Highland barley paper pasting device applied to batteries

A sticking device and technology for highland barley paper, which are used in battery assembly machines, secondary battery manufacturing, non-aqueous electrolyte storage batteries, etc., can solve the problems of skewed highland barley paper, narrow highland paper, and poor sticking, etc., and achieve stable support and guidance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The following is a further detailed description through specific embodiments:

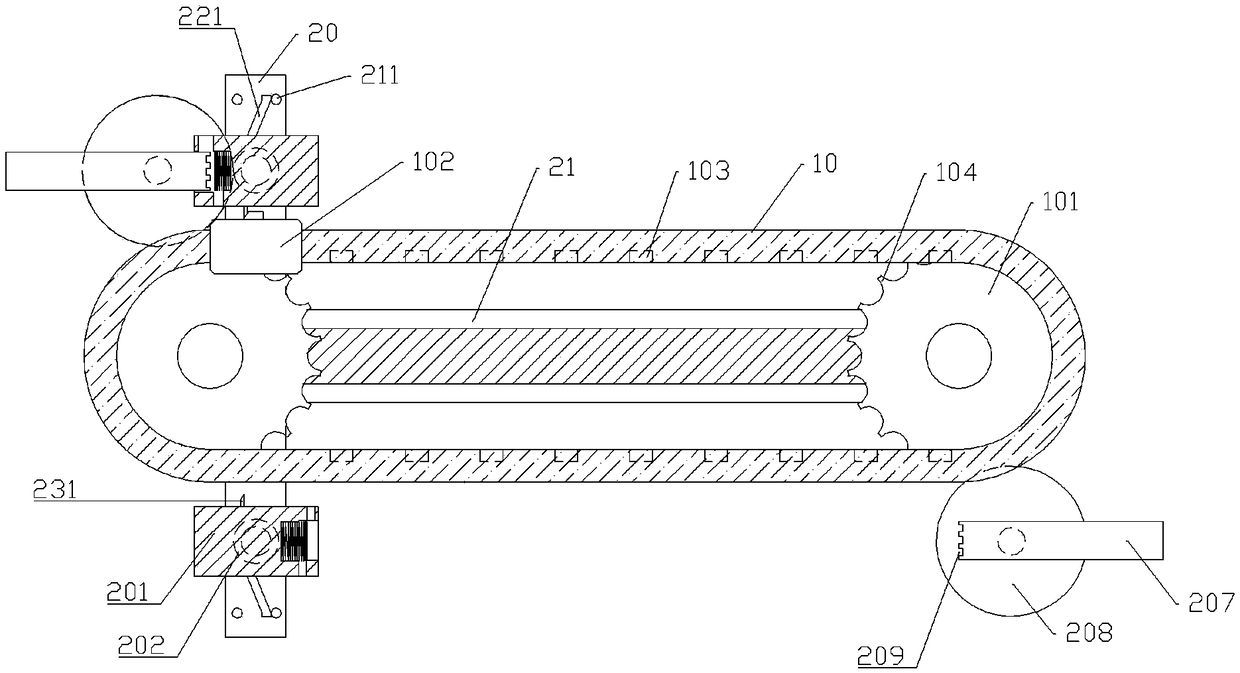

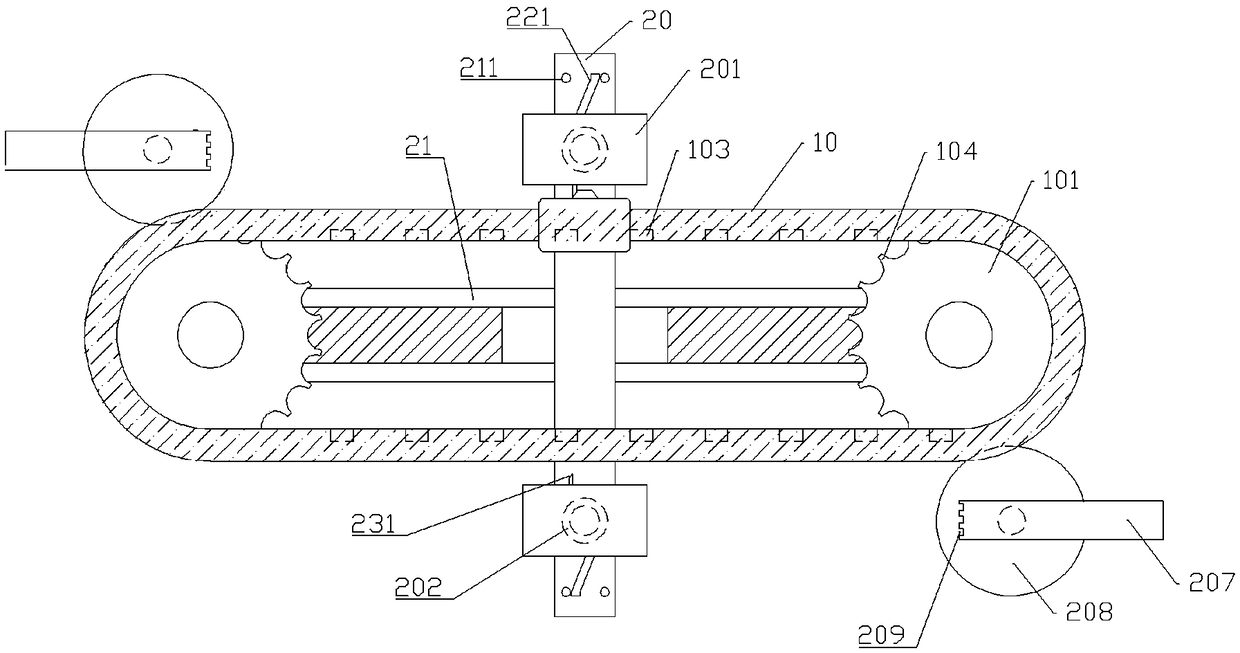

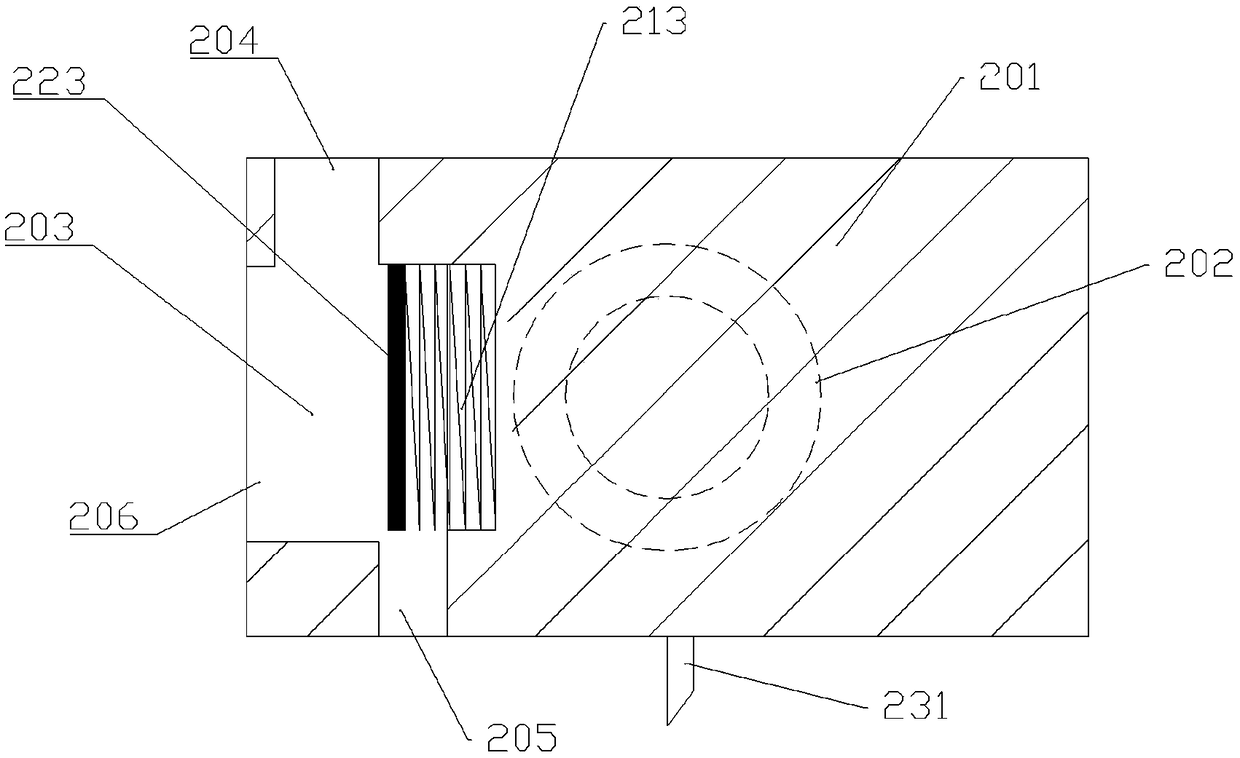

[0020] Reference numerals in the accompanying drawings include: conveyor belt 10, transmission wheel 101, shifting block 102, transmission slot 103, transmission tooth 104, connecting rod 20, slide rail 21, sticking block 201, blocking rod 211, limit rod 221, The lever 231 , the driven gear 202 , the accommodating cavity 203 , the compression spring 213 , the support plate 223 , the feeding port 204 , the discharging port 205 , the pressing port 206 , the top plate 207 , the driving gear 208 , and the groove 209 .

[0021] The example is basically as attached figure 1 , attached figure 2 and attached image 3 Shown: Highland barley paper sticking device for battery, including sticking mechanism and transmission mechanism.

[0022] The transmission mechanism includes a closed conveyor belt 10, a transmission wheel 101 that drives the conveyor belt 10 to move, and a dial block 102. The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com