Packing equipment for compressible waste recycling

A technology of waste and equipment, applied in the field of packaging equipment for compressible waste recycling, can solve the problems of large space occupation, poor packaging effect, environmental pollution, etc., to achieve reduced space occupation, convenient transportation, convenient packaging and post-processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

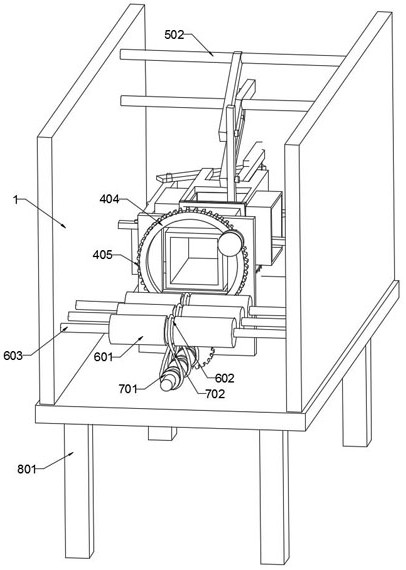

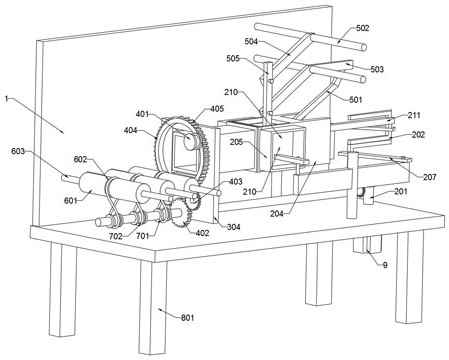

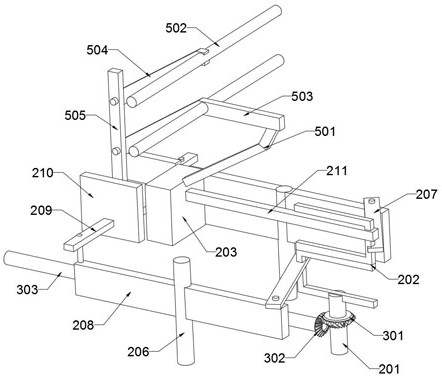

[0024] refer to Figure 1-5 , a packaging device for compressible waste recycling, comprising a case 1, a pretreatment mechanism and an auxiliary mechanism are installed inside the case 1;

[0025] The pretreatment mechanism includes a delivery pipe 204 fixedly connected to the inner wall of the cabinet 1 through a pillar. The first slider 203 is slidably connected to the delivery pipe 204. The side wall of the delivery pipe 204 is symmetrically penetrated and fixedly connected with a connecting pipe 205. Each connecting pipe 205 A second slider 210 is slidably connected inside, a rotating rod 206 is connected to the symmetrical rotation of the inner wall of the cabinet 1, a connecting plate 208 is fixedly connected to the side wall of the rotating rod 206, a motor 9 is installed on the bottom wall of the cabinet 1, and the output end of the motor 9 is coaxial A rotating shaft 201 is fixed, and after the rotating shaft 201 penetrates the inner wall of the chassis 1, it is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com