Packaging device for finished product of lampblack machine glass cover plate

A glass cover and range hood technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high labor intensity and reduce packaging speed, and achieve convenient storage and handling, ingenious and reasonable structural design, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

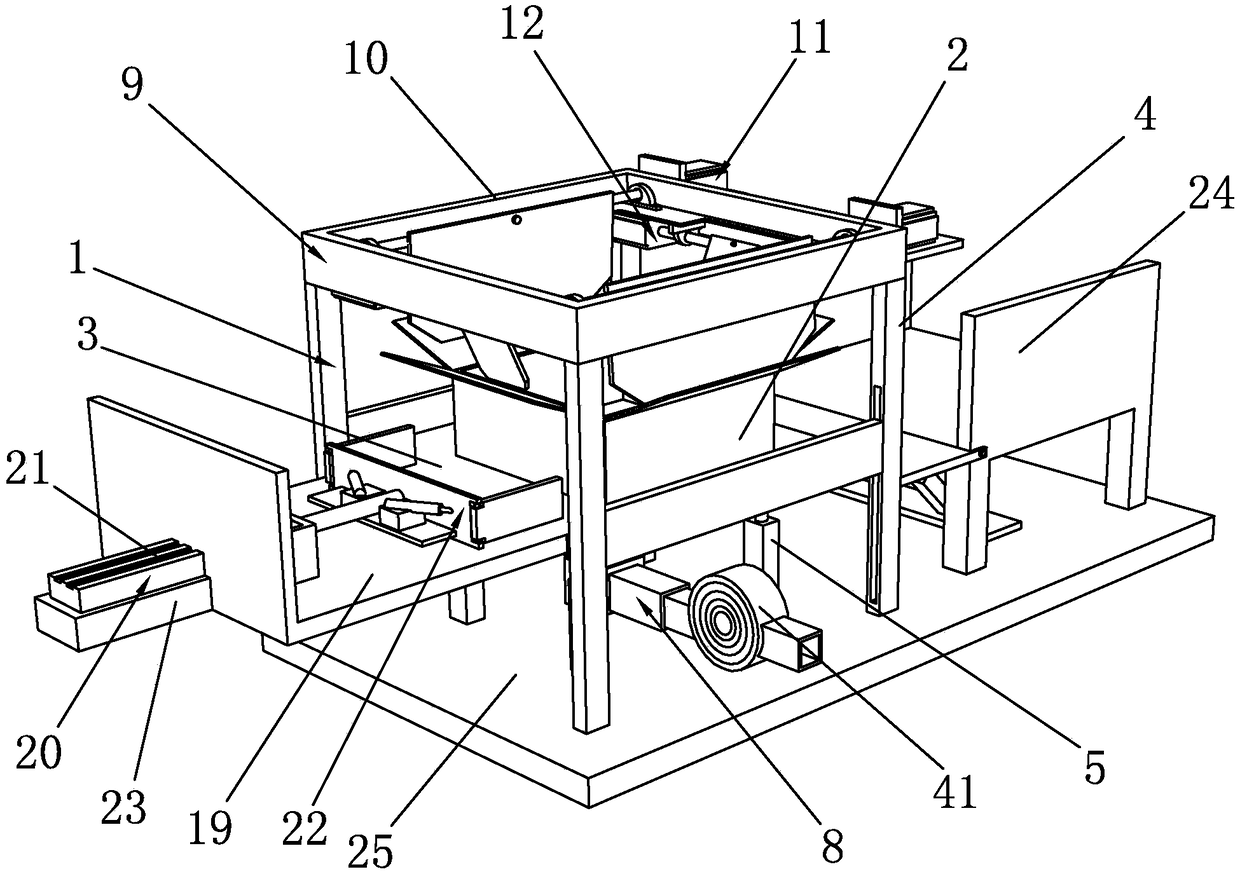

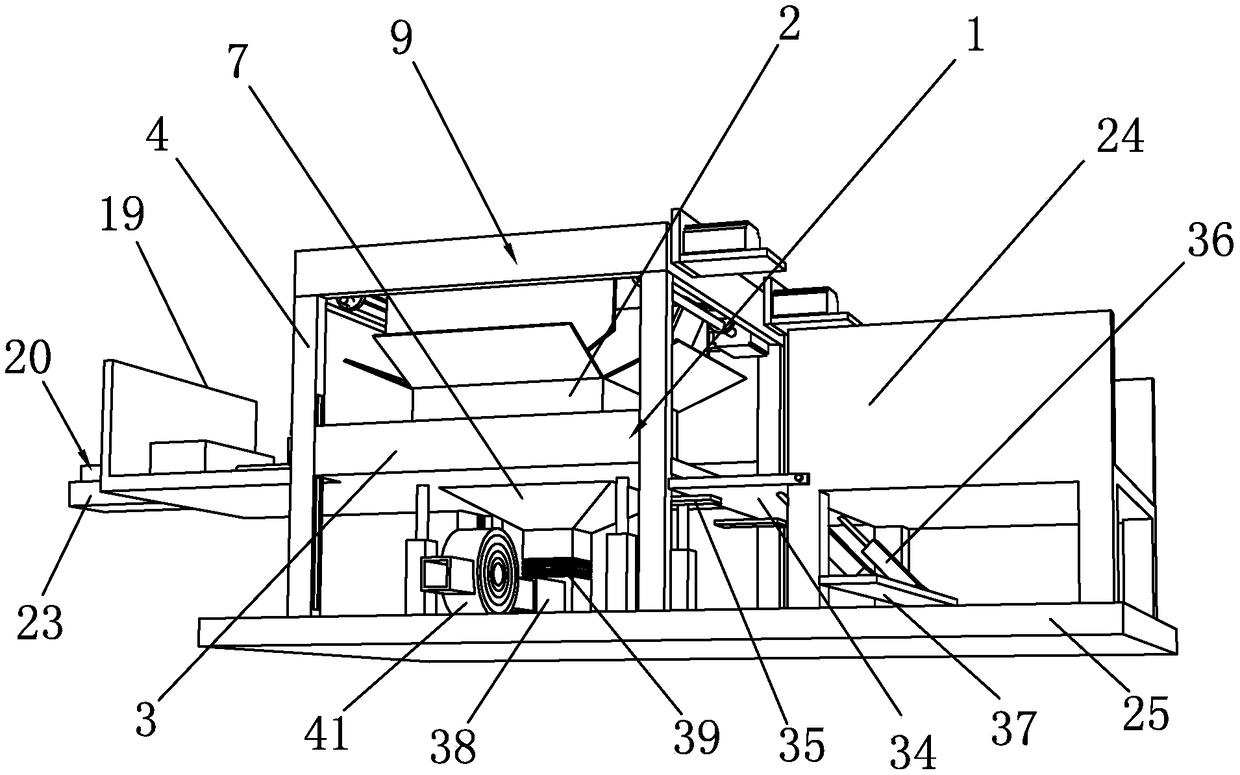

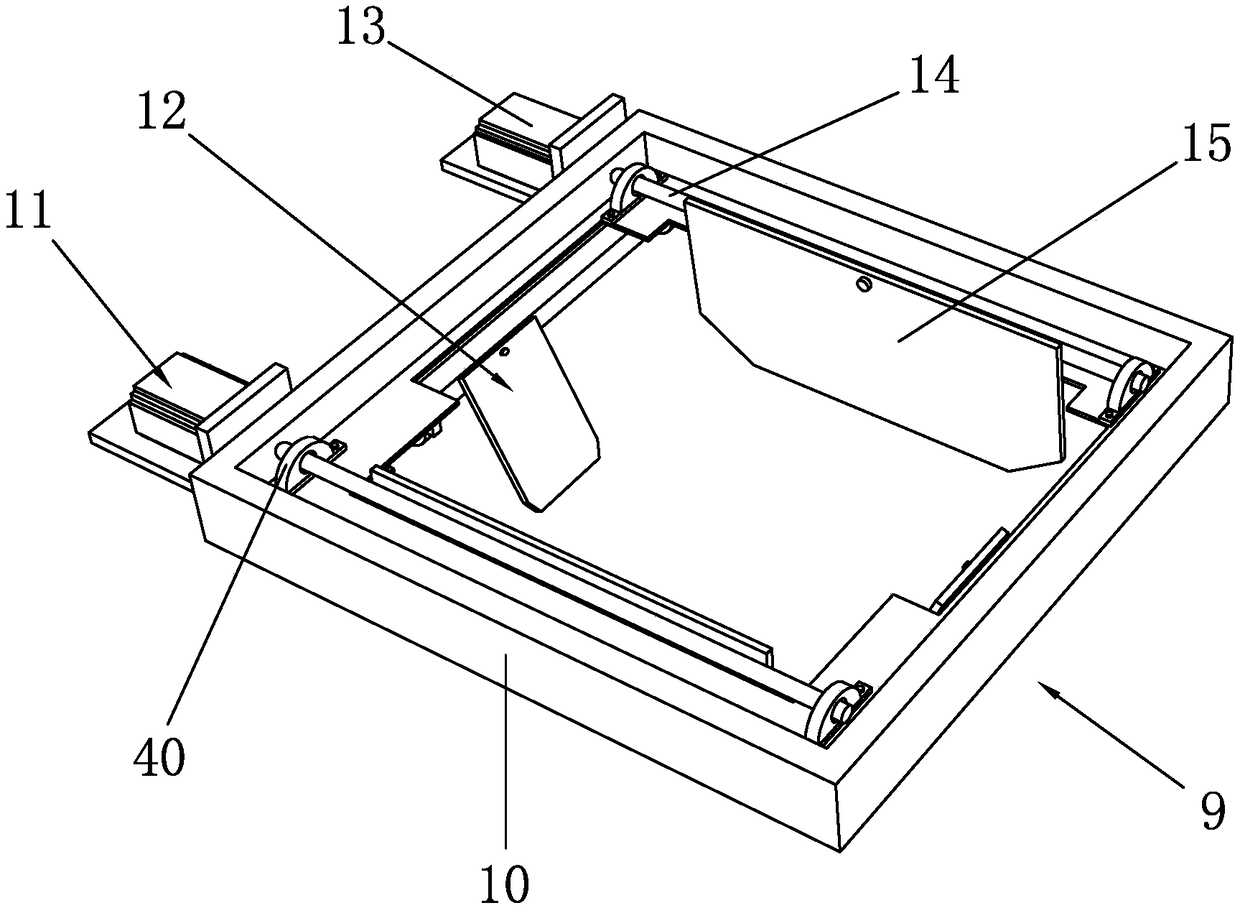

[0026] like Figure 1 to Figure 7 As shown, it is a packing device for the finished glass cover plate of range hood according to the present invention, which includes a packing table 1 and a packing box 2, the packing box 2 is located at the center of the packing table 1, and the packing table 1 includes a working platform 3 and a supporting column 4. The working platform 3 is located between the four supporting columns 4, the supporting column 4 is provided with a moving chute 26, the working platform 3 is provided with a moving slider 27, the moving slider 27 is matched with the moving chute 26, and the working platform 3. The moving slider 27 is clamped in the moving chute 26 and slides up and down along the moving chute 26. The design of the moving chute 26 and the moving slider 27 can facilitate the sliding up and down of the working platform 3 on the support column 4, changing The upper and lower heights of the working platform 3 move the packing boxes 2 of different hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com