Copper product cutting device with recovery structure

A technology for cutting devices and copper products, applied in shearing devices, feeding devices, pipe shearing devices, etc., can solve the problems of cooling liquid flowing away, low flexibility, waste, etc., and achieve convenient cleaning of waste, convenient use, and prevention of waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

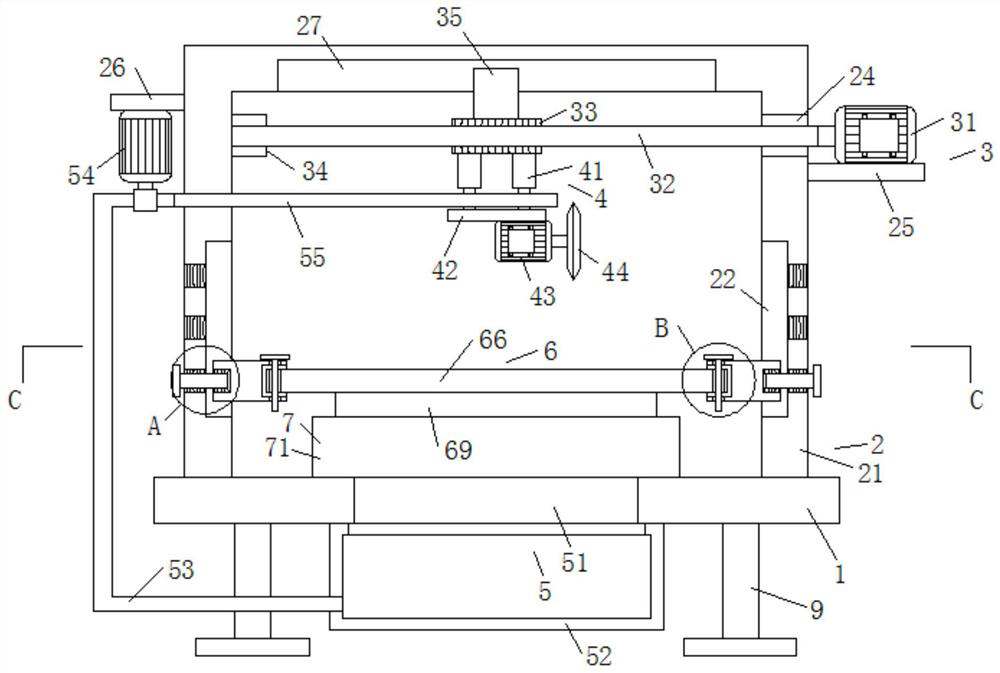

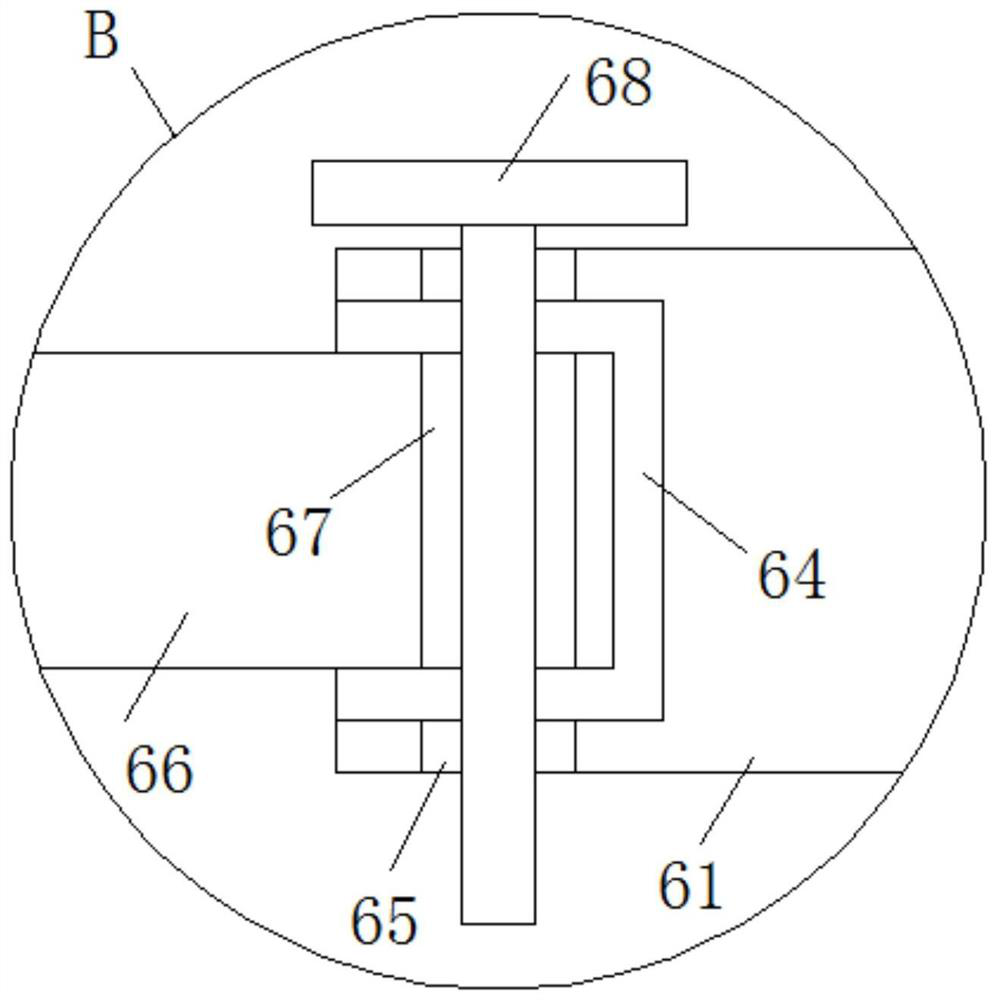

[0036]Example:Figure 1-7As shown, a copper product cutting device with a recovery structure comprising a base 1, the upper end of the base 1 is fixedly connected to a mounting mechanism 2, and the mounting mechanism 2 is fixed to the upper end fixed connection with a mobile mechanism 3, the mobile mechanism 3 The lower end is fixedly connected to a cutting mechanism 4, the base 1, the mounting mechanism 2, and the cutting mechanism 4 co-fixed connection with one water cooling mechanism 5, the mounting mechanism 2 is adjacent to the lower end, the position threaded connection is connected to a filter mechanism 6, the base 1 away from the water cooling mechanism 5 On the upper side, the upper end is fixedly connected to a recovery mechanism 7, and the recovery mechanism 7 is fixedly connected to a cleaning mechanism 8.

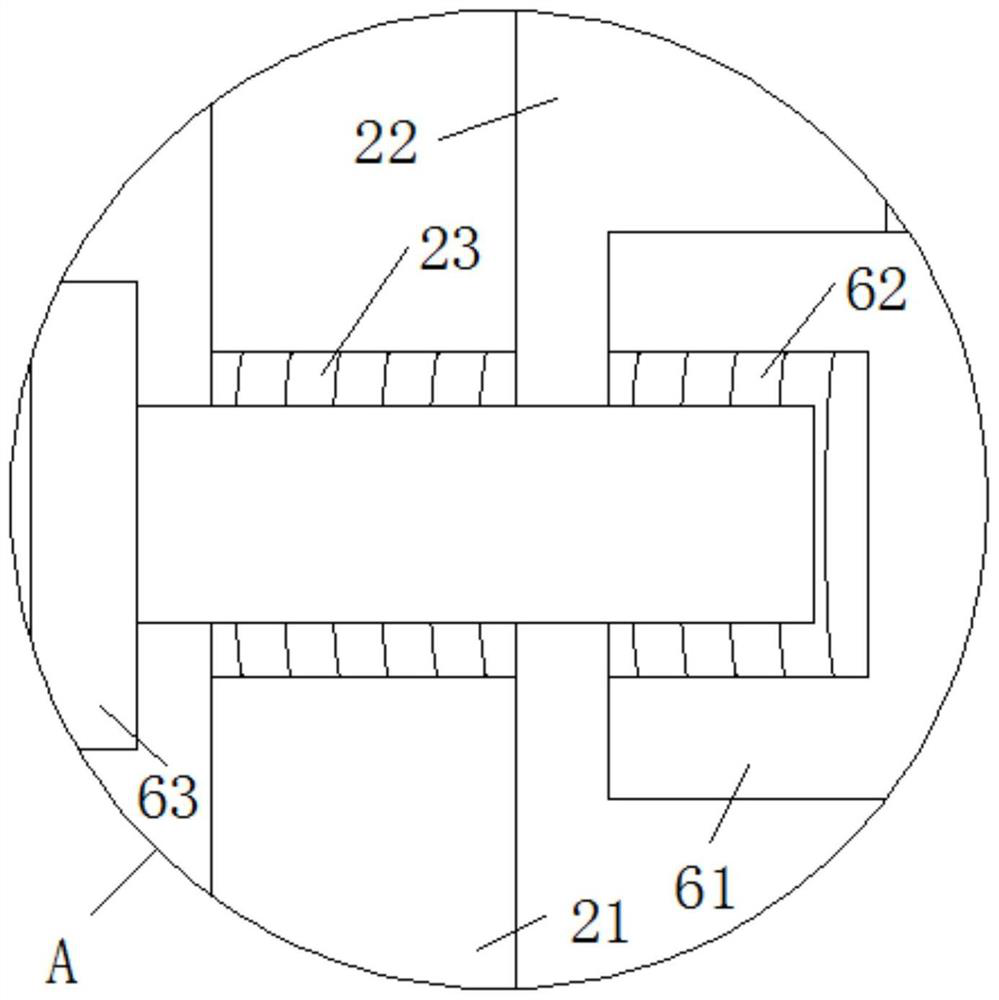

[0037]The mounting mechanism 2 includes a mounting frame 21, and a first mounting groove 22 is opened in the opposite side of the mounting frame 21 adjacent the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com