Plastic bag folding and pressing device

A technology of pressing device and plastic bag, applied in packaging and other directions, can solve problems such as looseness, time-consuming and labor-intensive, lack of pressing process, etc., and achieve the effect of reducing frictional resistance, improving production efficiency and facilitating folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

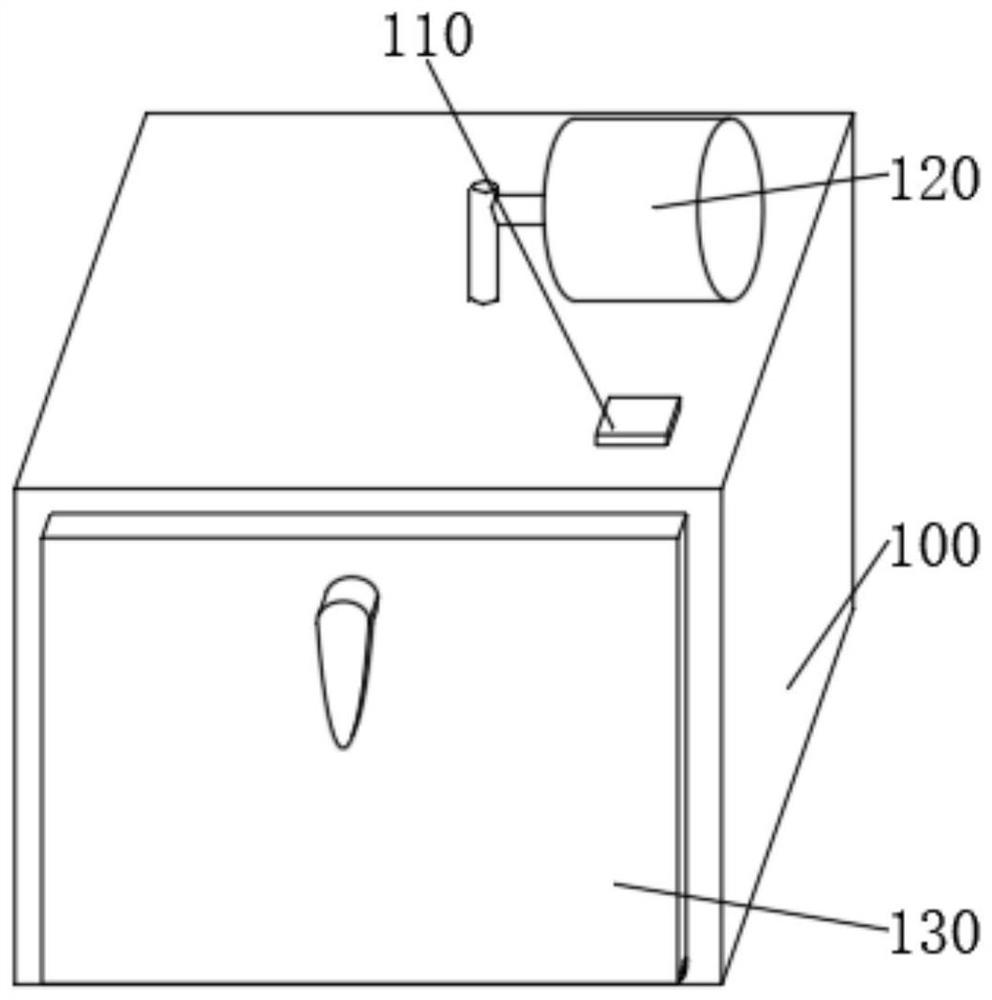

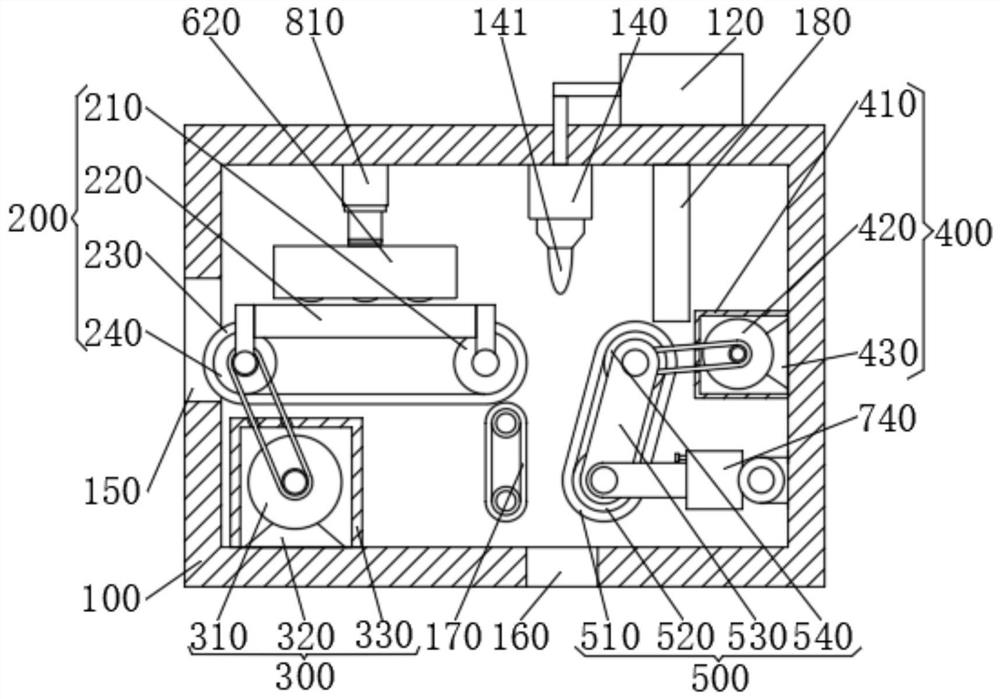

[0027] see Figure 1-4 and Figure 6-7, the present invention provides a technical solution: a plastic bag folding and pressing device, including a body 100, a transmission mechanism 200, a first power mechanism 300, a second power mechanism 400, a transmission mechanism 500, a leveling mechanism 600, and an extrusion mechanism 700 and telescopic mechanism 800, the transmission mechanism 200 is rotatably connected to the middle left side of the front and rear side walls of the body 100, the first power mechanism 300 is fixedly connected to the left side of the bottom of the body 100 by bolts, and the second power mechanism 400 is connected by bolts Fixedly connected to the middle of the right side wall of the inner cavity of the main body 100, the transmission mechanism 500 is rotatably connected to the middle right side of the front and rear side walls of the inner cavity of the main body 100, the leveling mechanism 600 is connected to the bottom of the telescopic mechanism 8...

Embodiment 2

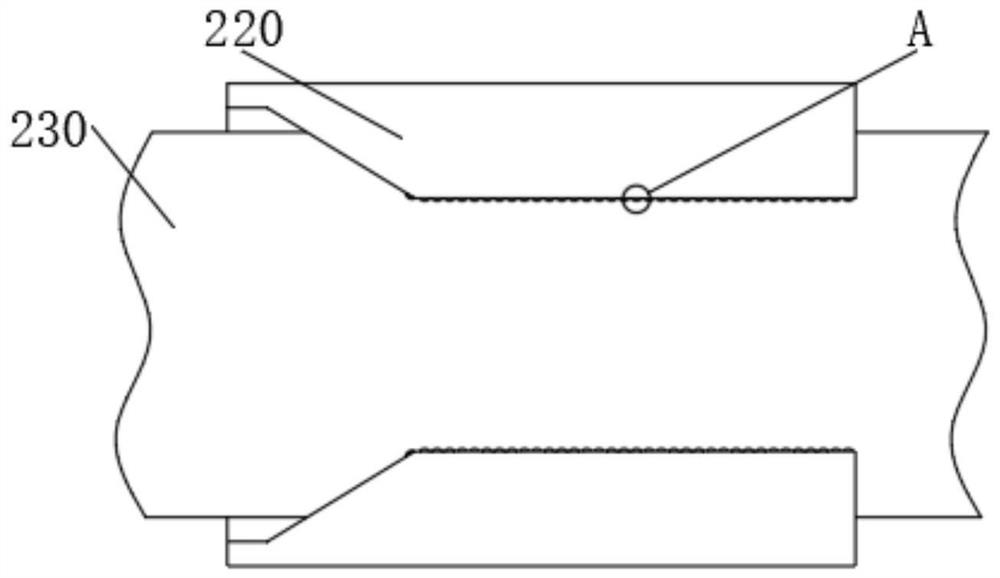

[0029] see figure 2 , the present invention provides a technical solution: a plastic bag folding and pressing device, including a body 100, a transmission mechanism 200, a first power mechanism 300, a second power mechanism 400, a transmission mechanism 500, a leveling mechanism 600, and an extrusion mechanism 700 and telescopic mechanism 800, the transmission mechanism 200 is rotatably connected to the middle left side of the front and rear side walls of the body 100, the first power mechanism 300 is fixedly connected to the left side of the bottom of the body 100 by bolts, and the second power mechanism 400 is connected by bolts Fixedly connected to the middle of the right side wall of the inner cavity of the main body 100, the transmission mechanism 500 is rotatably connected to the middle right side of the front and rear side walls of the inner cavity of the main body 100, the leveling mechanism 600 is connected to the bottom of the telescopic mechanism 800 through a rotat...

Embodiment 3

[0031] see Figure 1-2 and Figure 5 , the present invention provides a technical solution: a plastic bag folding and pressing device, including a body 100, a transmission mechanism 200, a first power mechanism 300, a second power mechanism 400, a transmission mechanism 500, a leveling mechanism 600, and an extrusion mechanism 700 and telescopic mechanism 800, the transmission mechanism 200 is rotatably connected to the middle left side of the front and rear side walls of the body 100, the first power mechanism 300 is fixedly connected to the left side of the bottom of the body 100 by bolts, and the second power mechanism 400 is connected by bolts Fixedly connected to the middle of the right side wall of the inner cavity of the main body 100, the transmission mechanism 500 is rotatably connected to the middle right side of the front and rear side walls of the inner cavity of the main body 100, the leveling mechanism 600 is connected to the bottom of the telescopic mechanism 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com