Patents

Literature

62results about How to "Easy to pack and handle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

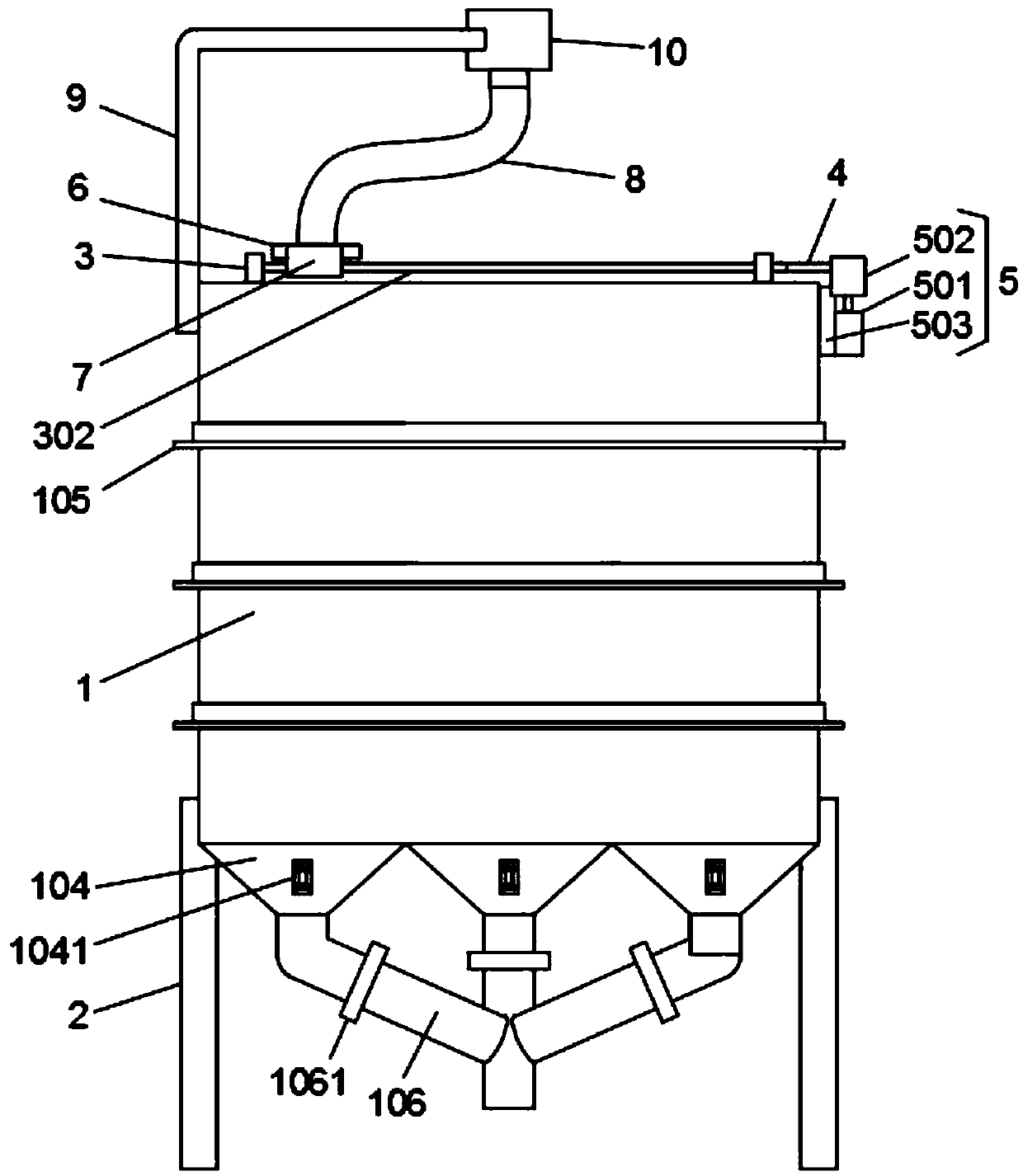

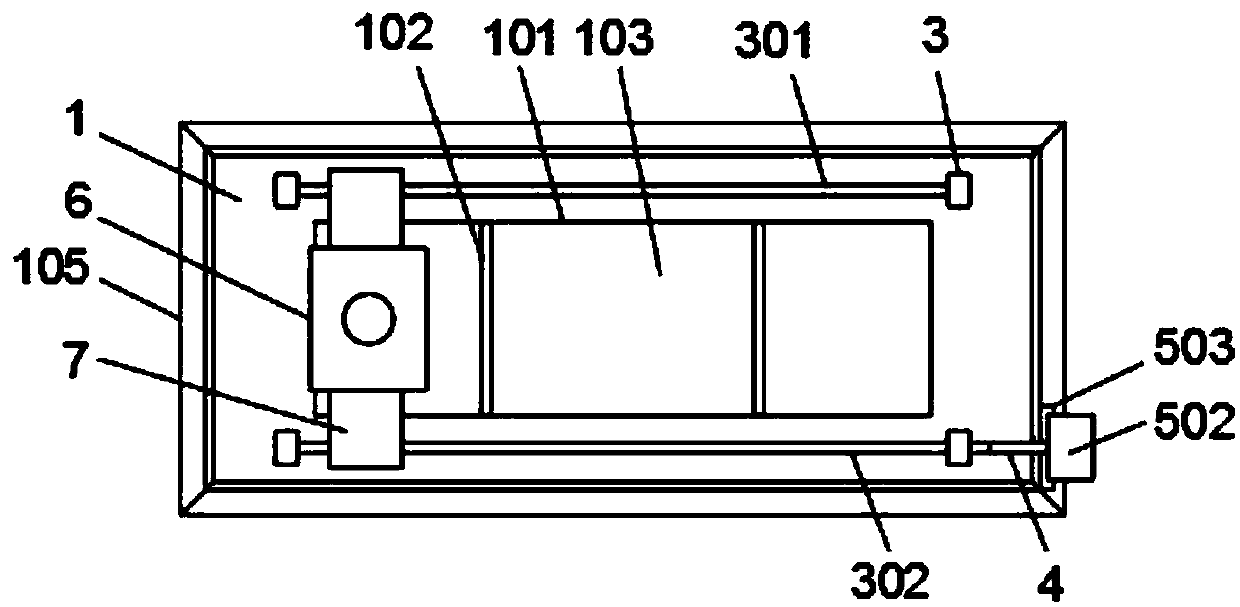

Feeding device for pesticide processing and packaging machine

InactiveCN106144024AEvenly distributedAvoid hoardingDrying gas arrangementsPackagingEngineeringMaterial distribution

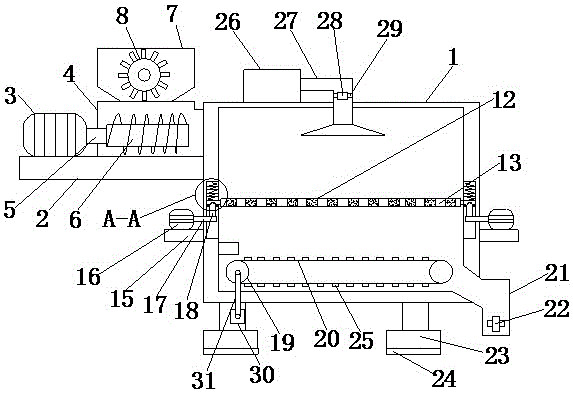

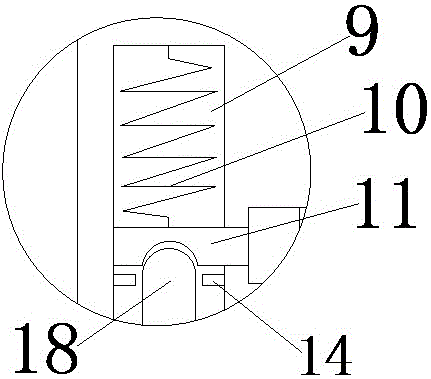

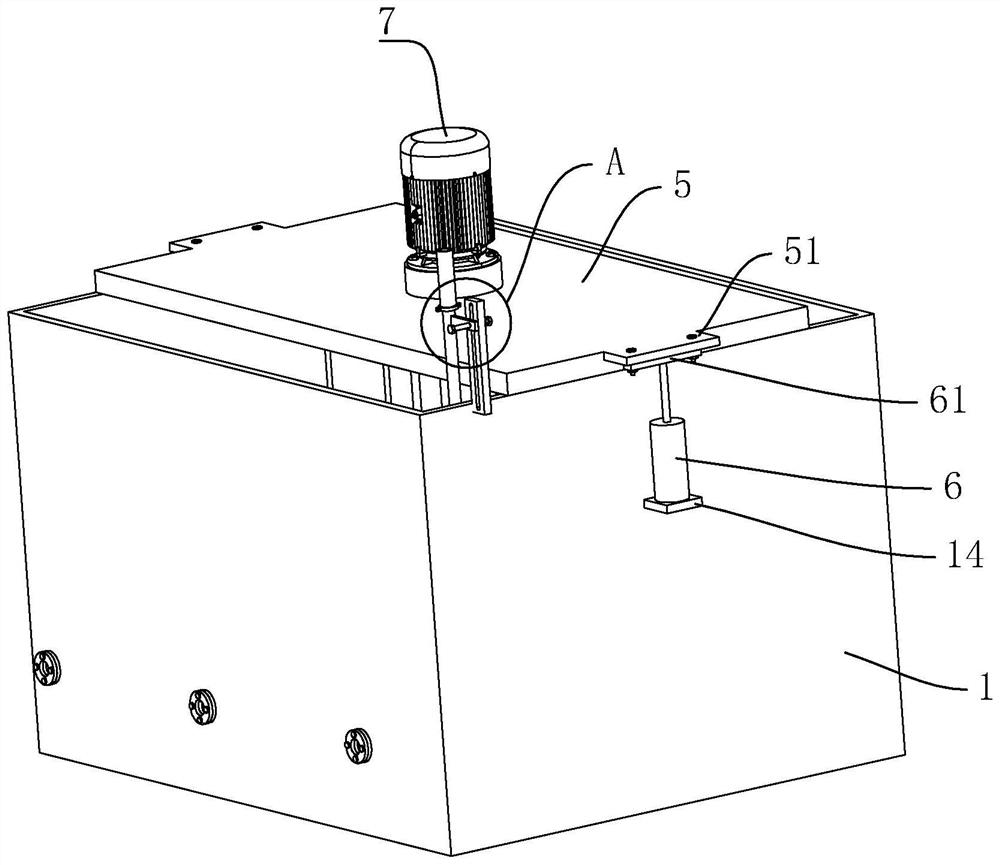

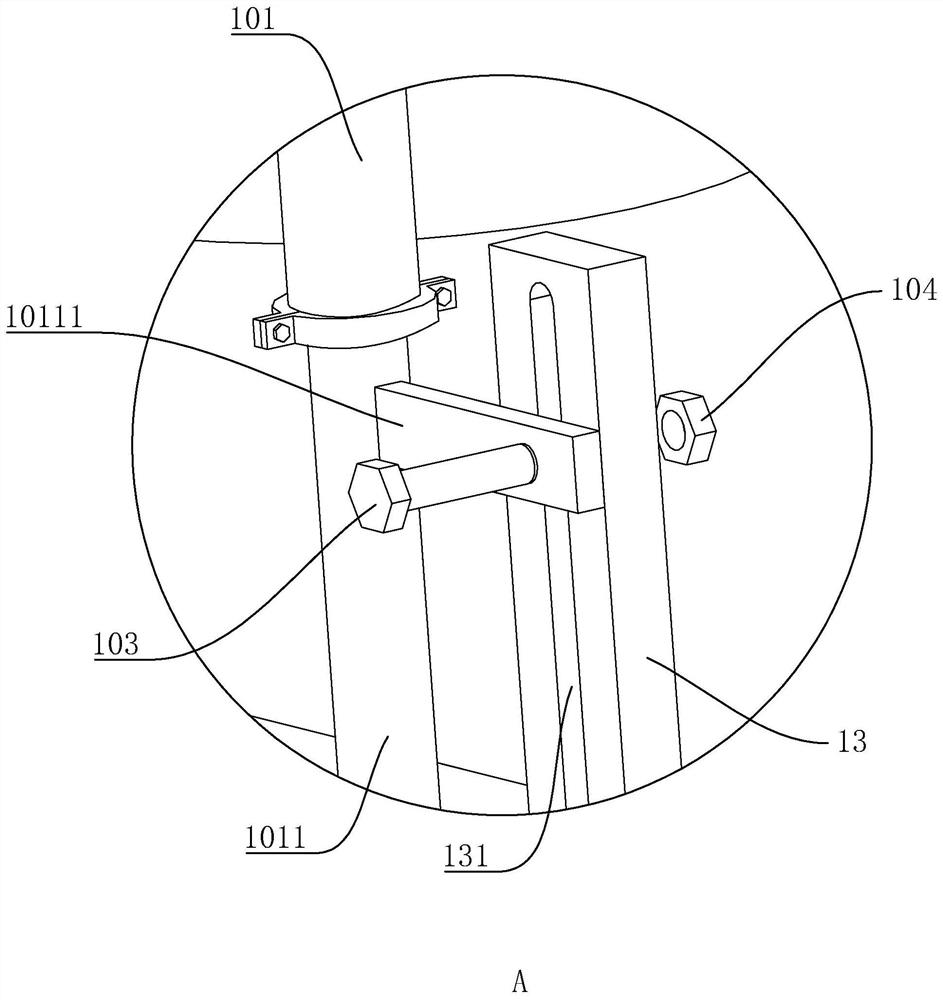

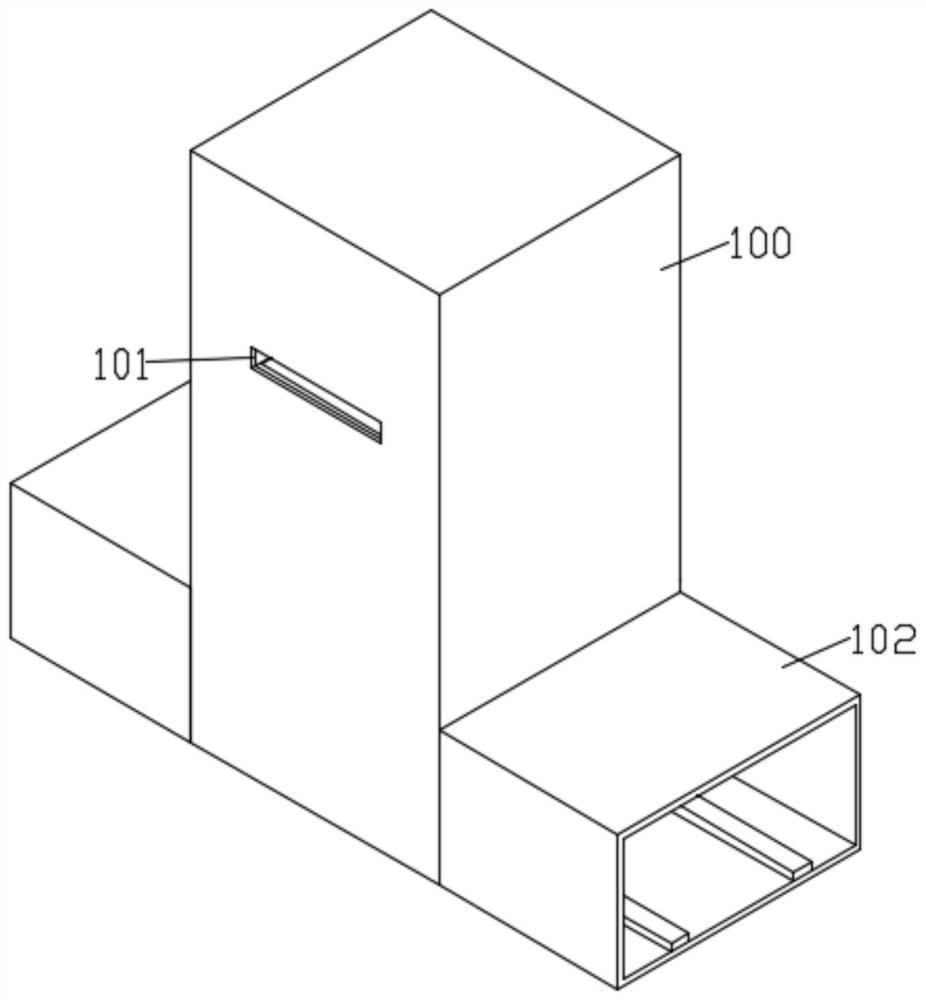

The invention discloses a feeding device for a pesticide processing and packaging machine. The feeding device comprises a feeding box. A first fixing plate is fixedly connected to one side of the feeding box. A first motor and a transfer box are fixedly connected to the top of the first fixing plate. The transfer box is located on the right side of the first motor. The side, far away from the first motor, of the transfer box communicates with the feeding box. A first rotary shaft is arranged on the first motor. According to the feeding device for the pesticide processing and packaging machine, materials enter the feeding box through a feeding hopper and the transfer box; a material distribution wheel is arranged in the feeding hopper, and a spiral shaft is arranged in the transfer box, so that the materials can evenly enter the feeding box, and the material accumulation phenomenon is avoided; and after the materials enter the feeding box, a vibration plate vibrates so that the materials can be evenly scattered on a conveyor belt, so that pesticide can be evenly distributed in a material box, the accumulation phenomenon is avoided, and accordingly the discharging accuracy is improved.

Owner:WUXI JIABAO PESTICIDE & PHARMA

Quartz glass tube waste material treatment machine and treatment method

InactiveCN112058360AImprove crushing efficiencyEasy to collectGrain treatmentsProcess engineeringWaste material

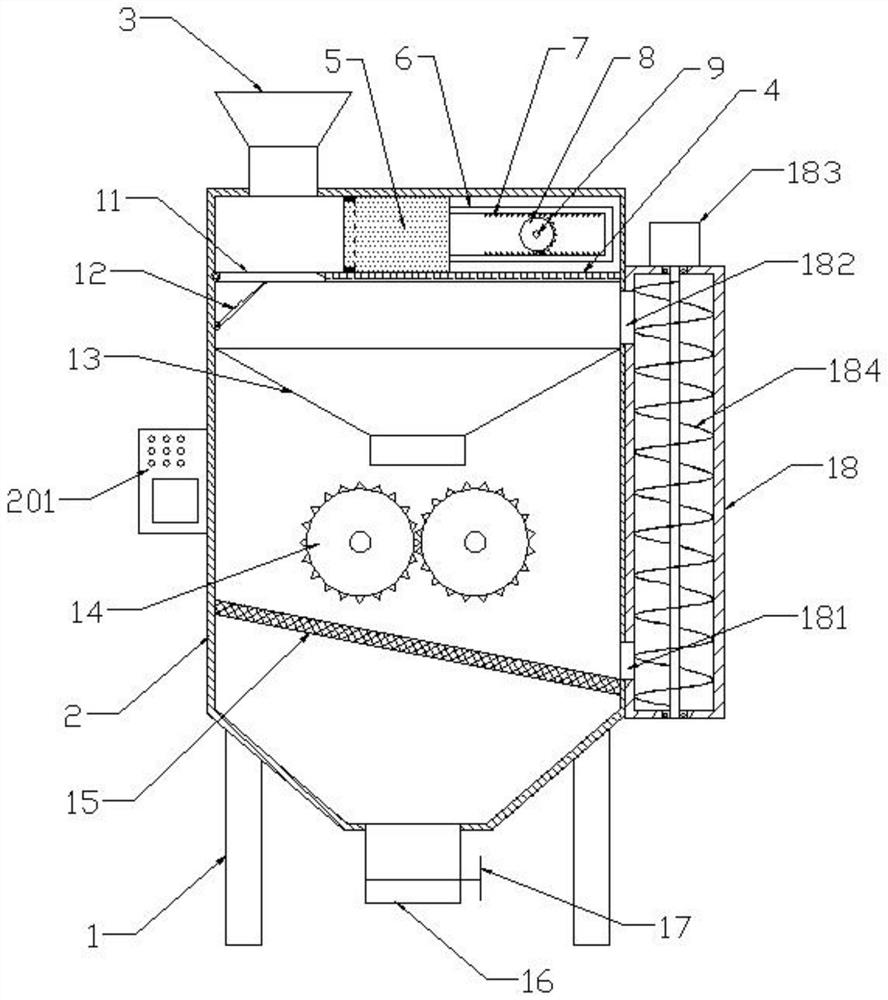

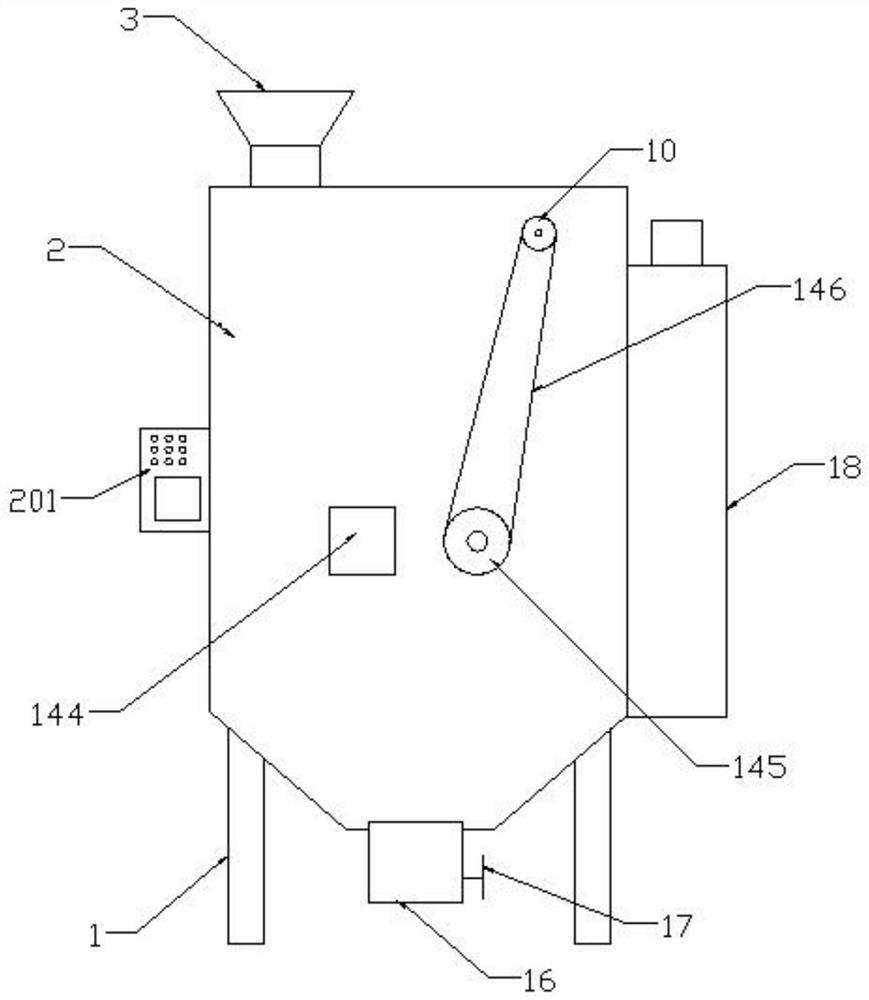

The invention discloses a quartz glass tube waste material treatment machine which comprises a rack. A treatment box is connected to the top of the rack. A feeding hopper communicates with the left side of the top of the treatment box. A supporting plate is connected to the upper portion of the right side wall of an inner cavity of the treatment box. A U-shaped rod is connected to the right end ofan extrusion block. Straight racks are vertically and symmetrically connected to the inner wall of the U-shaped rod. Semi-gears are connected to the straight racks in an engagement manner. A blockingplate is connected to the left end of the supporting plate in an abutting-against manner. An electric telescoping rod is hinged between the bottom of the blocking plate and the treatment box. A guidehopper is arranged below the blocking plate. A smashing mechanism is arranged below the guide hopper. A screen is connected to the lower portion of the inner cavity of the treatment box. The treatment machine is reasonable in structural design, waste materials can be extruded and smashed in advance, the smashing efficiency of the waste materials is improved, the waste materials with large particles can be conveyed into the smashing mechanism again to be smashed for a second time after being elevated, follow-up packing treatment is facilitated, and the recycling efficiency is improved.

Owner:LIANYUNGANG HONGYANG QUARTZ PROD

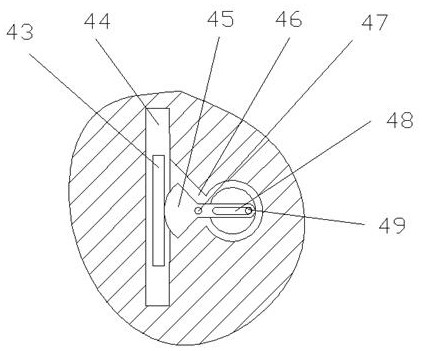

Centrifugal kitchen dustbin convenient to use

InactiveCN106275977AAvoid smallReduce the number of poursWaste collection and transferRefuse receptaclesSewageCentrifugal force

The invention discloses a centrifugal kitchen dustbin convenient to use and belongs to the field of living furniture. The centrifugal kitchen dustbin convenient to use is composed of a crank sliding block device and a crank rocker device. The centrifugal kitchen dustbin convenient to use is characterized in that the crank slide block device is composed of an extensible plate, a movable connecting rod, a swinging connecting rod and an upper foot treadle; the movable connecting rod is connected with the extensible plate and the swinging connecting rod through bolts correspondingly; the swinging connecting rod is fixedly mounted on the upper portion of the upper foot treadle; a centrifugal device is composed of a lower foot treadle, a centrifugal connecting rod, a large belt wheel, a belt, a small belt wheel and a rotary disc ; the centrifugal connecting rod is connected with the large belt wheel through a bolt; the large belt wheel is connected with the small belt wheel through the belt; a small belt wheel shaft is fixedly mounted on the lower side of the rotary disc; a bottom plate is fixedly mounted on a dolly frame through a screw; and four dolly wheels are mounted at the bottom of the dolly frame. The centrifugal kitchen dustbin convenient to use has the beneficial effects that kitchen waste can be treated in a separation mode, sewage drained in a separation mode can be discharged, and the waste can be conveniently and quickly packaged and cleared away.

Owner:宣城金博伟家居智能科技有限公司

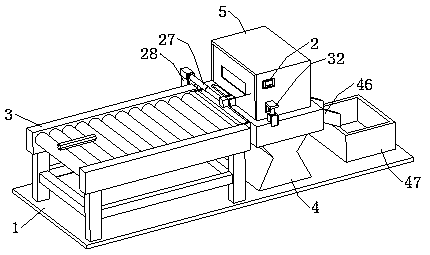

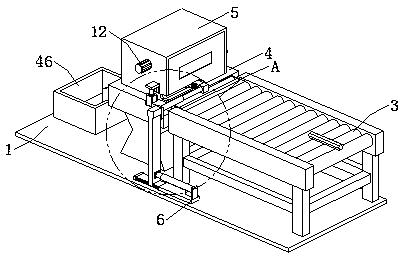

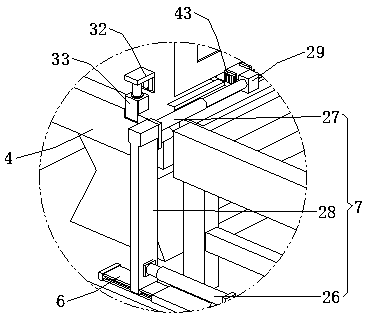

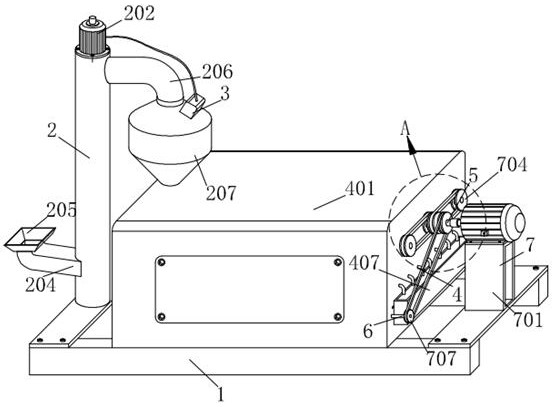

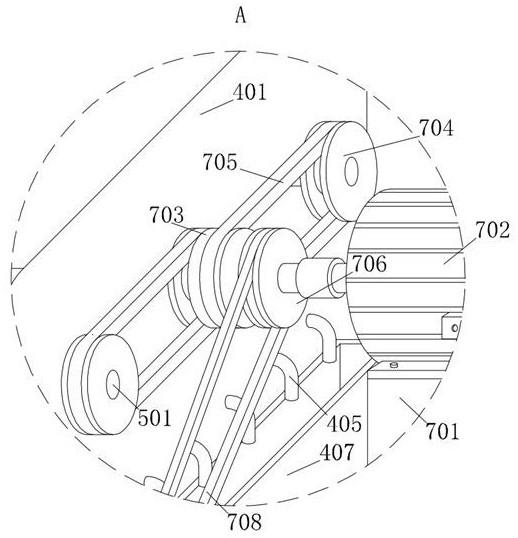

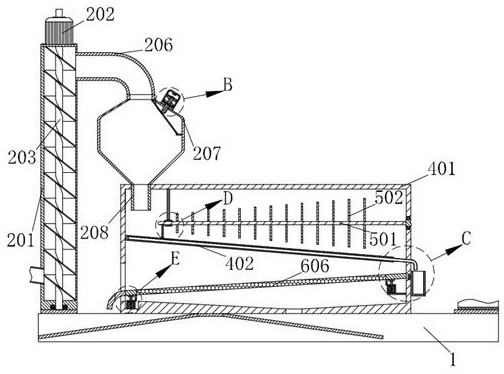

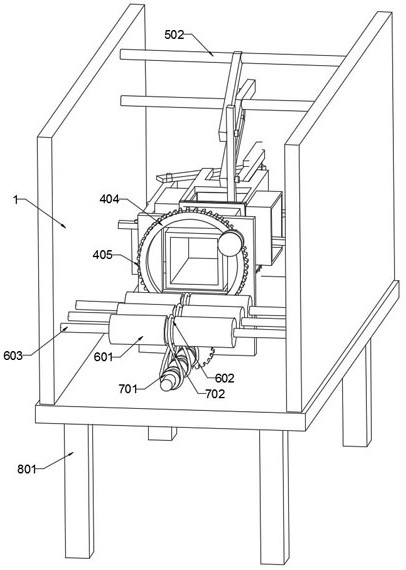

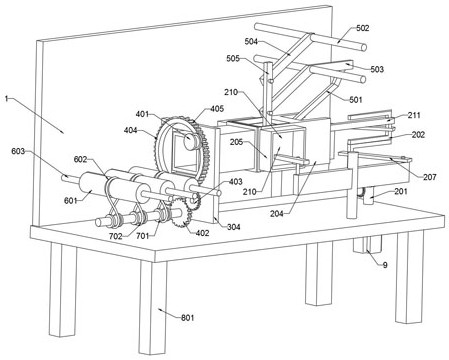

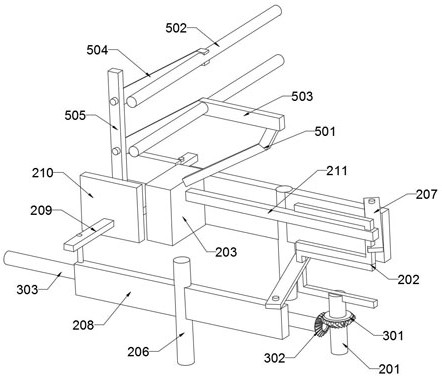

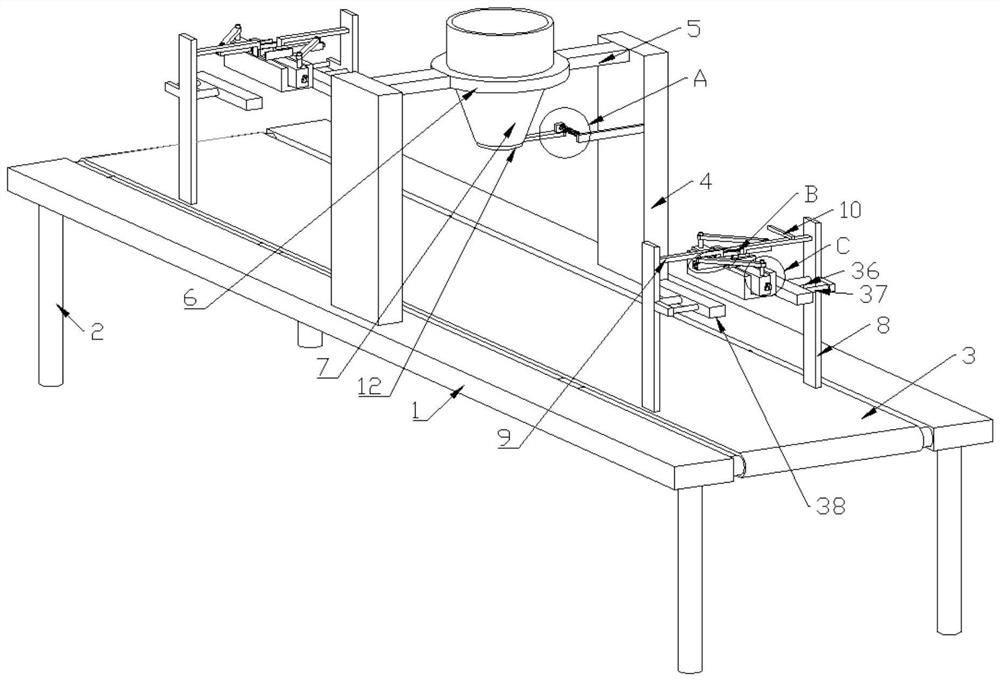

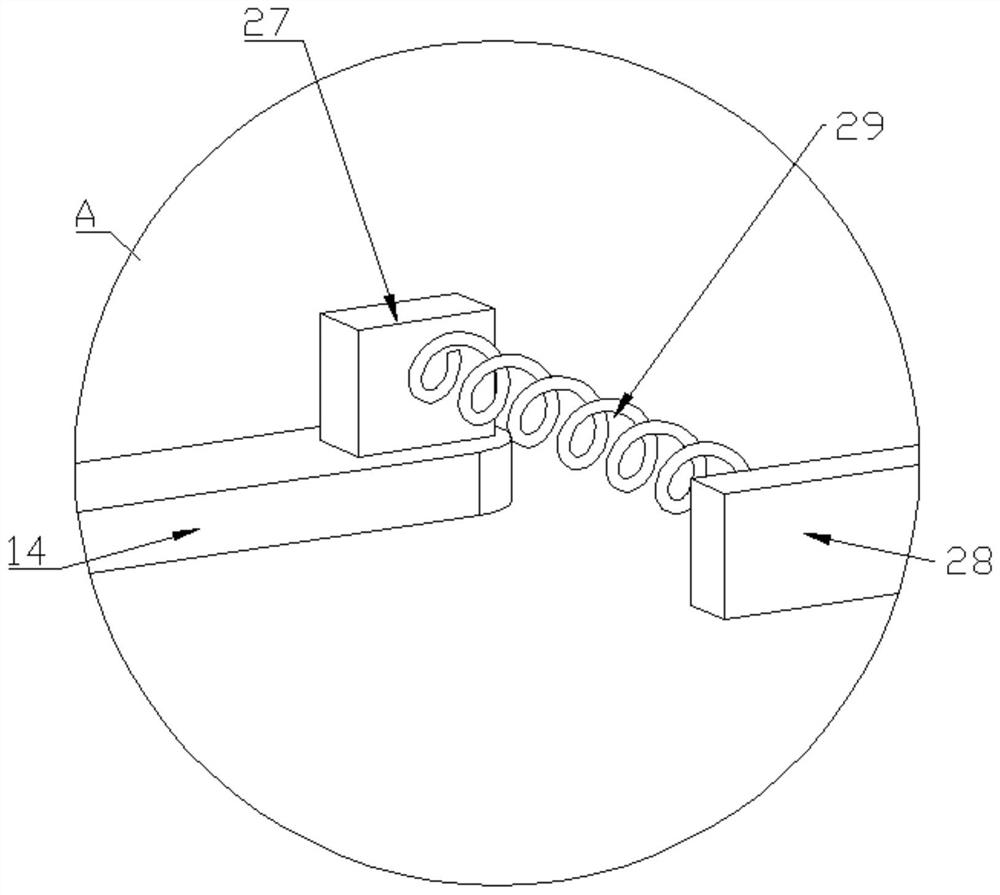

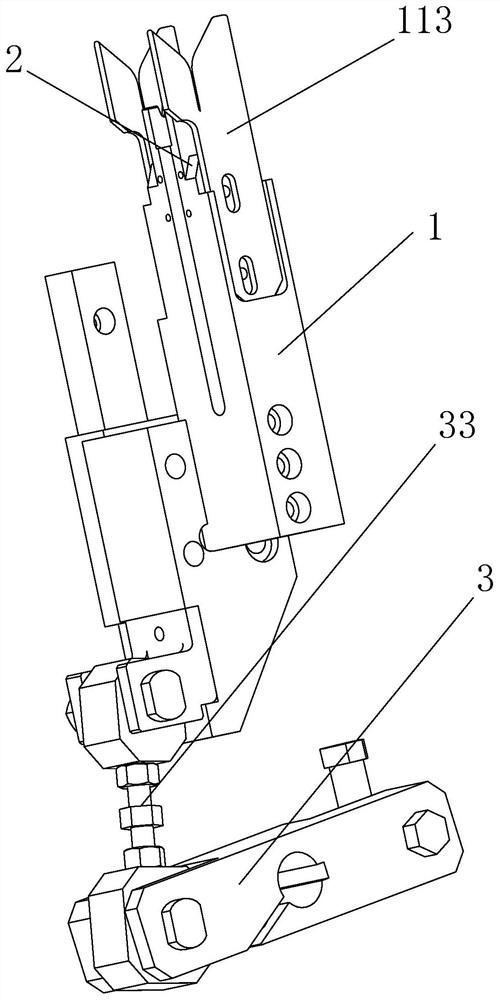

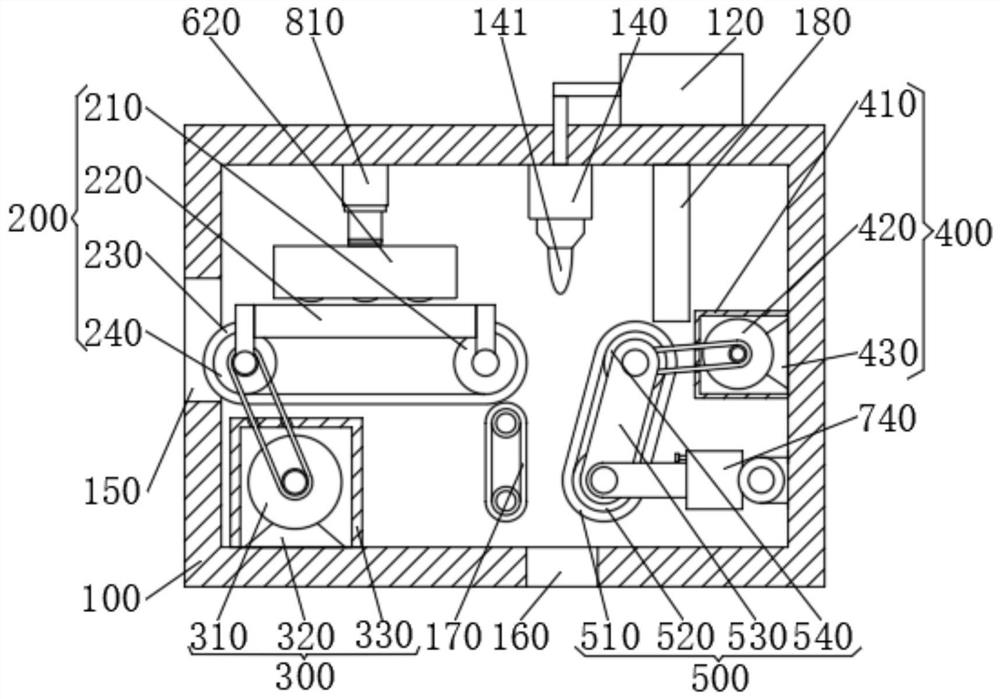

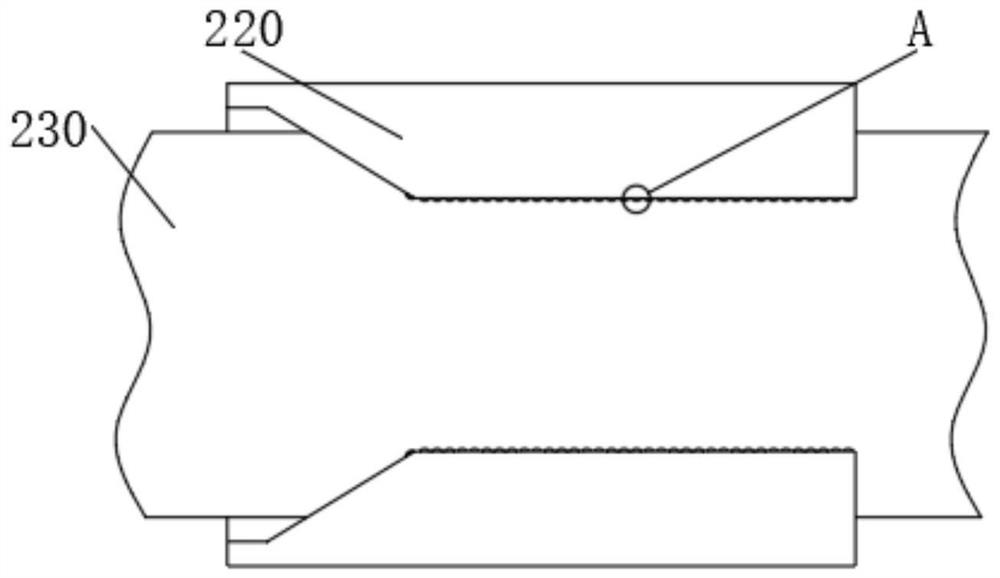

Dicing equipment for vegetable processing

InactiveCN110434926AUniform length and sizeEasy to pack and handleMetal working apparatusVegetable processingEngineering

The invention relates to the technical field of food processing, in particular to dicing equipment for vegetable processing. The dicing equipment comprises a base, the base is horizontally arranged, acontroller, a conveyor, a worktable, a pushing mechanism, a pressing mechanism and a dicing mechanism are further included, the pushing mechanism comprises a sliding table and a pushing assembly, thepressing mechanism comprises a pressing assembly and two sets of symmetrically-arranged buffer assemblies, the dicing mechanism comprises a driving assembly and a dicing assembly, and the pushing assembly, the pressing assembly and the driving assembly are all electrically connected with the controller. By means of the dicing equipment for vegetable processing, the even length and size of diced vegetables are ensured, packaging treatment of the vegetables is facilitated, and the daily edible needs of families can be met; and meanwhile, the appearance is good after dicing, sale of the vegetables is facilitated, the dicing speed is high, the cutting efficiency is greatly improved, the yield is improved, and the profit is increased.

Owner:朱海艳

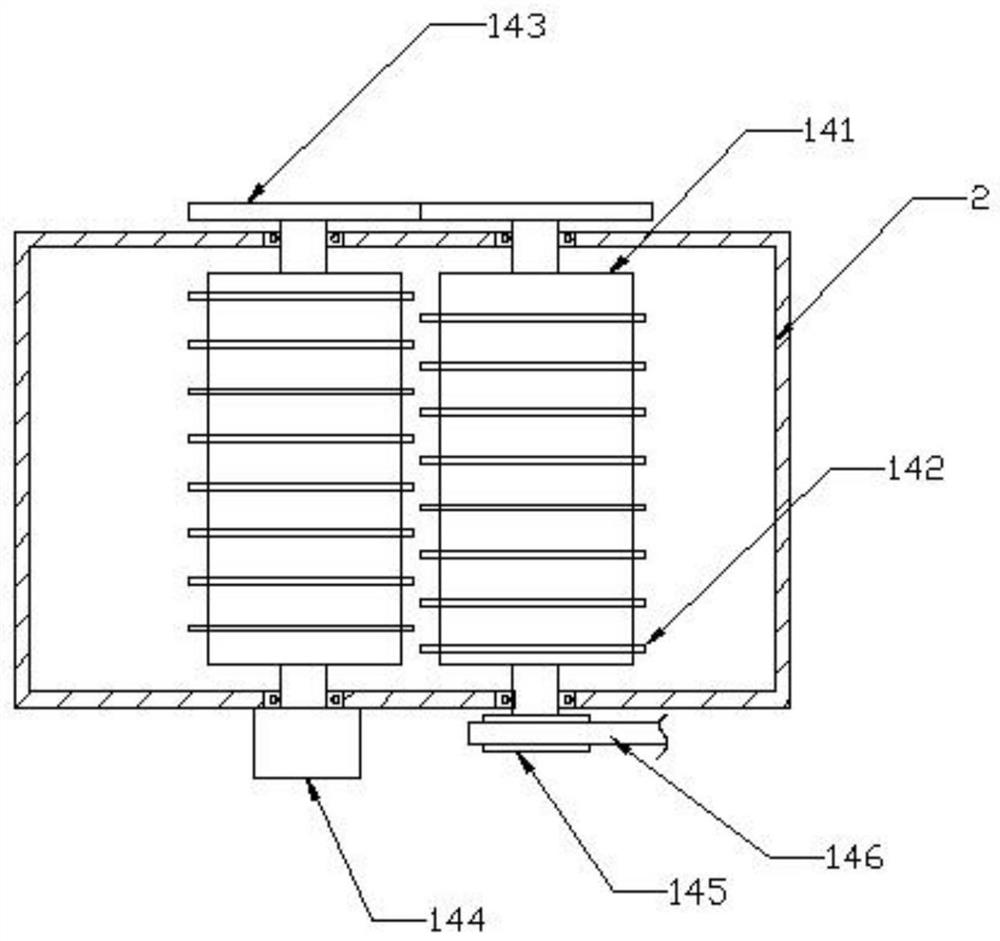

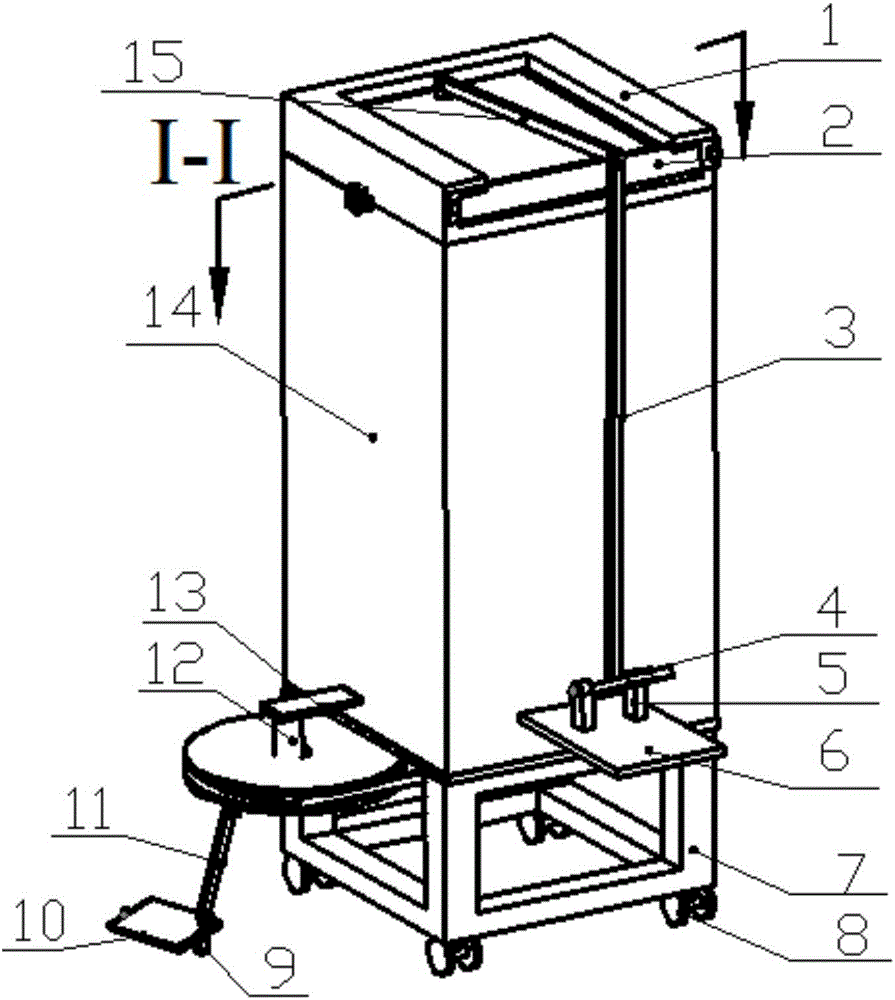

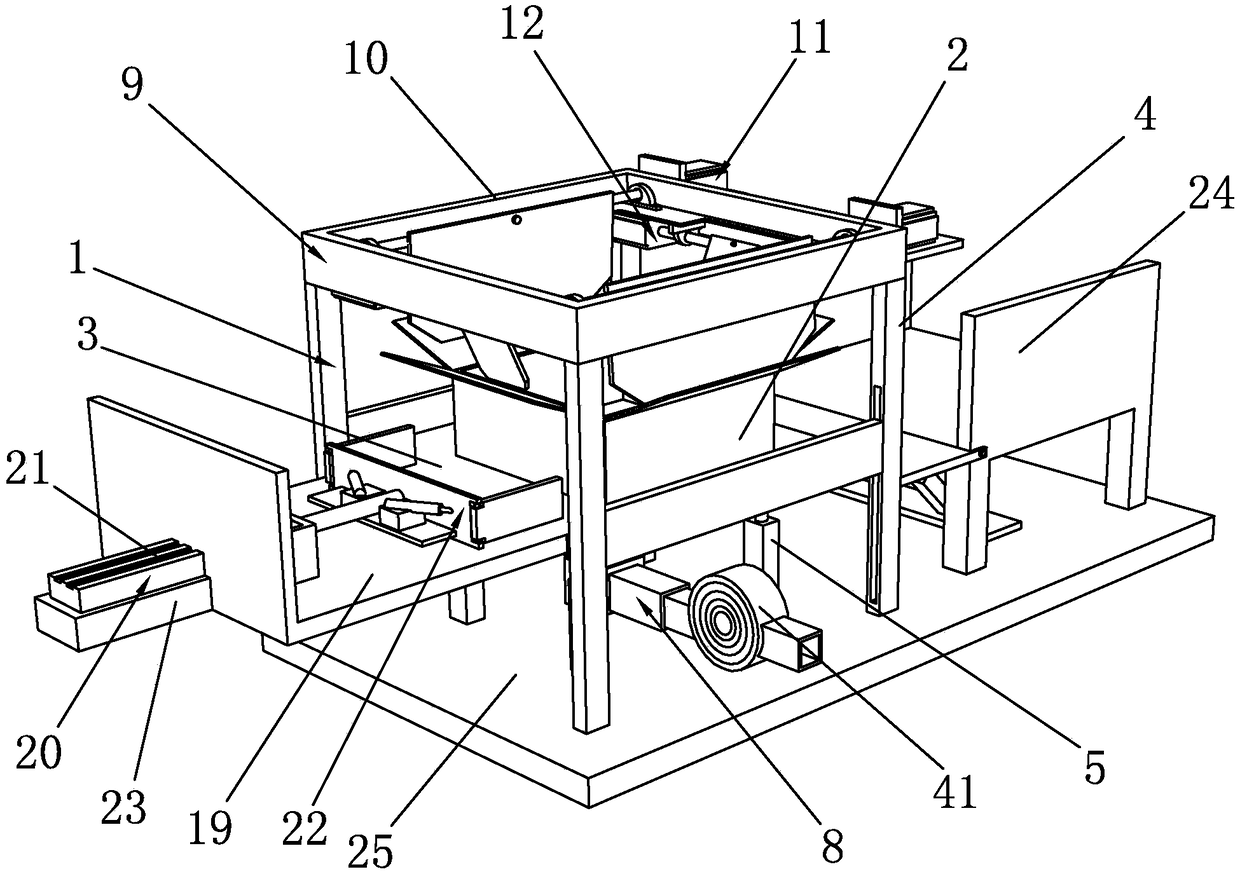

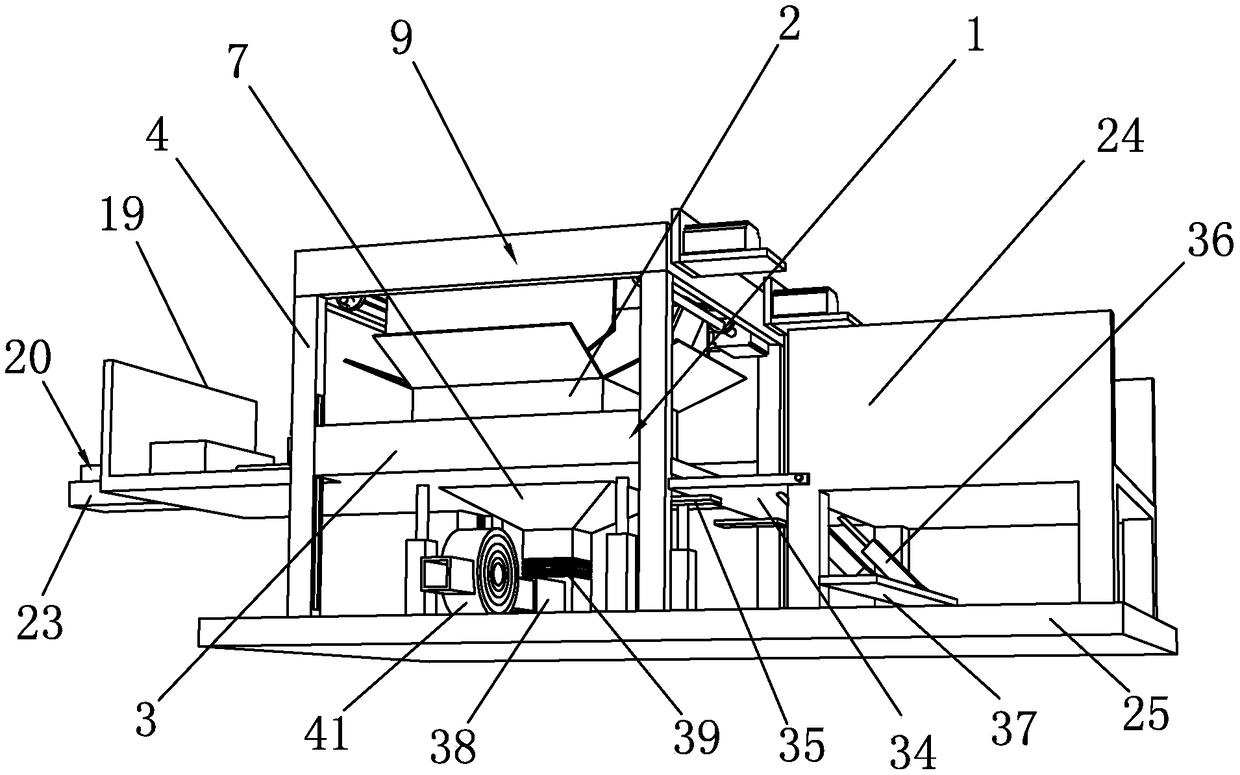

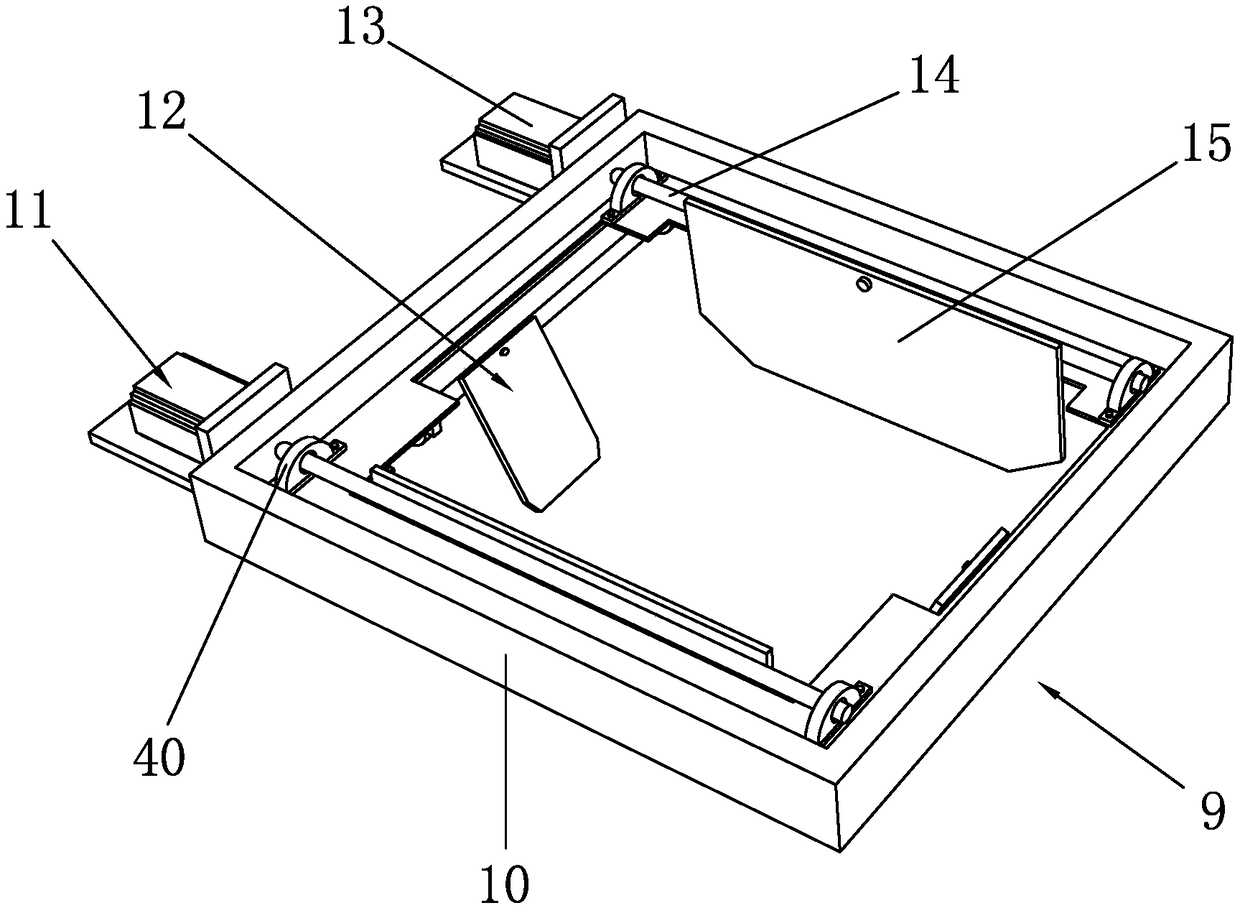

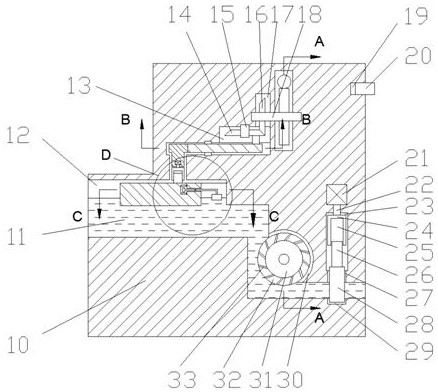

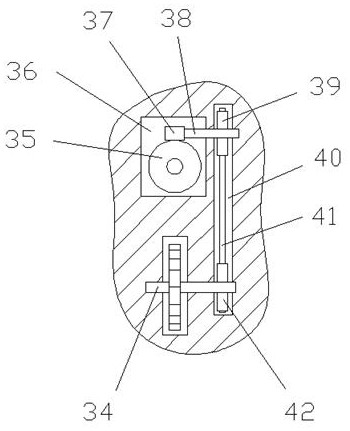

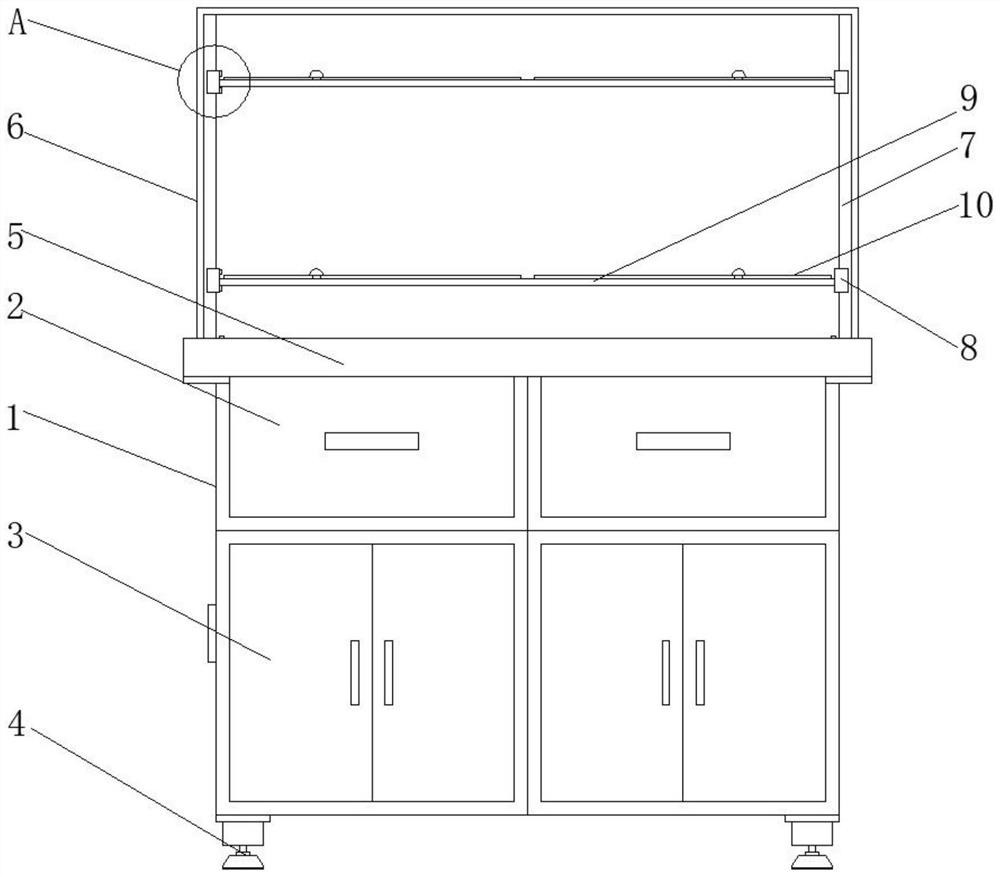

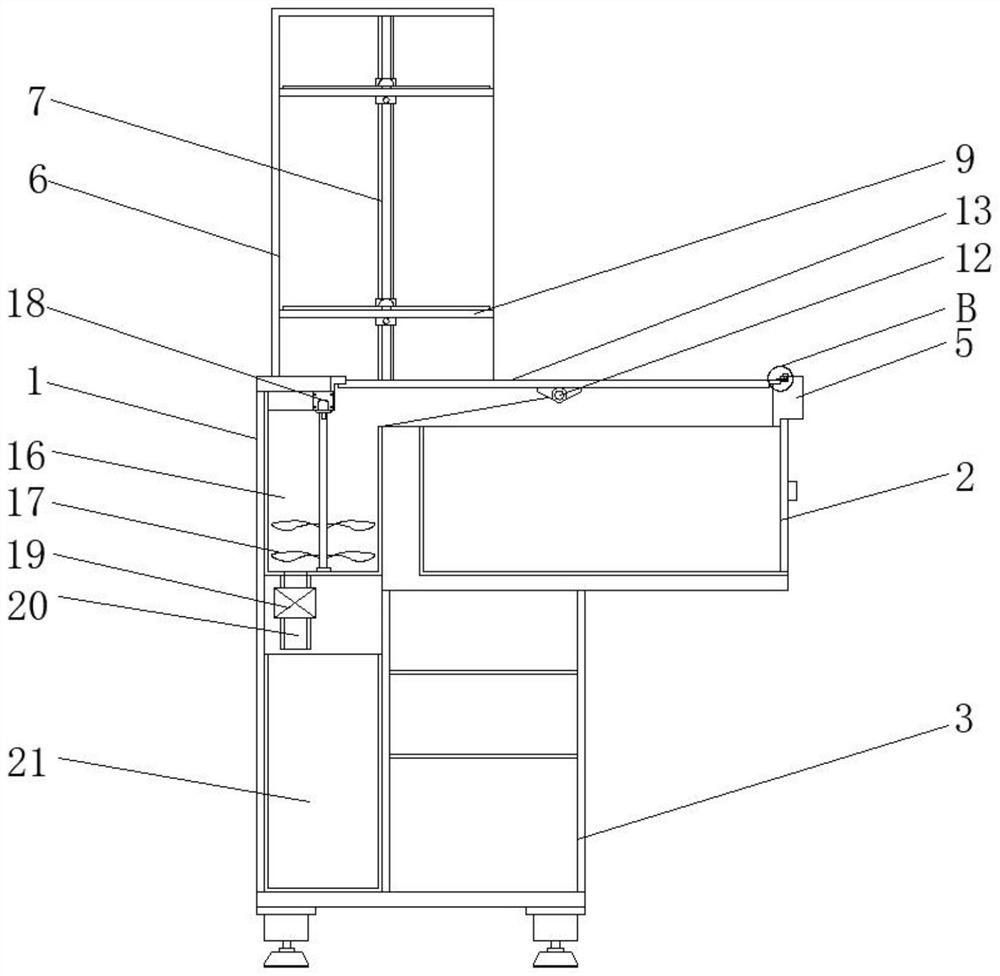

Packaging device for finished product of lampblack machine glass cover plate

InactiveCN109319188AEasy to pack and handleImprove continuityWrapper twisting/gatheringShock-sensitive articlesGlass coverFixed frame

The invention relates to a cutting mechanism and discloses a packaging device for a finished product of a lampblack machine glass cover plate. The packaging device comprises a packaging table and a packaging box. The packaging table comprises a working platform and supporting upright posts. The working platform is positioned among the four supporting upright posts. Lifting columns are uniformly arranged below the working platform. Air suction holes are uniformly formed in the center of the top surface of the working platform. An air suction bucket is arranged below the air suction holes. The air suction bucket is connected with an air suction opening of a blower through a connecting pipe. A pressing device is arranged at the top ends of the supporting upright posts. A fixing frame is connected with the supporting upright posts. An extension plate is arranged on one side of the working platform. A pushing device is arranged on the extension plate. A storage platform is arranged on the other side of the working platform. The packaging device for the finished product of the lampblack machine glass cover plate is reasonable in overall design, and the finished product of the glass coverplate is packaged and boxed by the packaging device, so that the operation safety performance can be improved, the labor intensity can be reduced, the work efficiency can be improved, and the use operation is more automatic.

Owner:嵊州市法帝电器有限公司

Water conservancy gate with garbage cleaning function

InactiveCN111997005AImprove cleaning efficiencyEasy to pack and handleBarrages/weirsWater wheelWater flow

The invention discloses a water conservancy gate with a garbage cleaning function. The water conservancy gate involves a dam body, a left-right through water flow cavity is formed in the dam body, theupper side of the water flow cavity communicates with a garbage push plate cavity with a leftward opening, the right end wall of the garbage push plate cavity is in sliding fit connection with a garbage push plate partially located in the water flow cavity, a vertically through floating block cavity with a rightward opening is formed in the right side of the garbage push plate, and the upper endwall of the garbage push plate cavity communicates with a lifting sleeve cavity. According to the water conservancy gate, continuous kinetic energy is provided for floating garbage cleaning in the mode that water flow pushes a waterwheel, the flowing speed is increased, operation of the garbage push plate is also accelerated, therefore the garbage cleaning work of the water conservancy gate is more environmentally friendly and efficient, a floating block is used for detecting the water level change so that the garbage cleaning push plate can be always located at the effective position, the garbage cleaning efficiency is improved, garbage is moved to the designated position through the push plate effect and a garbage and flowing water separation structure, and garbage packaging treatment isfacilitated.

Owner:缙云普层泵阀科技有限公司

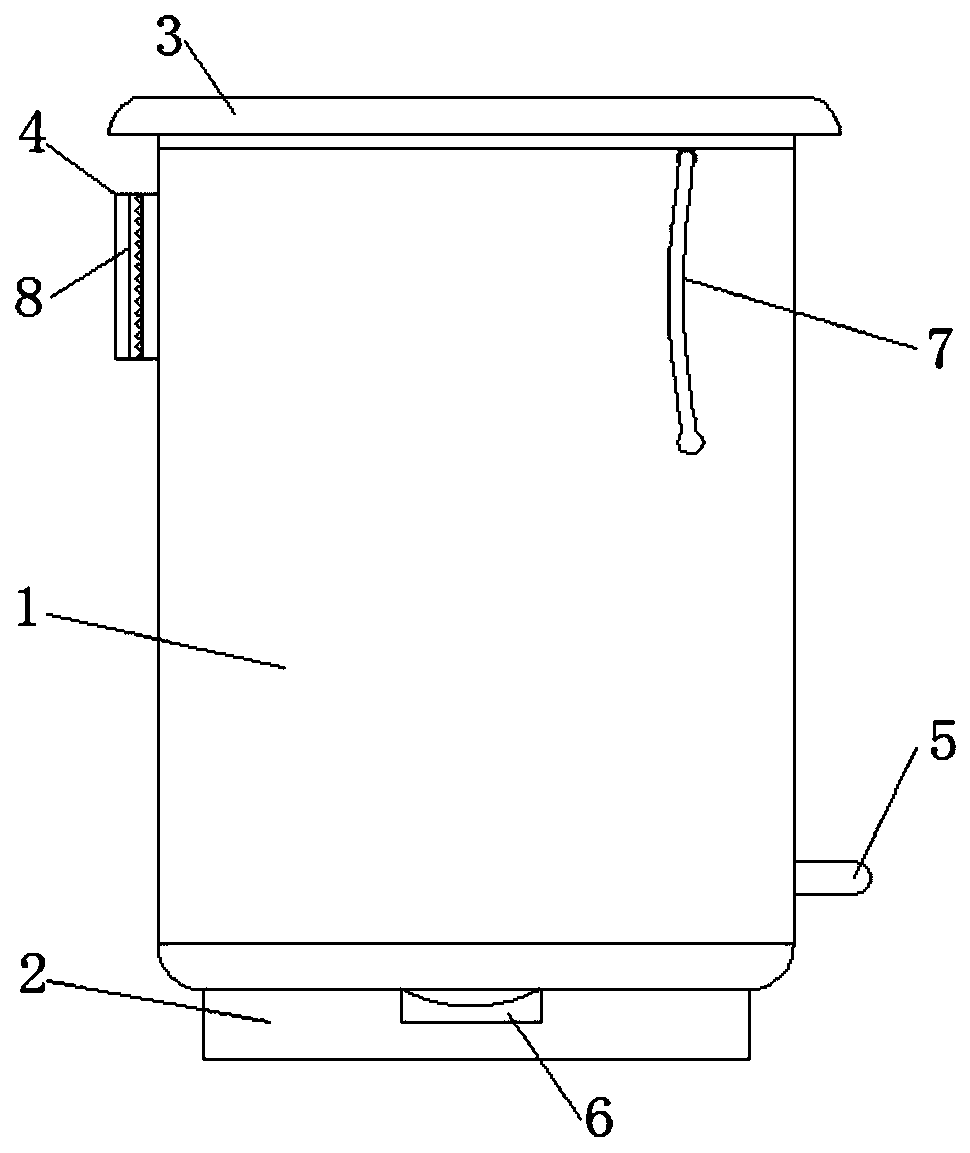

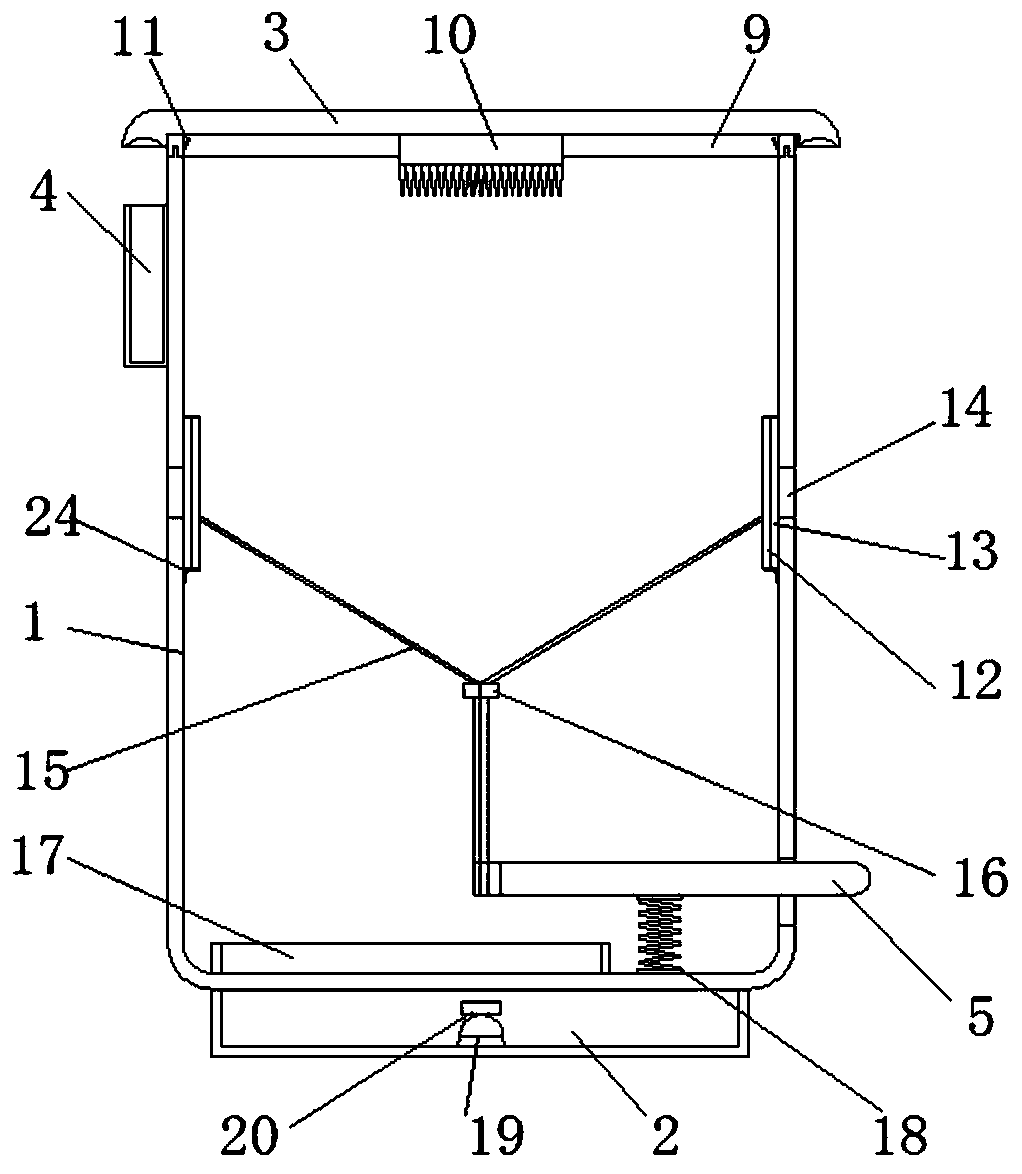

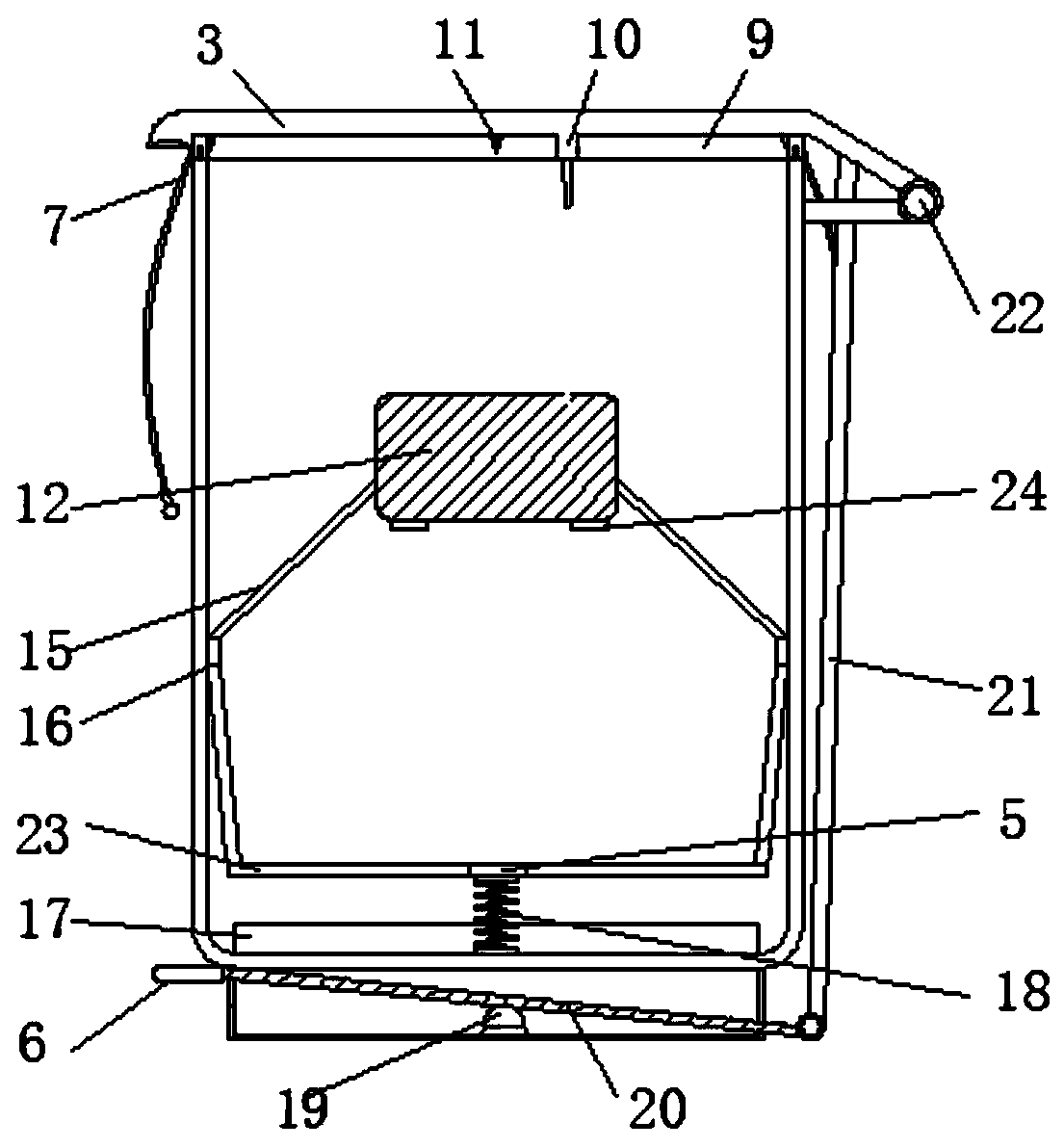

Environment-friendly garbage bin capable of preventing garbage from falling out

ActiveCN110877792AEasy to take outEasy to collectWaste collection and transferRefuse receptaclesStructural engineeringBin bag

An environment-friendly garbage bin capable of preventing garbage from falling out comprises a box body, a box cover, a box cover foot pedal, a movable bucket edge, pressure plates, a control rope, afulcrum and a supporting rod; one end of the box body is provided with a base, and a garbage bag extraction box is fixed on one side of the box body; and a pressure plate foot pedal is arranged on oneside, far away from the garbage bag extraction box, of the box body, the box cover foot pedal is arranged on one side of the base, and one side, close to the box cover foot pedal, of the box body isconnected with a drawstring. According to the environment-friendly garbage bin capable of preventing the garbage from falling out, the box body, the drawstring, the movable bucket edge and buckles arearranged, the drawstring is fixed to the outer side half circle of the movable bucket edge, the drawstring passes through the box body and is placed on two sides of the box body, the four buckles arearranged on the inner side of the movable bucket edge, so that four corners of a garbage bag can be locked in the buckles to fix the position of the garbage bag, and when the garbage bag needs to betaken out, the drawstring is pulled to drive the movable bucket edge to rotate along the box body to tighten an opening of the garbage bag to facilitate packaging and disposal of the garbage.

Owner:安徽华宇物业发展有限公司

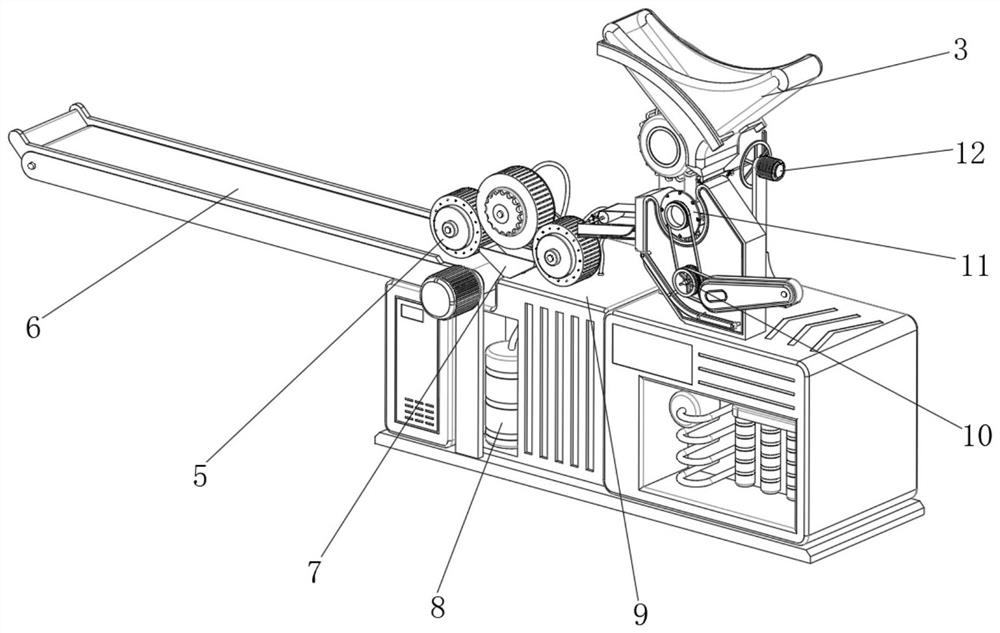

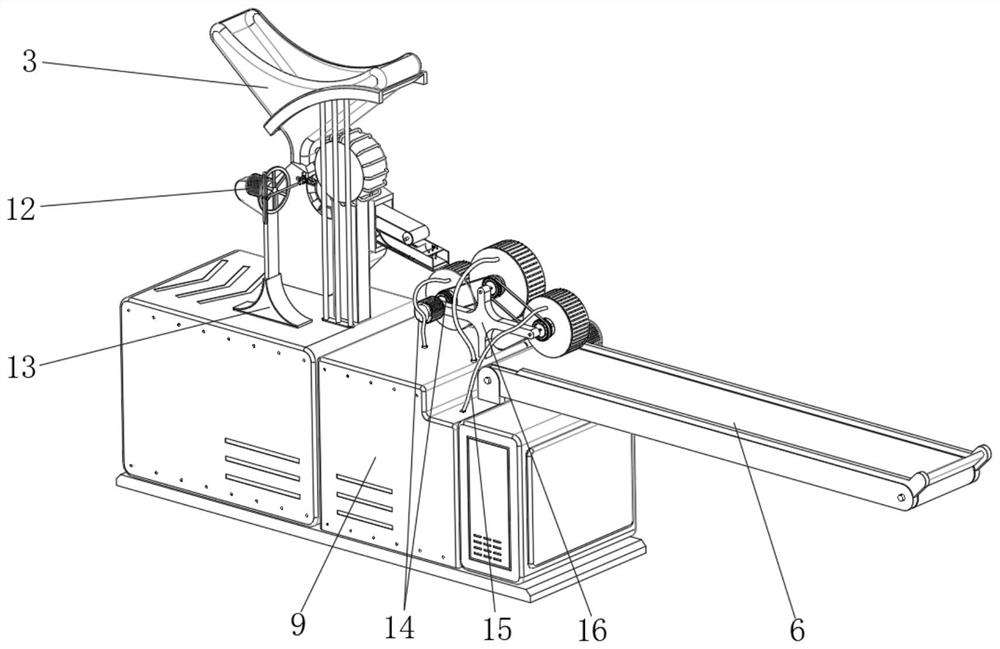

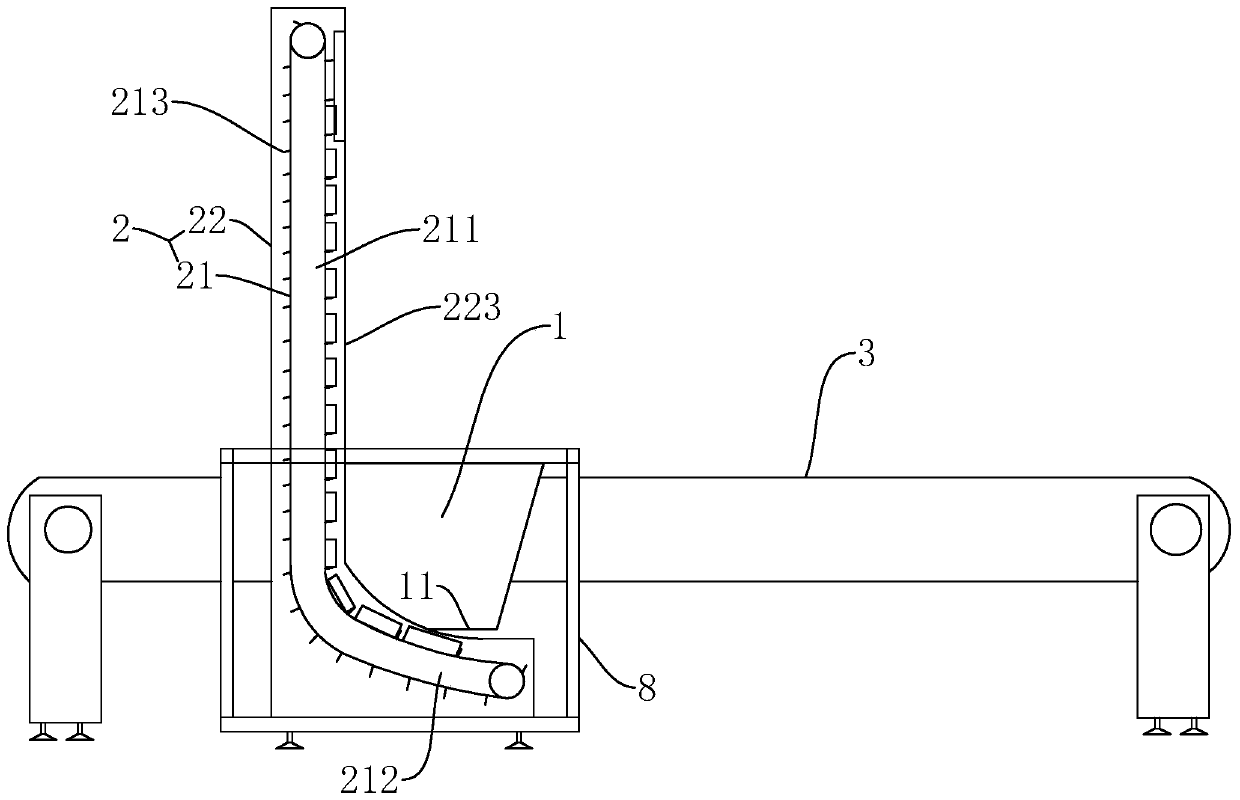

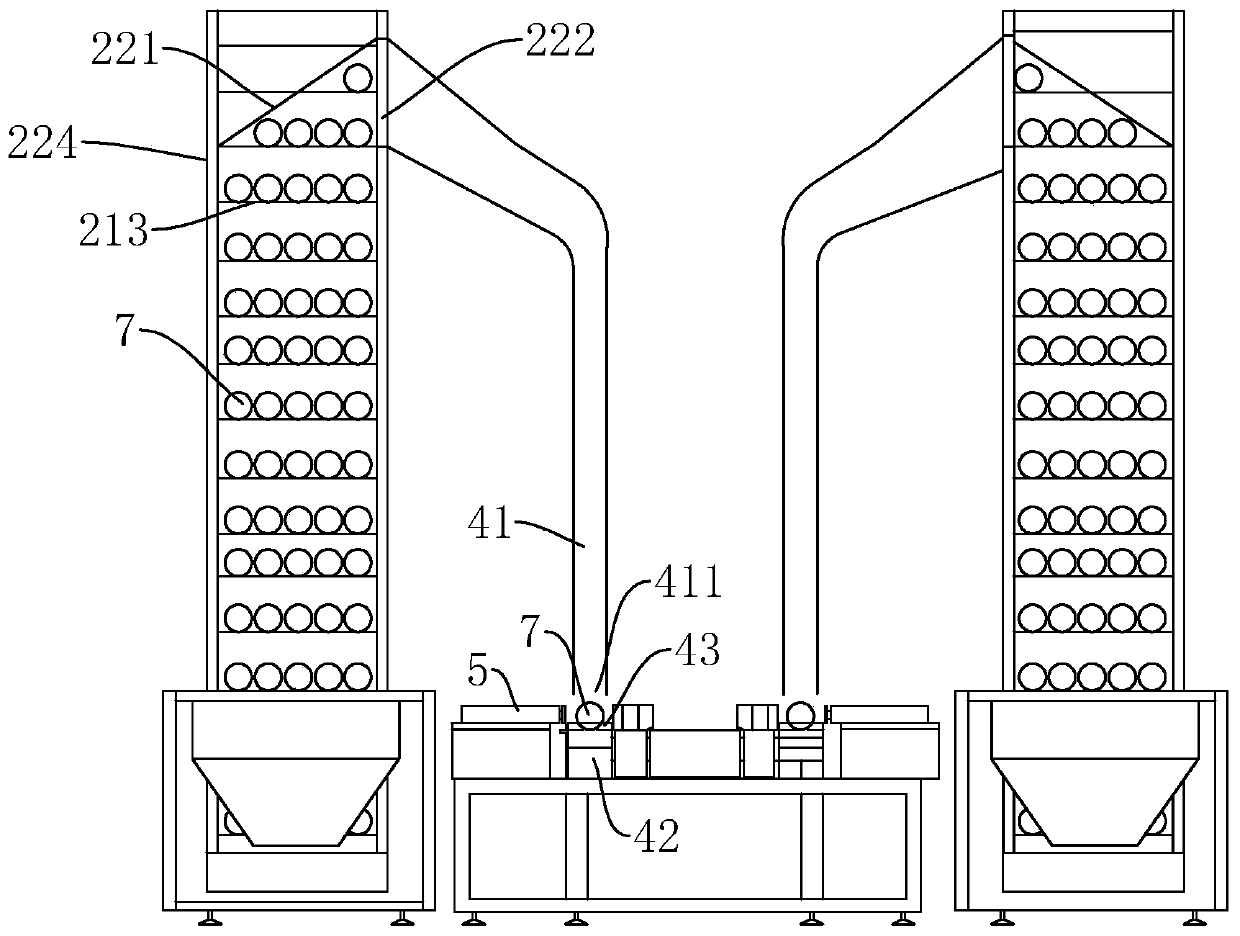

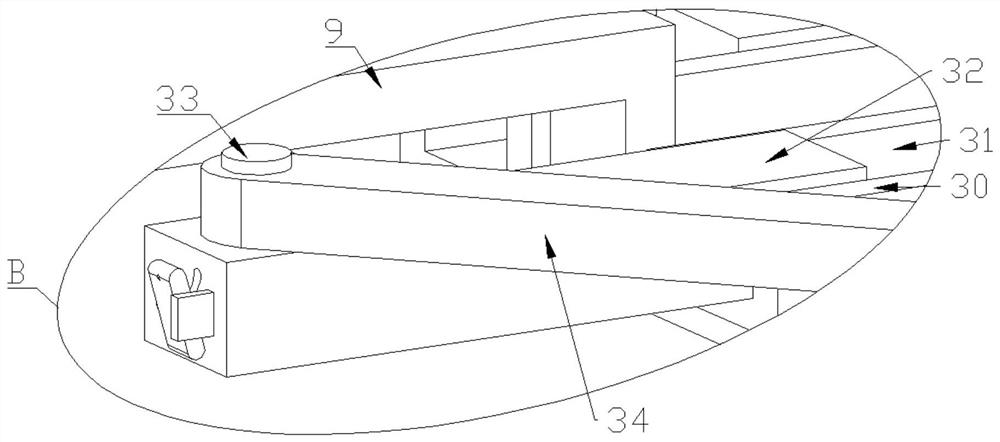

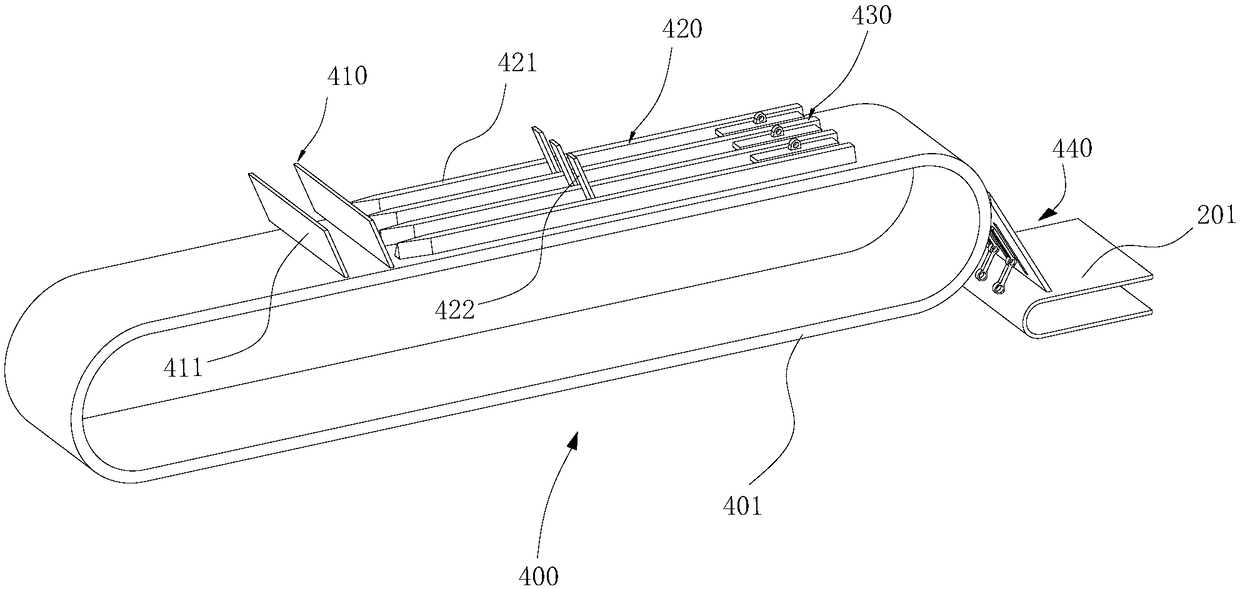

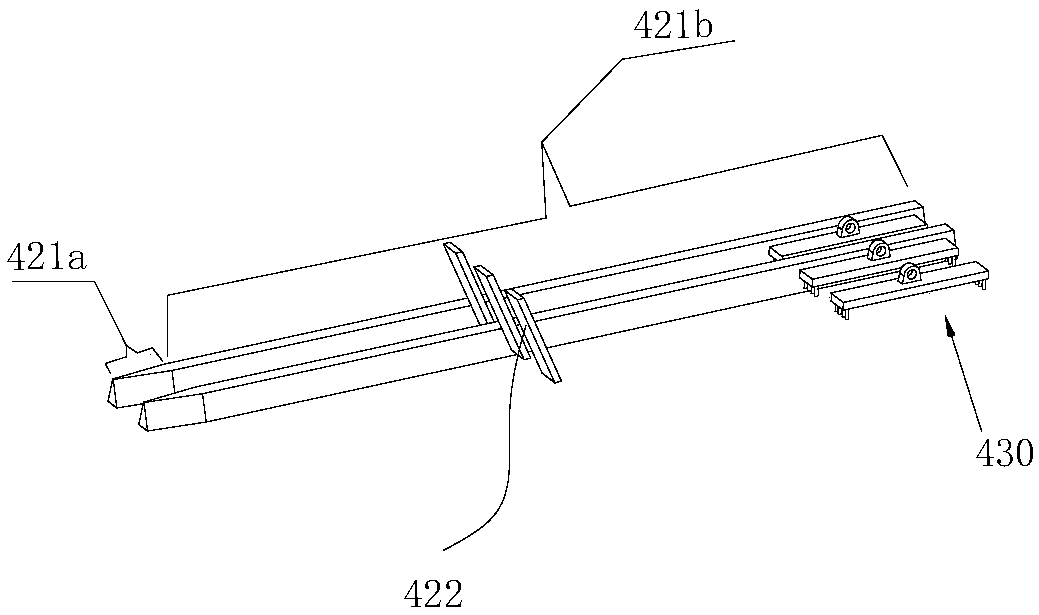

Pastry conveying system

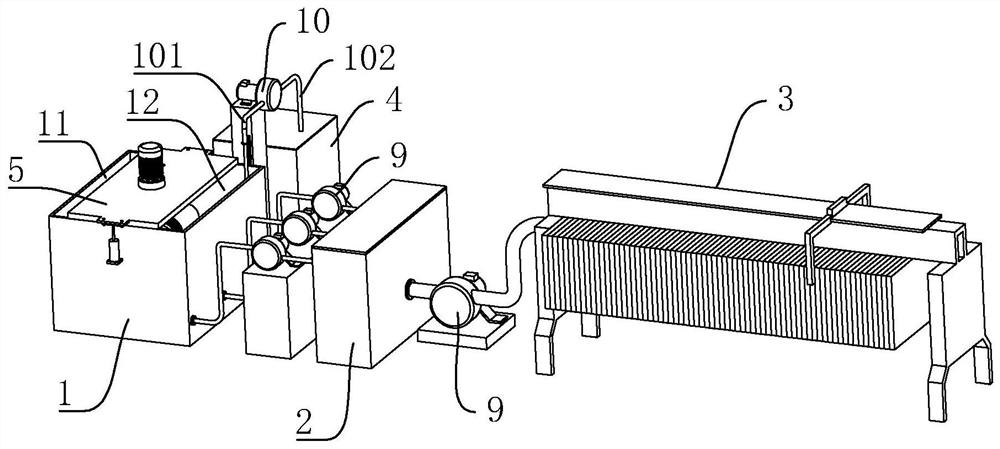

The invention provides a pastry conveying system which comprises a feed divider and a feeding device. The feed divider comprises two driving rollers and two oppositely arranged support frames, the driving rollers are erected between the support frames, a dividing conveyor belt is arranged on the driving rollers in a sleeving manner, and evenly arranged through holes are arranged in the dividing conveyor belt; a support plate is arranged between the support frames and penetrates the inner cavity in the dividing conveyor belt to be closely attached to the same, and a falling port is arranged inone end of the support plate; the feeding device comprises two roll shafts and two oppositely arranged support seats, the roll shafts are erected between the support seats, and a feeding conveyor beltis arranged on the roll shafts in a sleeving manner and penetrates the inner cavity of the feeding conveyor belt to be located right under the falling port. By the arrangement, square pastries can bedivided and sorted in batch, the pastries can be outlet in orderly arrangement and identical direction, and subsequent processing and packaging of the pastries are facilitated; the entire process runs continuously and cyclically, manual intervention is reduced, and production efficiency is greatly improved.

Owner:江西捷创自动化设备有限公司

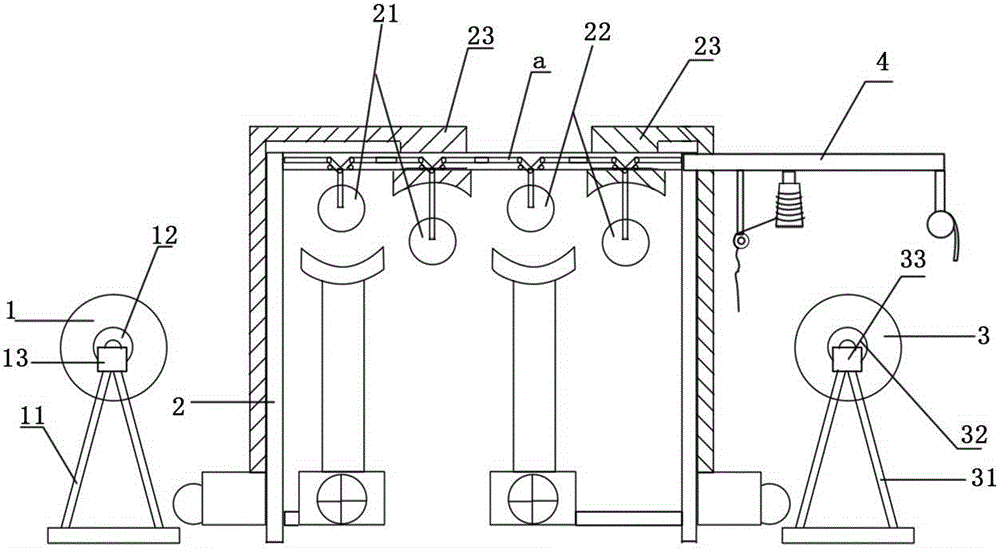

Efficient cloth rolling sanding equipment manufacturing method

The present invention provides an efficient cloth rolling sanding equipment manufacturing method. The efficient cloth rolling sanding equipment comprises a unwinding device, a sanding device and a winding device, wherein the unwinding device and the winding device are respectively arranged on the front end and the rear end of the sanding device, the sanding device comprises a coarse sanding device and a fine sanding device, the two sets of the sanding devices are respectively provided with a front surface sanding wheel and a back surface sanding wheel, the front surface sanding wheel and the back surface sanding wheel are aligned in an up-and-down staggered manner, the lower end of the sanding wheel positioned on the upper portion and the upper end of the sanding wheel positioned on the lower portion are respectively provided with a dust sucking device, the dust sucking device comprises a dust sucking port, a dust sucking pipeline, a fan and a recovery box, the unwinding device comprises a support frame, a cloth discharging guide roller and a metering device, the winding device comprises a support frame, a coiling guide roller and a metering device, and a packaging device is arranged above the winding device. According to the present invention, the structure is simple, the sanding can be performed on the front surface and the back surface of the cloth according to the coarse requirement and the fine requirement, the completed cloth coil can be conveniently packaged, and the dust can be prevented from falling down on the cloth.

Owner:TIANJIN FEITIAN FUZE TECH

Garlic screening machine convenient to feed and application method thereof

ActiveCN113546840AImprove work efficiencyAvoid cloggingSievingScreeningAnimal scienceAgricultural science

The invention relates to the technical field of garlic screening, in particular to a garlic screening machine convenient to feed and an application method thereof. The garlic screening machine convenient to feed comprises a bottom frame, wherein a feeding structure is installed on the bottom frame; an alarm structure is installed on the feeding structure; a dust collecting structure is installed on the bottom frame; a sweeping structure is installed on the dust collecting structure; a screening structure is installed on the dust collecting structure; and a transmission structure is installed on the bottom frame. Garlic needing to be screened is conveyed on the feeding structure, so that the working efficiency can be improved; through cooperation of the feeding structure and the alarm structure, the situation that the machine is stuck and damaged due to the fact that the interior of the feeding structure is blocked can be prevented, so that feeding can be better conducted, and blocking during feeding can be prevented; the dust collecting structure is installed on the bottom frame, so that dust carried in the garlic can be collected; and meanwhile, the dust on the surface of the garlic can be cleaned through the sweeping structure, and then is collected through the dust collecting structure.

Owner:邳州奇威食品科技有限公司

Building thermal insulation material production batching device with packaging function

InactiveCN111746862AEasy to open automaticallyEasy to limitMixer accessoriesWrapper twisting/gatheringElectric dischargeThermal insulation

The invention discloses a building thermal insulation material production batching device with the packaging function. The building thermal insulation material production batching device comprises a base plate, a driving motor, a driving device and a packaging bag feeding device. The outer side of the left end of the base plate is fixedly connected with supporting frames. A discharge pipe is welded to an opening of the lower sidewall of a batching box. The left end of a threaded rod penetrates through and is connected with the lower end of a movable block. A conveyor belt is mounted on the rear side of the right end of the base plate. An electric discharge valve is arranged at the joint of the discharge pipe and the batching box. The lower side of a discharge box is in hinge connection with a discharge plate. An opening of the front side of a fixed rack is fixedly connected with a discharge port of the packaging bag feeding device. The building thermal insulation material production batching device with the packaging function facilitates automatic opening of packaging bags and discharging, so that follow-up bagging is more convenient. Moreover, the building thermal insulation material production batching device with the packaging function can limit the packaging bags conveniently to prevent the packaging bags from toppling over and effectively improves the practicality.

Owner:刘保江

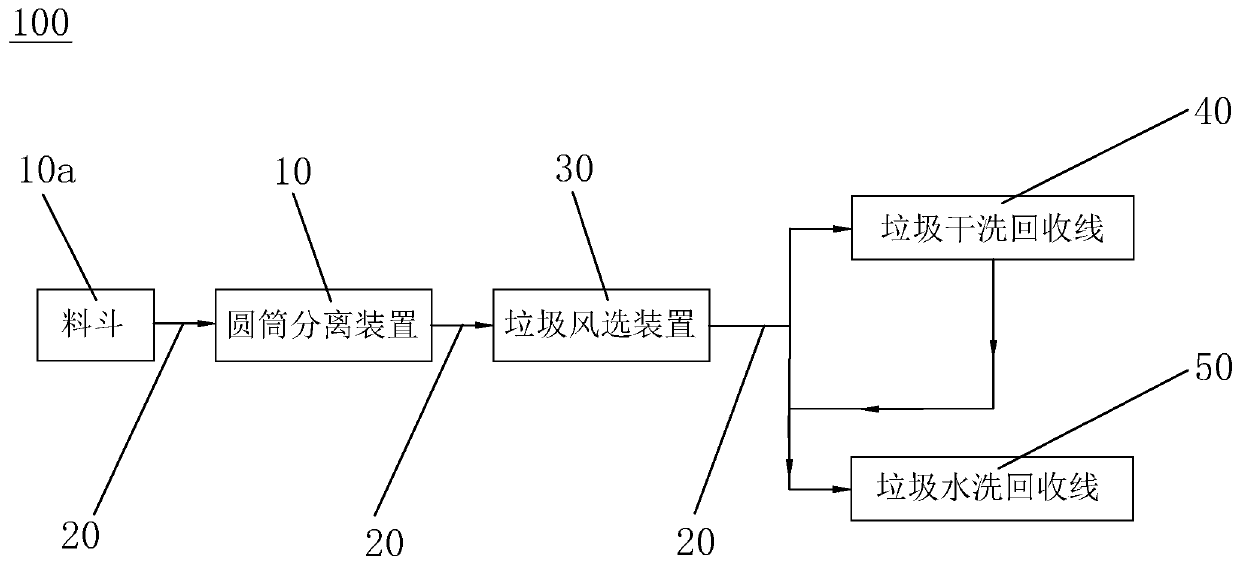

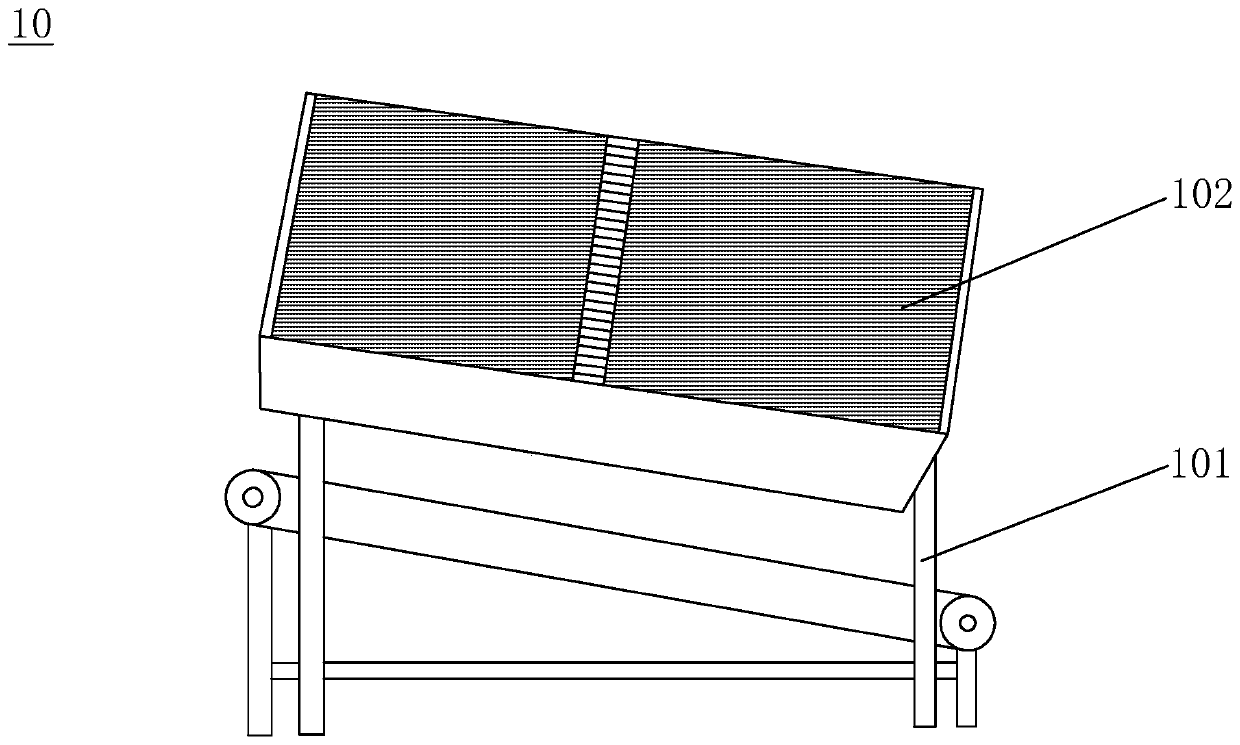

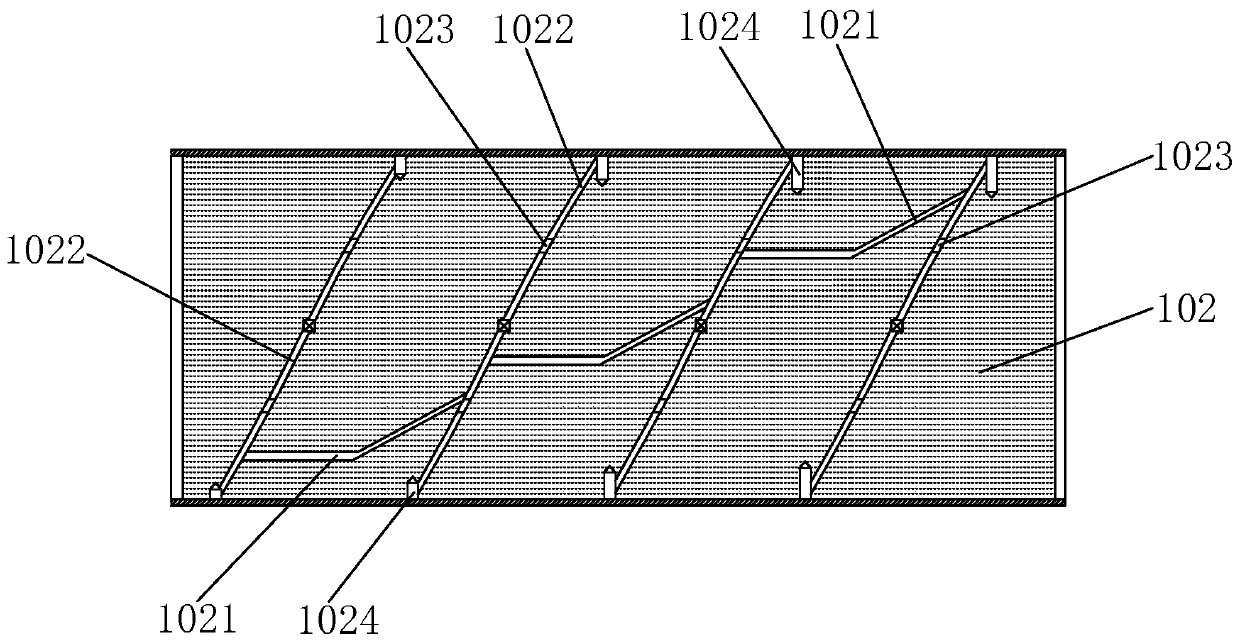

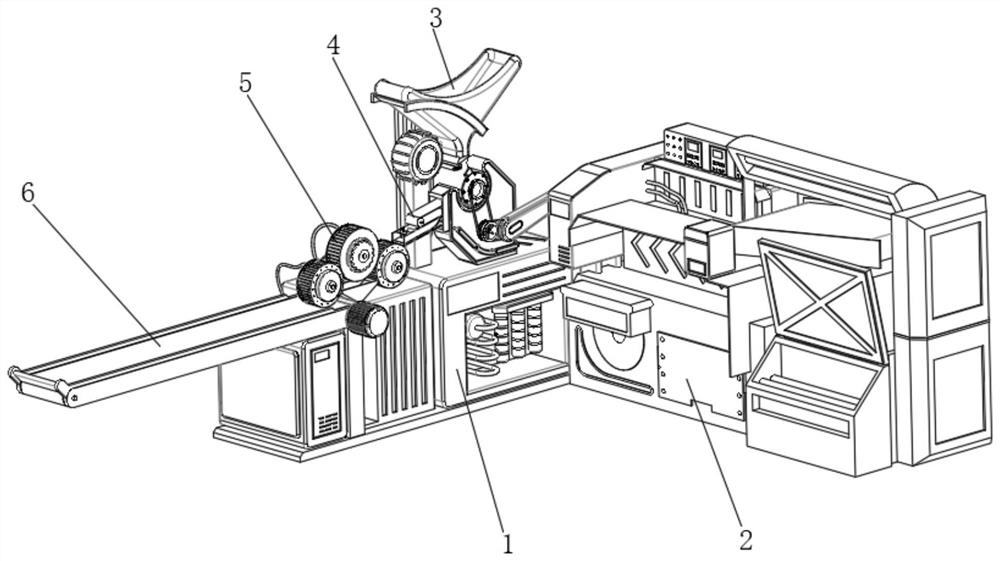

Garbage disposal and recovery system

The invention provides a garbage disposal and recovery system which comprises a garbage sorting line, a garbage dry-cleaning and recovery line, a garbage washing and recovery line and a conveying device. The garbage sorting line comprises a cylinder separating device and a garbage winnowing device which are sequentially connected through the conveying device. The discharge end of the garbage sorting line is connected with the feed end of the garbage dry-cleaning and recovery line and the feed end of the garbage washing and recovery line through the conveying device. The conveying device is arranged at the discharge end of the garbage washing and recovery line. The discharge end of the garbage dry-cleaning and recovery line is provided with the conveying device and / or connected with the feed end of the garbage washing and recovery line through the conveying device. By means of the garbage sorting line, the garbage washing and recovery line and the garbage dry-cleaning and recovery line,garbage can be separated, disposed and recovered, plastic in the garbage is effectively recovered and recycled, the environment is protected, and the environmental pollution can be reduced. Meanwhile, different types of disposal can be selected for different purity requirements, and the aim of saving resources is realized.

Owner:广东金之讯环保科技发展有限公司

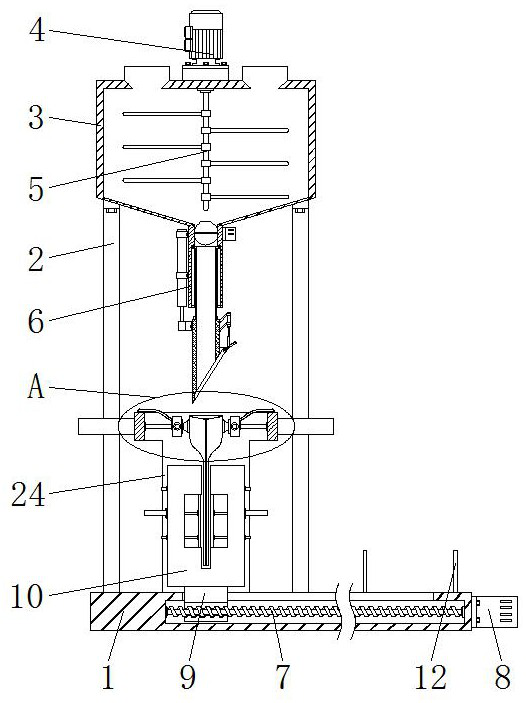

Suaeda glauca tea rolling machine and technology thereof

ActiveCN114431513AGuarantee fillingGuarantee product qualityTobacco treatmentCigarette manufactureProcess engineeringTea leaf

The invention discloses a suaeda glauca tea rolling machine and a process thereof, and relates to the technical field of tea rolling machines. The quality of tea rolls is improved. The tea rolling machine comprises tea rolling equipment and rolling equipment, the tea rolling equipment is arranged on one side of the output end of the rolling equipment, a feeding hopper is installed on the tea rolling equipment, a tea plugging mechanism is arranged at the bottom of the feeding hopper, and the tea plugging mechanism comprises a plugging rod and a driving part for driving the plugging rod to do reciprocating linear motion; the technology comprises the following steps: material selection: selecting a rolled tea raw material; cleaning the raw materials, and steaming the cleaned raw materials for 15-25 minutes; and flaking the steamed raw material, and then performing shredding to obtain a filamentous raw material. By arranging the feeding hopper, the rotating disc, the plug rod and other structures, tea rolling paper into which tea leaves are to be plugged can be fixed to the fixing head, processed tea leaves are added into the feeding hopper, the tea leaves are stacked in the tea plugging chamber through the feeding hopper, the tea leaves in the tea plugging chamber are pushed into the tea rolling paper through linear motion of the plug rod, and a tea roll is formed.

Owner:安徽天鹅茶业有限责任公司

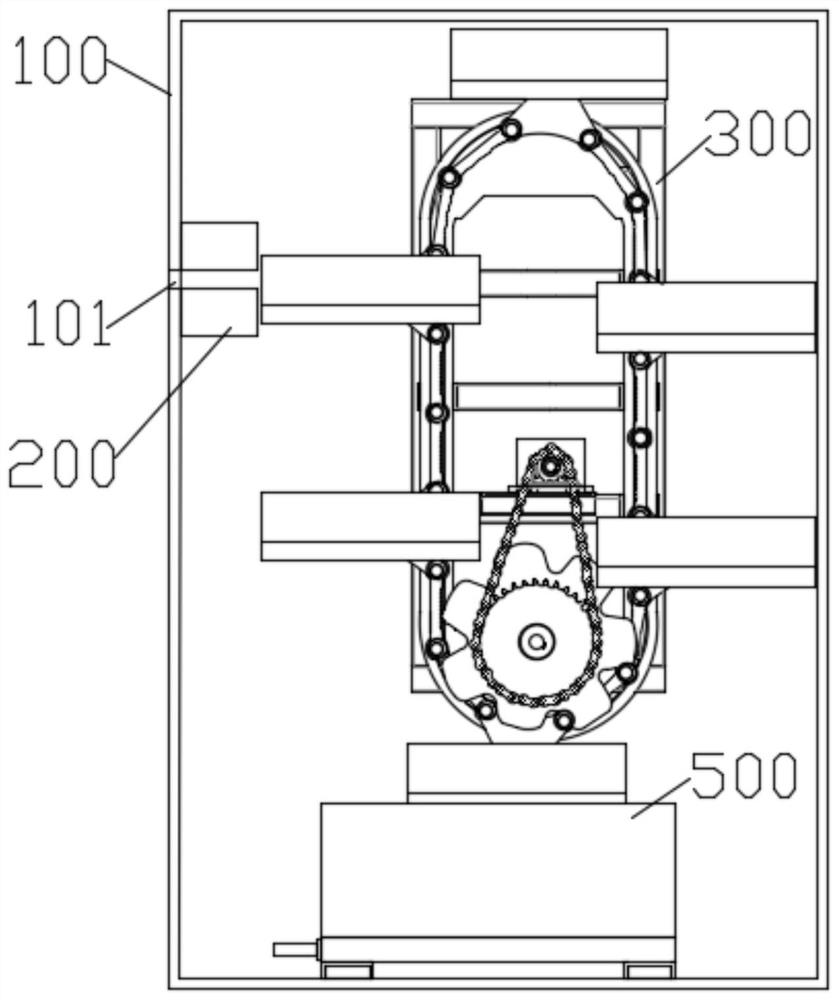

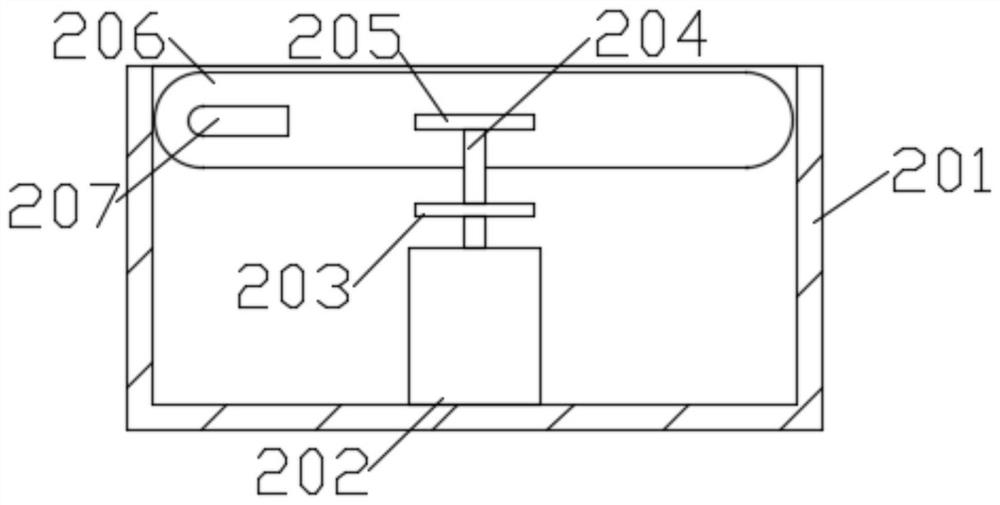

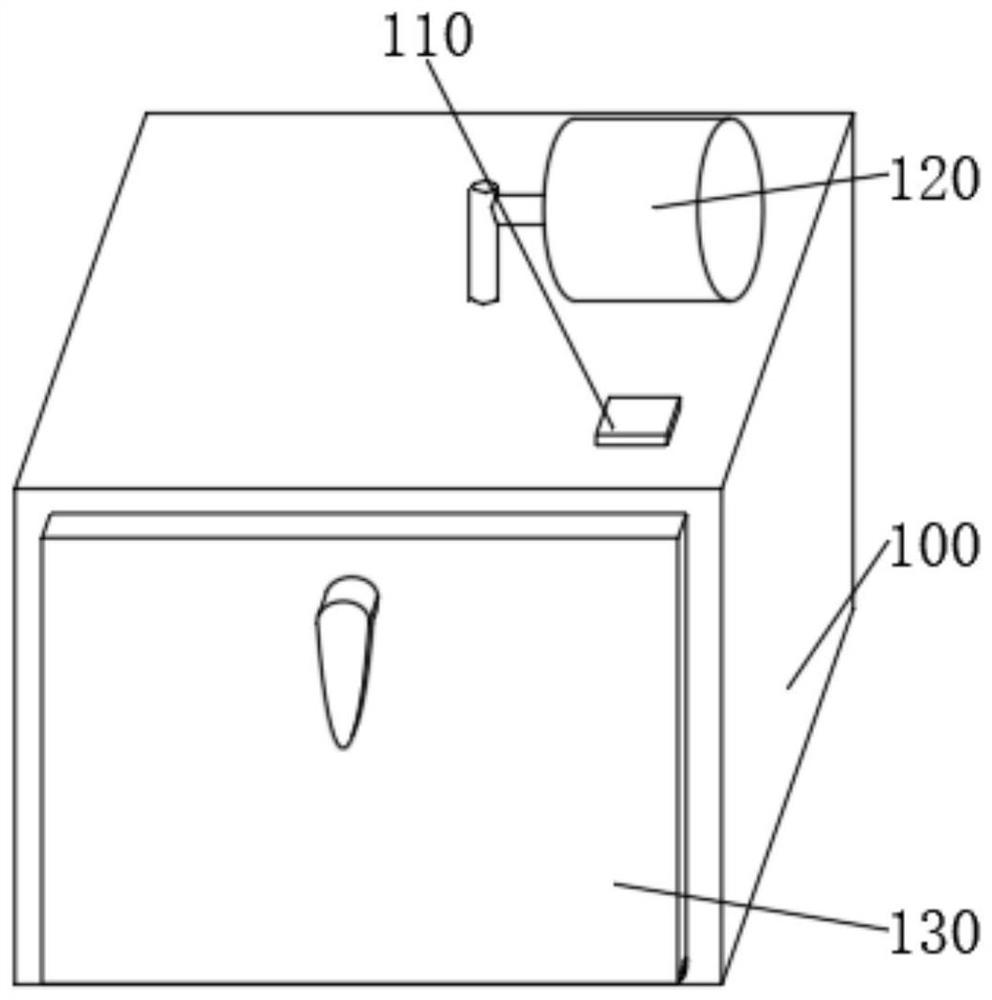

Packaging equipment for compressible waste recycling

ActiveCN113387022ATightly boundSmall footprintWeb rotation wrappingElectric machineProcess engineering

The invention discloses packaging equipment for compressible waste recycling. The packaging equipment comprises a machine box, a pretreatment mechanism and an auxiliary mechanism are installed in the machine box, the pretreatment mechanism comprises a conveying pipe fixedly connected to the inner wall of the machine box through a supporting column, a first sliding block is slidably connected into the conveying pipe, connecting pipes are symmetrically and fixedly connected to the side wall of the conveying pipe in a penetrating mode, a second sliding block is slidably connected into each connecting pipe, rotating rods are symmetrically and rotationally connected to the inner wall of the machine box, a connecting plate is fixedly connected to the side walls of the rotating rods, a motor is installed on the bottom wall of the machine box, a rotating shaft is coaxially fixed to the output end of the motor, and the rotating shaft penetrates through the inner wall of the machine box and then is fixedly connected with a rod shaped like a Chinese character' ji '. According to the packaging equipment for compressible waste recycling, a circular ring body slides on the side wall of the supporting plate, so that a packaging roller is driven to move synchronously, a packaging belt is wound around the packaging roller, and therefore the packaging roller drives the packaging belt to carry out winding type packaging on compressible waste after extrusion forming, and conveying is automatically carried out on the compressible waste.

Owner:南通市通州区茂润包装制品有限公司

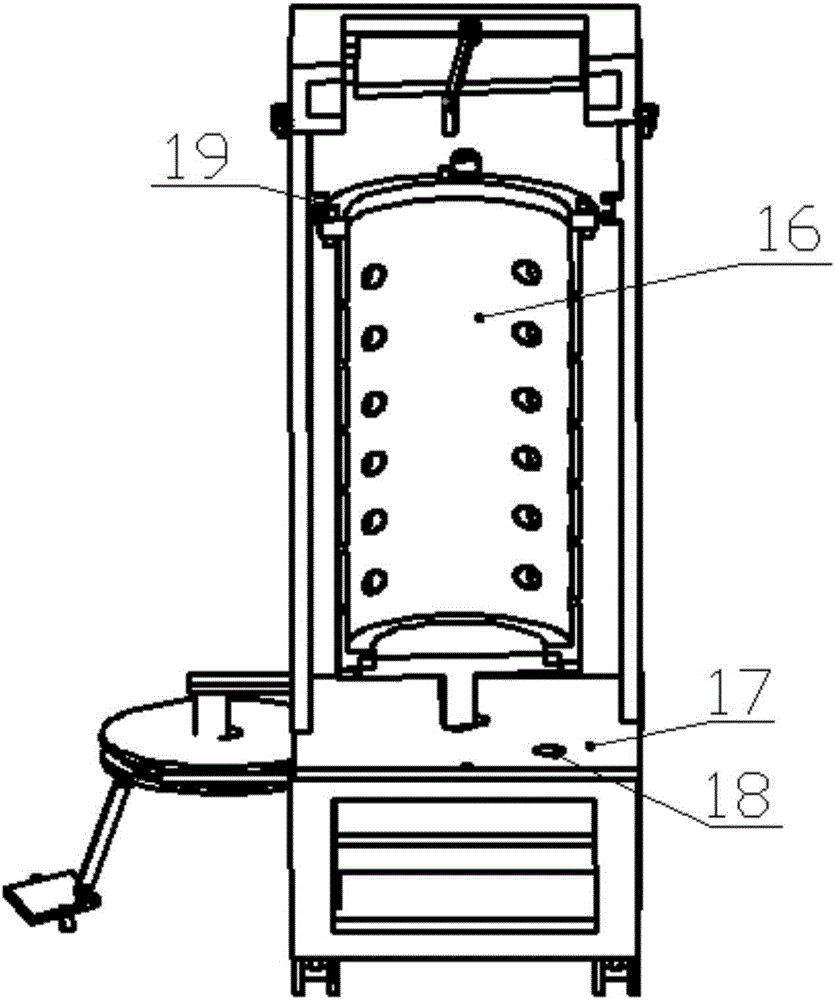

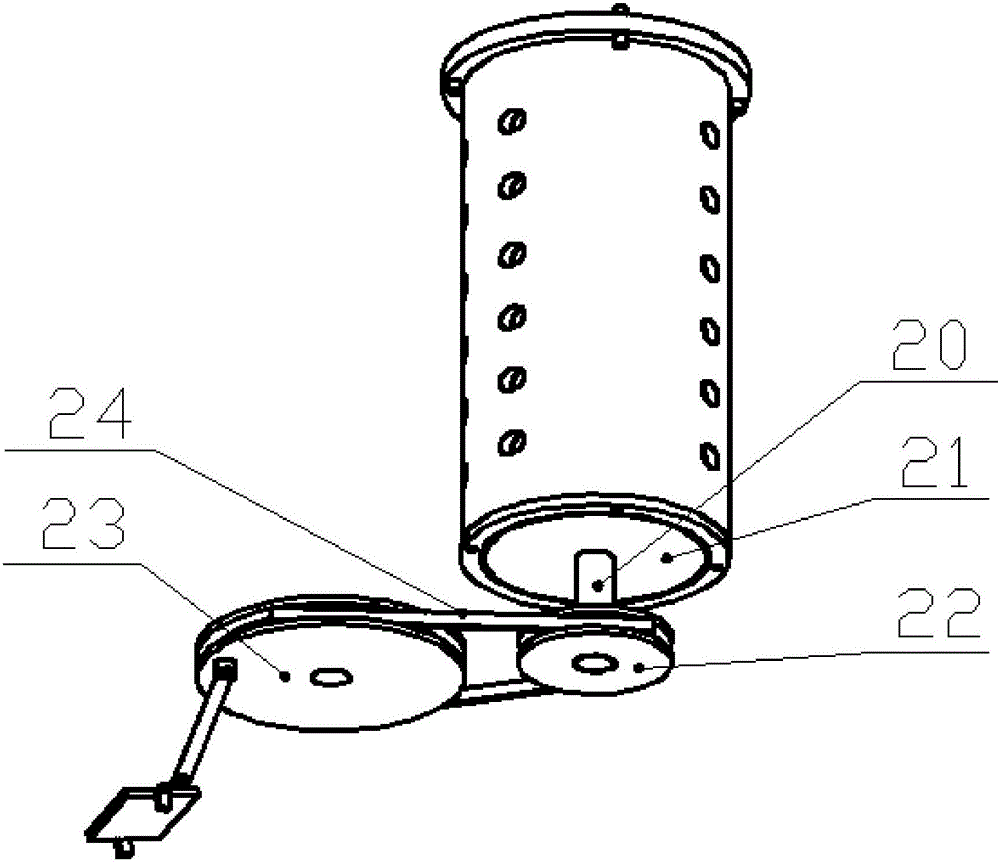

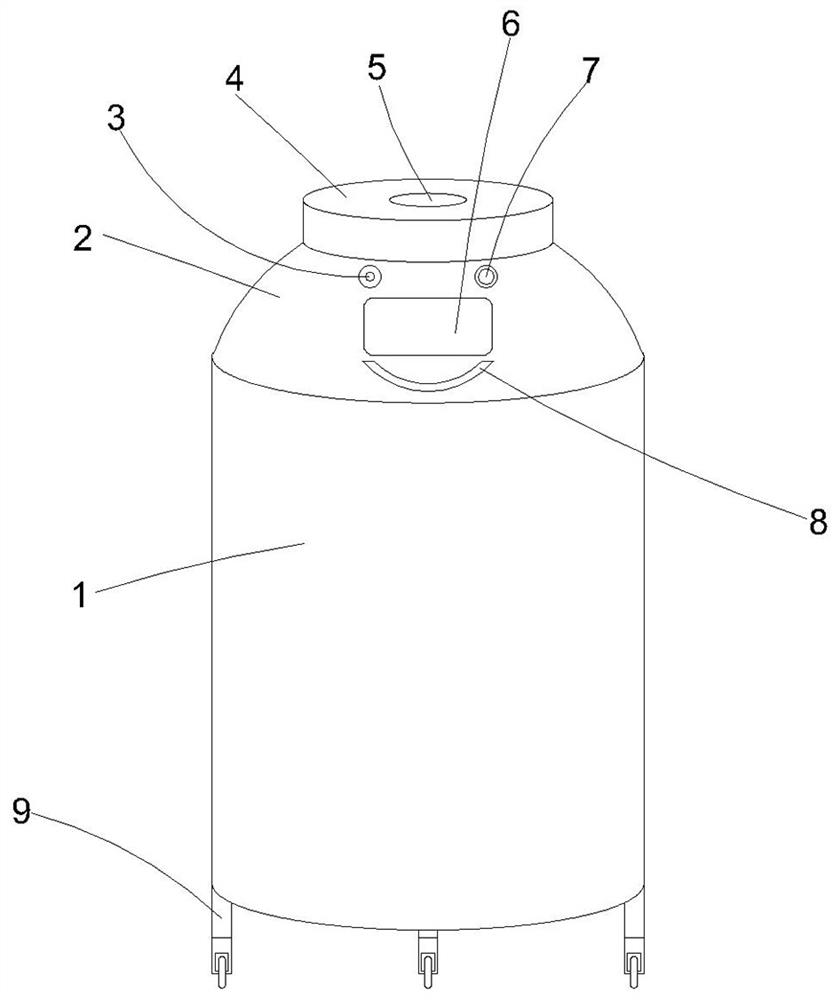

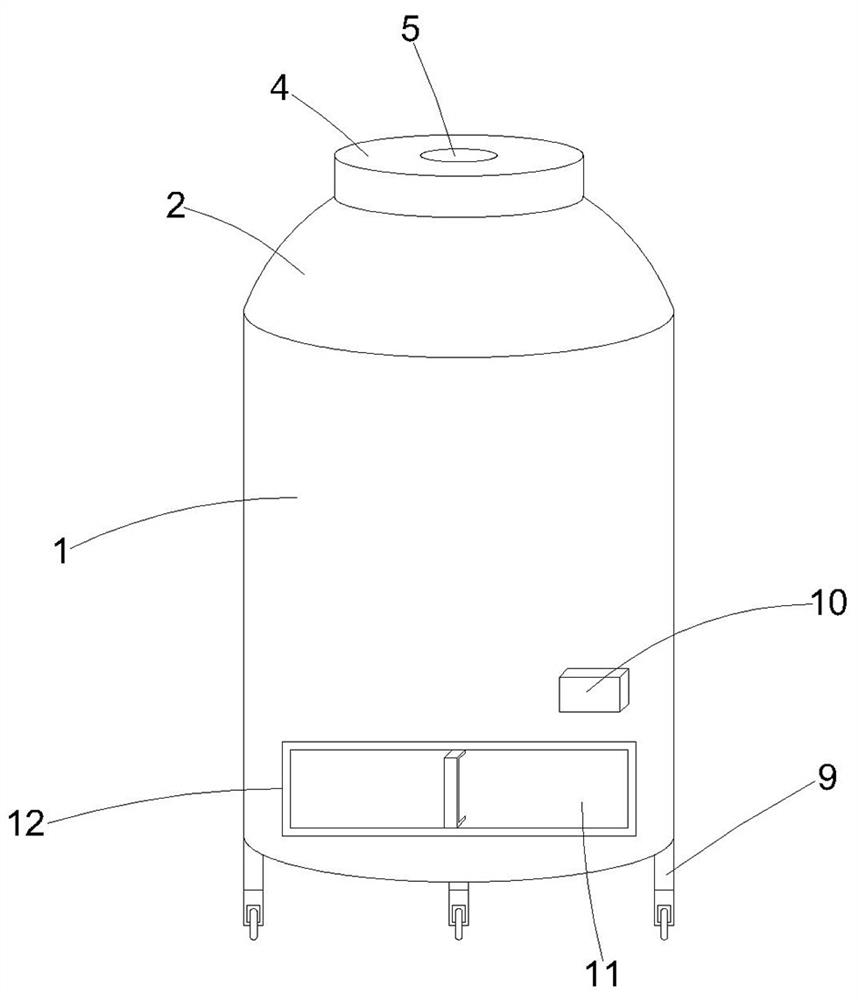

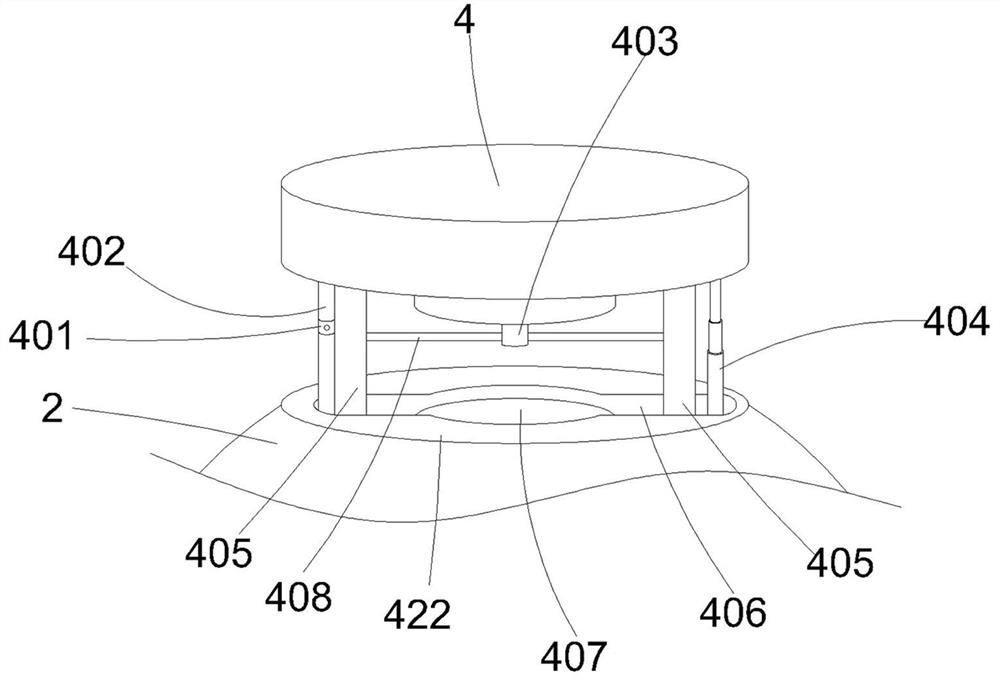

Blood sample temporary storage device and method for inpatient area

InactiveCN113830366AEasy to closeEasy to openWrapping material feeding apparatusPackage sterilisationBlood Collection TubeMedical waste

The invention belongs to the technical field of medical waste treatment, and particularly discloses a blood sample temporary storage device for an inpatient area. The blood sample temporary storage device comprises a temporary storage cylinder, wherein a sample temporary storage mechanism and a temporary storage control mechanism matched with the sample temporary storage mechanism are arranged in the temporary storage cylinder; a movement supporting mechanism is arranged on the bottom surface of the temporary storage cylinder; a temporary storage cover is arranged at the top end of the temporary storage cylinder, a temporary storage top surface is arranged at the top end of the temporary storage cover, a sample temporary storage opening is formed in the temporary storage top surface, and an automatic switch structure is arranged on the sample temporary storage opening; and a sample outlet matched with the temporary storage mechanism is formed in the temporary storage cylinder. According to the blood sample temporary storage device, by arranging the sample temporary storage mechanism and the temporary storage control mechanism in the temporary storage cylinder, collection and intelligent pretreatment actions of blood samples are achieved, centralized treatment and temporary storage of vacuum blood collection tubes are facilitated, the collection time of the vacuum blood collection tubes is effectively shortened, the time of contact with the vacuum blood collection tubes during manual operation is shortened, the collected vacuum blood collection tubes can be accurately recorded and counted, and the probability of losing the vacuum blood collection tubes is reduced.

Owner:HENAN CANCER HOSPITAL

Water surface garbage cleaning ship and garbage cleaning method

InactiveCN113002714AReduced occupied volumeReduce volumeWater cleaningWaterborne vesselsRemote controlUncrewed vehicle

The invention discloses a water surface garbage cleaning ship and a garbage cleaning method. The water surface garbage cleaning ship comprises a ship body, at least one unmanned aerial vehicle, at least two remote control tractors, at least one garbage surrounding net, a first conveying belt, a garbage crushing cabin, a garbage compression cabin and a second conveying belt; the unmanned aerial vehicle can detect the distribution condition of garbage on the water surface and provide remote control signal relay service for the remote control tractor, the remote control tractor is used for pulling the garbage surrounding net to gather the garbage on the water surface, the first conveying belt is arranged on the ship body, and the first conveying belt conveys the garbage from the water surface to the garbage crushing cabin;and the second conveying belt conveys the crushed garbage to the garbage compression cabin. The problems that an existing garbage cleaning ship is low in automation and intelligence degree, small in cleaning range, low in cleaning speed, low in efficiency and the like can be effectively solved, the garbage on the water surface can be rapidly and efficiently cleaned under the conditions of different water depths and water conditions, the garbage is compressed in size, and subsequent transportation and treatment of the garbage are facilitated.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

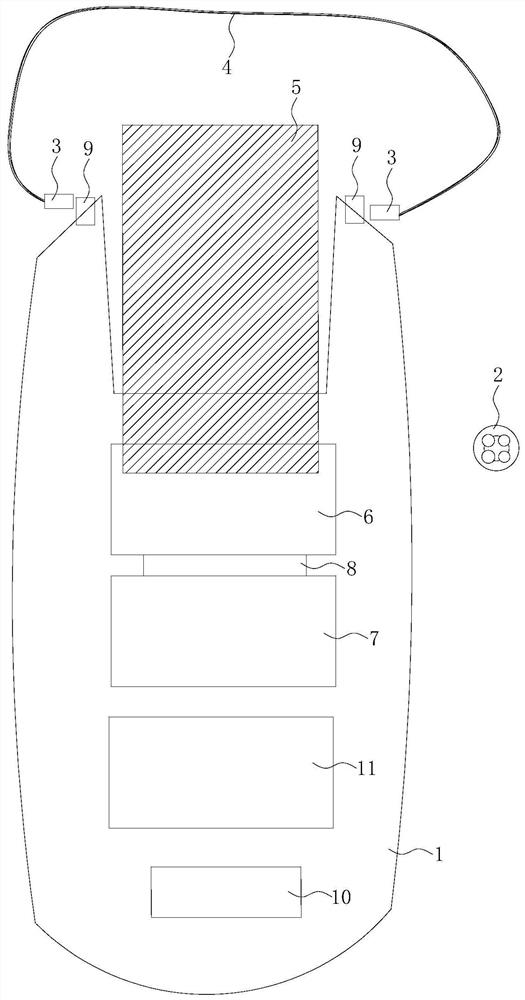

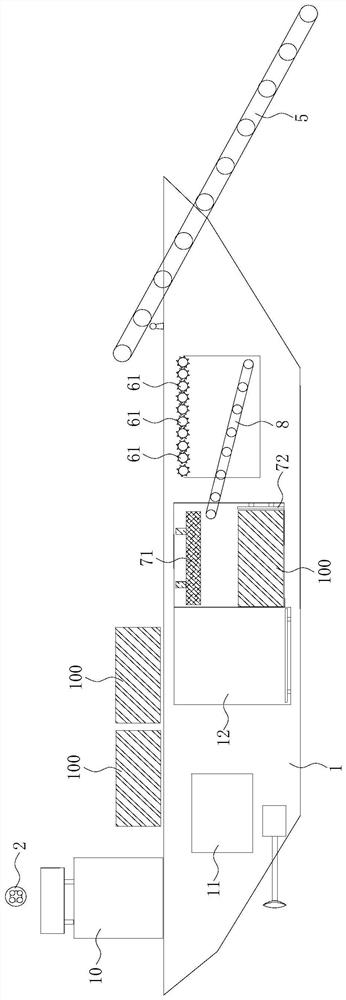

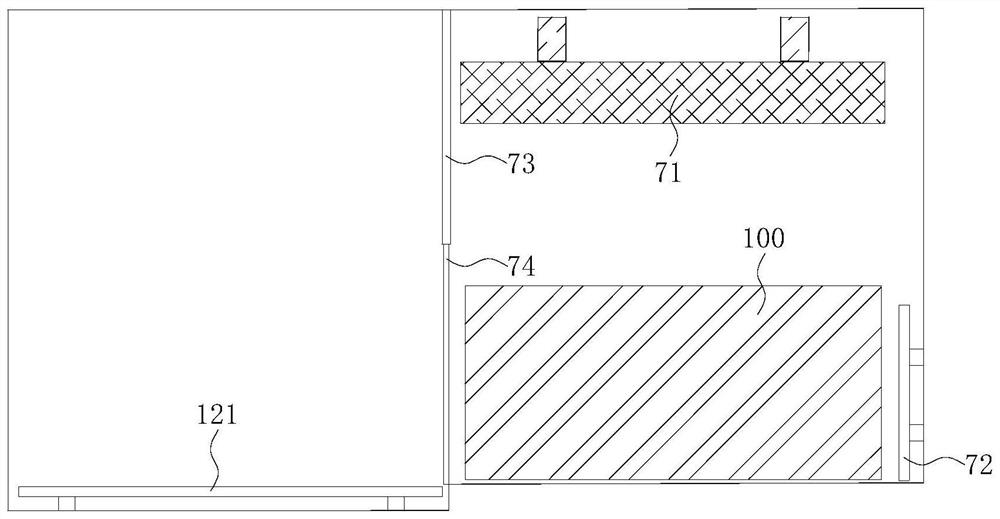

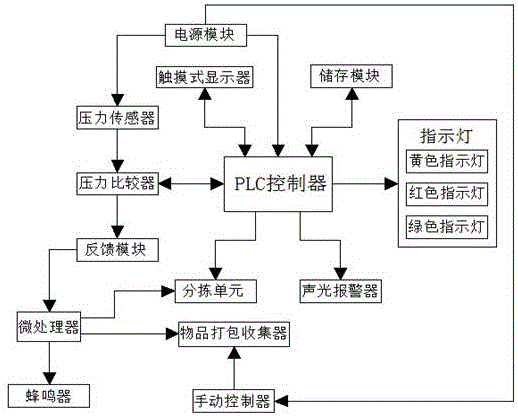

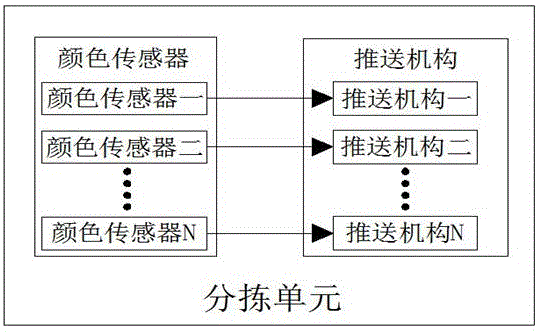

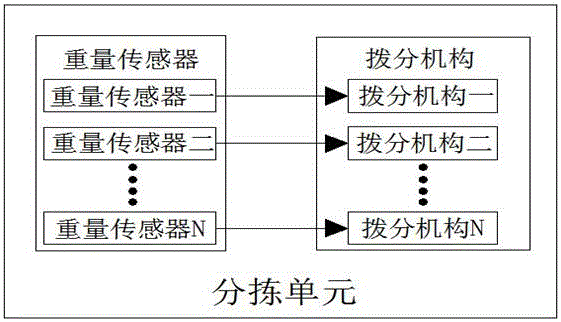

Sorting device for goods for daily use based on Internet of Things

InactiveCN106423901ASimplify complexityAvoid extremely inefficientSortingInternet of ThingsPressure sensor

The invention discloses a sorting device for goods for daily use based on Internet of Things. The sorting device comprises a PLC controller used for main control and a sorting unit arranged on a conveyor belt, wherein the output end of the PLC controller is separately connected with the input ends of the sorting unit, an audible and visual alarm and an indicator lamp, the PLC controller is also separately in bidirectional connection with a touch type display and a pressure comparator, the input end of the pressure comparator is connected with the output end of a pressure sensor, and the output end of the pressure comparator is connected with the input end of a microprocessor through a feedback module. The sorting device for goods for daily use based on Internet of Things simplifies the complexity of a sorting procedure, reduces labor use, has a complete sorting system for the goods for daily use, shortens working time, increases working efficiency, improves working effect, prevents objects from falling on the ground, avoids unnecessary difficulty and ensures the running of the whole system.

Owner:芜湖智美网络科技有限公司

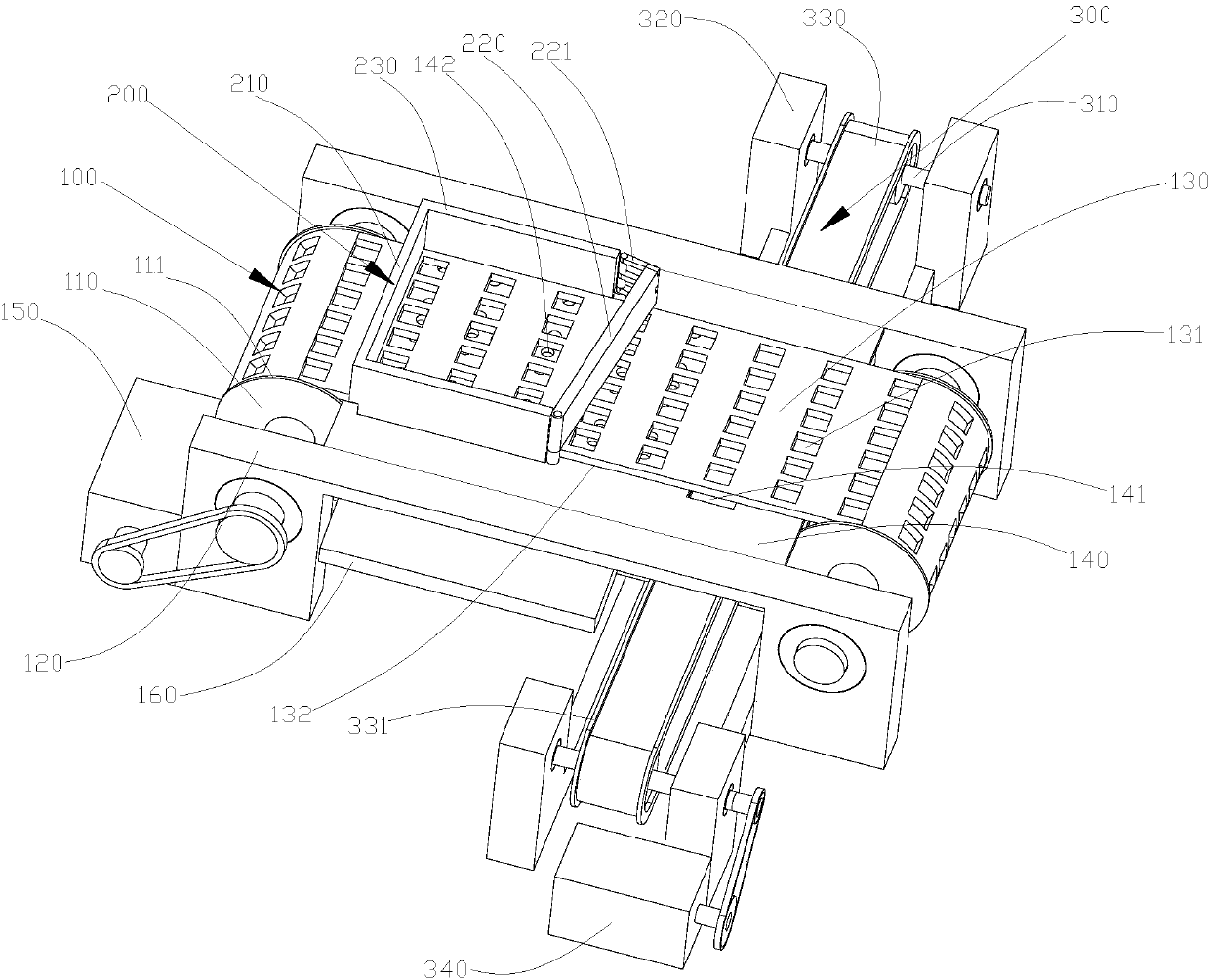

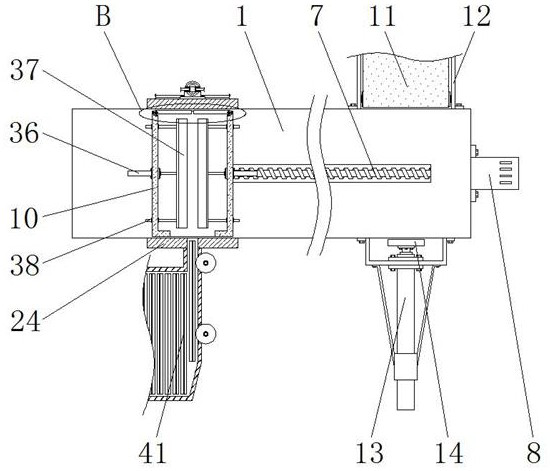

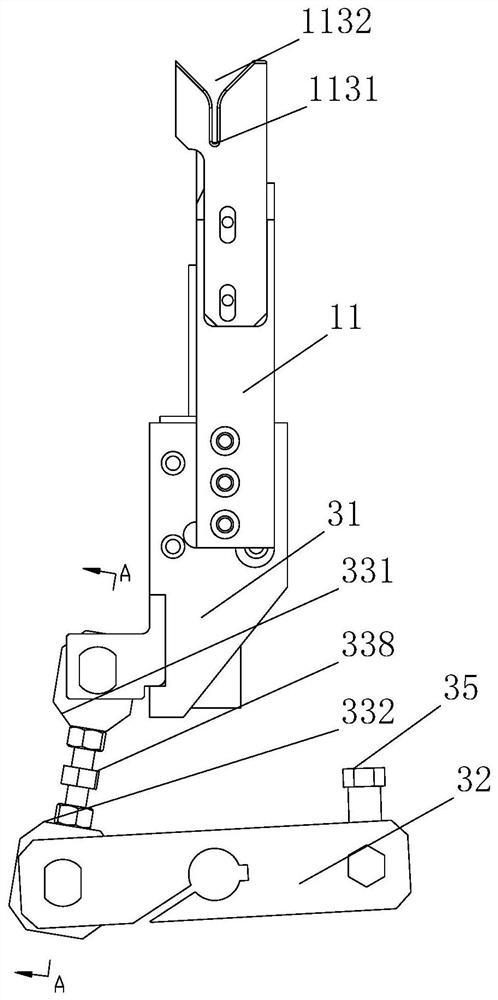

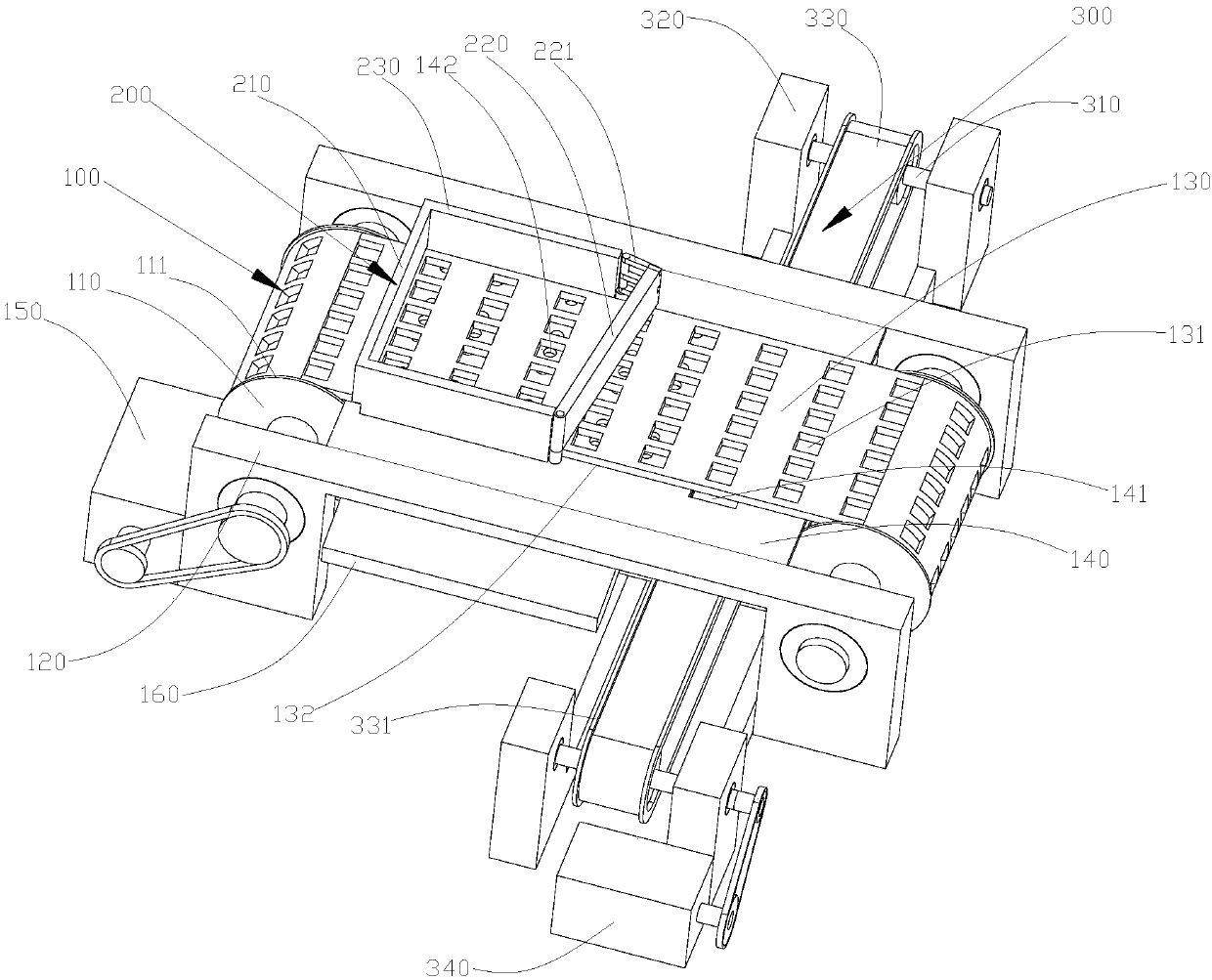

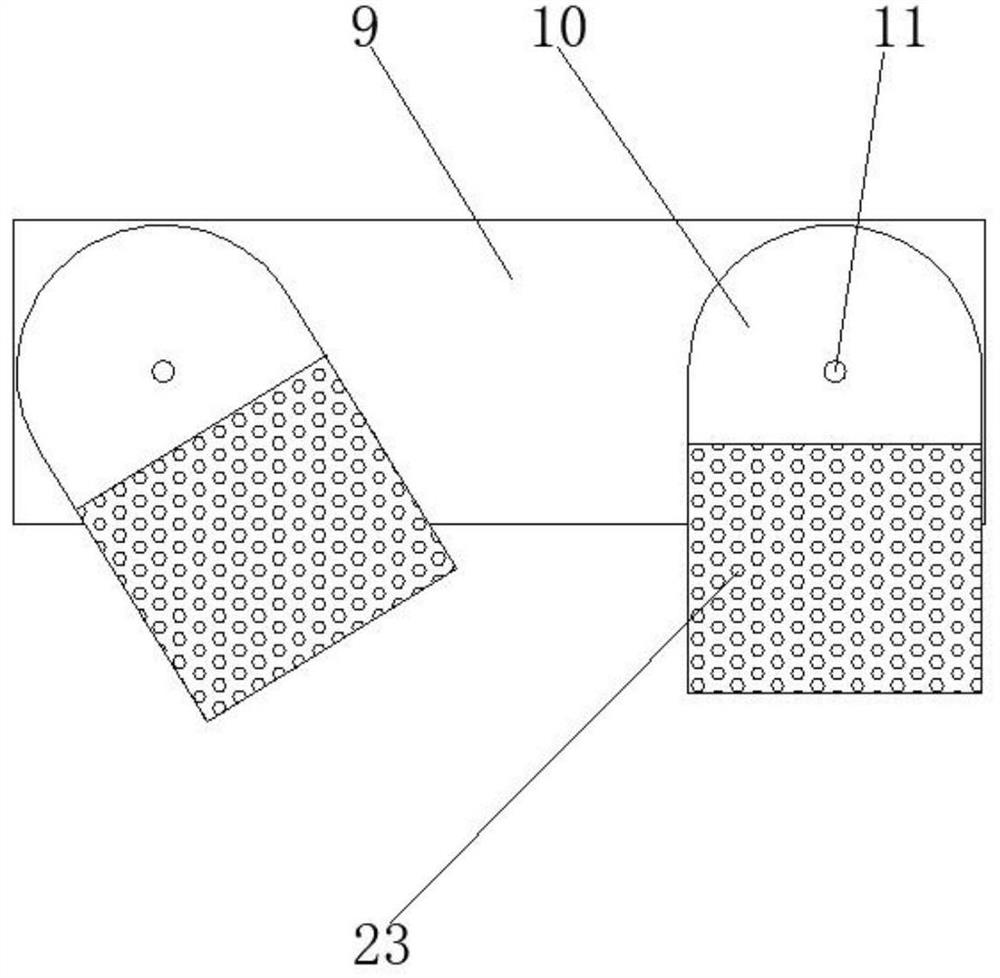

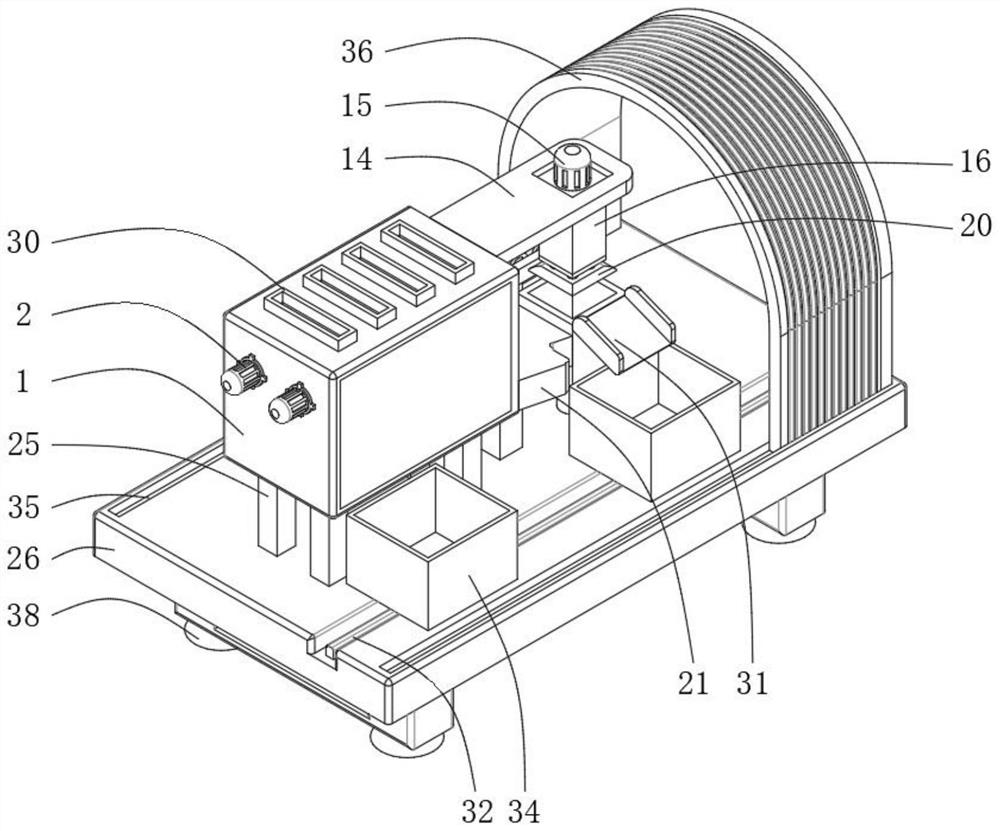

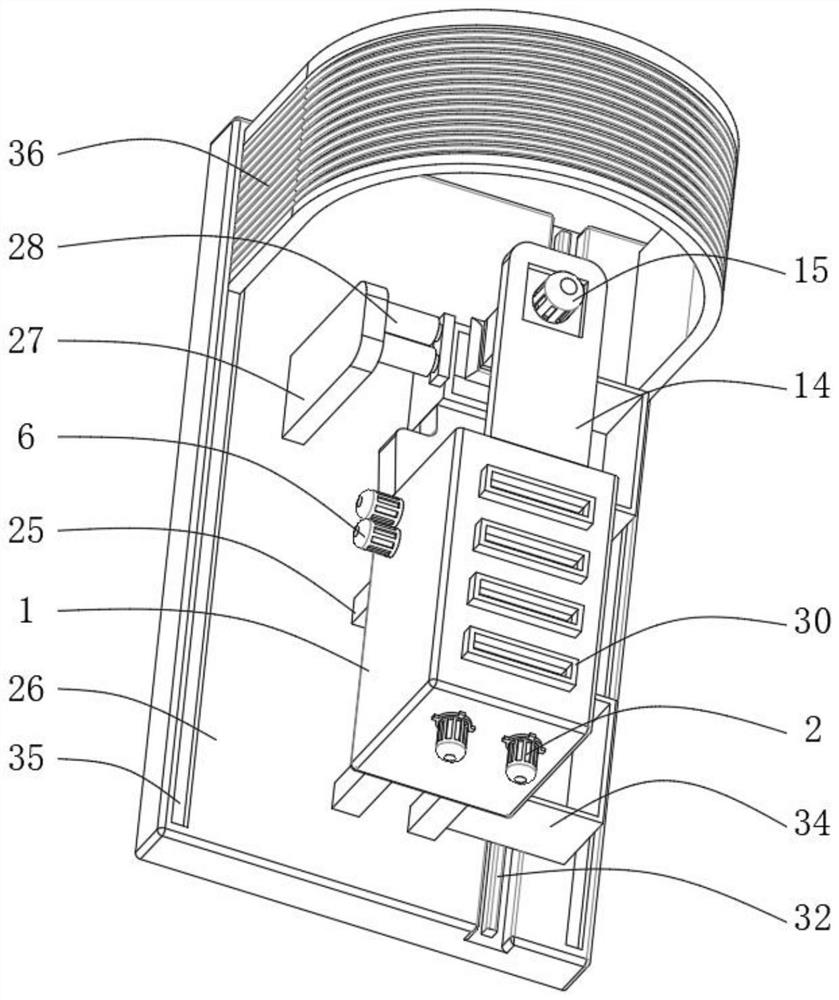

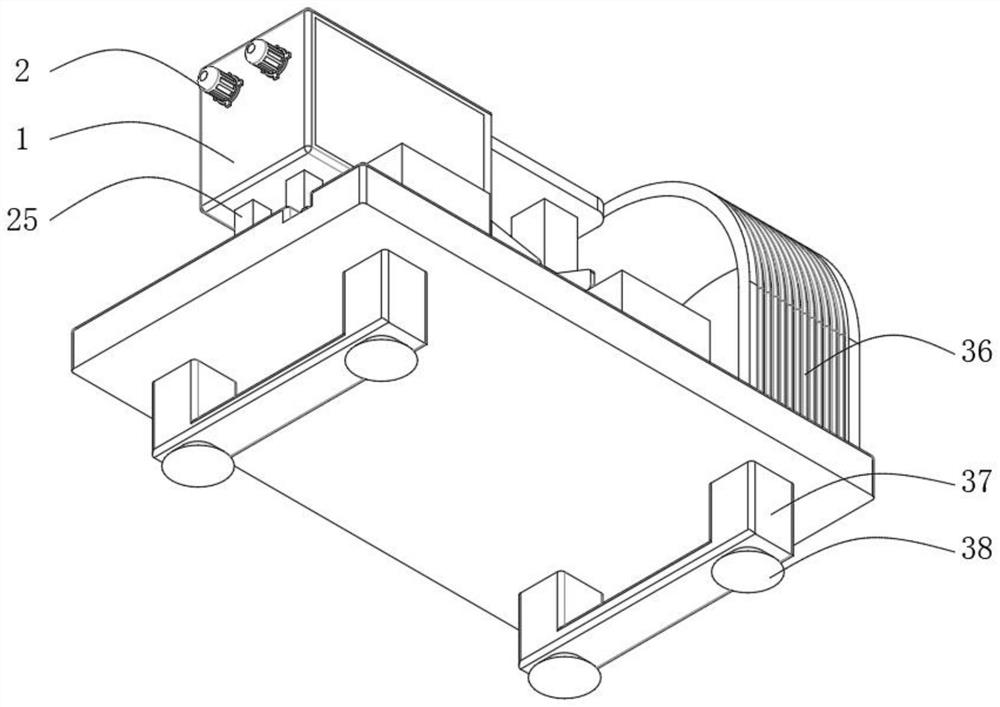

Arranging device of crawler pin shaft sealing packaging machine

PendingCN110562527AImprove packaging efficiencyEasy to pack and handlePackagingEngineeringPackaging machine

The invention discloses an arranging device of a crawler pin shaft sealing packaging machine. The arranging device comprises a hopper, a selecting mechanism, a distributing mechanism and a pushing mechanism; the selecting mechanism comprises a feeding belt and a frame; the feeding belt is arranged in the frame, is provided with supporting ribs, and is divided into a vertical feeding section and abottom receiving section; the bottom receiving section extends to a lower discharge port of the hopper; an outlet is formed in the upper side wall of the frame; a guide plate is arranged in the frame;the distributing mechanism comprises a guide rail, a horizontal driving assembly and a distributing plate; the upper end of the guide rail is connected with the outlet, and the lower end of the guiderail extends downwards; the distributing plate corresponds to the lower end of the guide rail, is provided with a plurality of distributing grooves which are arranged side by side, and is arranged onthe horizontal driving assembly; and the pushing mechanism is arranged on the side edge of the distributing mechanism and is capable of pushing sealing element products on the distributing plate outof the distributing plate. The arranging device is capable of arranging the sealing elements so that the sealing elements can be conveyed in order so as to facilitate packaging in conveying.

Owner:上海唯万密封科技股份有限公司

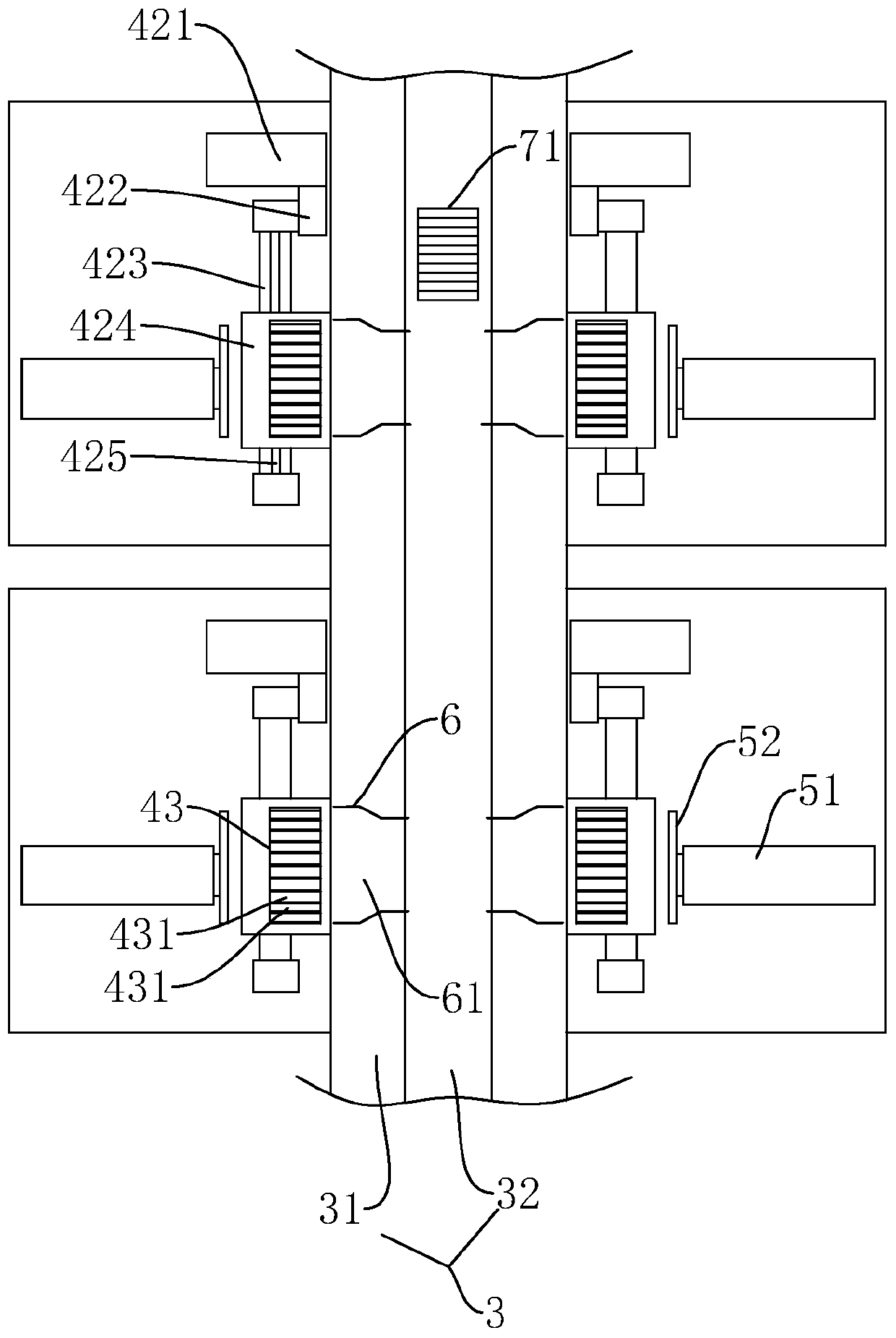

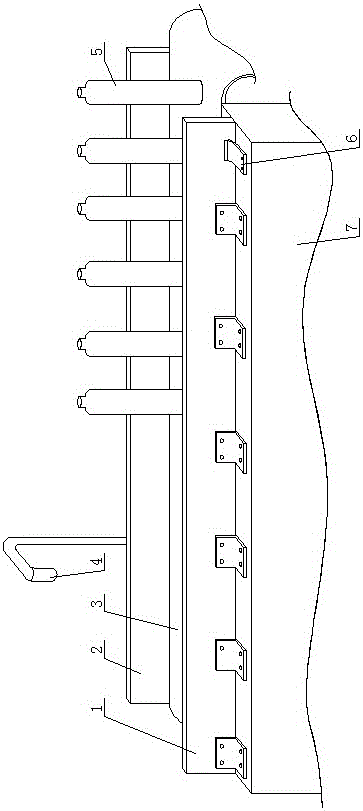

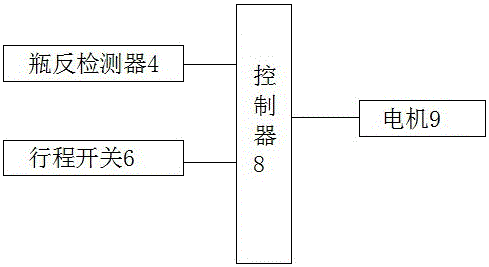

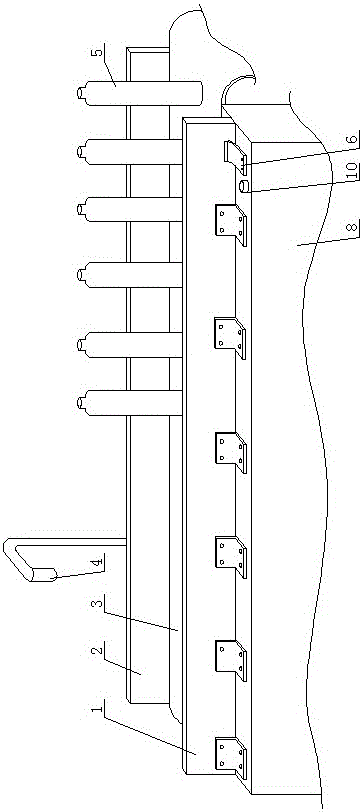

Bottle anti-inverting extrusion-preventing device for bottle unscrambler assembly line

PendingCN106697378AEasy to take outEasy to pack and handlePackaging automatic controlPackaging bottlesEngineeringAssembly line

The invention discloses a bottle anti-inverting extrusion-preventing device for a bottle unscrambler assembly line, and belongs to the field of bottle unscrambler devices. In order to solve the technical problem about how to avoid extruding of plastic bottles in a transmission process and a bottle reversing phenomenon of the plastic bottles, the bottle anti-inverting extrusion-preventing device structurally comprises a bracket, bottle unscrambler plates, travel switches and a bottle reversing detector, wherein the bottle unscrambler plates comprise a front bottle unscrambler plate and a rear bottle unscrambler plate; the front bottle unscrambler plate and the rear bottle unscrambler plate are oppositely fixed arranged above a conveyor belt front and back to form a U-shaped transmitting channel; the inner end part of at least one of the front bottle arranging unscrambler plate and the rear bottle unscrambler plate can be extruded by the plastic bottles to shift towards the outer side of the transmitting channel; the outer side of the inner end part of each bottle unscrambler plate capable of shifting is fixedly equipped with one travel switch; the bottle reversing detector is fixedly arranged above the transmitting channel; and the travel switch and the bottle reversing detector are connected to the controller. The bottle anti-inverting extrusion-preventing device can be used for detecting whether plastic bottles are blocked, extruded and reversely arranged or not, so that the bottle blocking problem and the bottle reversing problem can be conveniently processed timely.

Owner:泰安锦泰塑料制品有限公司

Sewage treatment system

InactiveCN111704219AEasy to pack and handleCutting costsSludge treatmentWater/sewage treatment by flocculation/precipitationWater treatment systemSludge

The invention relates to a sewage treatment system. The sewage treatment system comprises a wastewater collection tank with an opening in the upper end, a cover plate is arranged on the upper side ofthe wastewater collecting box; a water inlet is formed in the upper surface of the wastewater collecting box and is positioned on one side of the cover plate; a chemical feeding opening is formed in the upper surface of the waste water collecting box and located in the other side of the cover plate, a solid waste collecting box is arranged on the outer side of the waste water collecting box, a sludge pump is installed between the waste water collecting box and the solid waste collecting box, and a filter press is connected to the outer side of the solid waste collecting box. The sewage treatment system has the effects that filtered water can be recycled, and the cost is reduced.

Owner:浙江博凯文体用品有限公司

Machining process for scrap steel primary machining

InactiveCN111634054APromote full fragmentationAvoid difficult crushing and low crushing efficiencyWelding/soldering/cutting articlesGas flame welding apparatusMachining processIndustrial engineering

The invention relates to the technical field of scrap steel primary machining, and discloses a machining process for scrap steel primary machining. The machining process comprises the steps of collecting, specifically, residual steel from a steel machining factory and community waste steel scrap are collected and accumulated in an empty space of a workshop; and sorting, specifically, the collectedscrap steel is subjected to primary sorting, and the scrap steel difficult to enter a furnace for conveying and large in size is collected together and then subjected to primary machining by adoptinga cutting method. According to the machining process for scrap steel primary machining, the scrap steel is preliminarily sorted by adopting a sorting mode, different types of the scrap steel are sorted and then treated, and the scrap steel is crushed by adopting different modes so that the scrap steel can be fully crushed; and natural gas is used for cutting instead of oxygen, and the natural gasbelongs to pure energy without generating waste gas difficult to treat in the using process, and has high stability without accidents in the cutting process, so that the safety of the cutting processof the scrap steel primary machining is greatly improved.

Owner:江苏聚之再生科技有限公司

Material collecting device for PLA pipe machining and working method thereof

The invention discloses a material collecting device for PLA pipe machining and a working method thereof. The device comprises a pipe collecting chamber, wherein two inlet and outlet chambers are arranged on the two sides of the pipe collecting chamber, a pipe inlet is formed in one side of the pipe collecting chamber, two conveying mechanisms are installed on the inner wall of the same side of the pipe collecting chamber, a fixing frame is fixedly installed on the inner wall of one side of the pipe collecting chamber, an installing rail is fixedly installed on one side of the fixing frame, a rotating chain is rotatably installed on the installing rail, a plurality of fixing pieces are installed on the rotating chain, dedusting mechanisms are rotatably installed on the fixing pieces, and a plurality of collecting mechanisms are slidably installed between the two inlet and outlet chambers. According to the material collecting device, PLA pipes can be collected and dedusted in batches, and meanwhile, the PLA pipes are conveyed from the high position to the low position through lifting of the dedusting mechanisms in the collecting process, and the situation that in the process that the PLA pipes are collected from the high position through the gravity of the PLA pipes, the PLA pipes are damaged, and much flying dust is caused is avoided.

Owner:阜南县顺昌塑业有限公司

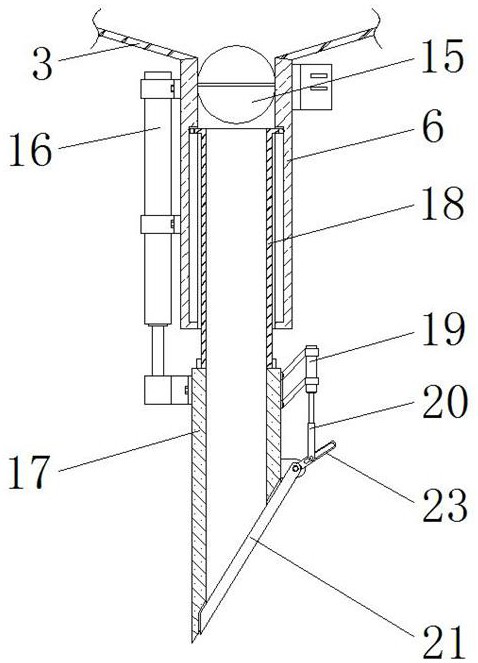

Split charging device and control method for veterinary drug production

ActiveCN113428425AThe process of veterinary drug packaging is simpleEasy to sealClimate change adaptationWrapper twisting/gatheringVeterinary drugMechanical engineering

The invention discloses a split charging device and control method for veterinary drug production, and relates to the technical field of split charging devices. The split charging device comprises a base plate, a funnel and multiple connecting plates located on one side of the funnel are arranged on the upper side of the base plate, and a first motor and a first threaded rod engaged with the output end of the first motor are arranged in each connecting plate. According to the split charging device, first sliding plates and second sliding plates are provided with positioning mechanisms used for fixing and unfixing split charging bags, the split charging bags containing veterinary drugs can be conveniently fixed and bagged, the veterinary drugs can be conveniently subjected to split charging treatment, and split charging bags of different specifications can be conveniently fixed; and through the arrangement of first groove channels, rotating plates are driven by the first sliding plates to drive the second sliding plates, so that split-charged veterinary drug split charging bags are adjusted, the split charging bags are subjected to hot melting and sealing treatment, the veterinary drug split charging process is simpler, and the split charging bags obtained after split charging are more convenient to seal.

Owner:安徽科尔药业有限公司

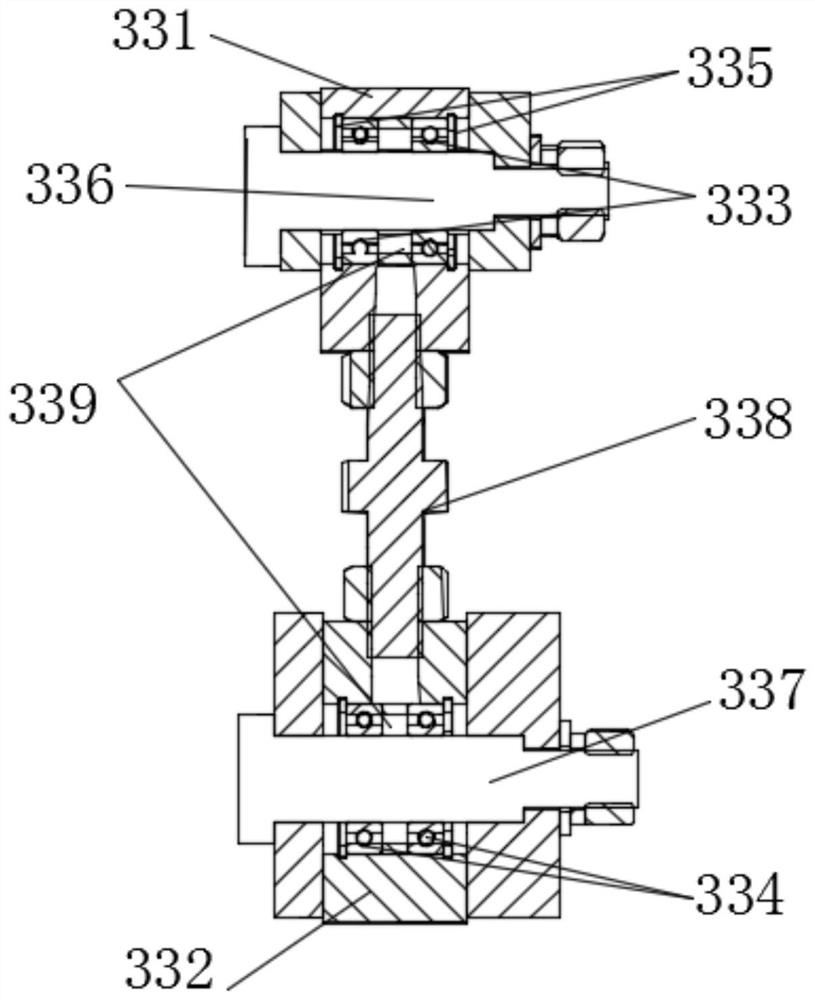

Forming device and packaging machine comprising forming device

PendingCN112722455AReduced commissioning timeImprove securityWrapper twisting/gatheringPackaging machinesMoulding deviceManufacturing engineering

The invention relates to the technical field of packaging machines, in particular to a forming device and a packaging machine comprising the forming device. The forming device comprises a negative pressure pipeline, a bundling mechanism and a swing mechanism. One end of the bundling mechanism is provided with a groove assembly used for fixing and keeping a sealing film to be of an arc-shaped structure, and the other end of the bundling mechanism is rotatably connected with the swing mechanism; the swing mechanism is used for driving the bundling mechanism to swing back and forth; and the forming device is arranged on the packaging machine. The forming device and the packaging machine comprising the forming device are convenient to install, easy and convenient to debug, simple in process and convenient to machine, and the productivity is improved. PVDC films are used for outer packaging of the product, packaging treatment is convenient, and environmental pollution is reduced. A preforming material is changed into a PVDC sealing film from a traditional aluminum wire, stress of a forming die in the forming process is reduced, abrasion of the forming die is reduced, and the service life of the forming die is prolonged.

Owner:BEIJING AEROSPACE ORIENTAL TECH DEVCO

A dough conveying system

The invention provides a pastry conveying system which comprises a feed divider and a feeding device. The feed divider comprises two driving rollers and two oppositely arranged support frames, the driving rollers are erected between the support frames, a dividing conveyor belt is arranged on the driving rollers in a sleeving manner, and evenly arranged through holes are arranged in the dividing conveyor belt; a support plate is arranged between the support frames and penetrates the inner cavity in the dividing conveyor belt to be closely attached to the same, and a falling port is arranged inone end of the support plate; the feeding device comprises two roll shafts and two oppositely arranged support seats, the roll shafts are erected between the support seats, and a feeding conveyor beltis arranged on the roll shafts in a sleeving manner and penetrates the inner cavity of the feeding conveyor belt to be located right under the falling port. By the arrangement, square pastries can bedivided and sorted in batch, the pastries can be outlet in orderly arrangement and identical direction, and subsequent processing and packaging of the pastries are facilitated; the entire process runs continuously and cyclically, manual intervention is reduced, and production efficiency is greatly improved.

Owner:江西捷创自动化设备有限公司

Material finishing method

Owner:王步熬

Straw pellet storage apparatus

The invention discloses a straw pellet storage apparatus. The straw pellet storage apparatus comprises a silo cell. Supporting columns are connected to the two sides of the lower end of the outer surface of the silo cell, a feeding port is formed in the upper part of the silo cell, two partition plates are arranged inside the silo cell so that three storage warehouses can be formed inside the silocell, discharging hopper warehouses are welded to the positions, corresponding to the storage warehouses, of the lower end surface of the outer part of the silo cell, supporting seats are fixedly installed on the positions, corresponding to the upper surface of the silo cell, of the outer side of the feeding port, sliding rods and threaded rods are correspondingly connected between the supportingseats which are located on the same side of the feeding port, one ends of the threaded rods are connected with driving assemblies through connecting shafts, the lower end of a conveying hopper is fixedly connected with a feeding hose, feeding plates are arranged between the sliding rods and the threaded rods, and the lower end of the feeding hose penetrates through and is fixedly connected with the centers of feeding plates. According to the straw pellet storage apparatus, the operation processes of storage and discharging of straw pellets are convenient, and using is facilitated.

Owner:颍上烨徽生物科技有限公司

Separation and purification device for microglial cells

InactiveCN112916153AAvoid affecting the experimental operationImprove stabilitySupporting apparatusGrain treatmentsEngineeringStructural engineering

The invention discloses a separation and purification device for microglial cells. The separation and purification device for the microglial cells comprises a main body frame, layer plates and a crushing box, wherein drawers are mounted on the front side surface of the main body frame; cabinet bodies are arranged below the drawers; bases are mounted at four corners of the bottoms of the cabinet bodies; an enclosure frame is mounted at the periphery of the outer edge of the upper part of the main body frame; a top frame is mounted at the upper part of the rear side of the enclosure frame; sliding rails are fixed to the inner walls of the left side and right side of the top frame; sliding blocks are connected to the inner sides of the sliding rails; each layer plate is mounted between the corresponding adjacent sliding blocks; rotating plates are arranged on the left side and right side of the upper part of each layer plate; rotating shafts are mounted at the joints of the rotating plates and the layer plates; the crushing box is mounted on the rear sides of the drawers; and crushing cutter bars are mounted inside the crushing box. According to the separation and purification device for the microglial cells, the crushing cutter bars are arranged and can crush experimental garbage inside the crushing box in the rotating process, and the crushed experimental garbage is more convenient to package, so that the treatment effect of the whole device on the experimental garbage is greatly enhanced.

Owner:THE FIRST PEOPLES HOSPITAL OF NANTONG

Plastic bag folding and pressing device

The invention discloses a plastic bag folding and pressing device, and belongs to the technical field of plastic bag production equipment. The plastic bag folding and pressing device comprises a body, a conveying mechanism, a first power mechanism, a second power mechanism, a conveying mechanism, a leveling mechanism, an extrusion mechanism and a telescopic mechanism, and the conveying mechanism is rotatably connected to the left side of the middle of the front side wall and the rear side wall of an inner cavity of the body; the first power mechanism is fixedly connected to the left side of the bottom of an inner cavity of the body through bolts, the second power mechanism is fixedly connected to the middle of the right side wall of the inner cavity of the body through bolts, and the conveying mechanism is rotatably connected to the right side of the middle of the front and rear side walls of the inner cavity of the body; and the leveling mechanism is rotatably connected to the bottom of the telescopic mechanism through a rotating shaft. The plastic bag folding and pressing device is reasonable in structural design, through the leveling mechanism, during folding, a plastic bag can be protected, manual work is replaced by machinery, time and labor are saved, the production efficiency is improved, through pressing treatment, the plastic bag is not prone to loosening after being folded, and later packaging treatment is facilitated.

Owner:怀宁县日升塑业有限公司

Finance and accounting paper smashing device with compacting and packaging structure

InactiveCN113499838AImprove compactionImprove crushing effectGrain treatmentsPressesStructural engineeringMechanical engineering

The invention provides a finance and accounting paper smashing device with a compacting and packaging structure, and belongs to the technical field of smashing equipment. The finance and accounting paper smashing device with the compacting and packaging structure comprises a smashing box, one side face of the smashing box is fixedly connected with a first servo motor, finance and accounting paper needing to be smashed enters the smashing box through a paper inlet, the finance and accounting paper is cut by a first smashing blade on a first fixed cutter sleeve firstly, the cut paper falls on a partition plate, and the partition plate is inclined, so that the paper subjected to primary cutting can slowly enter a second fixed cutter sleeve, is cut by a second smashing blade again and then falls into the bottom of the smashing box, a shredded paper push plate at the bottom of the smashing box can feed paper pieces subjected to secondary cutting into a connecting pipe, then the paper pieces enter a compacting box through the connecting pipe to be compacted, data can be smashed more seriously through two times of smashing, meanwhile, subsequent paper piece compaction can be more conveniently carried out, and the smashing effect is improved.

Owner:ZHEJIANG GUANGSHA COLLEGE OF APPLIED CONSTRTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com