A three-dimensional synchronous loading device for ultrasonic-assisted laser melting deposition forming of large-volume parts

A laser melting deposition, ultrasonic-assisted technology, used in additive manufacturing, additive processing, etc., can solve problems such as residual stress, reduce residual stress, inhibit directional growth, and promote the transformation of columnar crystals to equiaxed crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

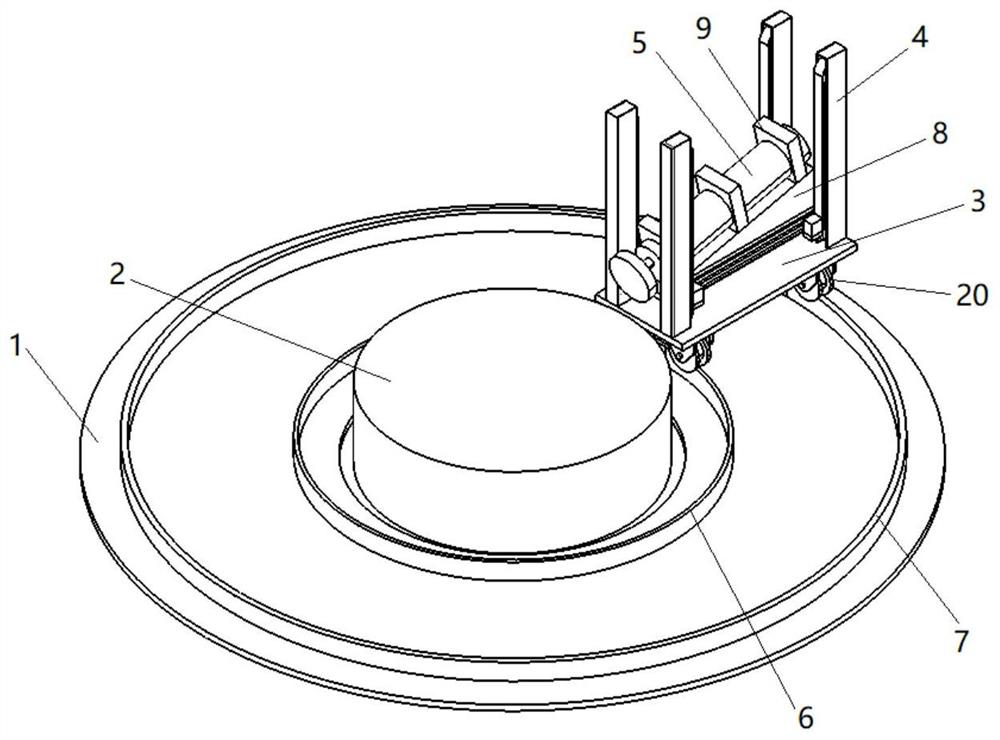

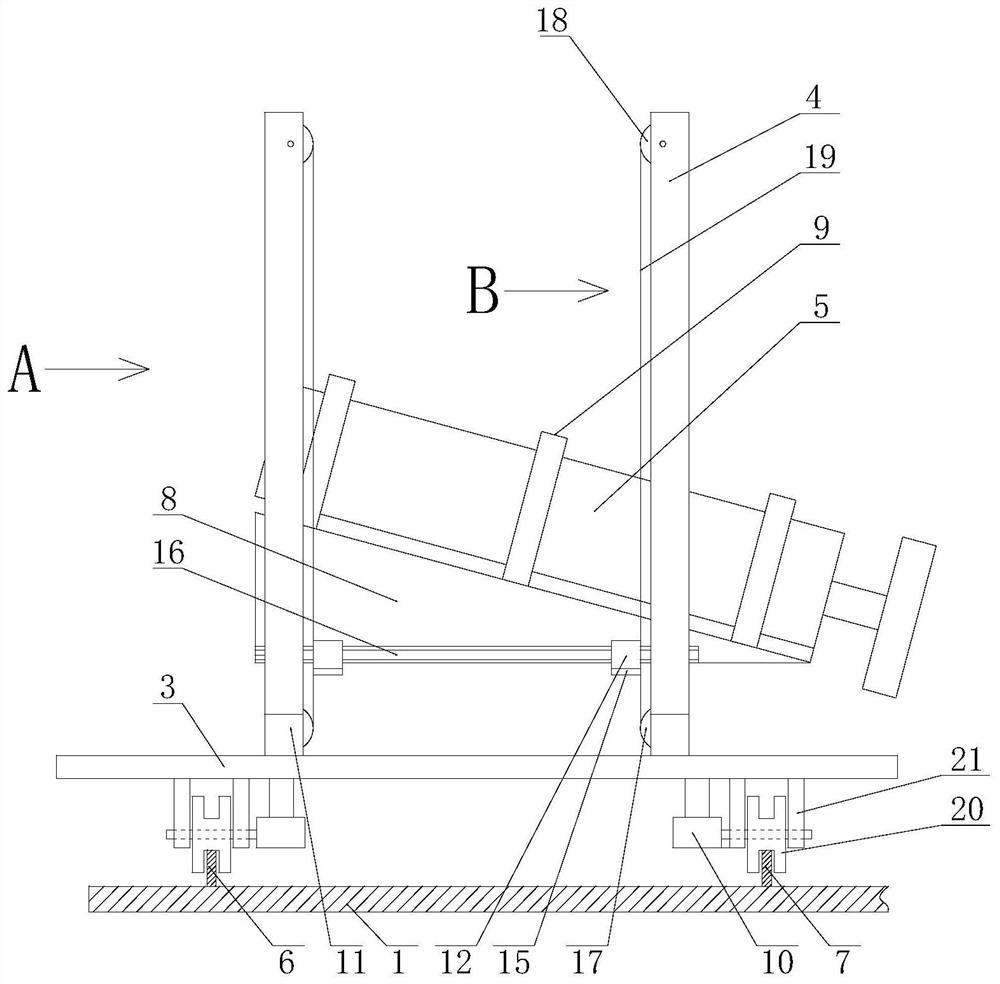

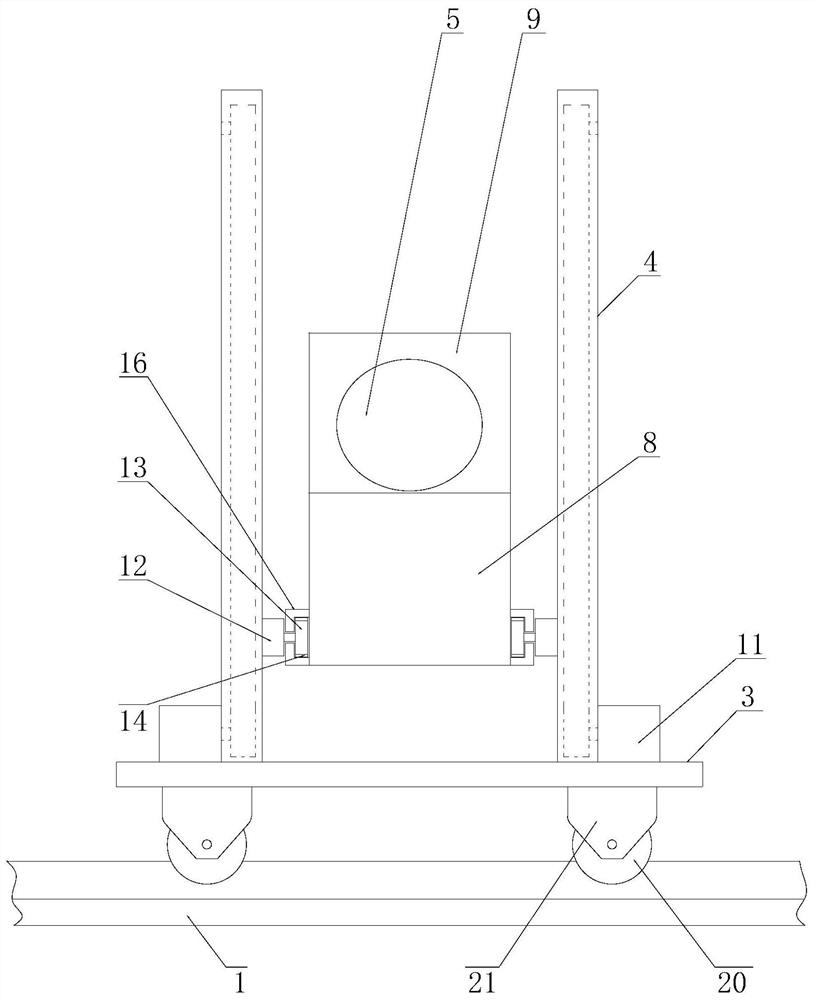

[0017] Embodiment 1: The three-dimensional synchronous loading device for ultrasonic-assisted laser melting deposition molding of large-volume parts in this embodiment is composed of a slide rail substrate 1, a deposition substrate 2, a bottom plate 3, a support column 4, an ultrasonic vibrator 5, an inner annular track 6, and an outer annular track. 7. Wedge-shaped base 8, several fixed plates 9, circumferential drive motor 10, lift drive motor 11, radial drive motor 12, radial drive pulley 13, first toothed belt 14, radial drive motor base 15, guide The groove 16, the driving pulley 17, the driven pulley 18, the second toothed belt 19, the moving pulley 20 and the moving pulley fixing frame 21 are constituted;

[0018] The slide rail substrate 1 is a circular plate, a circular hole is opened in the center of the slide rail substrate 1, and the deposition substrate 2 is arranged in the circular hole in the center of the slide rail substrate 1; The annular track 6 and the oute...

specific Embodiment approach 2

[0024]Embodiment 2: The difference between this embodiment and Embodiment 1 is that the radial drive pulley 13 , the driving pulley 17 and the driven pulley 18 are toothed pulleys.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the casing of the circumferential drive motor 10 is fixed on the lower surface of the bottom plate 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com