Composite flocculant and its flocculation method, recycling method and system

A composite flocculant, cyclic regeneration technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage multi-stage treatment, etc. The effect of transportation treatment and avoiding water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

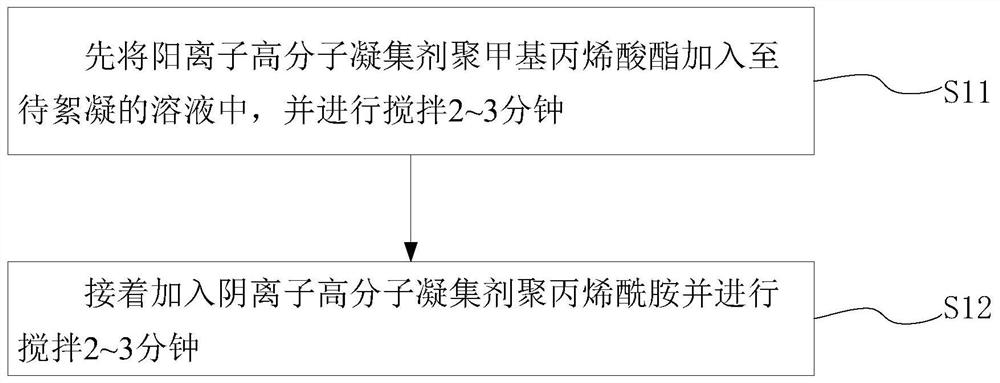

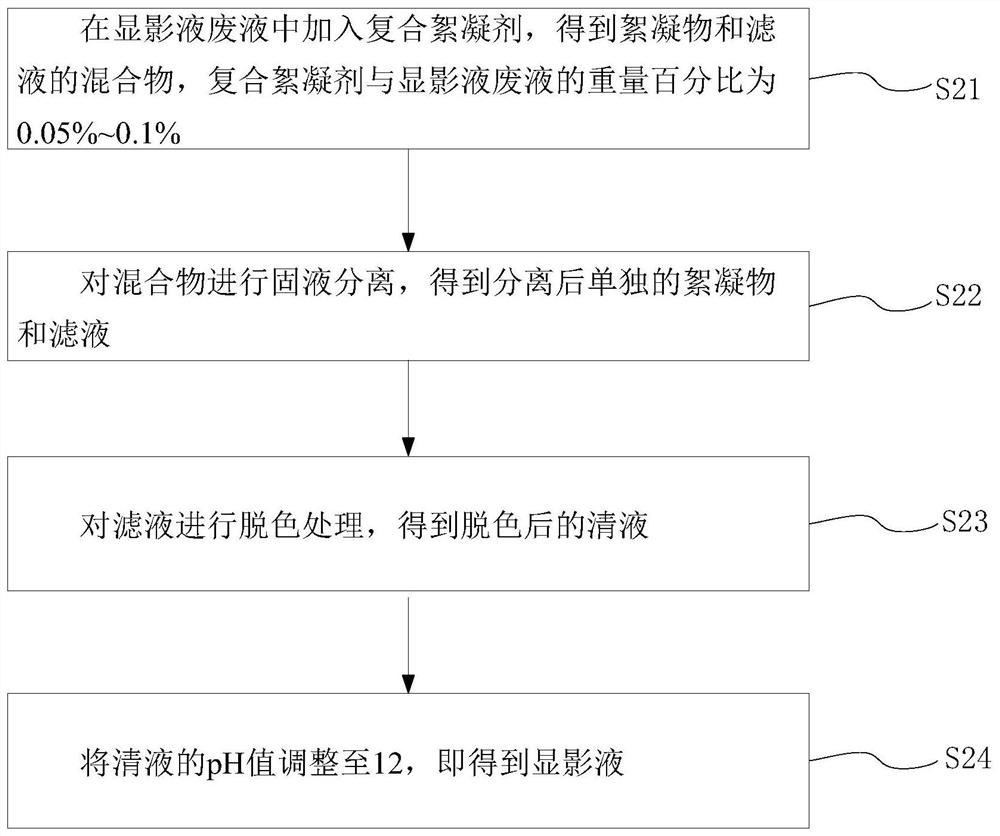

[0046] Taking the preparation of 1 kg of composite flocculant as an example, the components and contents of the composite flocculant are as follows:

[0047] Cationic polymer coagulant polymethacrylate 25% 250g

[0048] Anionic polymer coagulant polyacrylamide 75% 750g

[0049] The compound flocculant preparation method of present embodiment 1 is as follows:

[0050] A1, take by weighing 250g cationic macromolecule coagulant polymethacrylate, be dissolved in ethanol, preserve separately;

[0051] A2. Weigh 750g of anionic polymer coagulant polyacrylamide, dissolve it in deionized water, and store it separately.

Embodiment 2

[0053] Taking the preparation of 1 kg of composite flocculant as an example, the components and contents of the composite flocculant are as follows:

[0054] Cationic polymer coagulant polymethacrylate 60% 600g

[0055] Anionic polymer coagulant polyacrylamide 40% 400g

[0056] For the preparation method of the composite flocculant of this embodiment, refer to Example 1, and details are not repeated here.

Embodiment 3

[0058] Taking the preparation of 1 kg of composite flocculant as an example, the components and contents of the composite flocculant are as follows:

[0059] Cationic polymer coagulant polymethacrylate 50% 600g

[0060] Anionic polymer coagulant polyacrylamide 50% 500g

[0061] For the preparation method of the composite flocculant of this embodiment, refer to Example 1, and details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com