Simulator for friction force between denture groove and correction string

A friction, simulator technology, applied in the direction of arch wires, brackets, etc., can solve the problems of many rework, improper operation, difficult to control teeth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

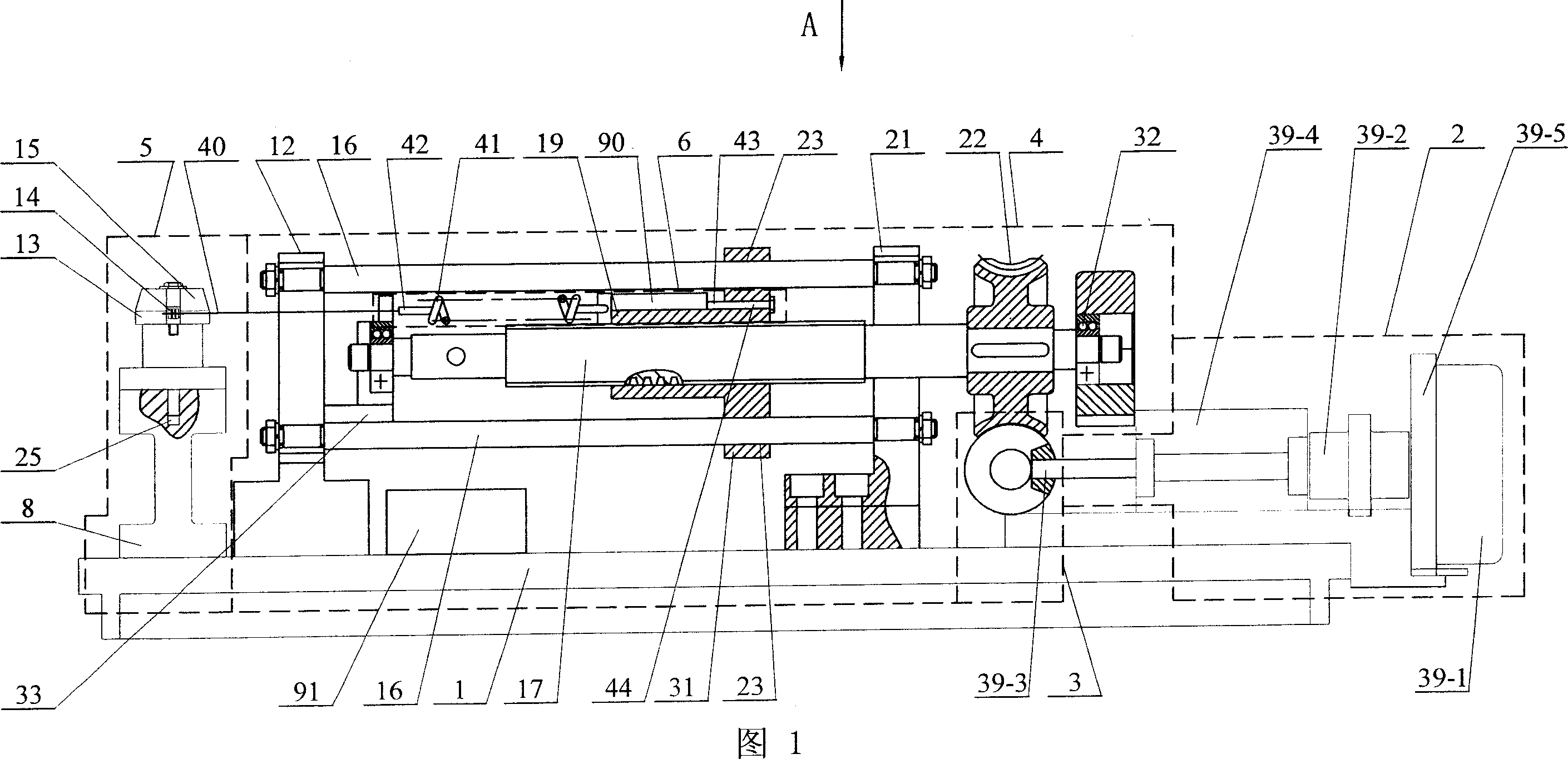

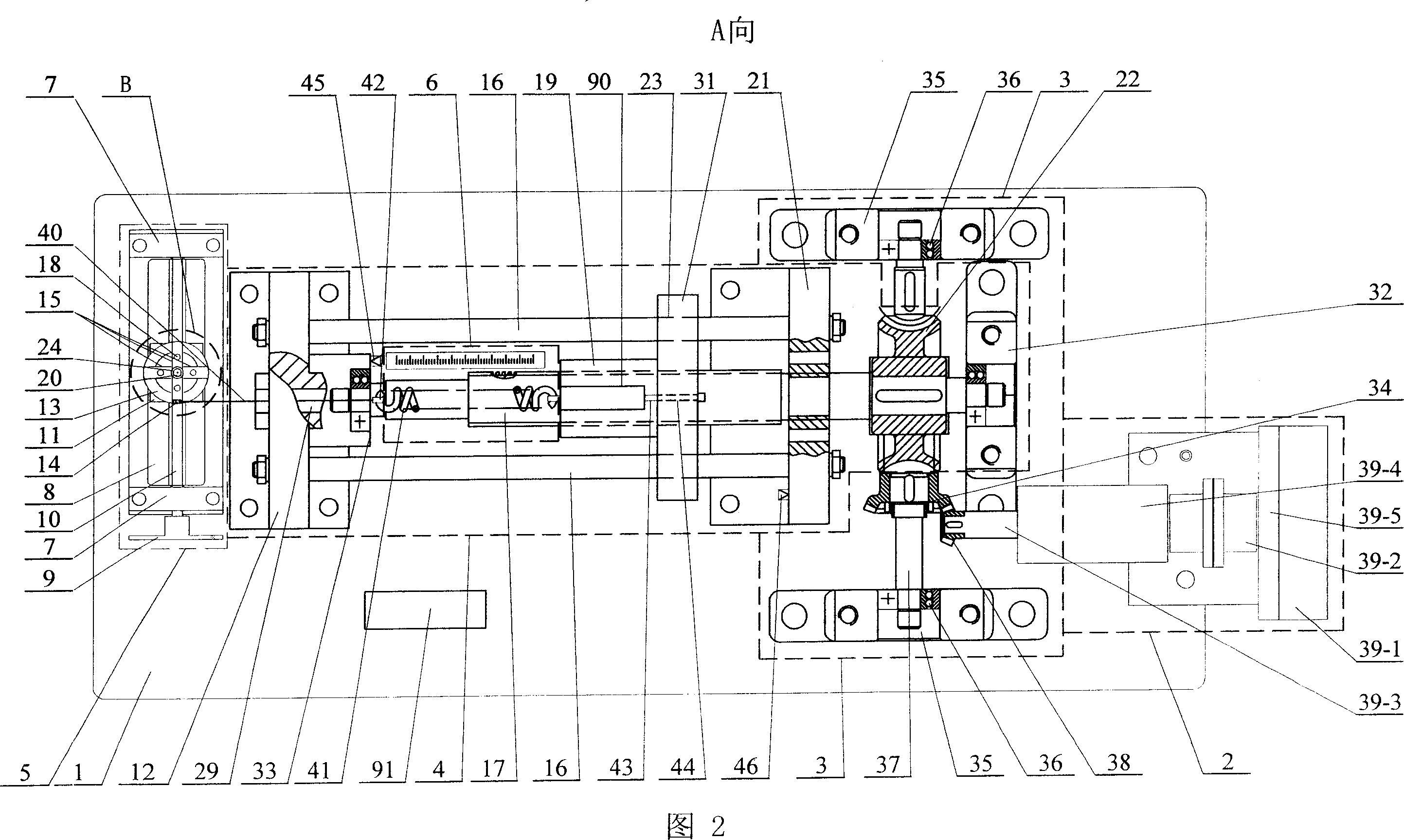

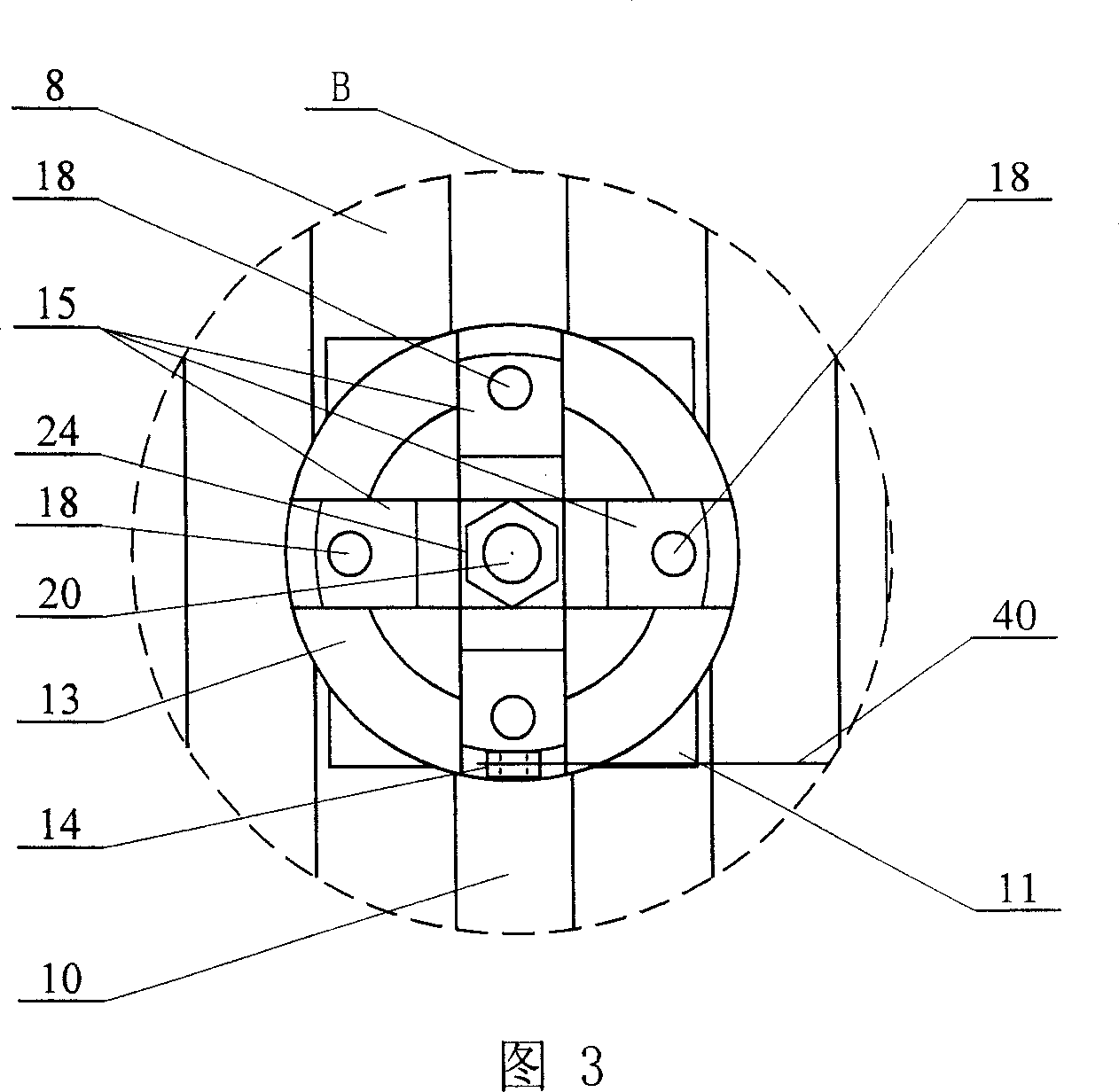

[0005] Specific embodiment one: (referring to Fig. 1-Fig. 13) this embodiment consists of base 1, power device 2, speed change mechanism 3, drive device 4, bracket positioning device 5, test device 6, pull sensor 90, signal amplifier 91 Composition; the bracket positioning device 5 is fixed on the left end of the upper part of the base 1, the driving device 4 is fixed on the upper part of the base 1 on the right side of the bracket positioning device 5, the speed change mechanism 3 is fixed on the base 1 on the right side of the driving device 4, and the power unit 2 is fixed on the base 1 on the right side of the transmission mechanism 3, the test device 6 is fixed on the upper side of the drive device 4, the power device 2 is connected to the transmission mechanism 3, the transmission mechanism 3 is connected to the drive device 4, and the pull sensor 90 Be arranged on the right side of the test device 6 in the driving device 4, the signal amplifier 91 is fixed on the base 1,...

specific Embodiment approach 2

[0006] Specific embodiment two: (see Fig. 2) the difference between this embodiment and specific embodiment one is that a left travel switch 45 and a right travel switch 46 are added on the driving device 4, and the left travel switch 45 is fixed on the left branch of the lead screw. On the right side of the seat 33, the right travel switch 46 is fixed on the left side of the right bracket 21, and other components and connections are the same as those in the first embodiment. The increased left travel switch 45 and right travel switch 46 can ensure the safe operation of the driving device.

[0007] Working principle: The working process of the present invention is carried out according to the three-dimensional movement characteristics and treatment requirements of clinical patients orthodontic treatment teeth (first determine the tooth to be treated is the tooth on the left and right of the upper jaw or the tooth on the left and right of the lower jaw) and correspondingly selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com