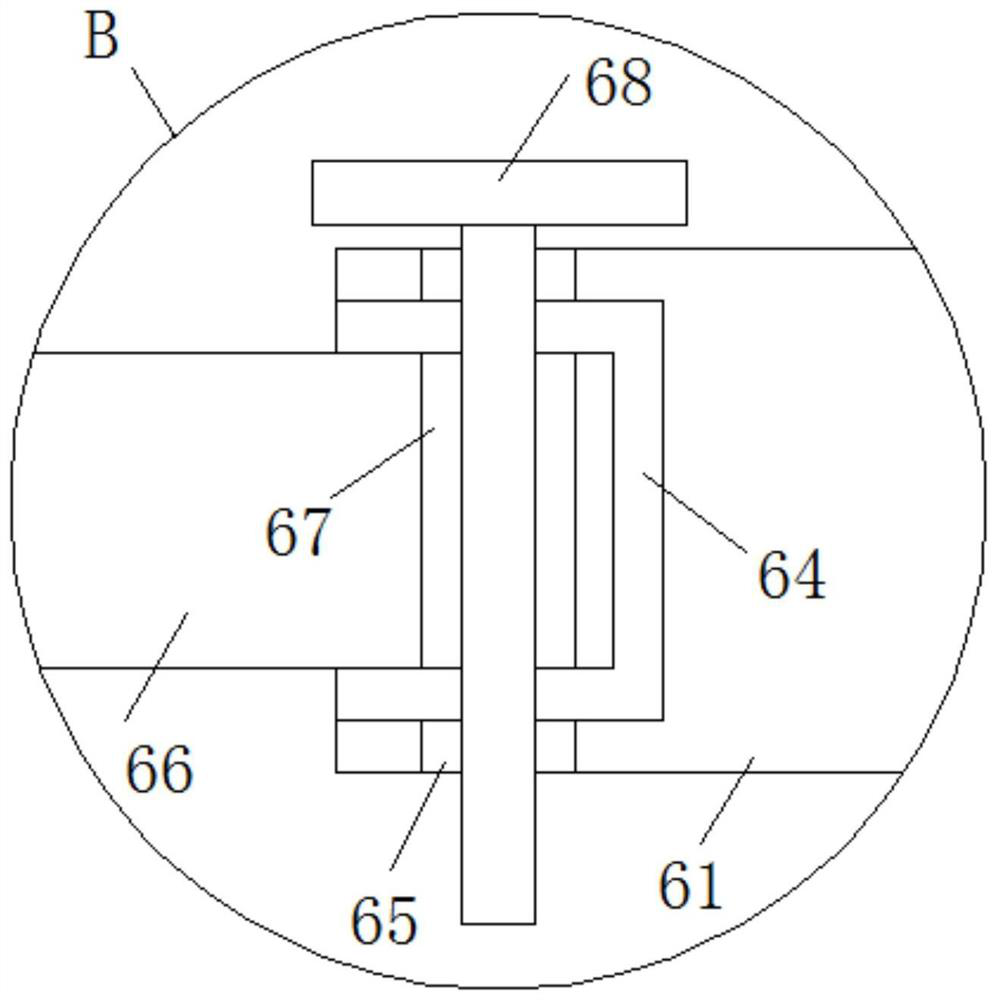

PendingCN108630999ASteady guidance and supportEasy to move simultaneouslyAssembling battery machinesFinal product manufactureEngineeringGear drive

Owner:贵州鸿兴时代动力新能源科技有限公司

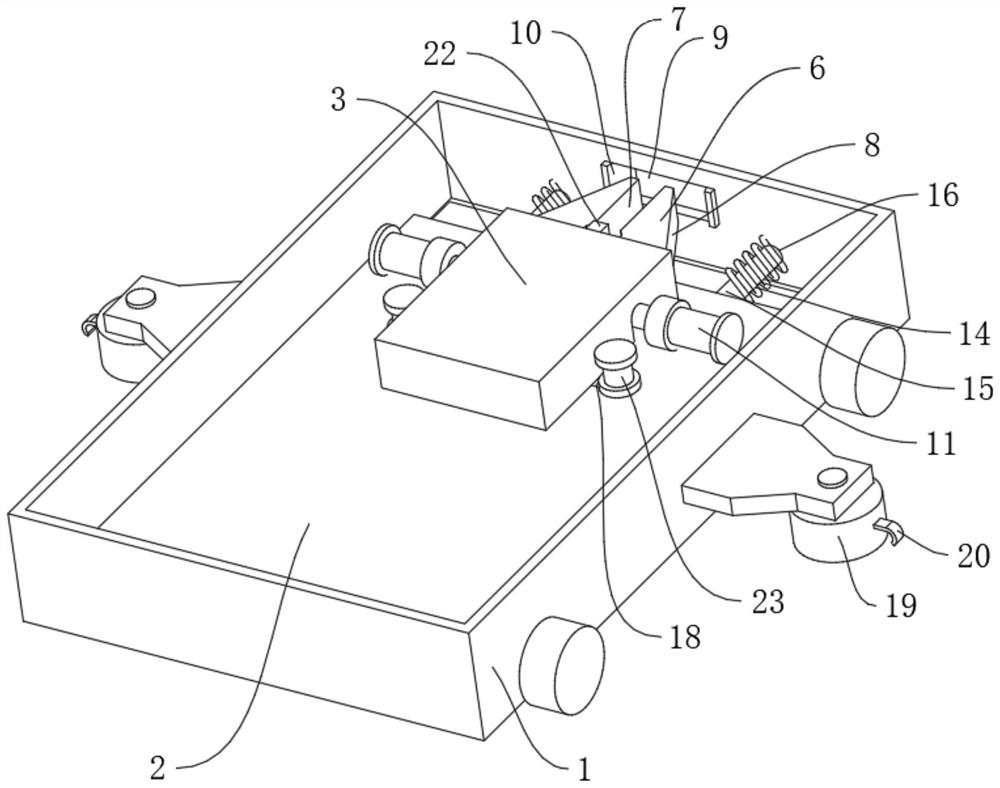

Cable breakpoint wiring device for electric power

ActiveCN111969504AEasy to fixEasy to separateLine/current collector detailsApparatus for removing/armouring cablesStructural engineeringInsulation layer

The invention discloses a cable breakpoint wiring device for electric power. The device comprises a body, a feeding mechanism is arranged in the middle of the upper surface of the body; a telescopic rod is mounted in the middle of the interior of the feeding mechanism; a material receiving opening is formed in the surface of the left side of the clamping mechanism; a second rack is arranged underthe right side surface of the clamping mechanism; a feeding hole is formed in the center of the left side surface of the body; a collecting box is mounted under the body; and the clamping mechanism and the cutting mechanism are arranged in the body. The body is arranged, so that the clamping mechanism and the cutting mechanism can be fixed conveniently, through arrangement of the cutting mechanism, body injuries caused by manual misoperation of a technician can be avoided conveniently through mechanical operation, meanwhile, through arrangement of the clamping mechanism, a cable insulation layer can be fixed conveniently, and therefore separation between the insulation layer and an electric wire is facilitated.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO

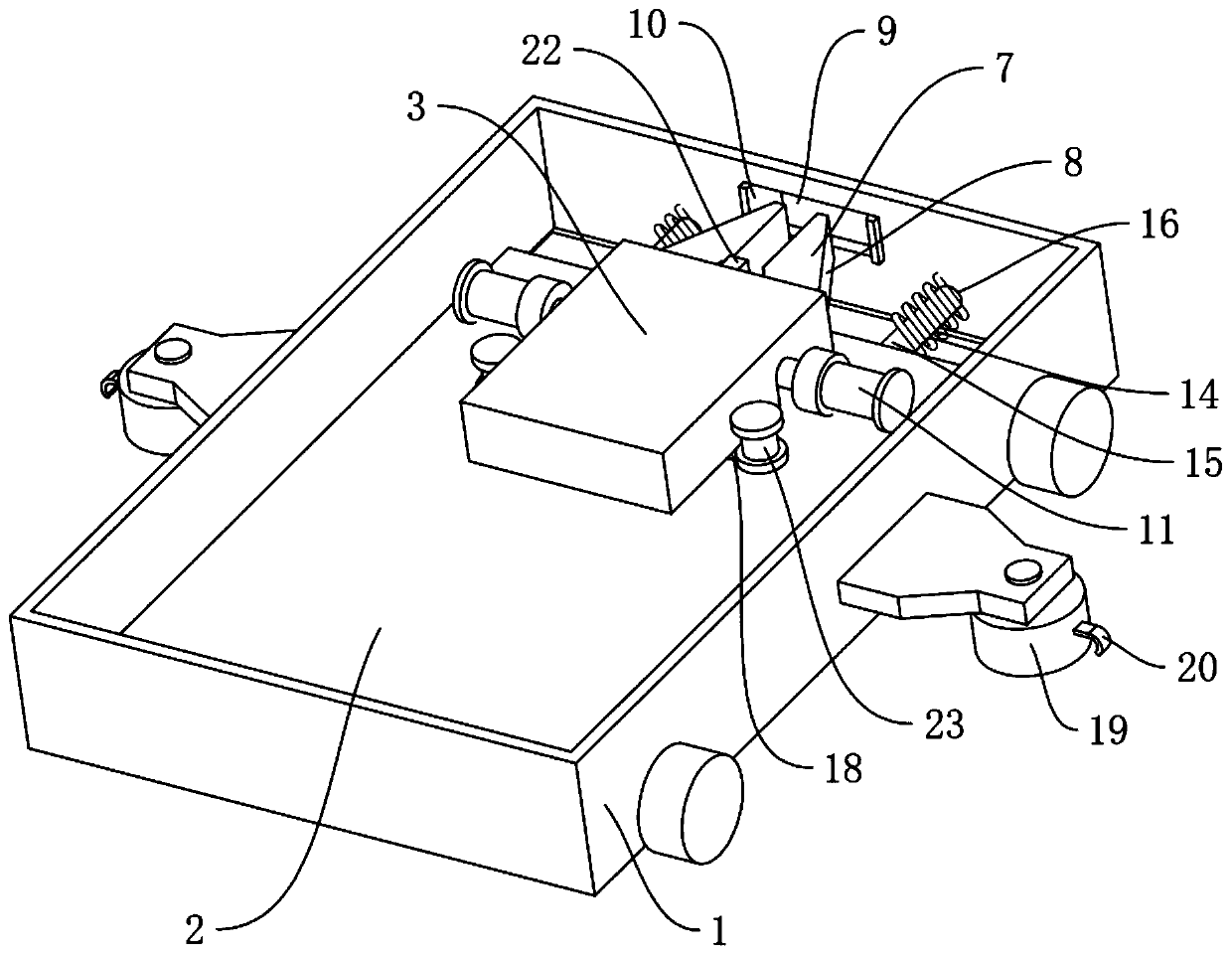

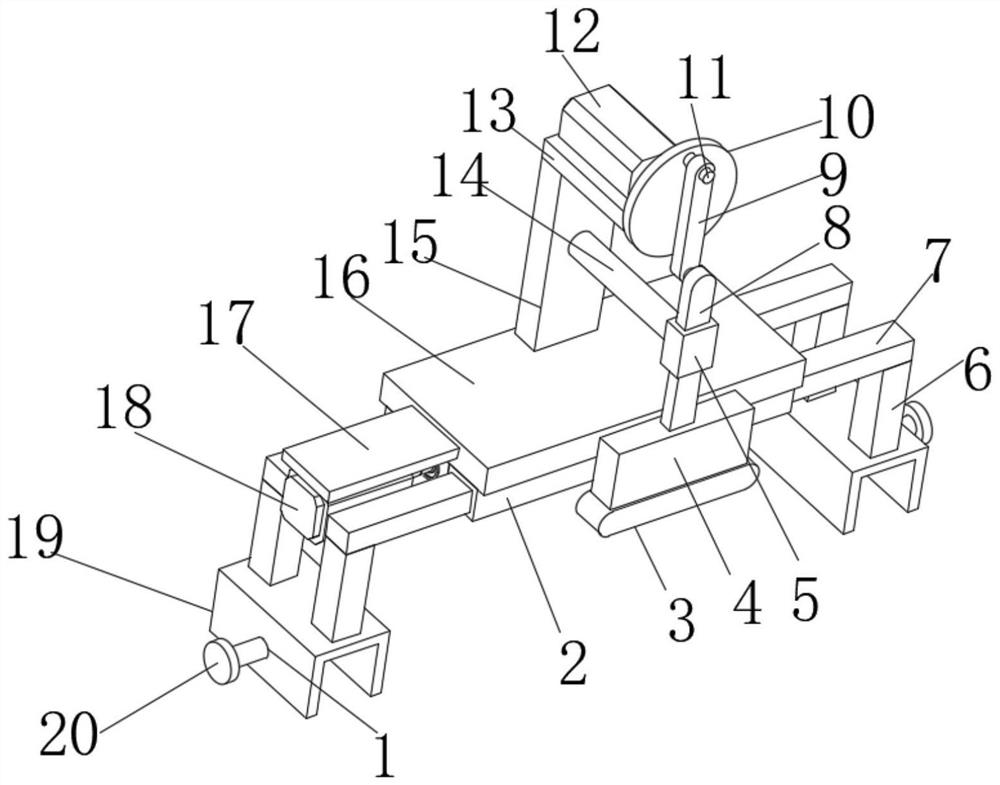

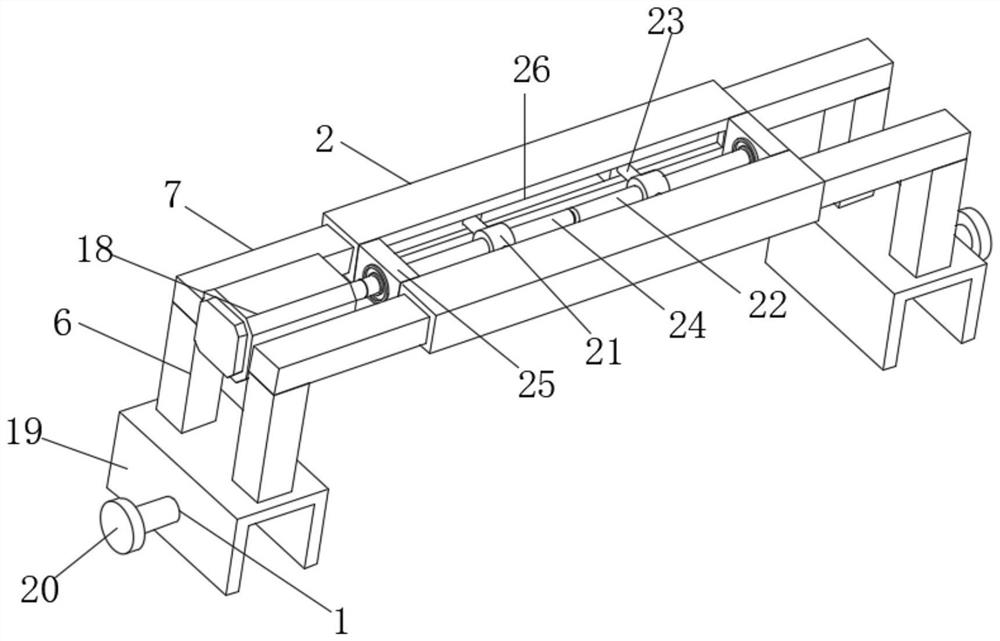

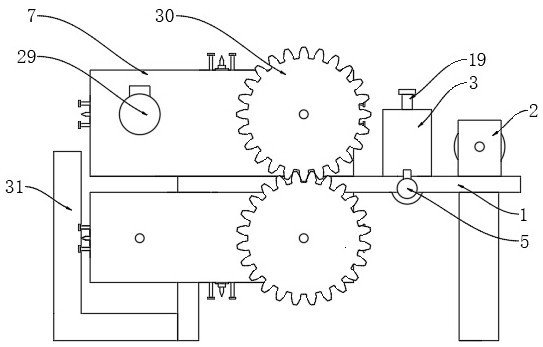

Continuous product detection device and method convenient for sampling

PendingCN114112486AEasy to move simultaneouslyFacilitate multi-style sampling processingWeighing by removing componentTransportation and packagingGear wheelControl engineering

The invention discloses a continuous product detection device and method convenient for sampling, and the device comprises a fixed seat, and an automatic clamping and sampling assembly is fixedly installed at the edge of the top end of the fixed seat. The automatic clamping and sampling assembly is mainly formed by combining an electric rotating shaft, a sampling driving gear, a sampling driven gear, a sampling connecting rod, a sampling sliding rod and a sampling connecting frame, the electric rotating shaft has the function of taking materials from a cutting knife, and the sampling driving gear, the sampling driven gear, the sampling connecting rod, the sampling sliding rod and the sampling connecting frame have the function of synchronously taking materials from a needle cylinder; through cooperation of the automatic clamping and sampling assembly and the rotary buffering and collecting assembly, a worker can conveniently carry out positioning and sampling treatment on materials, the material sampling process of the worker is optimized, the stability of the material sampling process is guaranteed, meanwhile, the worker can conveniently carry out storage treatment on sampled waste materials, and the working efficiency is improved. And the pollution to the external environment caused by peculiar smell generated by placing the waste materials everywhere is avoided.

Owner:刘萍

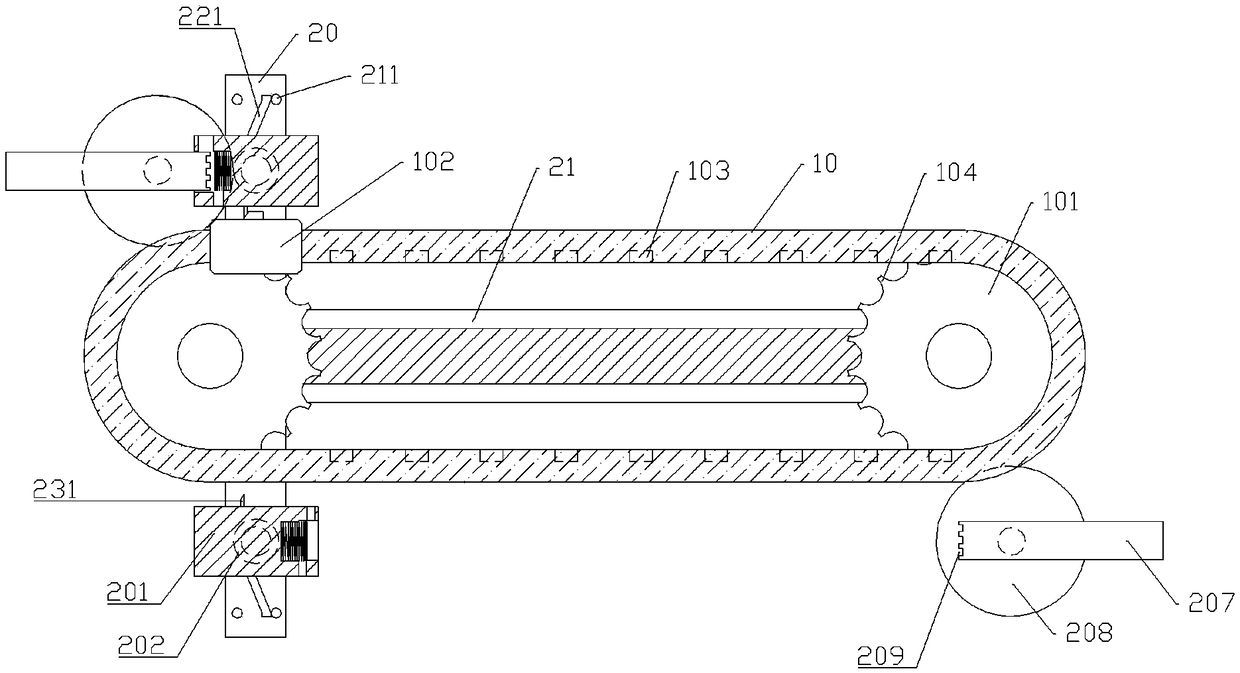

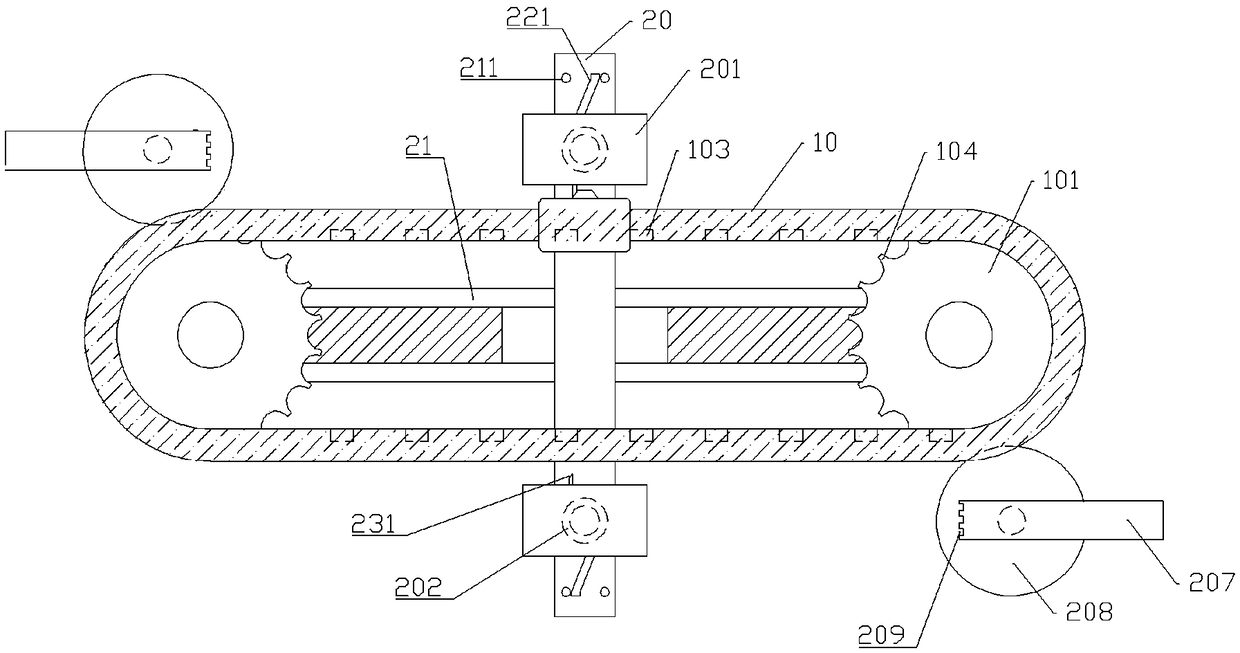

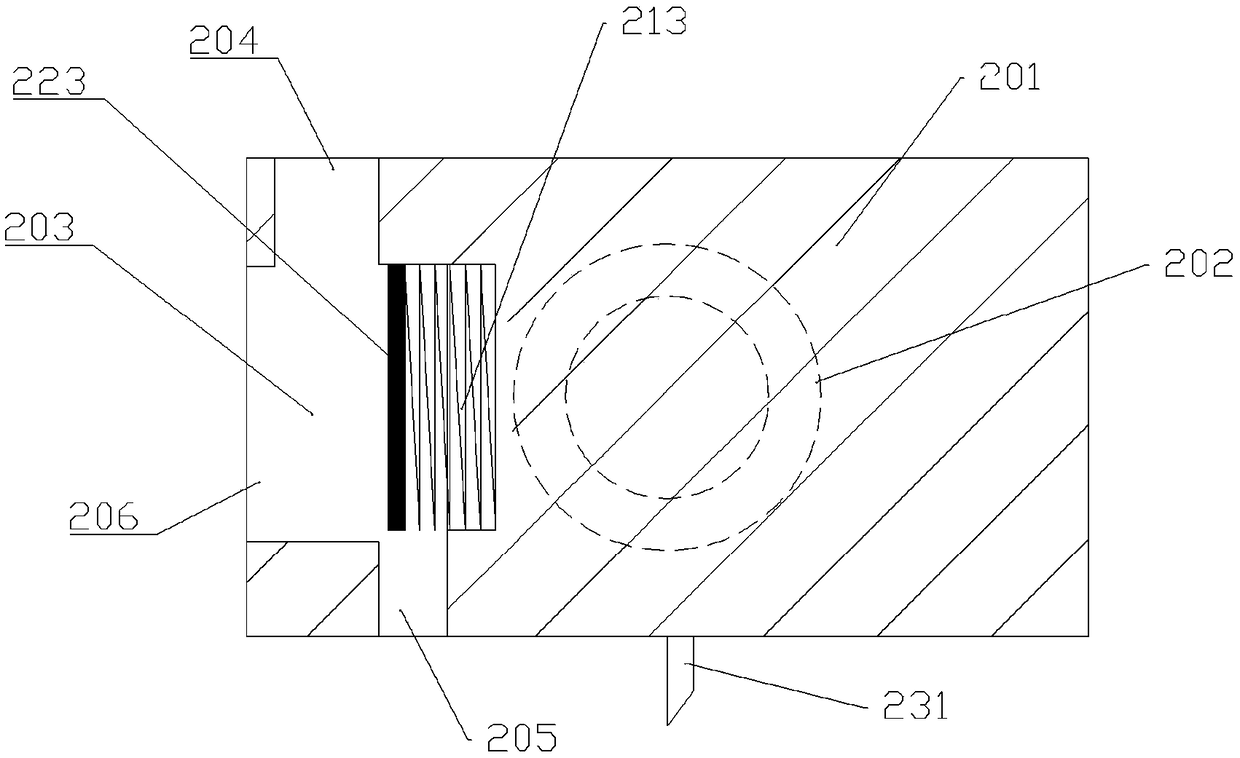

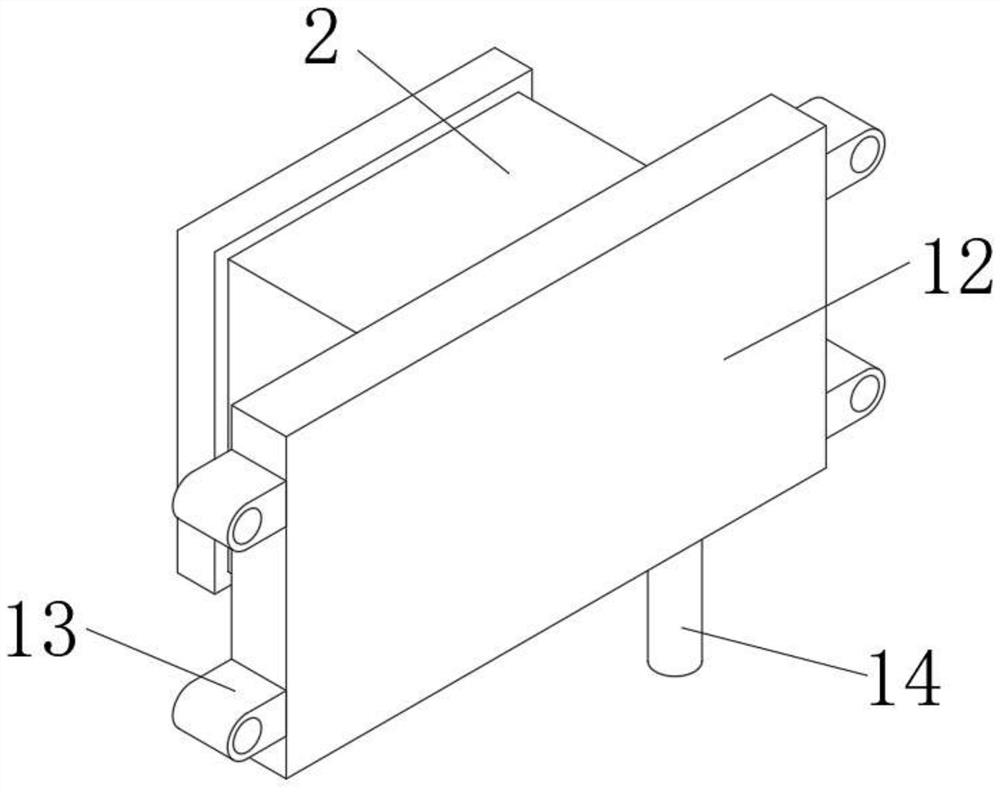

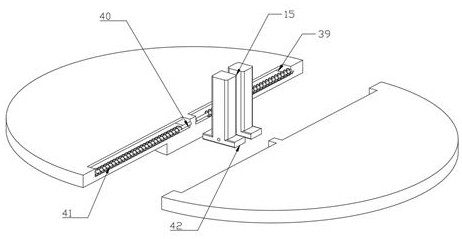

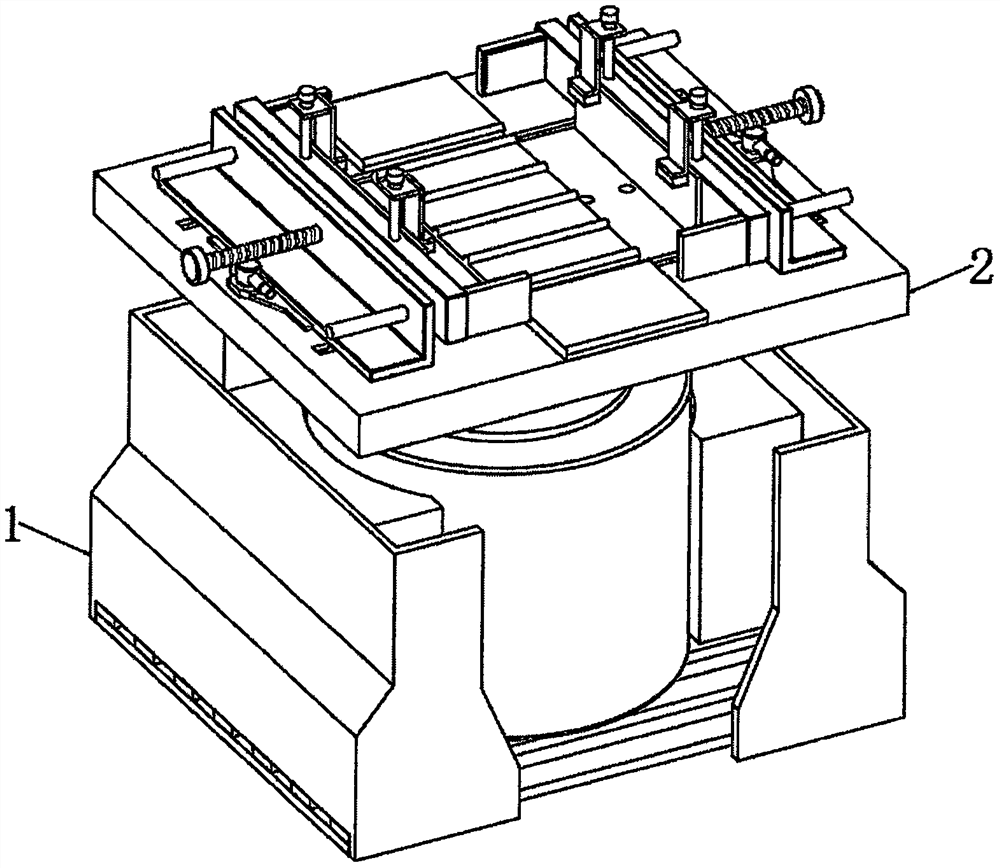

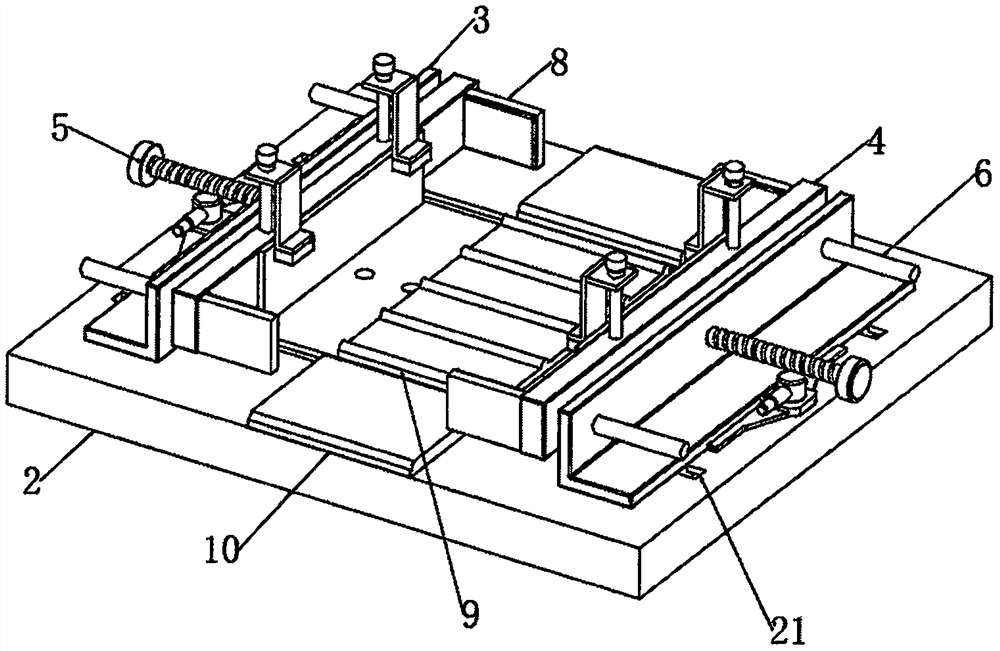

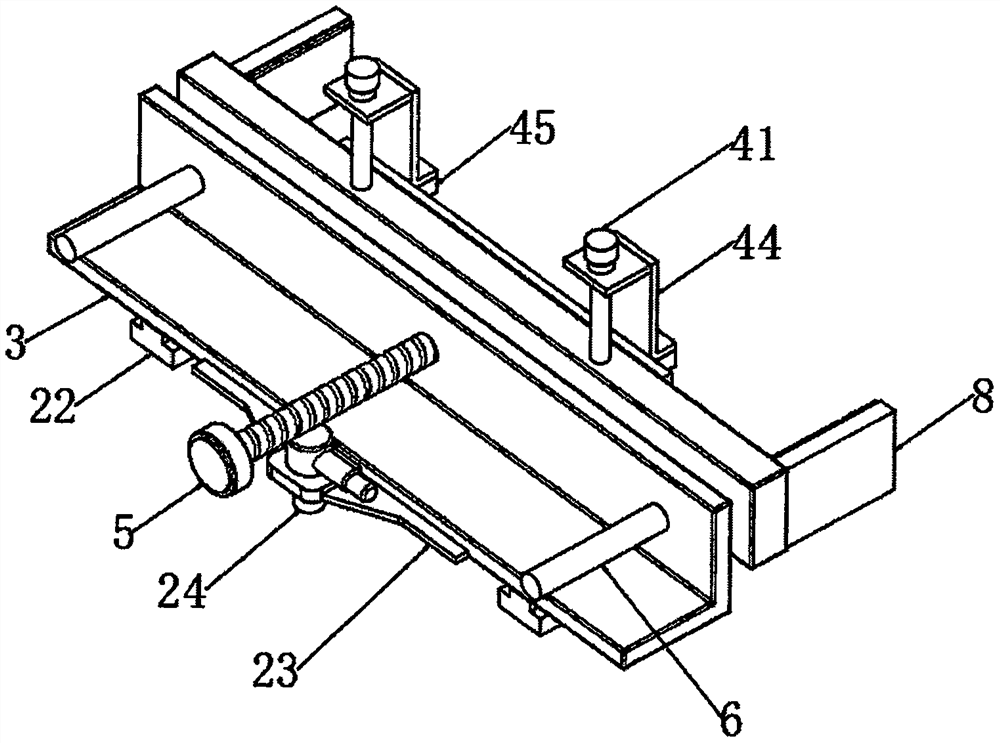

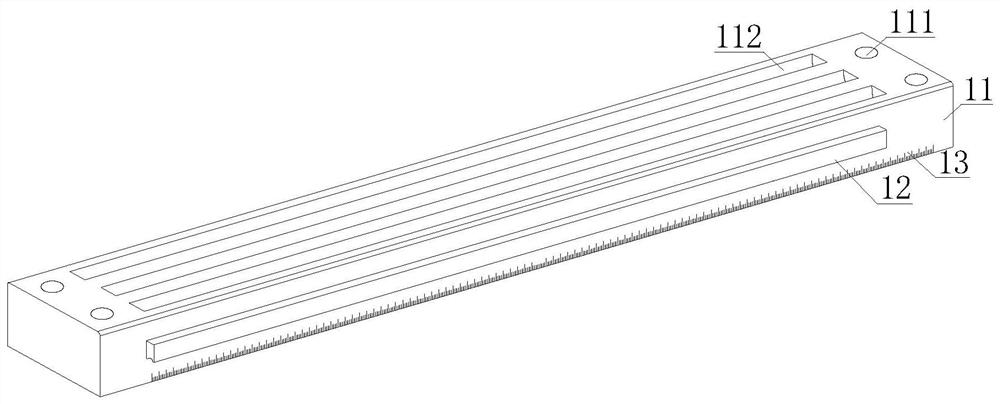

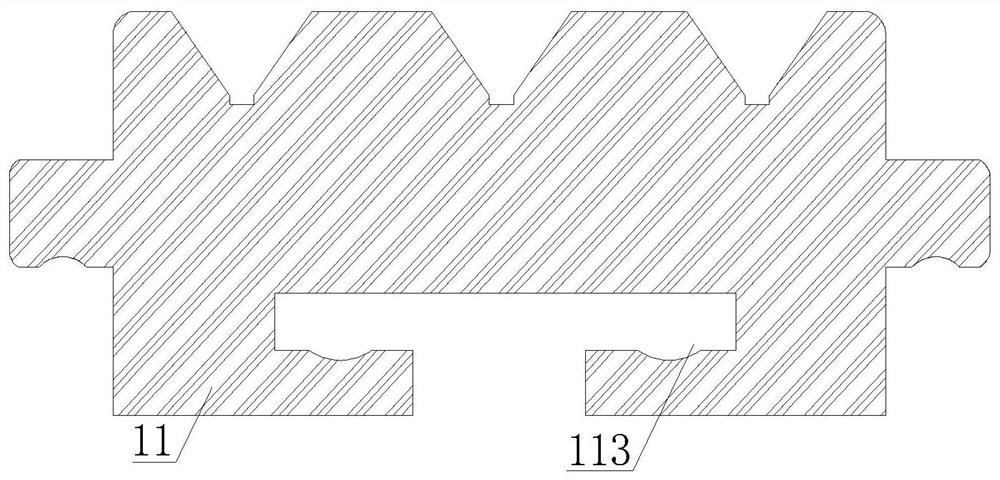

Drawing driving mechanism in seamless steel pipe drawing machine

The invention discloses a drawing driving mechanism in a seamless steel pipe drawing machine. According to the technical scheme, the drawing driving mechanism in the seamless steel pipe drawing machine is characterized by comprising a vehicle body arranged on the drawing machine and driven through a chain, wherein the vehicle body is slidably connected to the drawing machine in the length direction of a seamless steel pipe, and the vehicle body is provided with a clamping mechanism used for clamping the end surface of the seamless steel pipe, two connecting mechanisms used for being kept connected with the chain, and a disassembling and assembling mechanism used for disassembling and assembling the clamping mechanism. According to the drawing driving mechanism in the seamless steel pipe drawing machine, the end part of the seamless steel pipe can be ensured to be clamped and fixed, the seamless steel pipe can be driven to synchronously move, and meanwhile, clamping blocks can be disassembled and replaced.

Owner:ZHEJIANG TIANYANG STEEL TUBE CO LTD

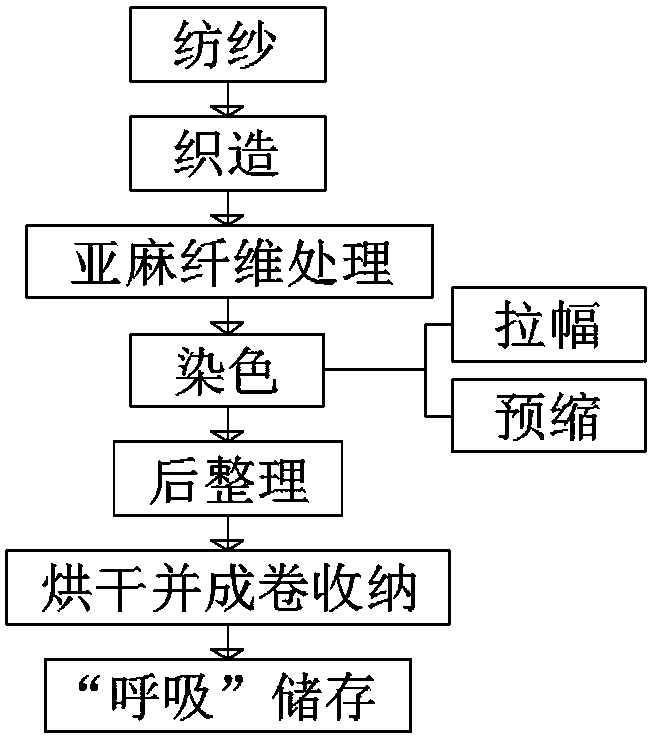

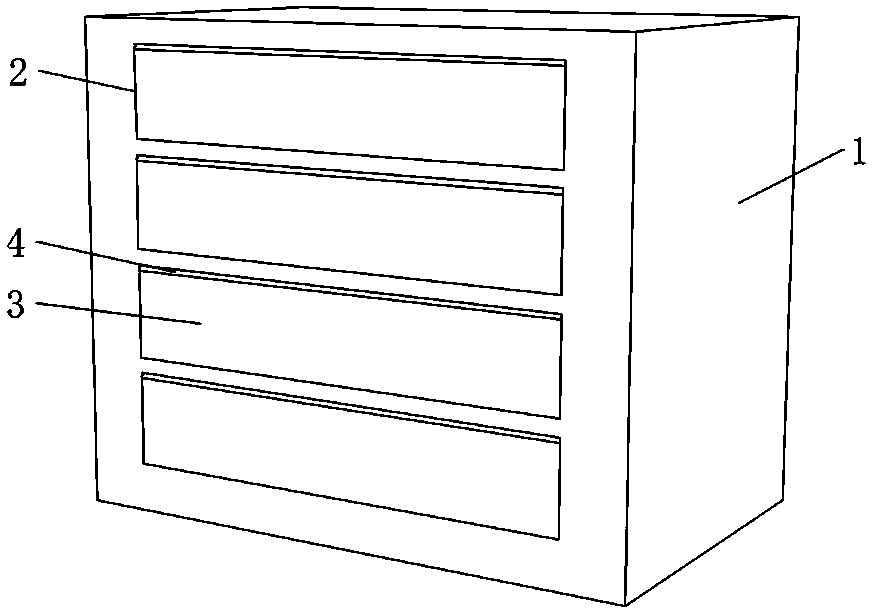

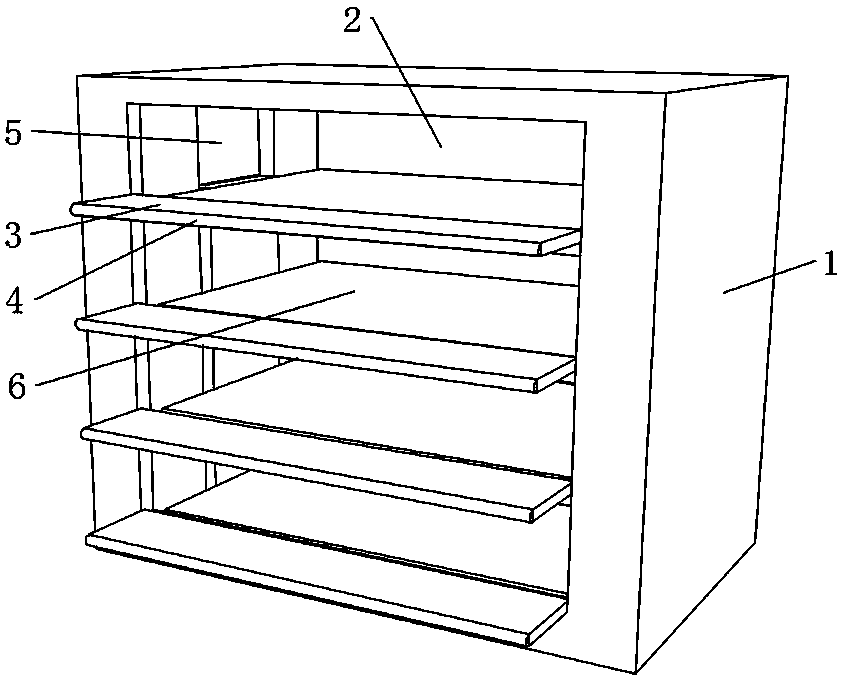

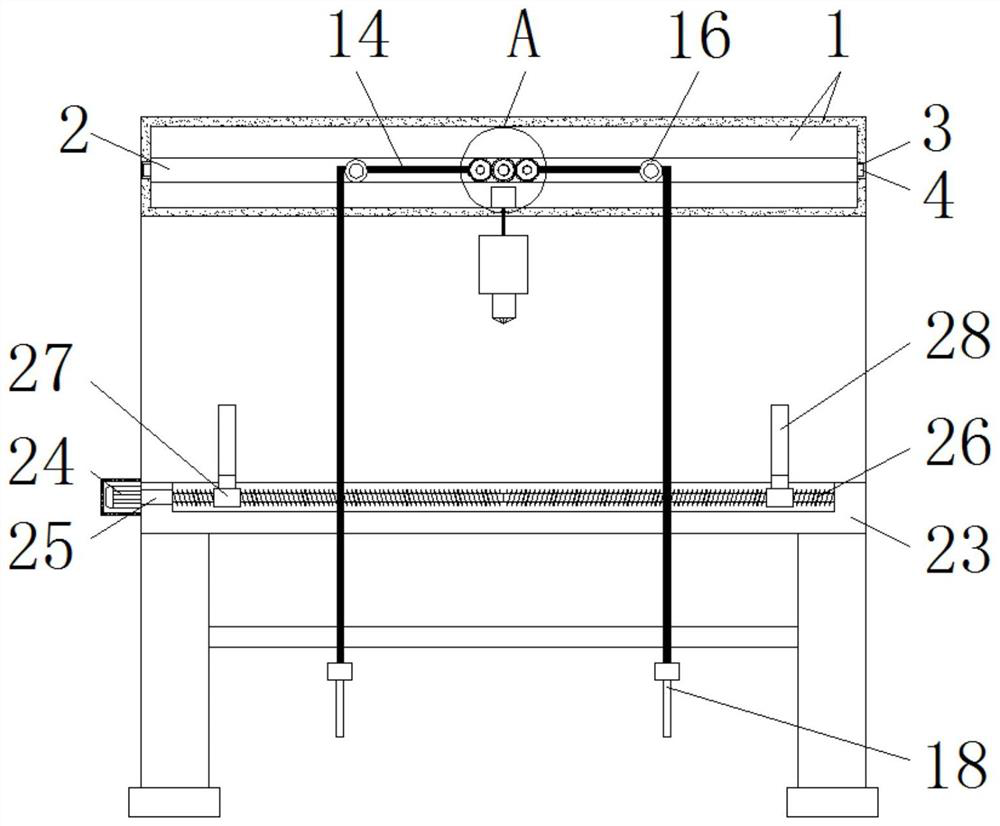

Making and storage technology of antibacterial and washable linen fabric

InactiveCN110565236AExtended storage timeImprove washabilityWeft knittingWarp knittingState of artEngineering

The invention discloses a making and storage technology of an antibacterial and washable linen fabric, and belongs to the field of linen fabric making. According to the making and storage technology of the antibacterial and washable linen fabric, after the linen fabric is made based on the technology flow, the collected linen fabric is stored through a breathing storage machine, a breathing boarddrives the linen fabric to reciprocate up and down at the same time, and air ventilation in the linen fabric is kept all the time; by controlling variables of the environmental conditions in the breathing storage machine in cooperation with a test on the firmness of the linen fabric, the conditions of the breathing storage machine which are most suitable for storing the linen fabric can be obtained, and the influence of the external environment on the firmness of the linen fabric in the storage process of the linen fabric is reduced; compared with a storage mode for the linen fabric in the prior art, the technology greatly prolongs the storage time after the linen fabric is made, and improves the washability after the linen fabric is cut.

Owner:宜兴市新东茂纺织科技有限公司

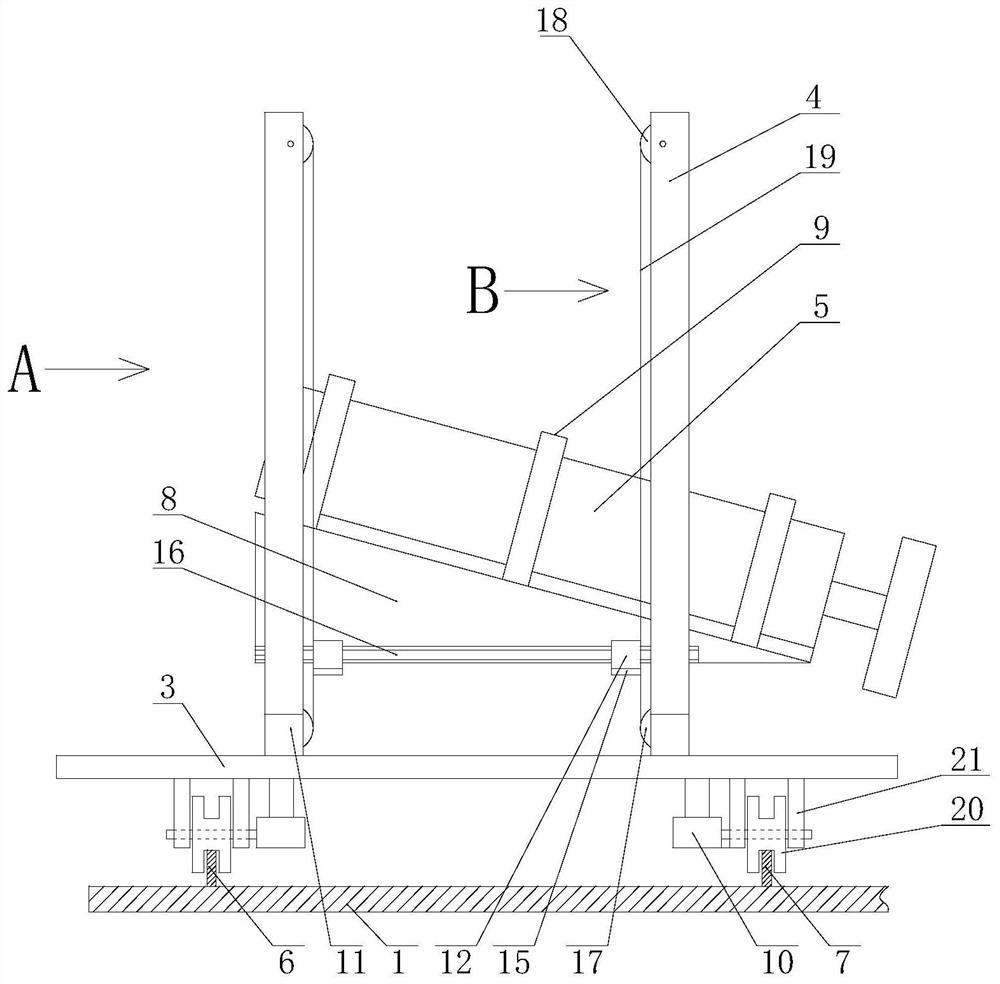

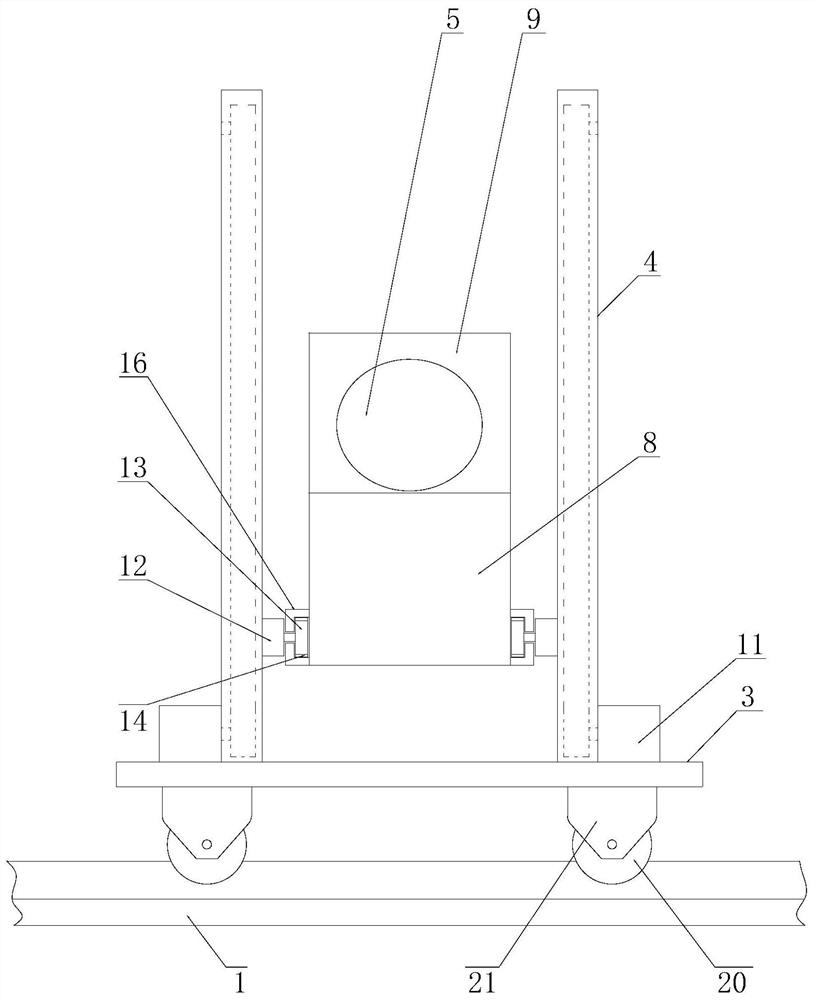

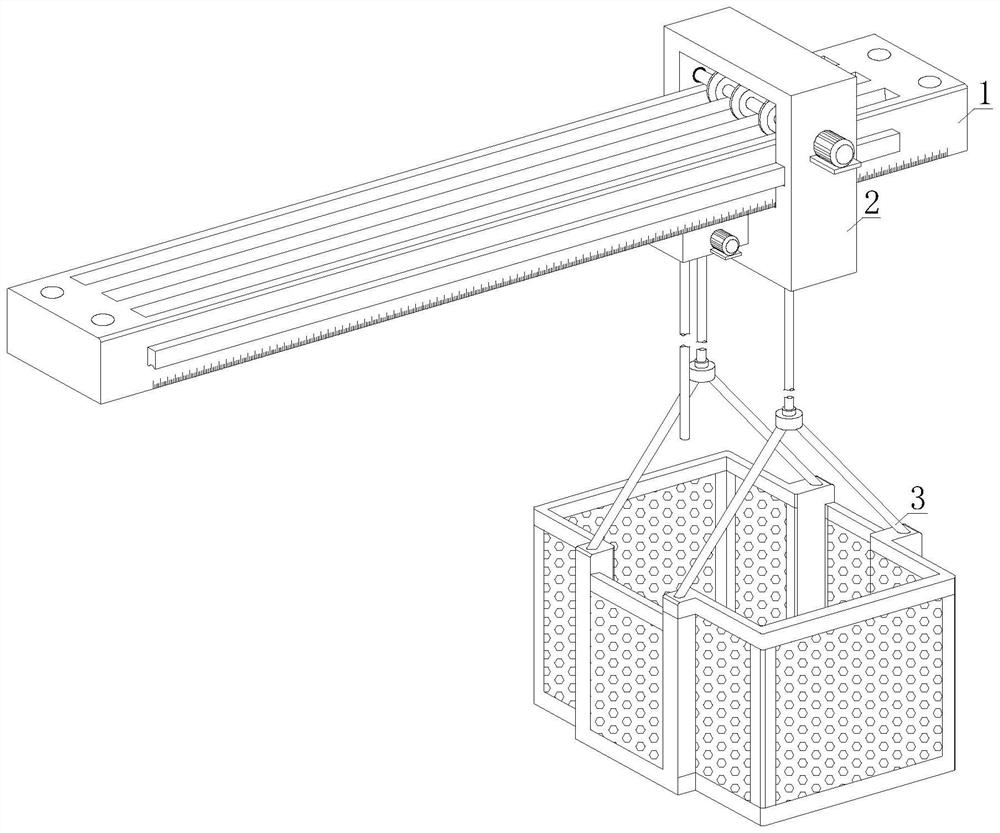

High-altitude component hoisting construction method

InactiveCN110790118AAchieve protectionImprove stabilityLoad-engaging elementsIndustrial engineeringWire rope

The invention discloses a high-altitude component hoisting construction method, and relates to the technical field of steel structure appliances. The construction method comprises the following construction steps of 1, welding two tripod bodies with the same size through a component, fixedly mounting walking wheels at the bottoms of the tripod bodies, installing a manual electric hoist on the upper ends of the tripod bodies, installing a steel wire rope on the manual electric hoist, fixedly installing a hoisting piece at one end of the steel wire rope, and connecting the other end of the steelwire rope to a wire rope winding disc through winding; 2, fixedly mounting the two ends of the component on the hoisting piece; and 3, moving the component to a designated position through the tripodbodies, then rotating the wire rope winding disc so that the component rises to a designated position, and then rising the component above the upper side of a beam frame through moving the tripod bodies. According to the high-altitude component hoisting construction method, rapid movement and hoisting can be realized, and the stability is high, so that the speed is high during hoisting construction, and energy and cost can be saved; and meanwhile, synchronous movement is facilitated so that time can be saved, and the stability of the component can be improved during movement, and therefore the protection of the component can be effectively realized.

Owner:淮安市淮宁钢结构有限公司

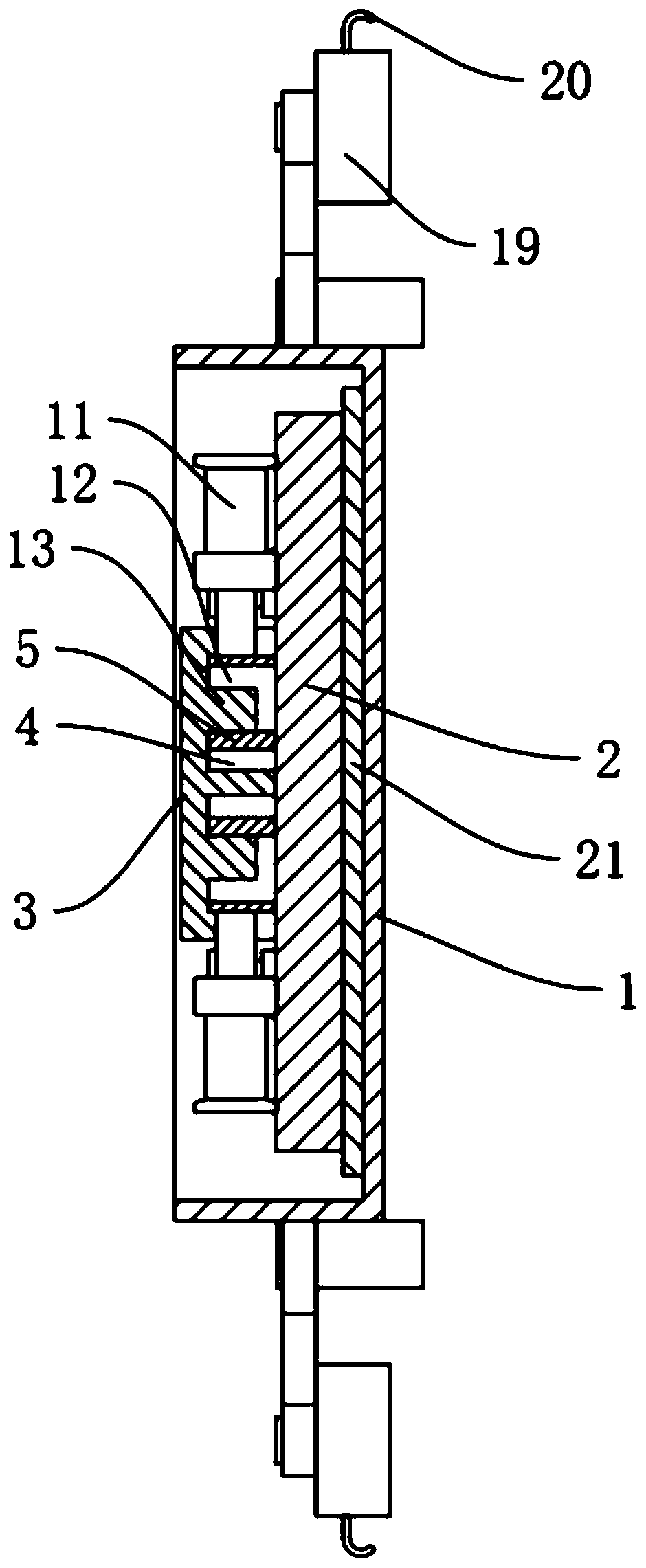

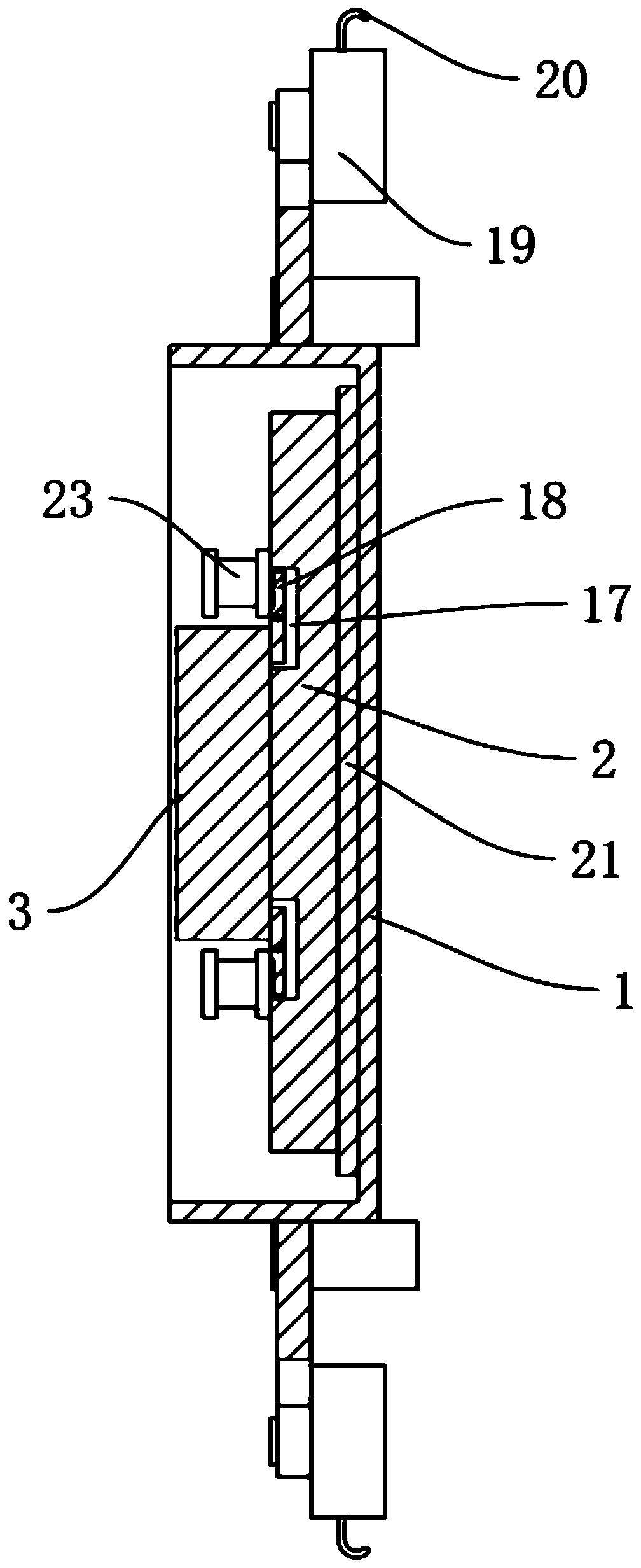

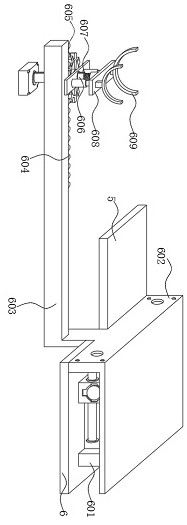

A graphite electrode resistivity detection device

ActiveCN112285422BAdjustable sizeEasy to fixResistance/reactance/impedenceGraphite electrodeElectric machinery

The invention discloses a graphite electrode resistivity detection device, which comprises a hanging board, a driving motor and a detection platform. A slide bar is arranged inside the hanging board, and a chute is opened inside the hanging board. A slide plate is connected, and the slide plate is installed on the outside of the slide bar. A toggle rod is arranged outside the hanging plate, and a connecting rod is connected to the bottom of the toggle bar, and the connecting rod is located inside the hanging plate. A positioning rod is arranged on the outside, and the positioning rod is located inside the hanging plate. In this graphite electrode resistivity detection device, the two sleeve rods sleeved on the screw rod are relatively moved through the opposite threads on both sides, and the movement of the sleeve rods drives the movement of the clamping ring, thereby facilitating the adjustment of the clamping ring. The wide distance can be adjusted according to the size of the graphite electrode, which is convenient for the clamping ring to fix the graphite electrode, which is beneficial to prevent the graphite electrode from shifting during detection and improve the detection efficiency.

Owner:滁州市技术监督检测中心

Graphite electrode resistivity detection device

ActiveCN112285422AAdjustable sizeEasy to fixResistance/reactance/impedenceGraphite electrodeElectric machinery

The invention discloses a graphite electrode resistivity detection device, and the device comprises an upper hanging plate, a driving motor and a detection table, a sliding rod is arranged in the upper hanging plate, a sliding groove is formed in the upper hanging plate, a sliding plate is connected in the sliding groove, the sliding plate is installed outside the sliding rod, and a poking rod isarranged outside the upper hanging plate; the bottom of the poke rod is connected with a connecting rod, the connecting rod is located in the upper hanging plate, a positioning rod is arranged outsidethe connecting rod, and the positioning rod is located in the upper hanging plate. According to the graphite electrode resistivity detection device, the two sleeve rods sleeving the screw rod relatively move through the threads in the opposite directions on the two sides, and the sleeve rods move to drive the clamping rings to move, so that the wide distance between the clamping rings can be conveniently adjusted according to the size of a graphite electrode, and the graphite electrode can be conveniently fixed by the clamping rings; and the graphite electrode does not deviate during detection, so that the detection efficiency is improved.

Owner:滁州市技术监督检测中心

Terminal direct printing device of two-dimensional animation design product

The invention discloses a terminal direct printing device of a two-dimensional animation design product, and relates to the field of animation design printing. In the terminal direct printing device of the two-dimensional animation design product, two ends in a device box both are in sliding connection with a printer, an external surface of the device box is movably connected with a rotating tubethrough clamping, one end of the rotating tube is in threaded connection with a threaded rod, an end part of the threaded rod stretches to the inside of the rotating tube to rotationally connect a push rod, the push rod is in sliding connection with an inner wall of the rotating tube, and one end, far away from the threaded rod, of the push rod stretches to the inside of the device box and fixedlyconnects a clamping connection component; the clamping connection component is rotationally connected on an inner side wall of the device box and at the side opposite to the push rod; a moving component is movably inserted at the external surface of the device box and located under the rotating tube, and the end part of the moving component stretches to the inside of the device box and respectively in transmission connection with two groups of printers. The terminal direct printing device of the two-dimensional animation design product is convenient for printing animation patterns on side faces of a package box of an animation product.

Owner:广州市天狮包装印刷有限公司

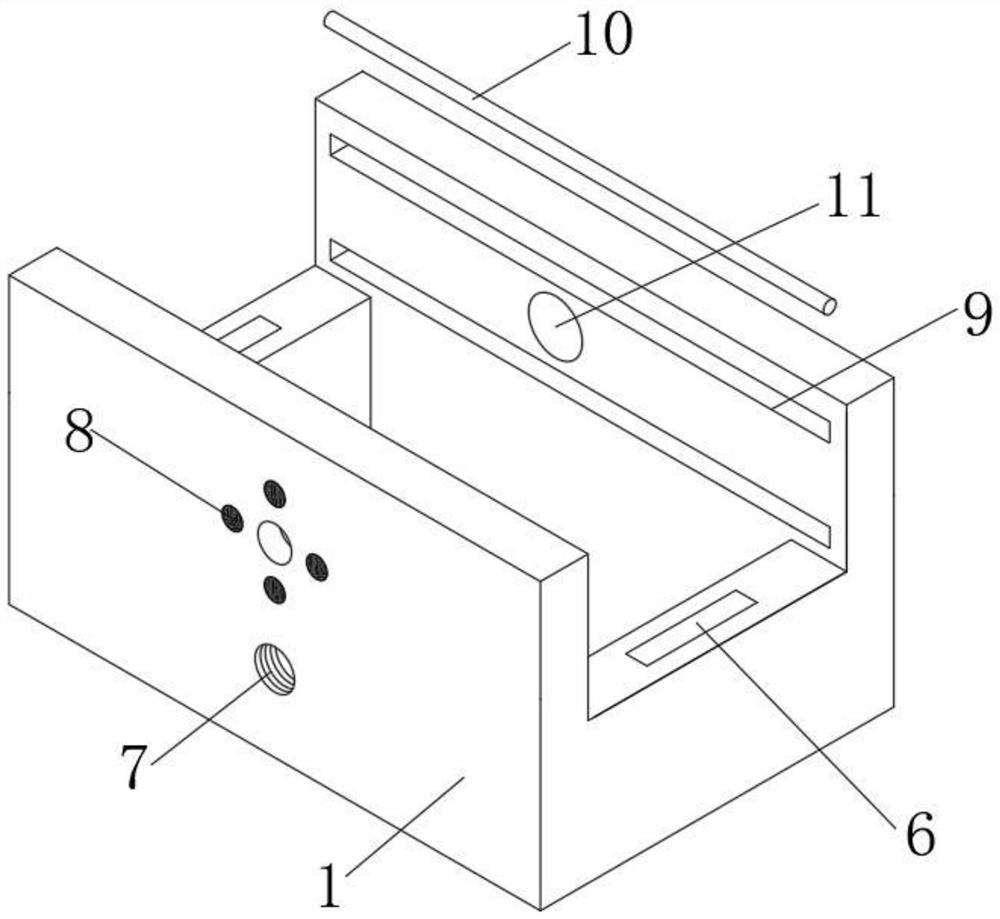

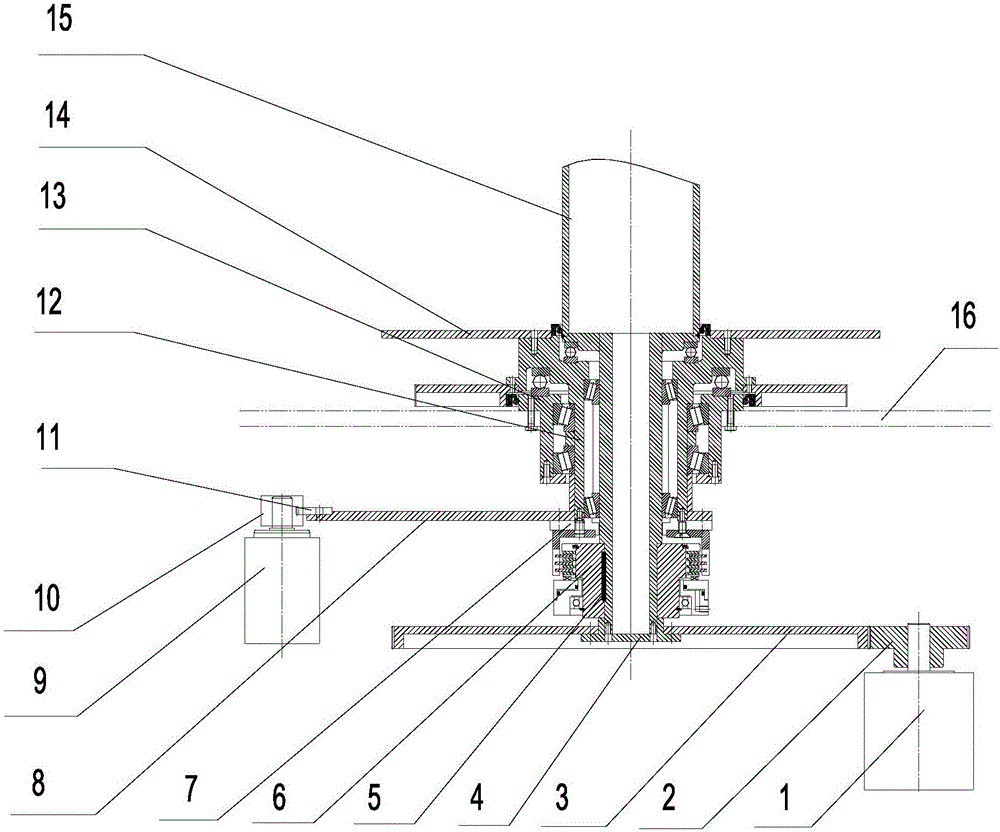

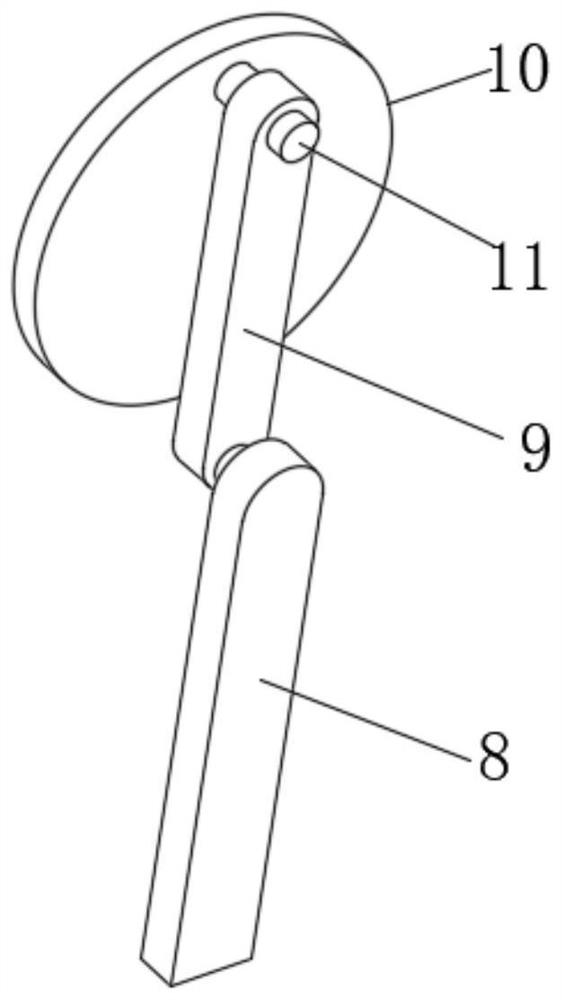

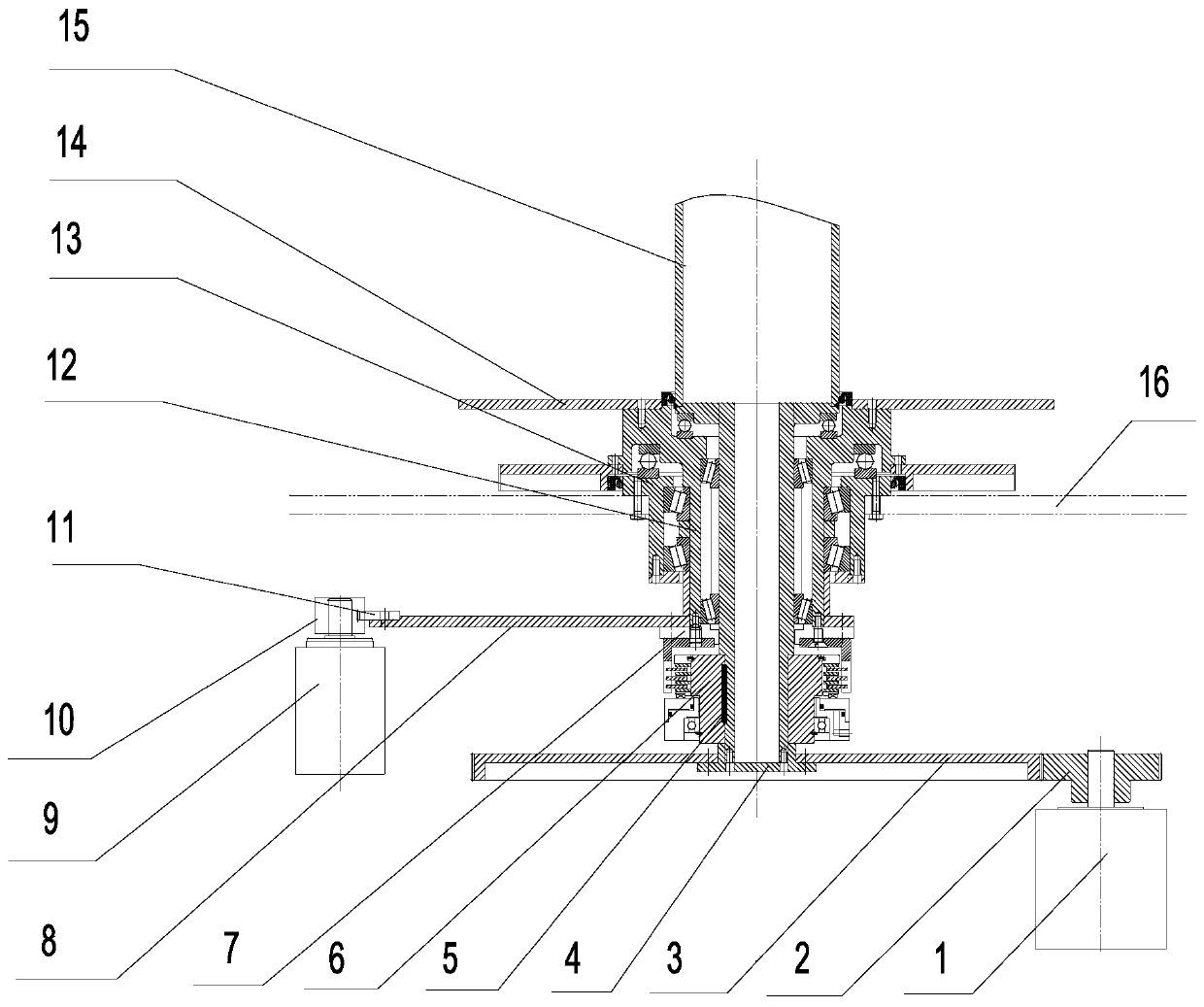

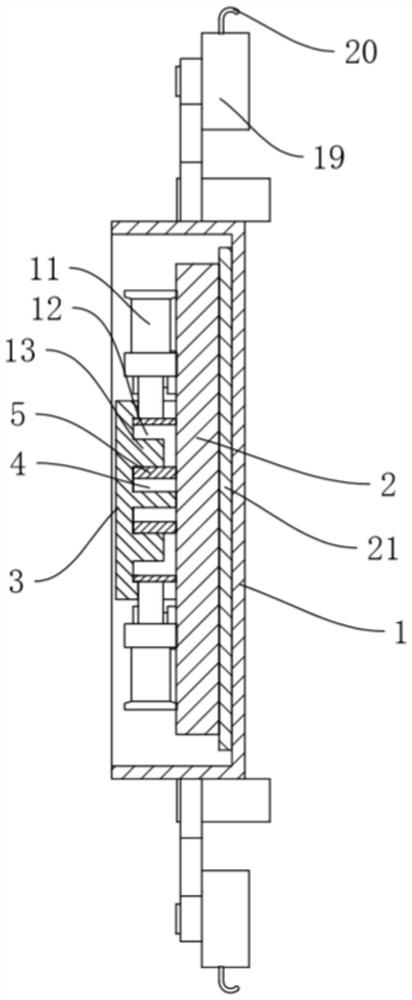

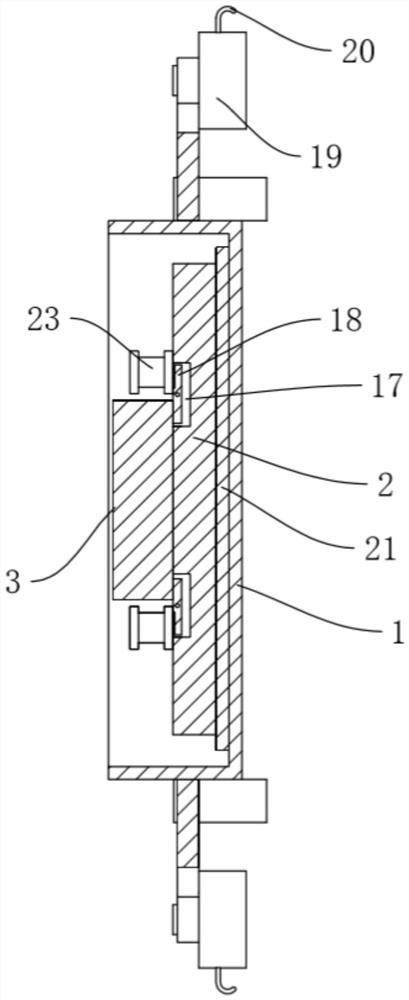

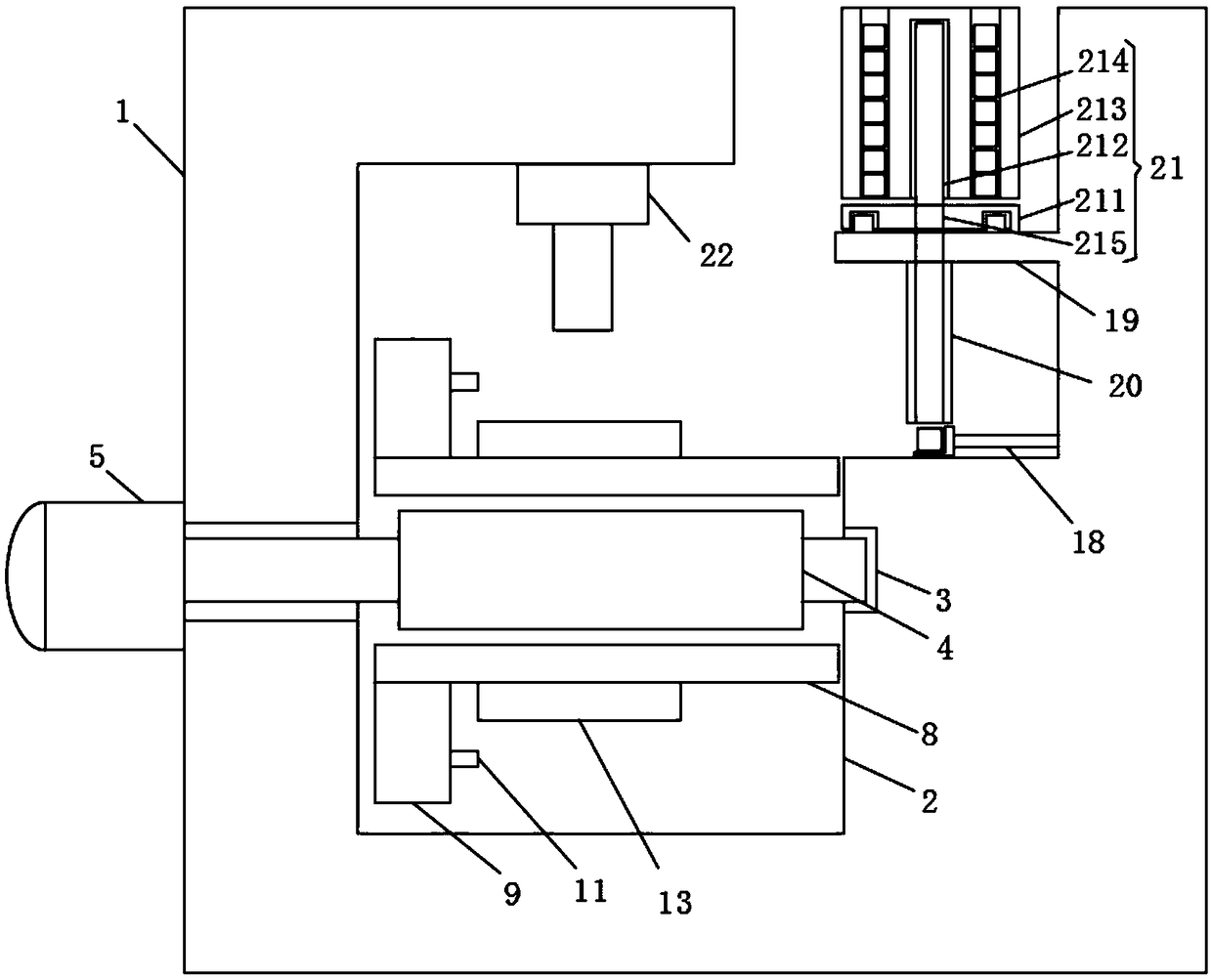

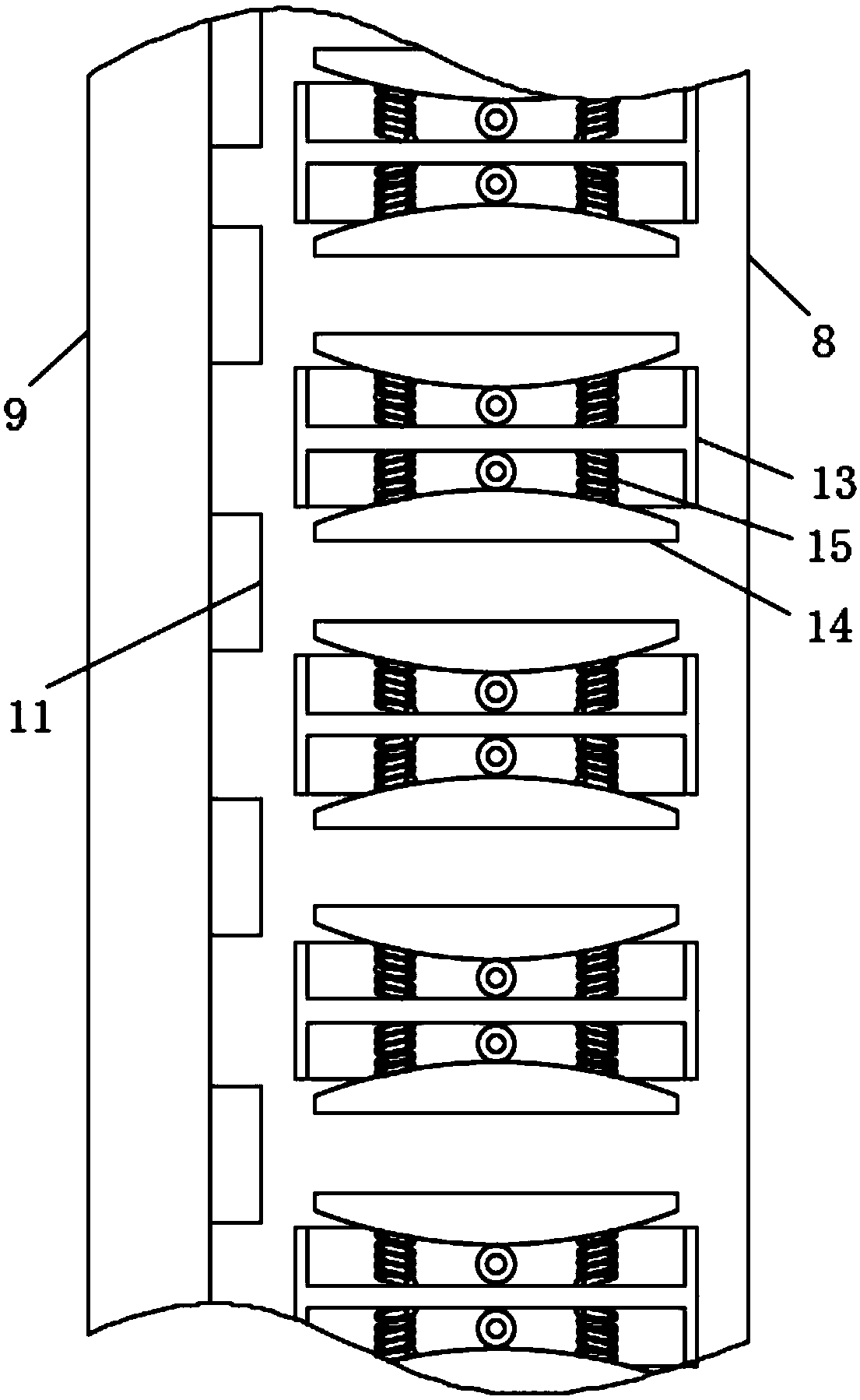

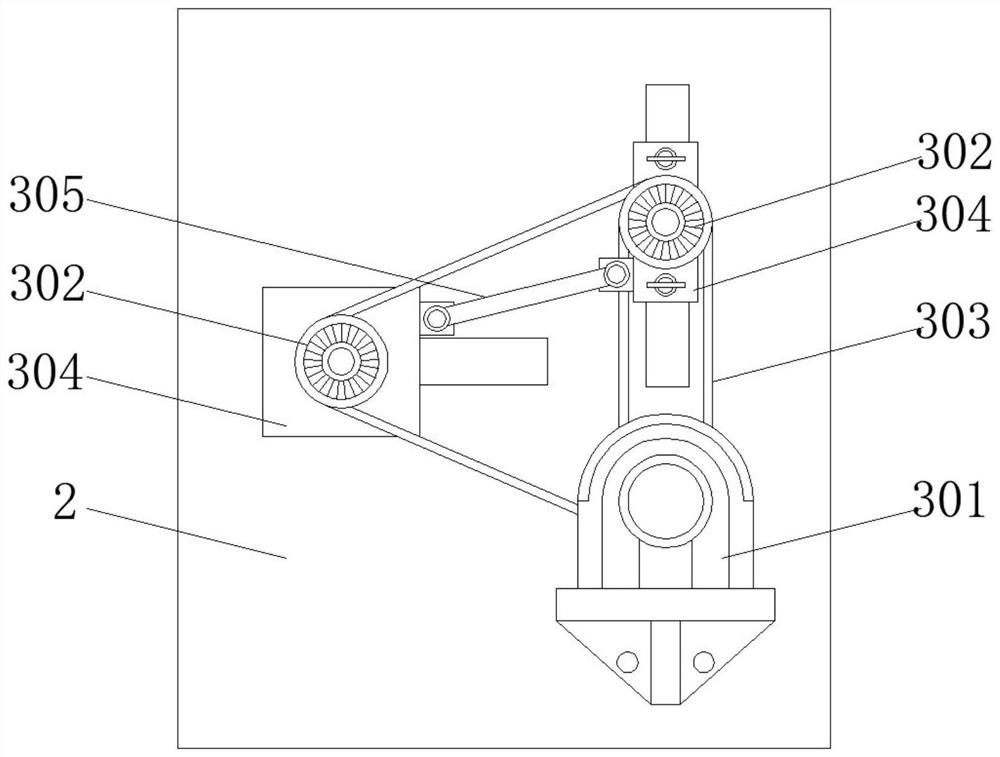

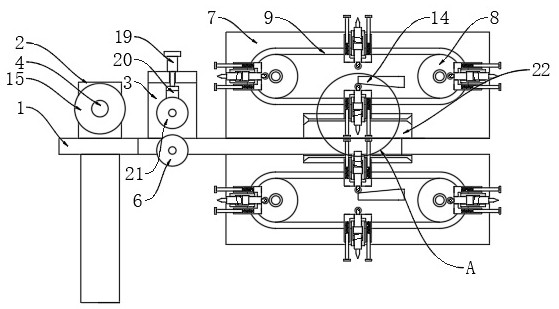

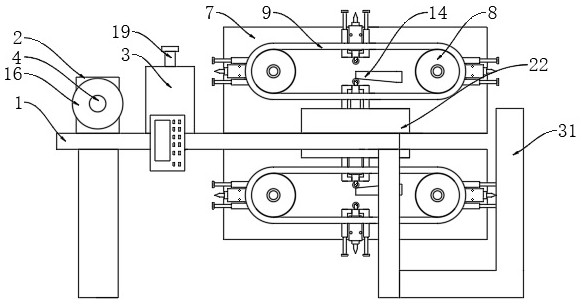

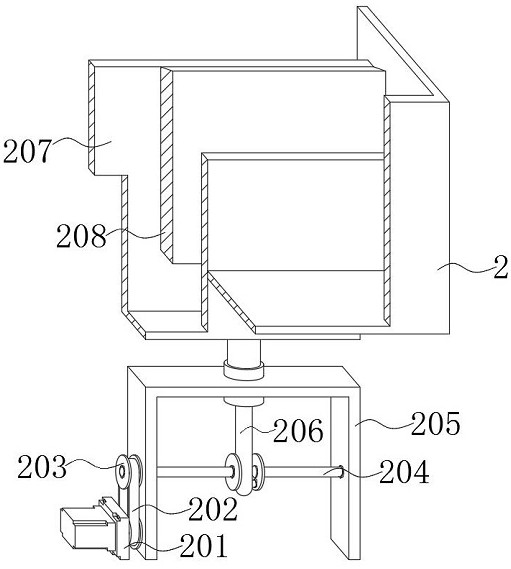

Synchronous tracking device for light inspection machine

ActiveCN106770353AEasy to detectEasy to move simultaneouslyOptically investigating flaws/contaminationSynchronous motorClutch

The invention provides a synchronous tracking device for a light inspection machine. The synchronous tracking device comprises a clutch (6), a tracking motor (9), a tracking shaft sleeve (12), a bearing block (13) and a tracking rotary plate (14) fixedly connected with the tracking shaft sleeve (12), wherein an image acquisition device is mounted on the tracking rotary plate (14); the bearing block (13) is fixedly mounted on a mounting cross beam (16) of the light inspection machine; the tracking shaft sleeve (12) is located in the bearing block (13) and nested on the spindle (15) of the light inspection machine; the clutch (6) is used for connecting the spindle (15) with the tracking shaft sleeve (12), when the clutch is in an engaged state, the tracking shaft sleeve (12) rotates along with the spindle (15), and when the clutch (6) is in an unengaged state, the tracking motor (9) drives the tracking shaft sleeve (12) to rotate in the direction opposite to the rotation direction of the spindle (15). With the adoption of the synchronous tracking device, the image acquisition device can keep synchronous rotation along with the rotary plate better.

Owner:长沙汇一制药机械有限公司

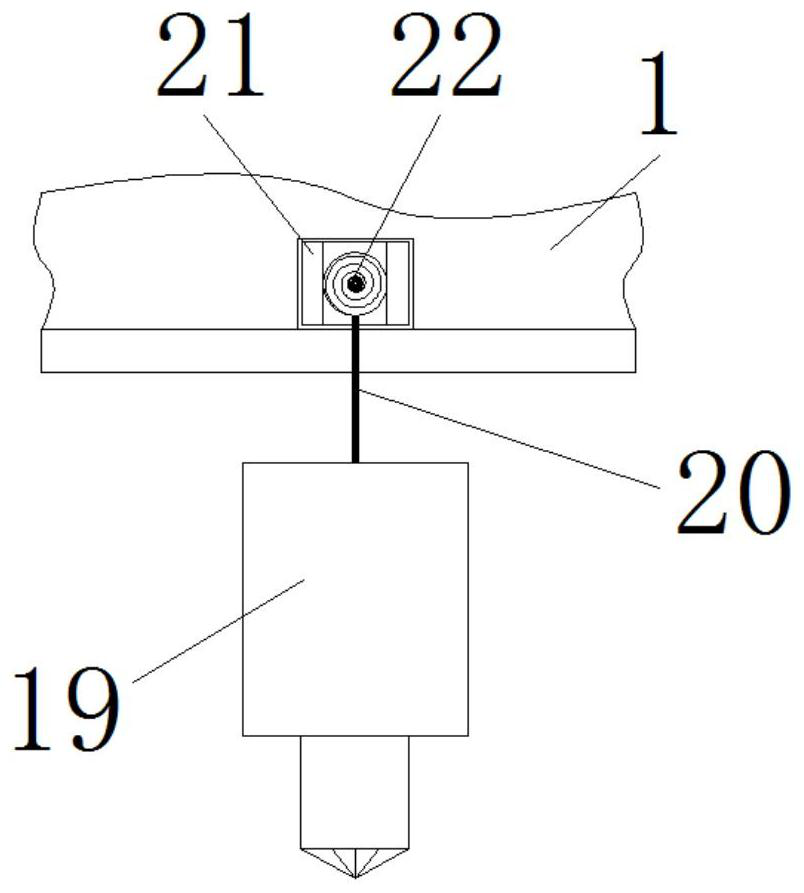

Chest compression device for patient breathing recovery

PendingCN114191279AEasy to move simultaneouslyPress operation continuesElectrotherapyHeart stimulationPhysical medicine and rehabilitationReciprocating motion

The invention relates to the technical field of medical instruments, in particular to a chest compression device for patient respiration recovery, which comprises a base, a vertical plate is mounted at the top of the base through screws, a first motor mounting seat is mounted at the top end of the vertical plate through screws, and a first driving motor is mounted at the top of the first motor mounting seat through screws. By arranging the first driving motor, the circular plate, the second connecting rod, the first connecting rod, the sliding limiting mechanism and the pressing block, the first driving motor works after being powered on and is used for driving the circular plate to rotate, the circular plate drives the second connecting rod to do arc motion, and the second connecting rod drives the first connecting rod to do reciprocating motion in the vertical direction through the sliding limiting mechanism; the first connecting rod can conveniently drive the pressing block to synchronously move in the vertical direction, medical staff can be conveniently replaced to conduct chest pressing operation on the critical patient, and compared with manual chest pressing operation, the operation convenience is improved.

Owner:马伟

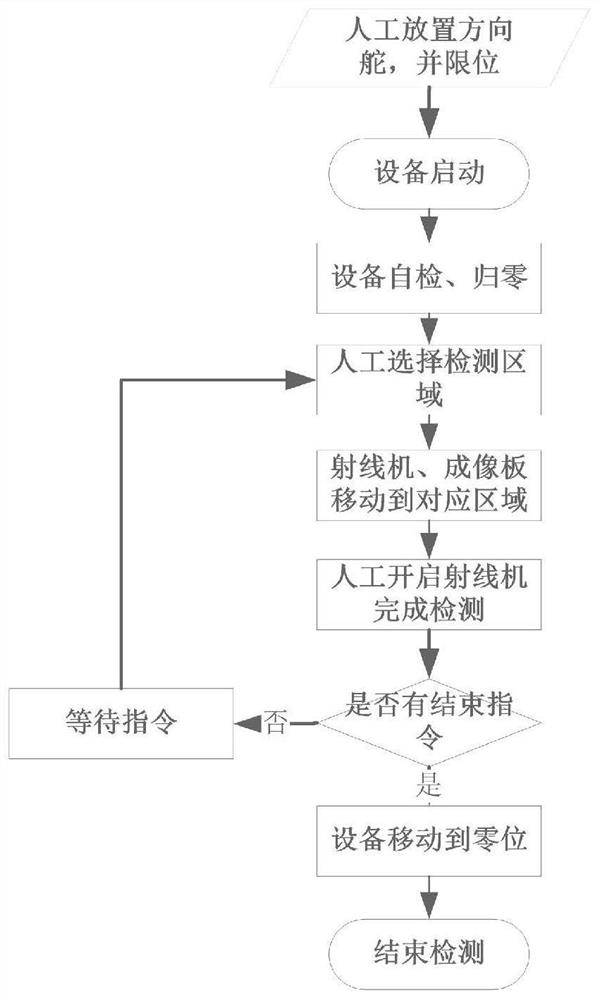

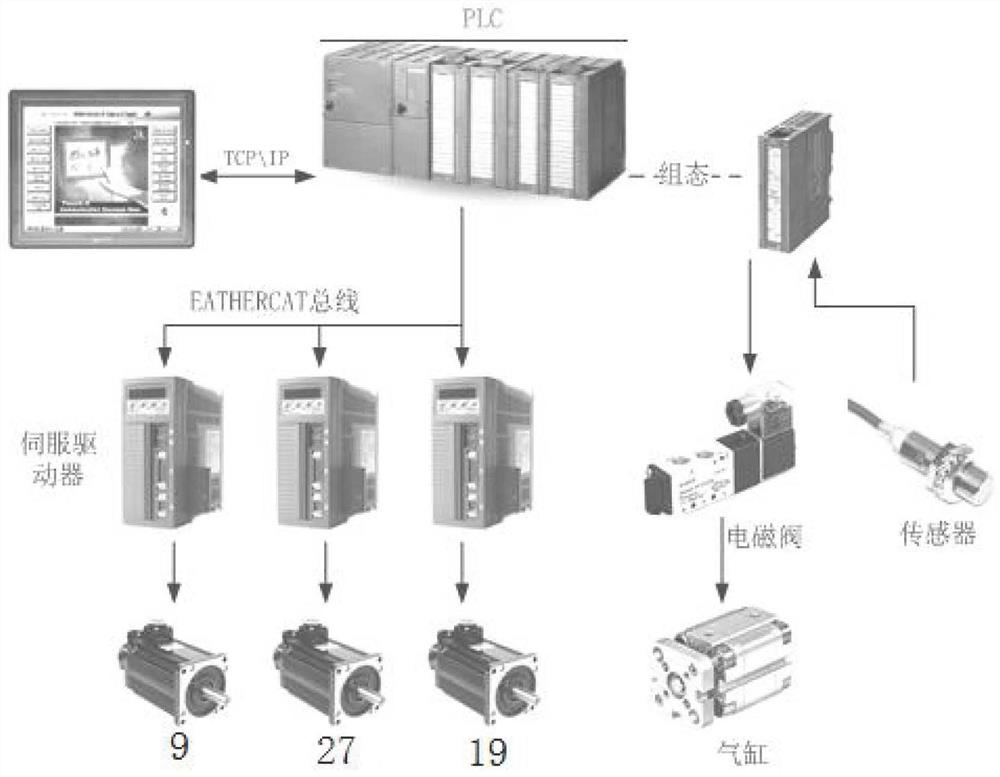

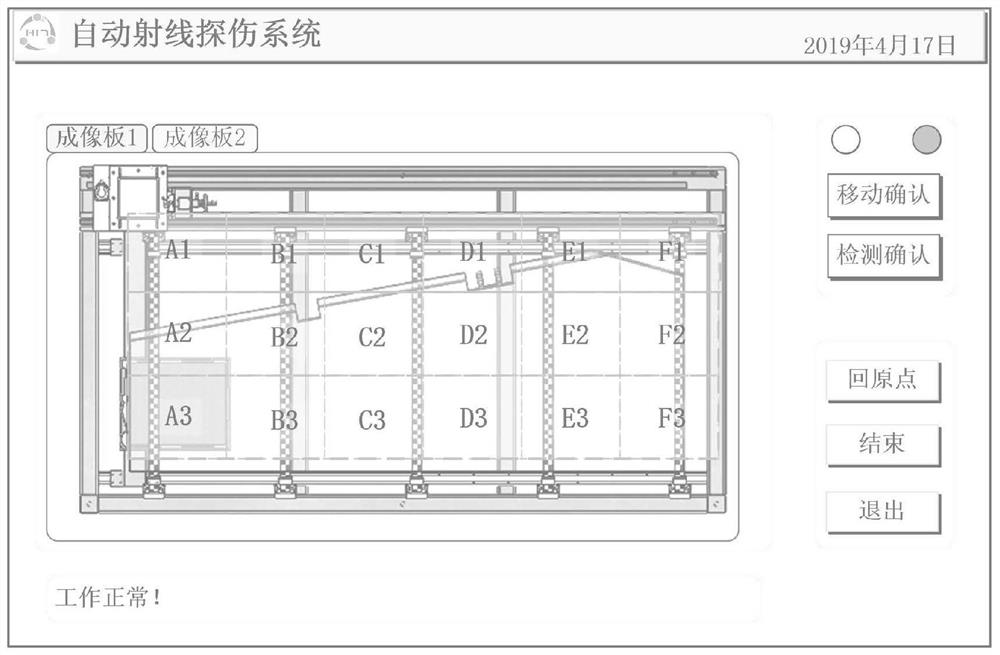

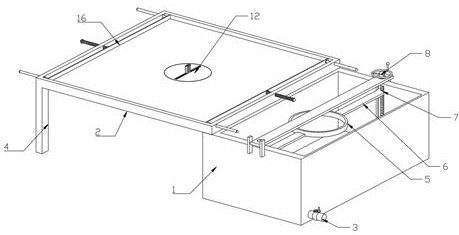

An automatic system for aircraft rudder ray detection

ActiveCN110702713BEasy to move simultaneouslyMake sure to move in syncMaterial analysis by transmitting radiationControl systemControl engineering

Owner:国营芜湖机械厂

A tie-dyeing device for textile dyeing

ActiveCN113463309BEasy to hold and turnFacilitates spiral pleatsTextile treatment machine arrangementsTextile treatment carriersPolymer scienceEngineering

The invention discloses a tie-dyeing device for textile dyeing, which comprises a dipping box and an operating table. A drainage pipe is arranged on the lower wall of one side of the dipping box, and two symmetrically arranged on the side wall of the bottom of the operating table. Supporting legs, the dipping tank is also provided with a support bracket, the front end and the rear end wall of the support bracket are respectively provided with connecting rods, and the first slider is respectively provided on one end wall of the two connecting rods , The top wall of the dipping tank is also provided with an adjustment mechanism, the adjustment mechanism includes a first screw, a mounting plate and an adjustment block, and a rotation mechanism is also provided in the wall at the middle position of the bottom of the operation table. A tie-dyeing device for textile dyeing according to the present invention: through the setting of the rotating mechanism, the cloth can be easily clamped and rotated, and the cloth can be conveniently formed into common spiral folds. The arrangement of the limiting mechanism is convenient for temporarily limiting the rotated cloth to prevent it from falling apart and affecting the subsequent dripping.

Owner:海门市冬夏纺织品有限公司

A synchronous tracking device for light inspection machine

InactiveCN106770353BEasy to detectEasy to move simultaneouslyOptically investigating flaws/contaminationElectric machineryEngineering

The invention provides a synchronous tracking device for a light inspection machine. The synchronous tracking device comprises a clutch (6), a tracking motor (9), a tracking shaft sleeve (12), a bearing block (13) and a tracking rotary plate (14) fixedly connected with the tracking shaft sleeve (12), wherein an image acquisition device is mounted on the tracking rotary plate (14); the bearing block (13) is fixedly mounted on a mounting cross beam (16) of the light inspection machine; the tracking shaft sleeve (12) is located in the bearing block (13) and nested on the spindle (15) of the light inspection machine; the clutch (6) is used for connecting the spindle (15) with the tracking shaft sleeve (12), when the clutch is in an engaged state, the tracking shaft sleeve (12) rotates along with the spindle (15), and when the clutch (6) is in an unengaged state, the tracking motor (9) drives the tracking shaft sleeve (12) to rotate in the direction opposite to the rotation direction of the spindle (15). With the adoption of the synchronous tracking device, the image acquisition device can keep synchronous rotation along with the rotary plate better.

Owner:长沙汇一制药机械有限公司

Drawing drive mechanism in a seamless steel pipe drawing machine

The invention discloses a drawing driving mechanism in a seamless steel pipe drawing machine. The key points of the technical solution are: a drawing driving mechanism in a seamless steel pipe drawing machine, which includes a car set on the drawing machine and driven by a chain. body, the car body is slidably connected to the drawing machine along the length direction of the seamless steel pipe, the car body is provided with a clamping mechanism for clamping the end face of the seamless steel pipe, two sets of connecting mechanisms for maintaining the connection with the chain, and The disassembly mechanism for disassembly and assembly of the clamping mechanism. The invention can ensure that the end of the seamless steel pipe is clamped and fixed, drives the seamless steel pipe to move synchronously, and at the same time disassembles and replaces the clamping blocks respectively.

Owner:ZHEJIANG TIANYANG STEEL TUBE CO LTD

Automatic assembling device of flat copper wheel for plastic-steel door and window

The invention discloses an automatic assembling device of a flat copper wheel for a plastic-steel door and window. The automatic assembling device comprises an assembling machine, a driving roller, aconveying belt, an electric push rod and a material cylinder; a rotating groove is formed in the bottom of the assembling machine, the rotating groove is of a rectangular column structure, limiting holes are formed in the inner wall of the rotating groove, driving rollers are inserted into the limiting holes, the other ends of the driving rollers penetrate through the outer wall of the assemblingmachine and are in transmission connection with the power output end of a motor, and meshing strips are fixedly connected to the surfaces of the driving rollers; and the conveying belt is arranged onthe outer sides of the driving rollers, a vertical plate is fixedly connected to the surface of the conveying belt, a lifting groove is formed in the surface of the vertical plate, a pressing plate isconnected to the interior of the lifting groove in a sliding mode, an adjusting rod is arranged on the surface of the pressing plate, and the adjusting rod is arranged on the outer wall of the vertical plate in a penetrating mode. According to the automatic assembling device, the vertical plate and a segmented piece are arranged on the conveying belt, the positions of the vertical plate and the segmented piece are adjusted according to different types and sizes of the copper wheel fittings, so that the application range of the assembling machine is enlarged.

Owner:胡湘粤

Machining equipment for iron special-shaped buckle opening health maintenance

InactiveCN112058783AImprove the heating effectEasy to separatePolishing machinesCleaning using toolsCircular discBall screw

The invention discloses machining equipment for iron special-shaped buckle opening health maintenance. The machining equipment comprises a bottom chassis; a water tank is arranged in the bottom chassis; fixed seats are symmetrically arranged on the two sides of a supporting base on the surface of the top of the bottom chassis; a connecting base is connected between the inner sides of ball screws;a servo motor is installed on the top surface of the connecting base; an output end of the servo motor crosses the inside of the connecting base and is connected with a disc; and a cleaning mechanismis arranged at the bottom of an adjusting rod. The water tank and a lifting mechanism are arranged in the bottom chassis, the water tank is divided into a structure with an upper side layer and a lower side layer, water and equipment can be separated conveniently, water stored in the upper layer of the water tank can be heated conveniently through the arrangement of a heating rod, damage to a punch when surface dirt is hard in texture and directly brushed is avoided, meanwhile, through the arrangement of the lifting mechanism, a rotating head can be conveniently brought into the water tank tobe soaked, and therefore cleaning of the dirt on the surface of the rotating head is facilitated.

Owner:重庆数智源智能装备科技有限公司

Copper product cutting device with recovery structure

ActiveCN112621355AEasy to clean up wasteAvoid wastingFeeding apparatusTube shearing machinesCooling fluidManufacturing engineering

Owner:湖北鑫西能金属制品有限公司

Testing device for vehicle fuel cell

The invention relates to the technical field of testing devices, in particular to a vehicle fuel cell testing device which comprises vibration testing equipment, a workbench is installed at the top of the vibration testing equipment, movable supports are connected to the two sides of the top of the workbench through sliding fixing assemblies, and clamping blocks are arranged on the sides, close to each other, of the movable supports. The interior of the movable support is in threaded connection with a locking screw rod, and one end of the locking screw rod is movably connected to the outer surface of the clamping block through a bearing. According to the invention, the sliding rail and the guide block are in sliding connection, so that the movable bracket can move on the top of the workbench conveniently, the two sides of the fuel cell are preliminarily limited and fixed, the fuel cell is conveniently mounted on the upper surface of the workbench to receive a vibration test, and the fuel cell is effectively prevented from being damaged when the fuel cell is fixed on the workbench. A plurality of groups of bolts are needed, the test operation is complicated, and the working efficiency of operators is also reduced.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

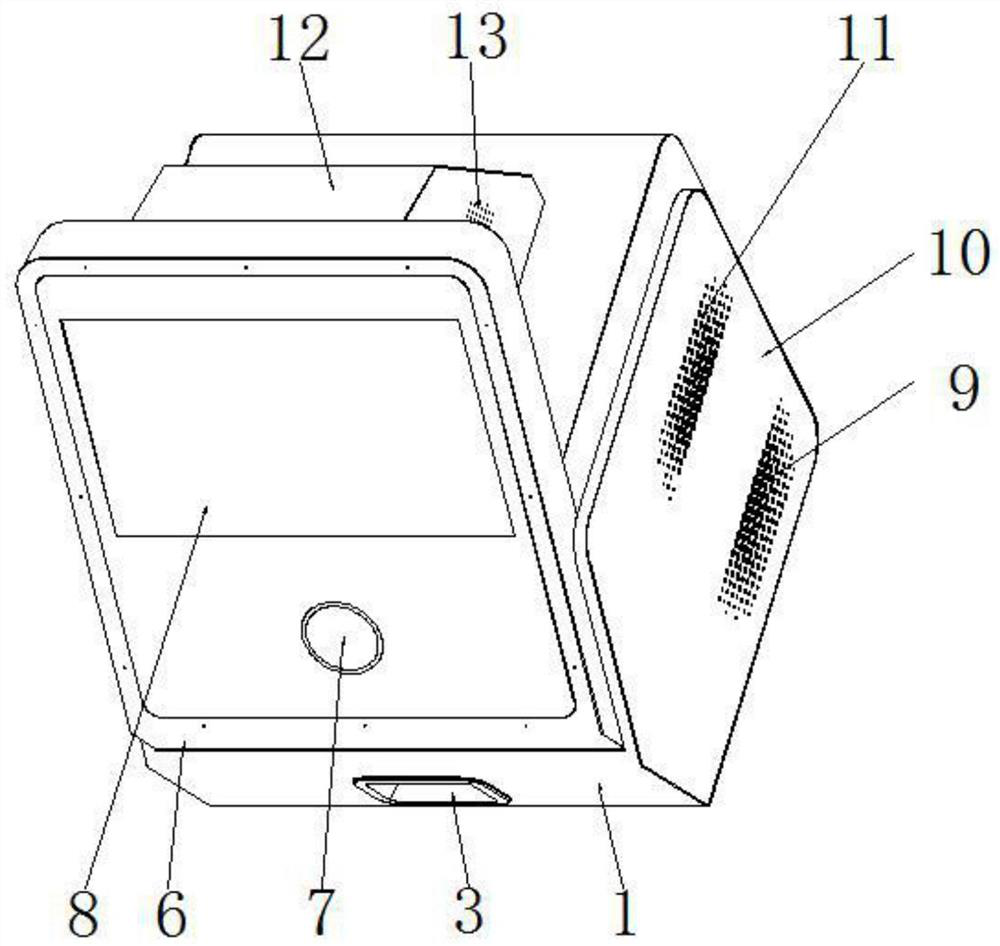

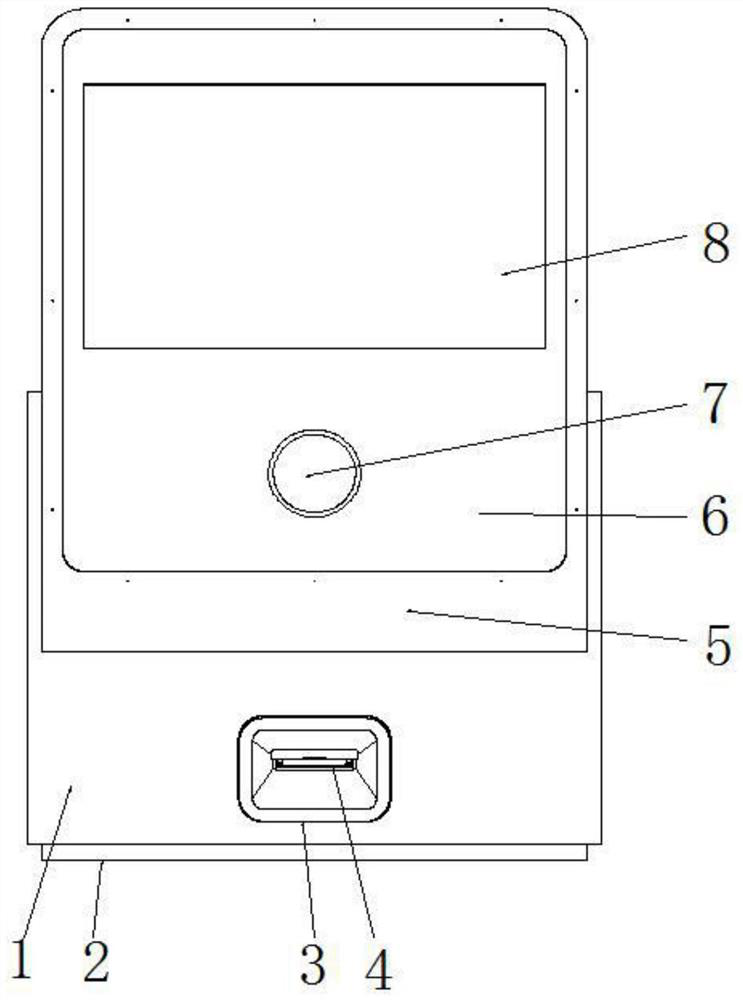

Automatic fluorescence detection equipment

PendingCN113405973AHigh movement accuracyFlexible useIndividual particle analysisData informationFluorescence

The invention discloses automatic fluorescence detection equipment which comprises a lower machine body, an upper machine body and a PC, a base is arranged at the bottom of the lower machine body, the upper machine body is mounted at the upper end of the lower machine body, the PC is mounted on the upper machine body, a rear cover shell is arranged at the rear part of the PC, a microscope is mounted in the middle of a top plate, a movable plate is arranged at the front end of the lower portion of the microscope, a rear fixed plate is arranged at the rear end of the lower portion of the microscope, an objective lens is installed on the lower portion of the movable plate, the lower end of the objective lens faces a movable platform, and the movable platform is located in the middle of the upper end face of the base. The automatic fluorescence detection equipment is reasonable in structural arrangement, microscopic previewing, photographing and full-automatic sample scanning can be conveniently carried out, data information can be locally stored and can also be exported to external equipment, use is more flexible and intelligent, the two hands of detection workers are liberated, the overall fluorescence detection efficiency is improved, and use is faster and more automatic.

Owner:苏州图墨医疗科技有限公司

A cable breakpoint connection device for electric power

InactiveCN111969504BEasy to fixEasy to separateLine/current collector detailsApparatus for removing/armouring cablesPower cableControl theory

The invention discloses a cable breakpoint connection device for electric power, which comprises a main body, a feeding mechanism is arranged in the middle of the upper surface of the main body, and a telescopic rod is installed in the middle of the feeding mechanism, and the left surface of the clamping mechanism is arranged There is a material receiving port, a second rack is provided under the right side surface of the clamping mechanism, and a material feeding port is provided in the center on the left side surface of the main body, and a collection box is installed under the main body. The holding mechanism and the cutting mechanism are set inside the main body. Through the setting of the main body, it is convenient to fix the clamping mechanism and the cutting mechanism, and through the setting of the cutting mechanism, it is convenient to avoid physical injury caused by the manual operation error of the master through mechanical operation. Through the arrangement of the clamping mechanism, it is convenient to fix the cable insulation layer, thereby facilitating the separation of the insulation layer from the electric wire.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO

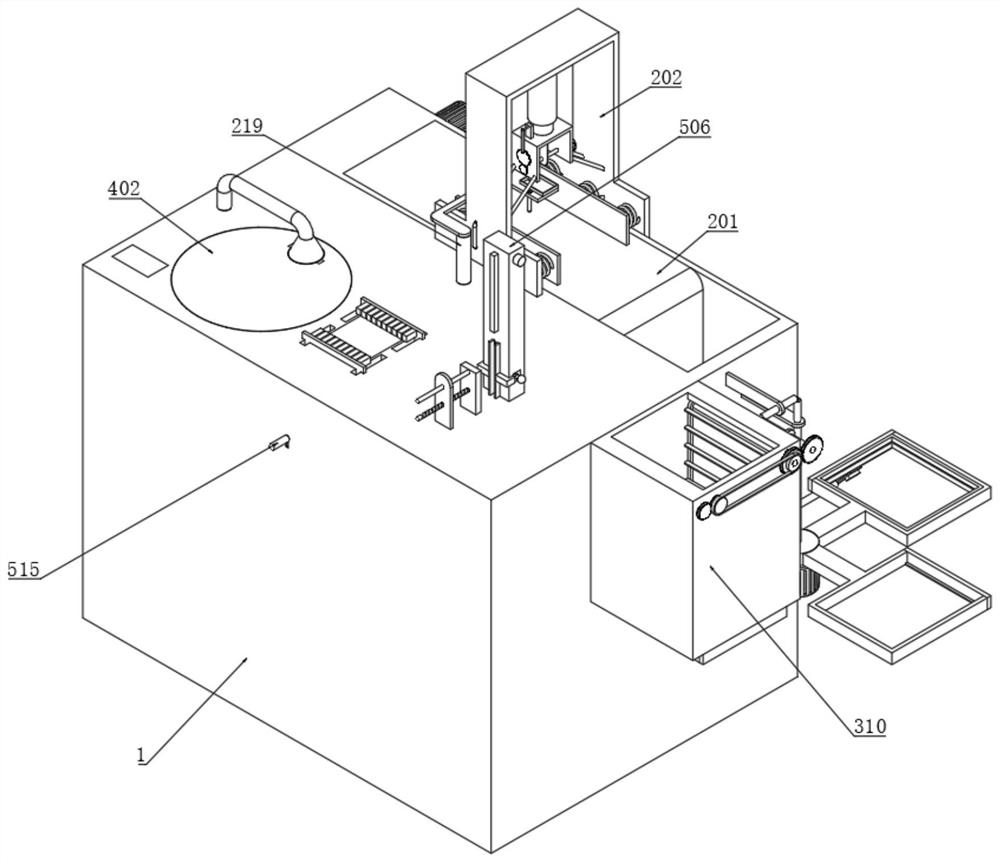

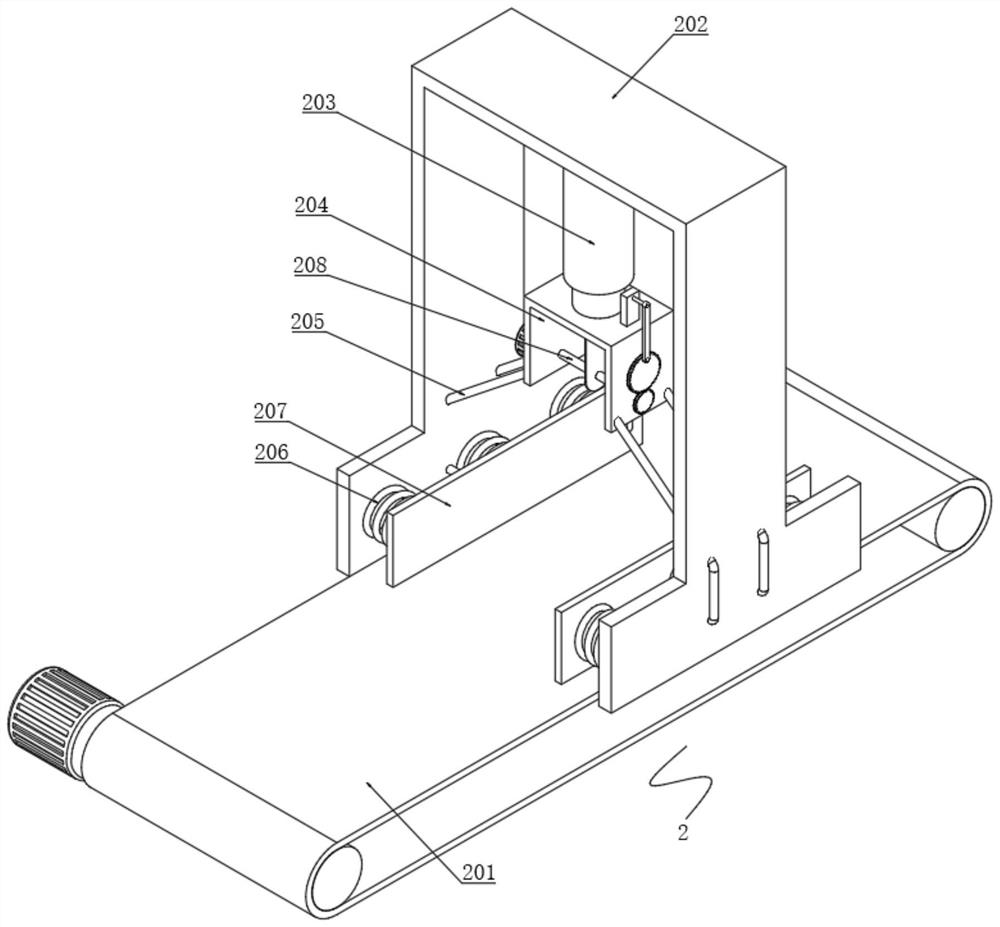

Crossed threaded groove drum-shaped cam inner groove barb polishing, detecting and machining production equipment

InactiveCN113310796AReduce deliveryEasy to moveMaterial strength using tensile/compressive forcesCamScrew thread

The invention discloses crossed threaded groove drum-shaped cam inner groove barb polishing, detecting and machining production equipment which comprises a machining case, wherein a feeding bin is fixedly connected to the left side of the top end face of the machining case in a welded mode, a rotary discharging assembly is arranged on the portion, which is on the right side of a conveying assembly, of the outer side of the machining case, and a displacement adjusting assembly is fixedly mounted on the right side of the top end face of the machining case through bolts. According to the invention, the conveying assembly and the displacement adjusting assembly are arranged on the two sides of the rotary discharging assembly; through arrangement of the conveying assembly, blanks of groove drums can be conveniently delivered one by one; meanwhile, through arrangement of the displacement adjusting assembly, the position of the polishing head and the position of the detecting assembly can be conveniently moved and adjusted; and the groove drums can be conveniently driven to rotate while being limited and clamped through the arrangement of a sorting, mixing and discharging assembly, and polishing and detecting of the groove drums are combined together, so that operation steps are reduced, and the production efficiency is improved.

Owner:长沙市立鑫工业设计有限公司

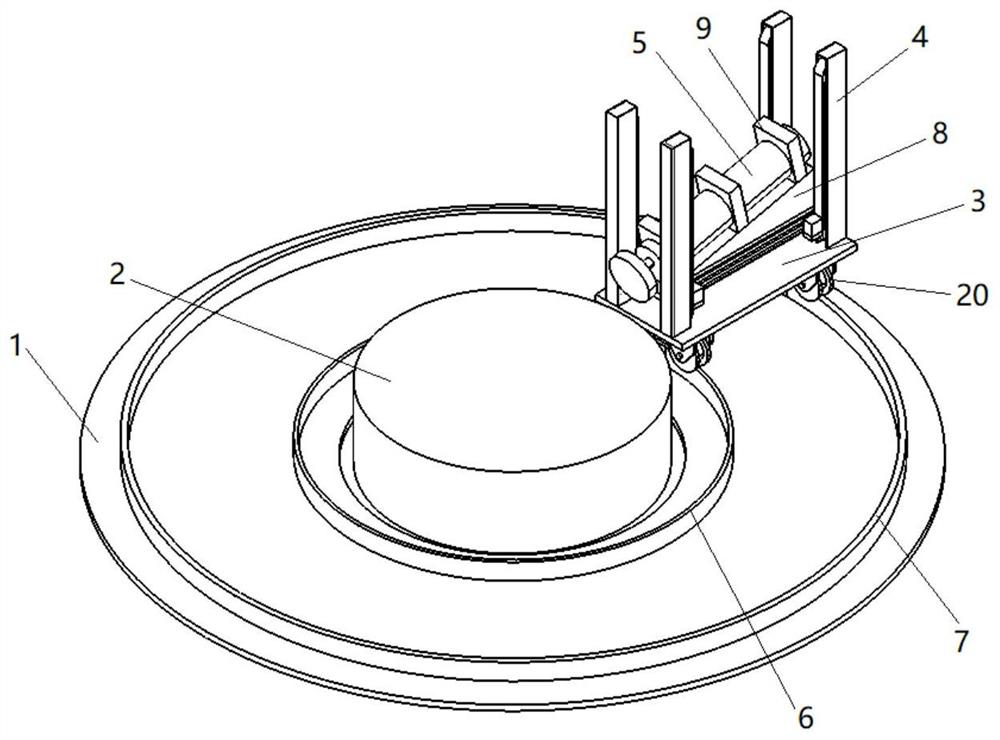

A three-dimensional synchronous loading device for ultrasonic-assisted laser melting deposition forming of large-volume parts

ActiveCN113102778BRealize three-dimensional movementInhibition of directed growthAdditive manufacturing apparatusElectric machineryEngineering

A three-dimensional synchronous loading device for ultrasonic-assisted laser melting deposition molding of large-volume parts relates to a three-dimensional synchronous loading device for ultrasonic-assisted laser melting deposition molding. The device consists of slide rail substrate, deposition substrate, bottom plate, support column, ultrasonic vibrator, inner annular track, outer annular track, wedge base, fixed plate, circumferential drive motor, lift drive motor, radial drive motor, radial drive pulley, The first toothed belt, the radial drive motor base, the guide groove, the driving pulley, the driven pulley, the second toothed belt, the moving wheel and the moving wheel fixing frame are formed. The invention realizes the real-time loading of the auxiliary ultrasonic field in the process of forming large-volume parts by laser melting deposition, and solves the problem of easy formation of directional structure in the parts and the problems of large residual stress in the parts when forming large-volume parts by laser melting deposition. The present invention is suitable for laser melting deposition of parts.

Owner:HARBIN INST OF TECH

Automatic distance-adjusting labeler guardrail punching and bending machining and production equipment

InactiveCN112893622AEasy stampingImprove accuracyMetal-working feeding devicesShearing machinesElectric machineryStructural engineering

The invention discloses automatic distance-adjusting labeler guardrail punching and bending machining and production equipment. The equipment comprises a bottom case, wherein a punching component is fixedly arranged at the left side of the top end face of the bottom case through a bolt; a supporting seat is arranged at the right side of the top end face of the bottom case; and a bending component is connected to the end of the right side of a flow guide frame. According to the equipment, the punching component and the bending component are arranged at the left side and the right side of the top end face of the bottom case correspondingly, a guardrail is conveniently driven to move while the guardrail is punched through the arrangement of an adjusting transmission component, meanwhile, the flow guide frame, the bending component and a flow guide groove of the bottom case are conveniently driven to be located on the same horizontal line through the arrangement of the supporting seat, and through the arrangement of a rotating motor and a first single-shaft pneumatic cylinder, after the bending component is driven to rotate, the first single-shaft pneumatic cylinder drives a cutting head to cut off the guardrail, repeated operation caused by deviation of radian data during manual turning is avoided, and therefore the radian data accuracy during bending is facilitated.

Owner:东阳市君泽钓具有限公司

Non-woven fabric cutting device capable of achieving different cutting sizes

The invention discloses a non-woven fabric cutting device capable of achieving different cutting sizes. The non-woven fabric cutting device comprises a fixing frame, wherein a material roller support and an n-shaped support are fixedly connected to the upper surface of the fixing frame, a through hole is formed in the front face of the material roller support, a rotating shaft is rotatably connected to the inner wall of the through hole, a servo motor is fixedly connected to the back face of the fixing frame, a main rotating roller is fixedly connected to the output end of the servo motor, and fixing plates are fixedly connected to the upper surface and the lower surface of the fixing frame. The non-woven fabric cutting device is reasonable in structure; through arrangement of a belt pulley, a conveying belt, an n-shaped guide rail, a gear motor, a gear, a guide plate, a step column and pressing plates, the gear motor can be started conveniently, and thus the belt pulley and the non-woven fabric move synchronously; and under the action of the inclined guide plate, the step column is extruded, and the pressing plates on the two sides of a cutting blade press non-woven fabric tightly, and meanwhile, the non-woven fabric is cut by the cutting blade, so that pause is not needed, and the production efficiency is effectively improved.

Owner:东莞市青之森礼品有限公司

Turning production equipment for bevel angle threads in non-standard conical fastening part

PendingCN113600935AAvoid time consumingEasy advanced adjustmentThread cutting feeding devicesThread cutting machinesEngineeringManual handling

The invention discloses turning production equipment for bevel angle threads in a non-standard conical fastening part. The equipment comprises a bottom machine box, a feeding device is fixedly connected to the end of the right side of the bottom machine box through a bolt, a conveying groove is formed at the left side of the end face of the top of the bottom machine box, and a tapping device is fixedly connected to the end of the front face of the bottom machine box through a bolt. The feeding device and a pushing device are arranged at the right side of a flow guide groove and the right side of the conveying groove correspondingly, the effects of automatic feeding and intermittent conveying on blank materials of parts are conveniently achieved, time consumption generated when the parts are calibrated during manual feeding is avoided, meanwhile, the tapping device and an adjusting device are arranged in a clamping plate, in the process of driving the parts to rotate, the position and the moving path of a tapping head are conveniently adjusted in an advanced manner, so that adjustment is conveniently performed according to different hole diameters of threads in the parts, the flexibility of the tapping head is embodied, time is short, manual operation is avoided, and automatic turning machining is is formed.

Owner:合肥北屋智能科技有限公司

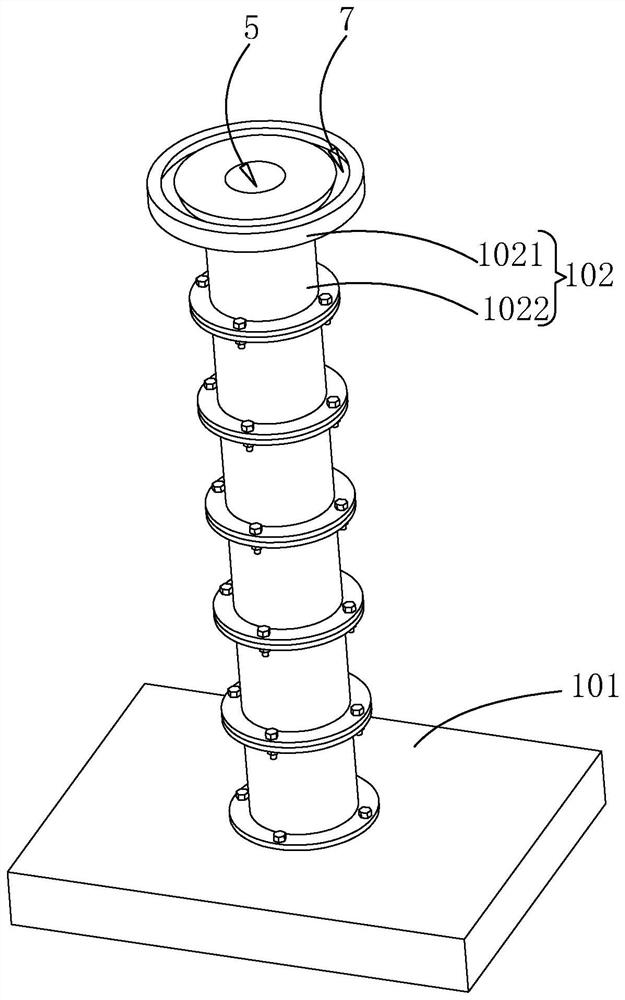

Manned lifting type vertical shaft measuring device and operation method thereof

InactiveCN112357711AImprove safety performanceHigh flexibilityElevatorsBuilding liftsMeasurement deviceInstrumentation

The invention discloses a manned lifting type vertical shaft measuring device, and meanwhile discloses an operation method of the manned lifting type vertical shaft measuring device. The manned lifting type vertical shaft measuring device comprises a supporting mechanism, an adjusting mechanism and a manned measuring mechanism; the adjusting mechanism sleeves the outer side of the supporting mechanism; and the manned measuring mechanism is arranged at the lower end of the adjusting mechanism. The device has the beneficial effects that the whole device is high in safety performance, can bear any small and medium-sized measuring instrument to measure a vertical shaft, is high in use flexibility, is suitable for vertical shafts with different calibers, and is convenient to use and popularize.

Owner:江西大吉山钨业有限公司

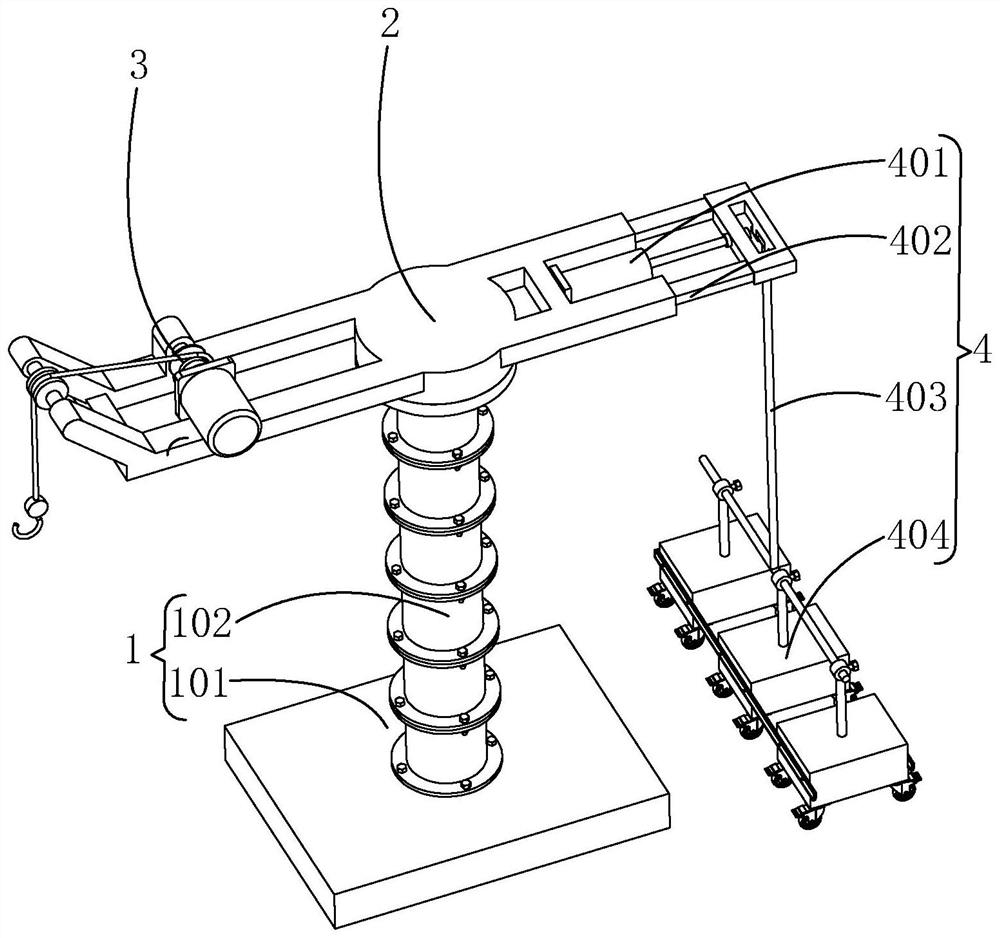

A kind of building hoisting equipment and hoisting method

The present application relates to a hoisting device for construction and a hoisting method, comprising a support frame, a rotating device, a hoisting device and a balancing device, the balancing device is located on the side of the mounting frame away from the hoisting device, and the balancing device includes a balancing cylinder, a balancing device, and a balancing device. A frame, a connecting rod and a balance block, the balance cylinder is connected to the mounting frame, one end of the balance frame is slidably connected to the mounting frame, the piston rod of the balance cylinder is connected to the balance frame; one end of the connecting rod is connected to the balance frame The frame is connected, and the other end is connected with a balance block, and the end of the balance block away from the connecting rod is located above the base. The present application has the effect of improving the use safety of the hoisting equipment.

Owner:平凉市新世纪建筑工程有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com