Patents

Literature

41results about How to "Reduce the number of pours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

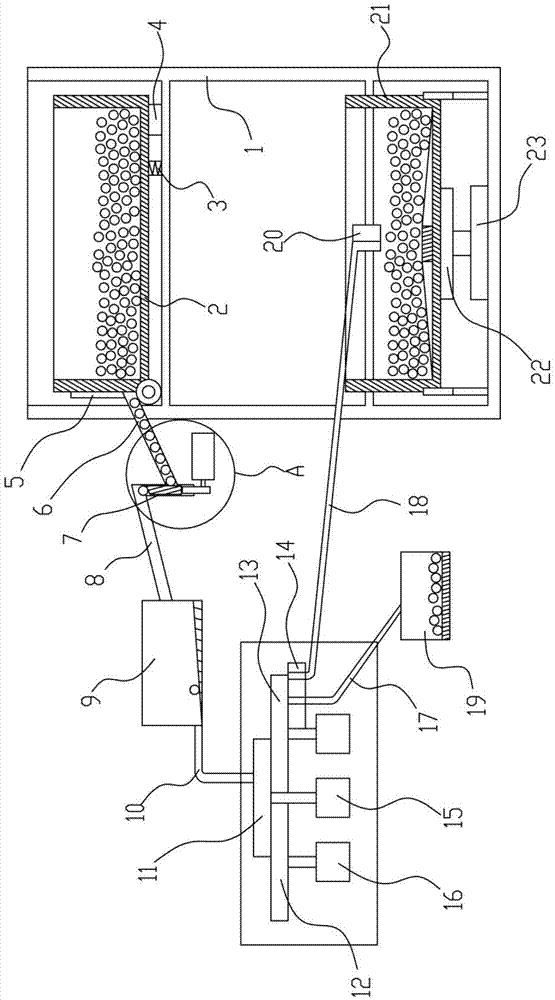

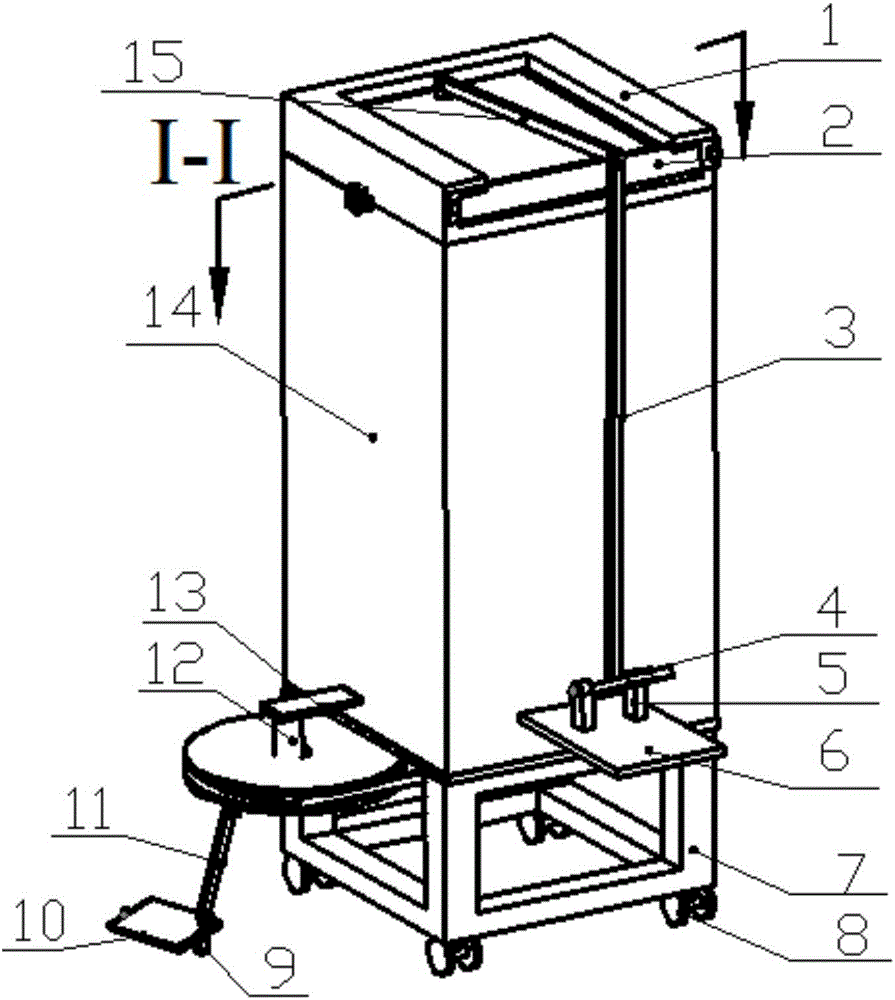

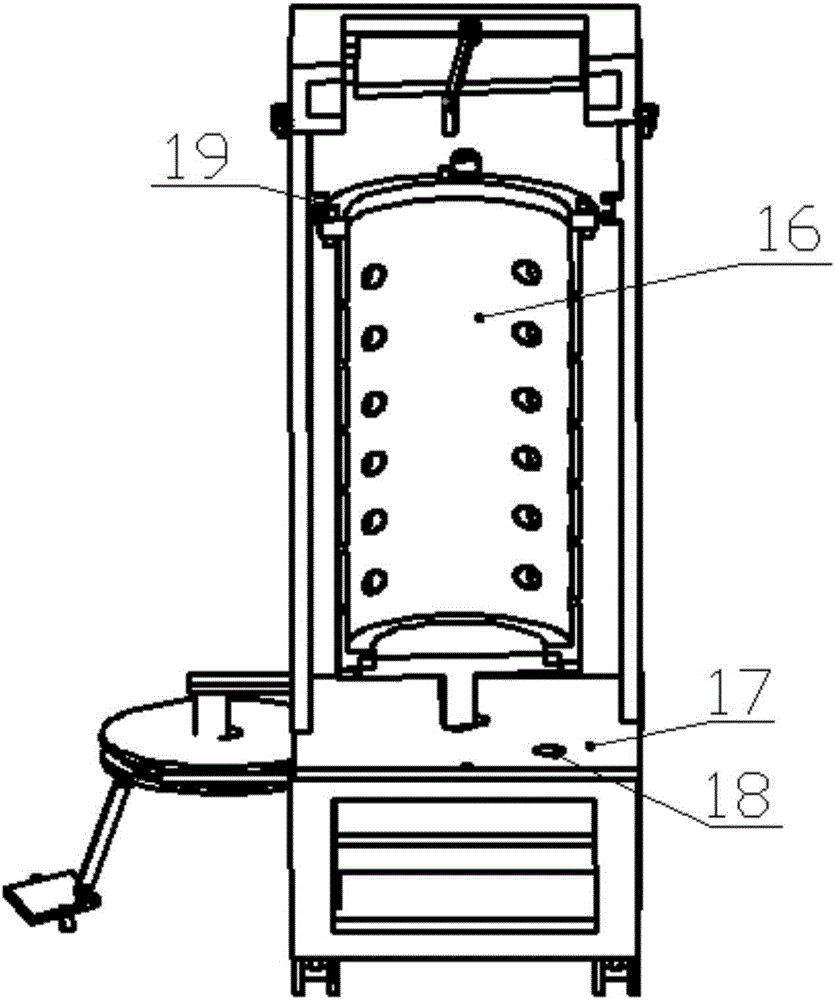

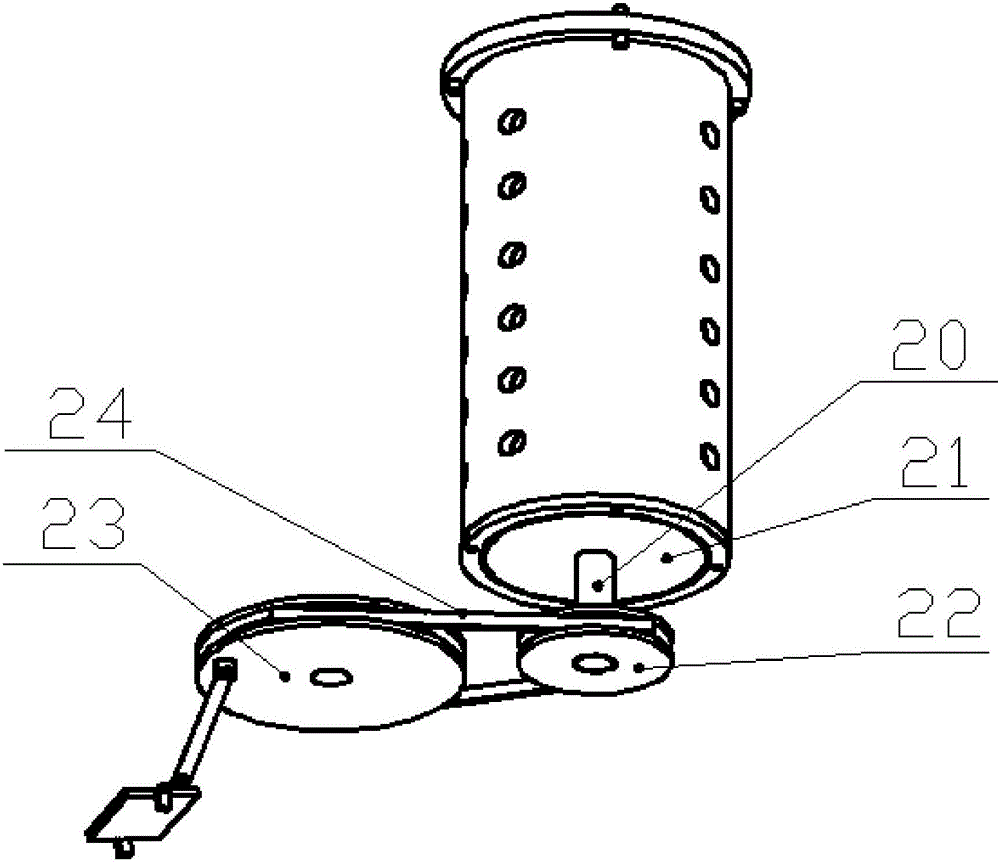

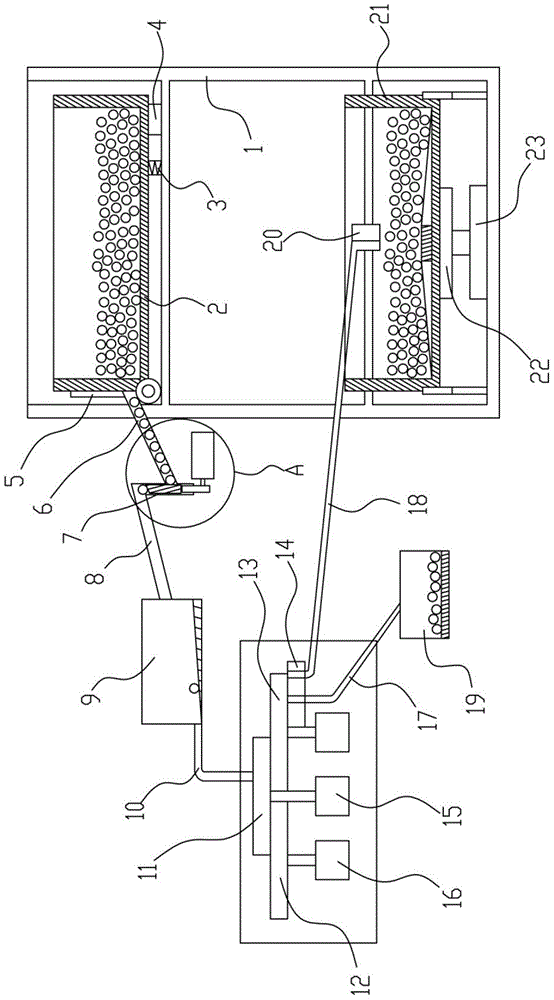

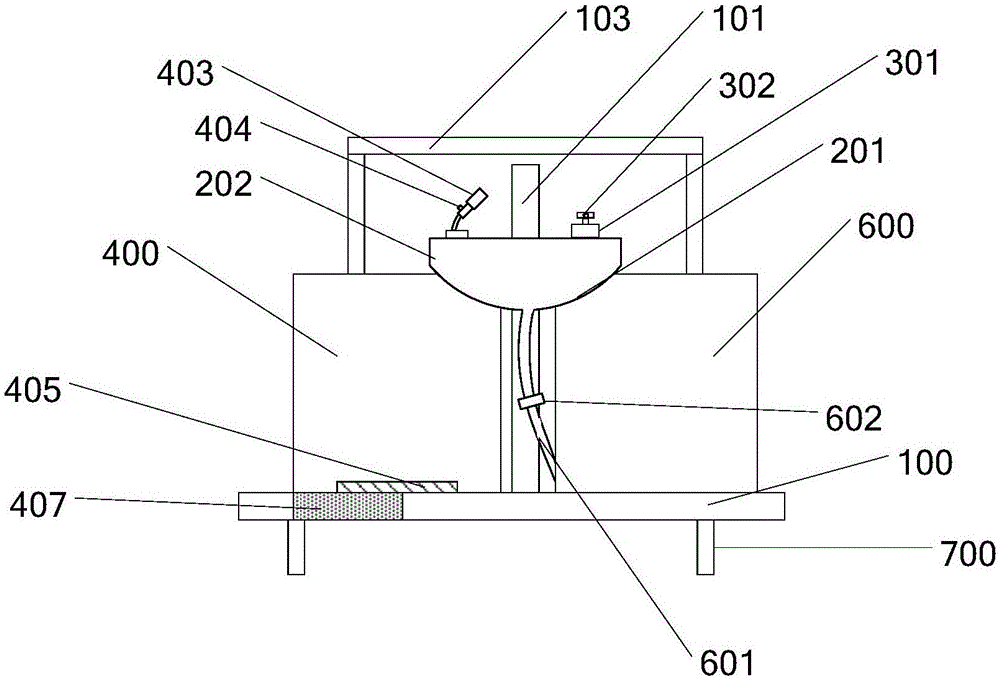

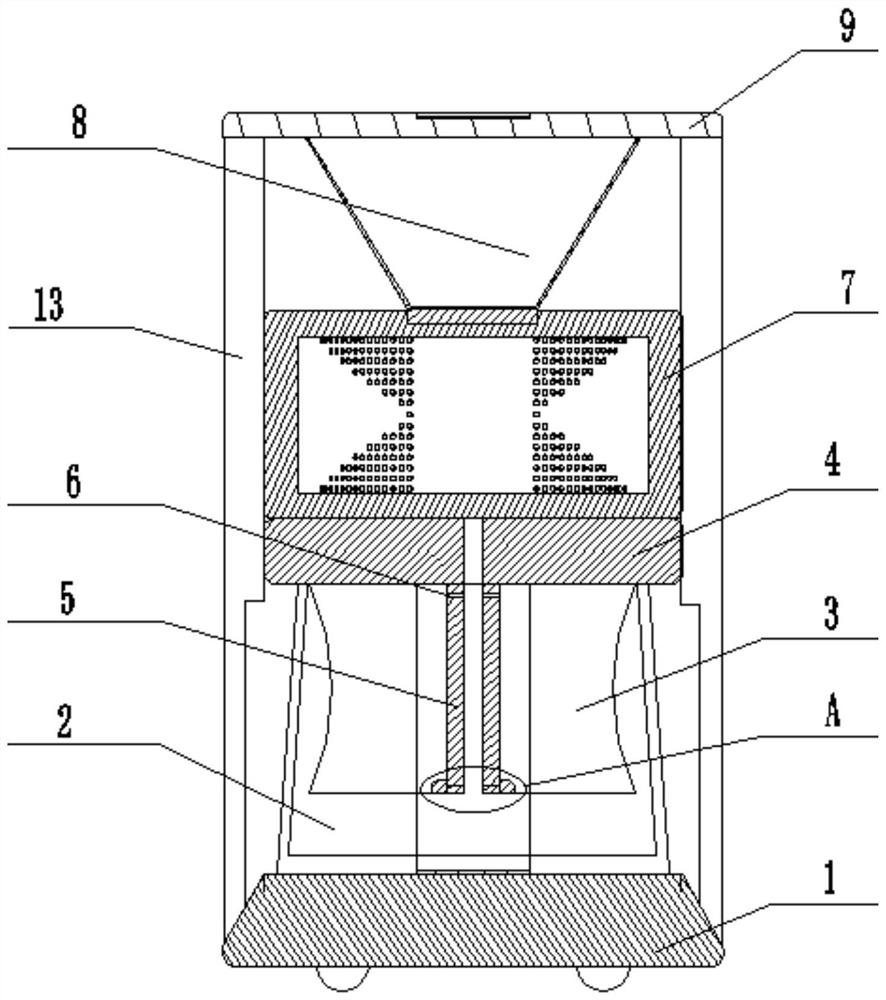

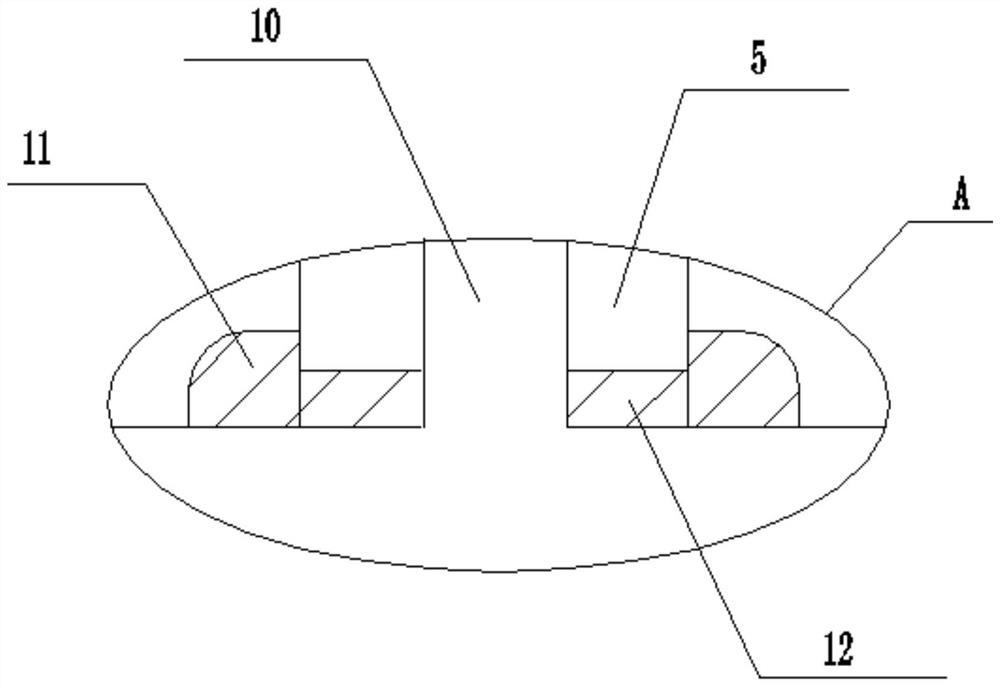

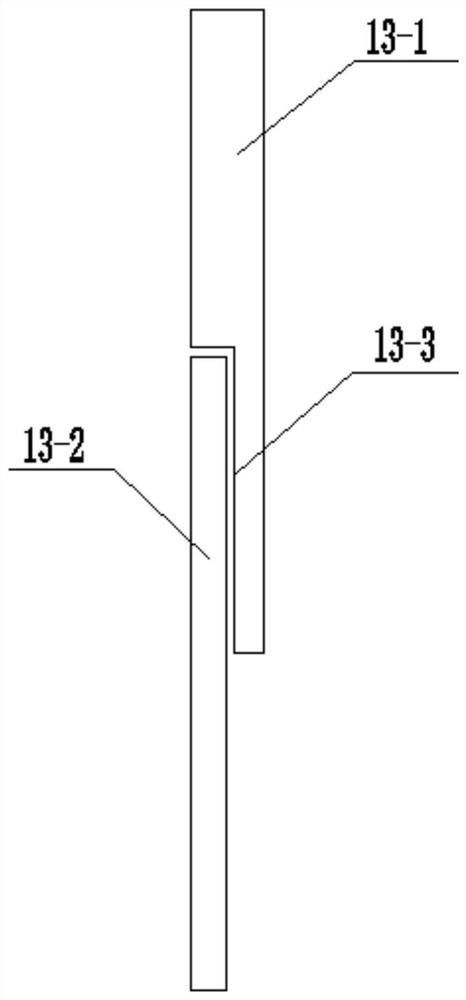

Automatic steel ball sorting device

The invention discloses an automatic steel ball sorting device, which comprises a frame, a loading bucket, a discharging bucket, a waste ball cabin, a quantitative ball supply device, a feeding box, a detection device and a control device, wherein the lower end of the loading bucket is provided with a gravity sensor; one side of the loading bucket is hinged to the frame; a single-side elevating device is arranged on the other side of the loading bucket; the loading bucket is connected with the quantitative ball supply device and the feeding box through a loading channel; the feeding box is connected with the detection device through a feeding channel; the detection device is connected with the waste ball cabin and the discharging bucket respectively through a discharging channel; a distance sensor is arranged above the discharging bucket; the lower end of the discharging bucket is provided with a horizontal elevating device. The automatic steel ball sorting device has the advantages of no need of manual attendance for a long time, lower processing cost, constant loading frequency, higher sorting efficiency and avoidance of secondary defects caused by falling of steel balls into the discharging bucket.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

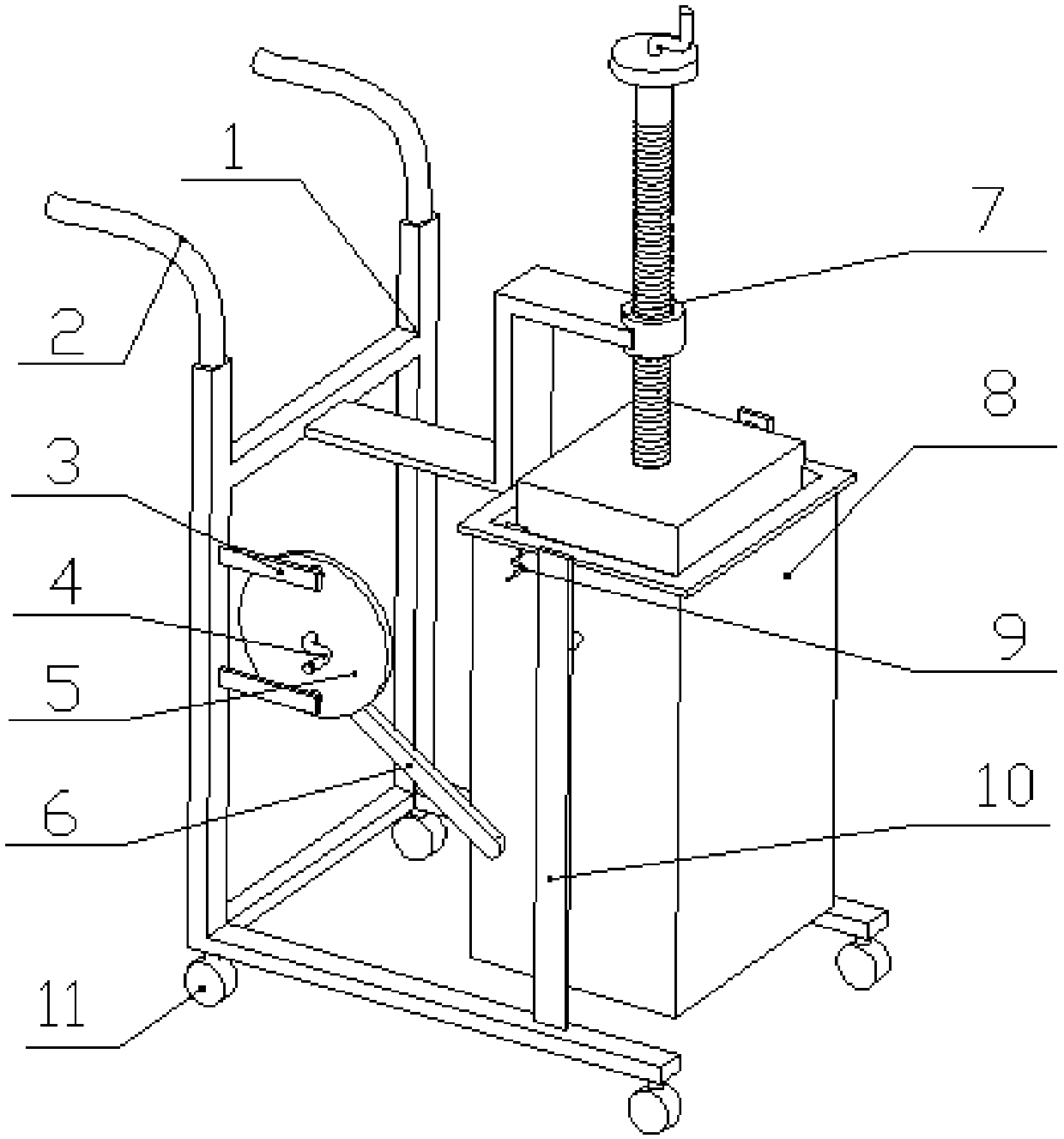

Automatic dumping type medical dustbin

InactiveCN107840043AGuaranteed Stability and ReliabilityProtect healthRefuse receptaclesPressesHandrailVehicle frame

An automatic dumping type medical dustbin is composed of a frame, handrails, crank fixing plates, a dumping hand crank, a crank disc, a connecting rod, a compressing and crushing mechanism, a dustbin,a garbage pushing mechanism, a dustbin fixing plate, wheels, a crank boss and a rotating connecting pipe. The dustbin and the dustbin fixing plate are connected together through the rotating connecting pipe, and the dustbin can freely rotate around the rotating connecting pipe. The crank disc is fixed to the two crank fixing plates. The dumping hand crank is fixedly mounted on the front portionsof the crank fixing plates. The crank boss is fixedly mounted on the rear portions of the crank fixing plates. One end of the connecting rod and the crank boss are connected together, and the other end of the connecting rod is connected with a connecting column on the side face of the dustbin. The compressing and crushing mechanism is mounted above the dustbin. The garbage pushing mechanism is mounted in the dustbin. The automatic dumping type medical dustbin has the beneficial effects that the whole device structure is simple, and operation is convenient; direct contact with medical garbage is avoided; the number of times of garbage dumping is reduced; and the work efficiency is improved.

Owner:鲍兆伟

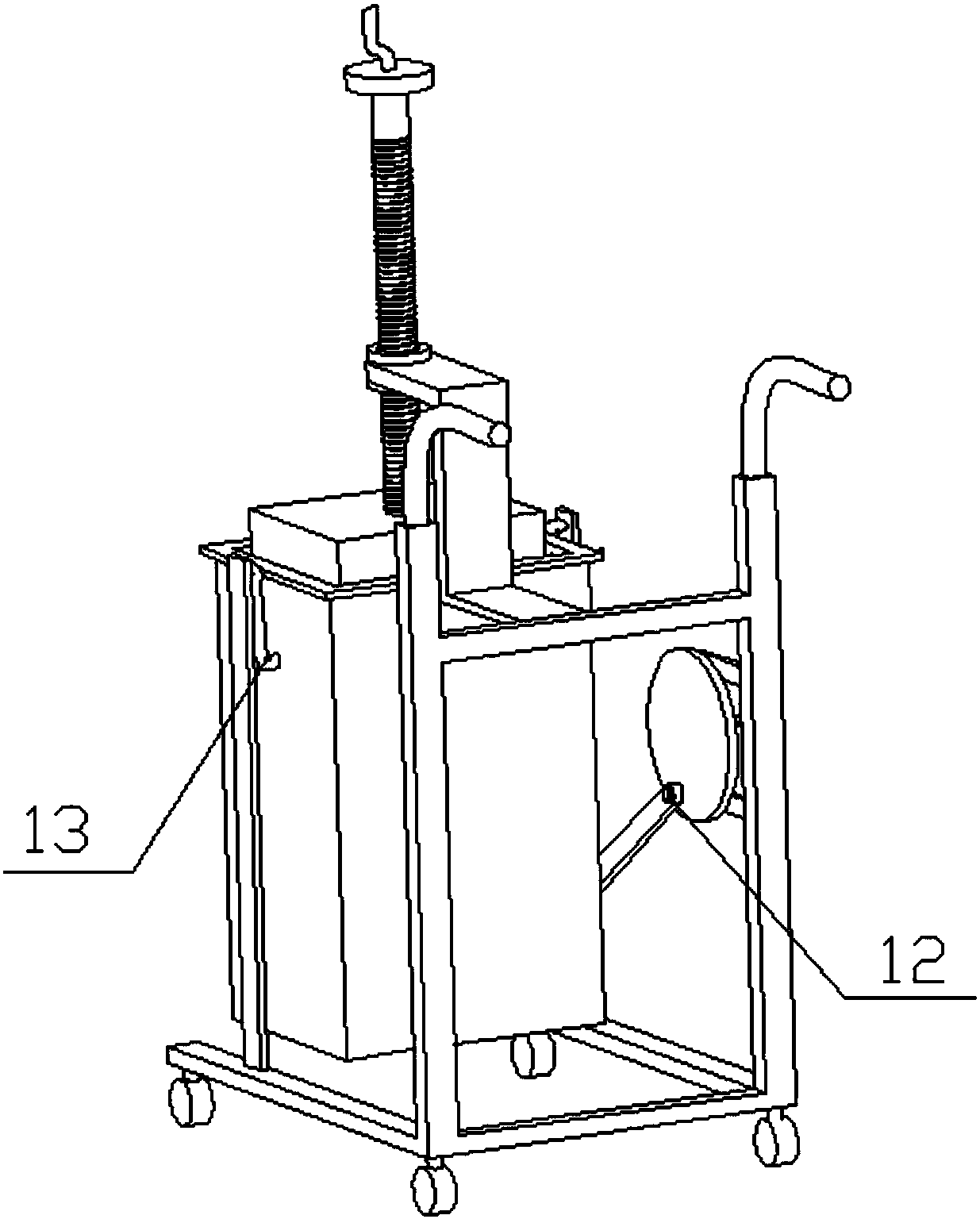

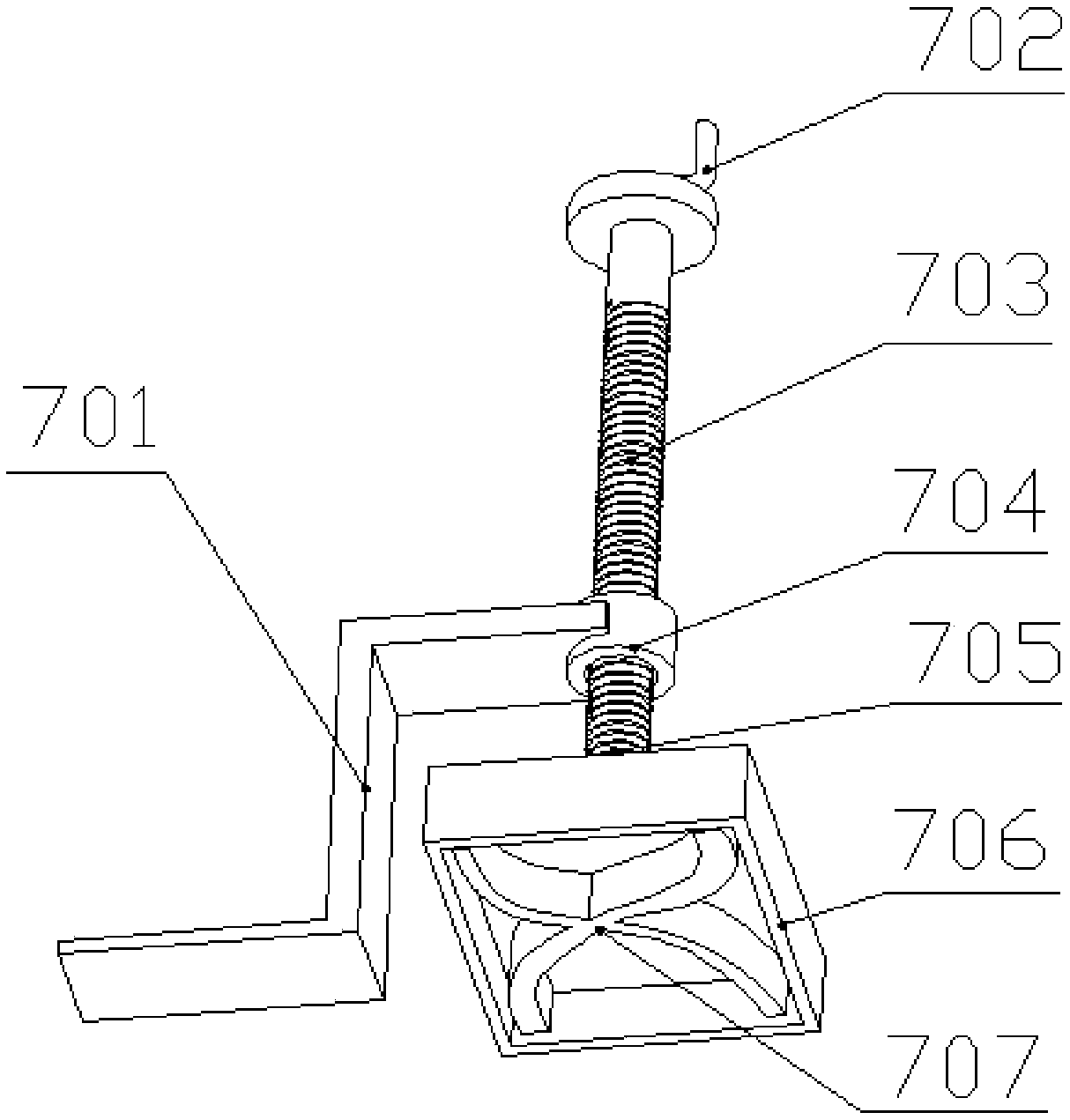

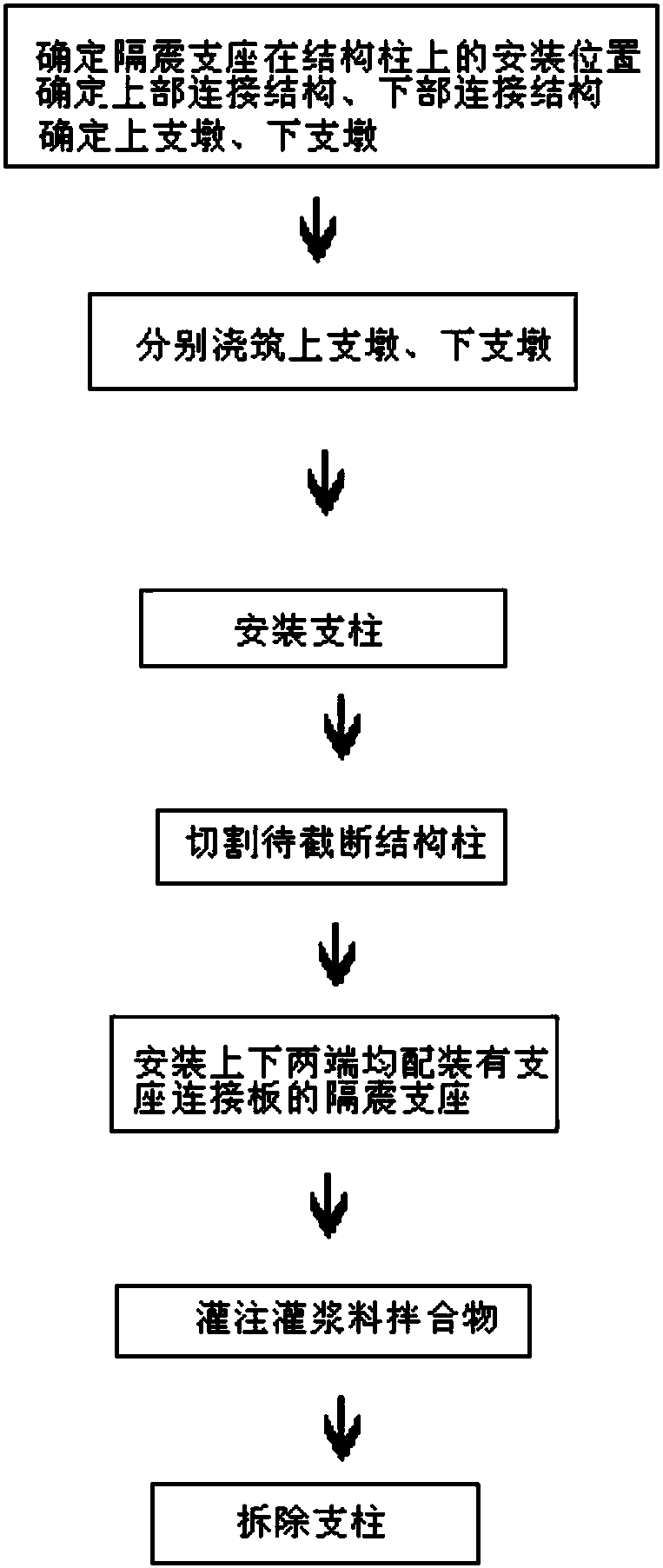

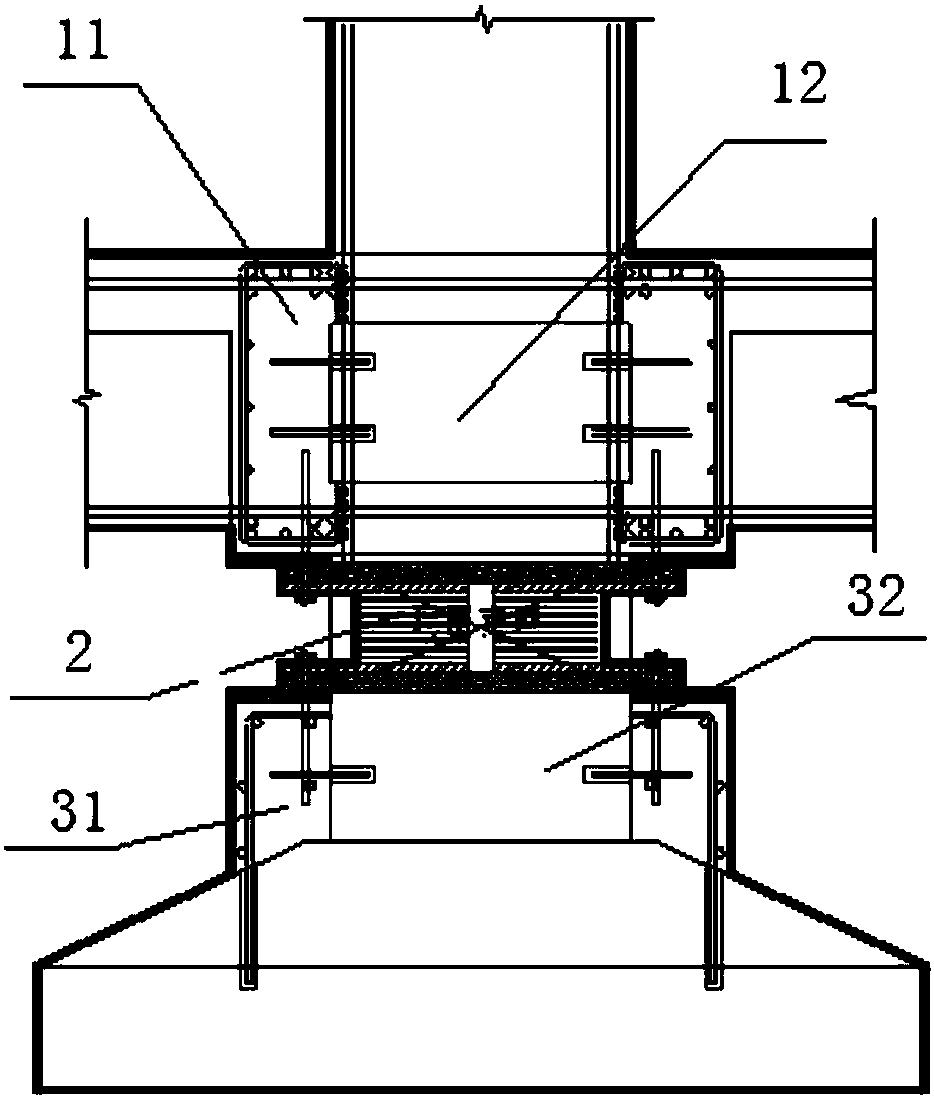

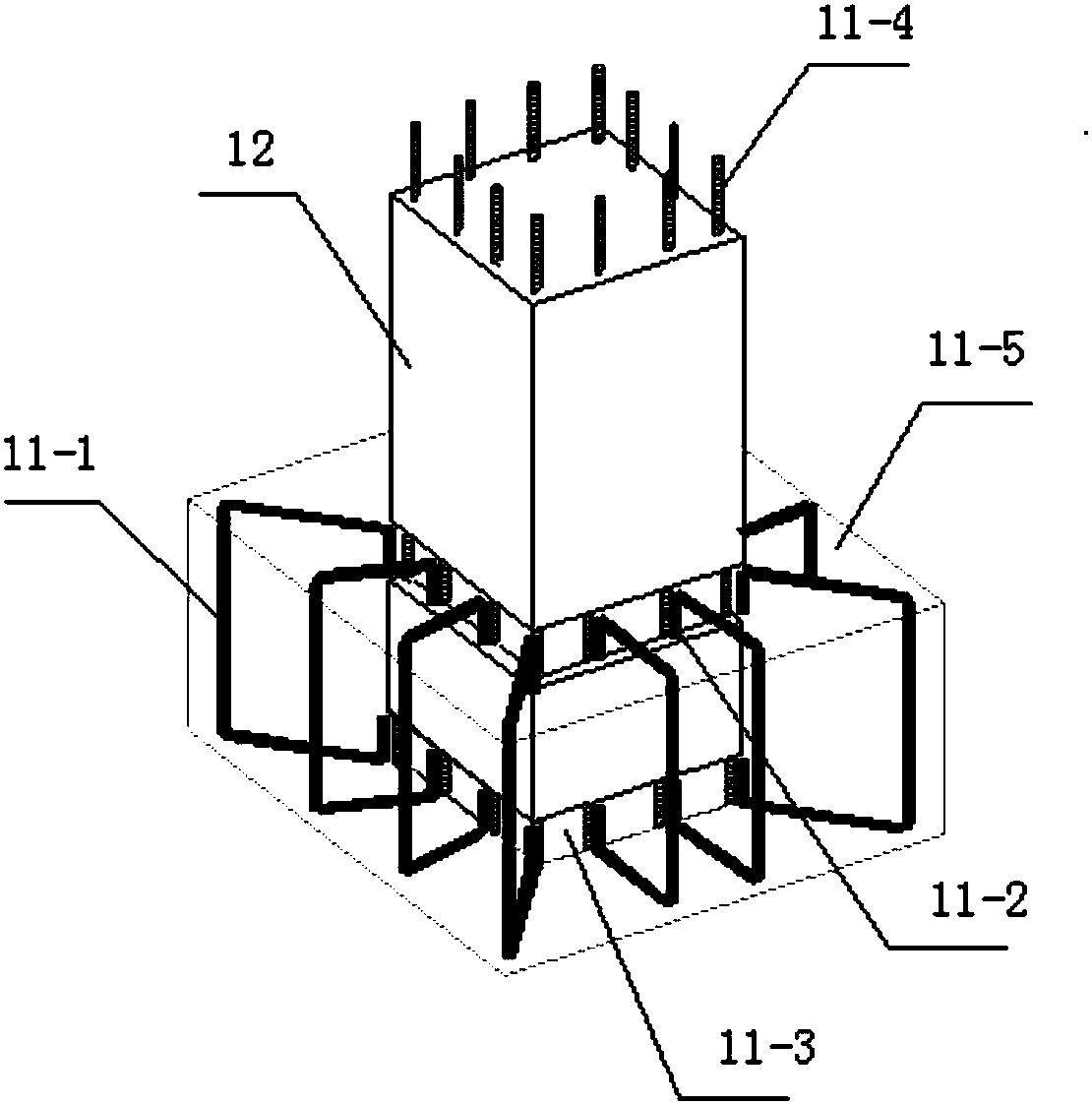

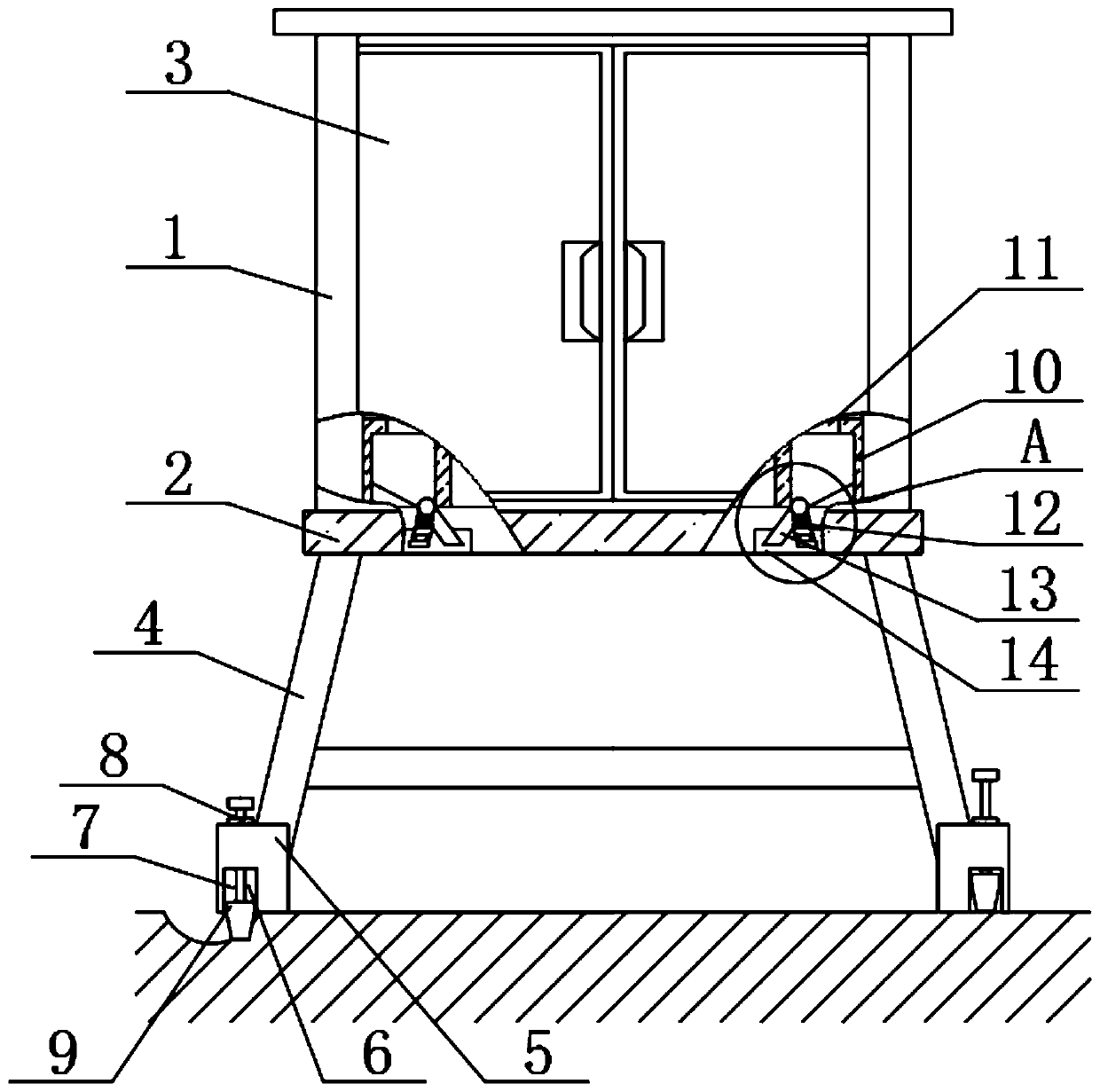

Existing building shock isolation reinforcement construction process

ActiveCN107724559AImprove construction levelSolve the real problemBuilding repairsProtective buildings/sheltersButtressIsolation layer

The invention discloses an existing building shock isolation reinforcement construction process which includes the steps: firstly, constructing a lower buttress; secondly, constructing an upper buttress; finally, cutting a structure column and mounting a shock isolation bearing in a shock isolation layer space. In addition, in order to consolidate normal implementation of the shock isolation reinforcement construction process, a specific upper buttress structure, a shock isolation bearing mounting structure and an underpinning structure are designed. By the aid of the construction process, themounting quality of the shock isolation bearing can be improved, manufacturing cost is reduced, and total construction time is greatly shortened.

Owner:南京百西思建筑科技有限公司

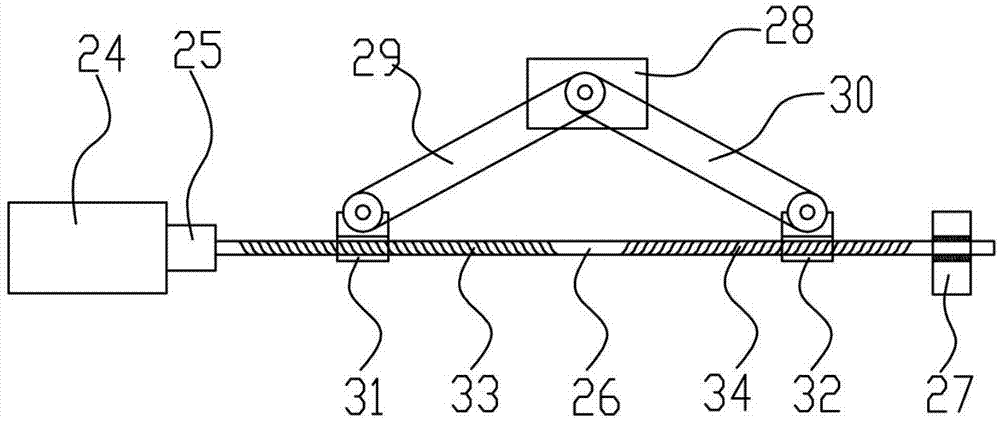

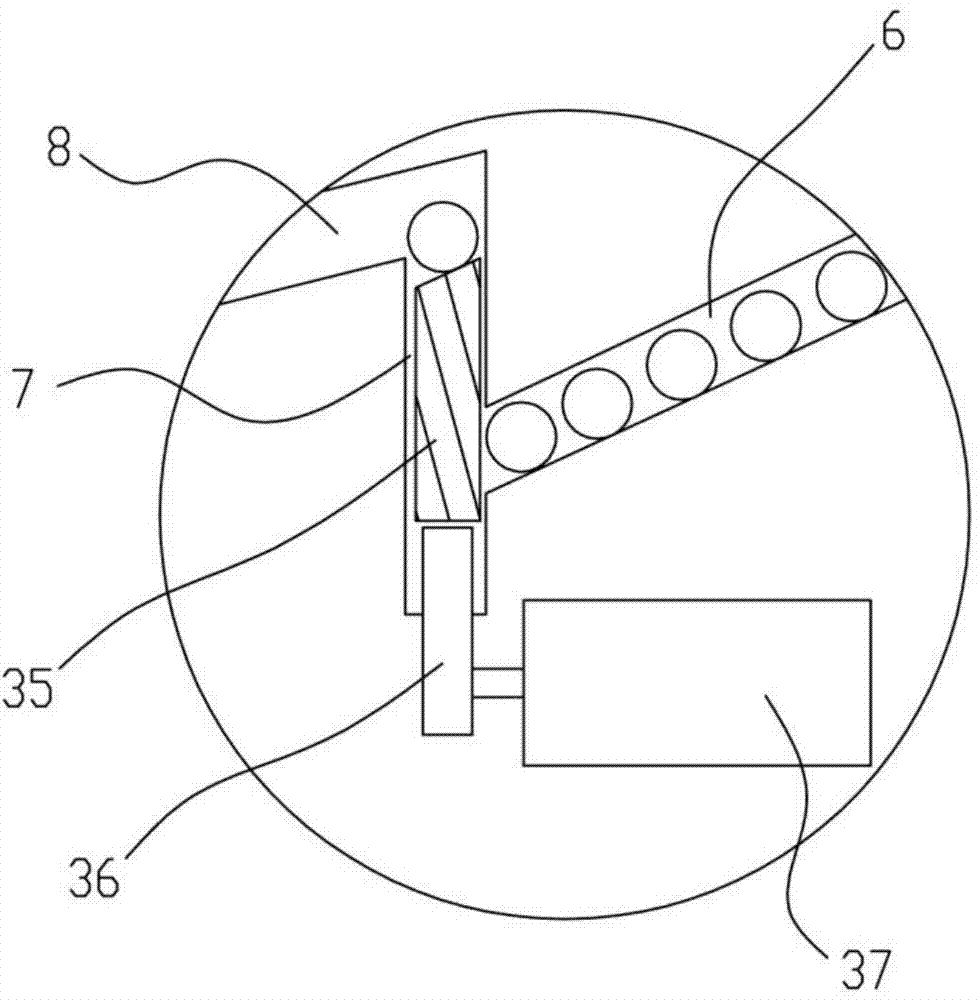

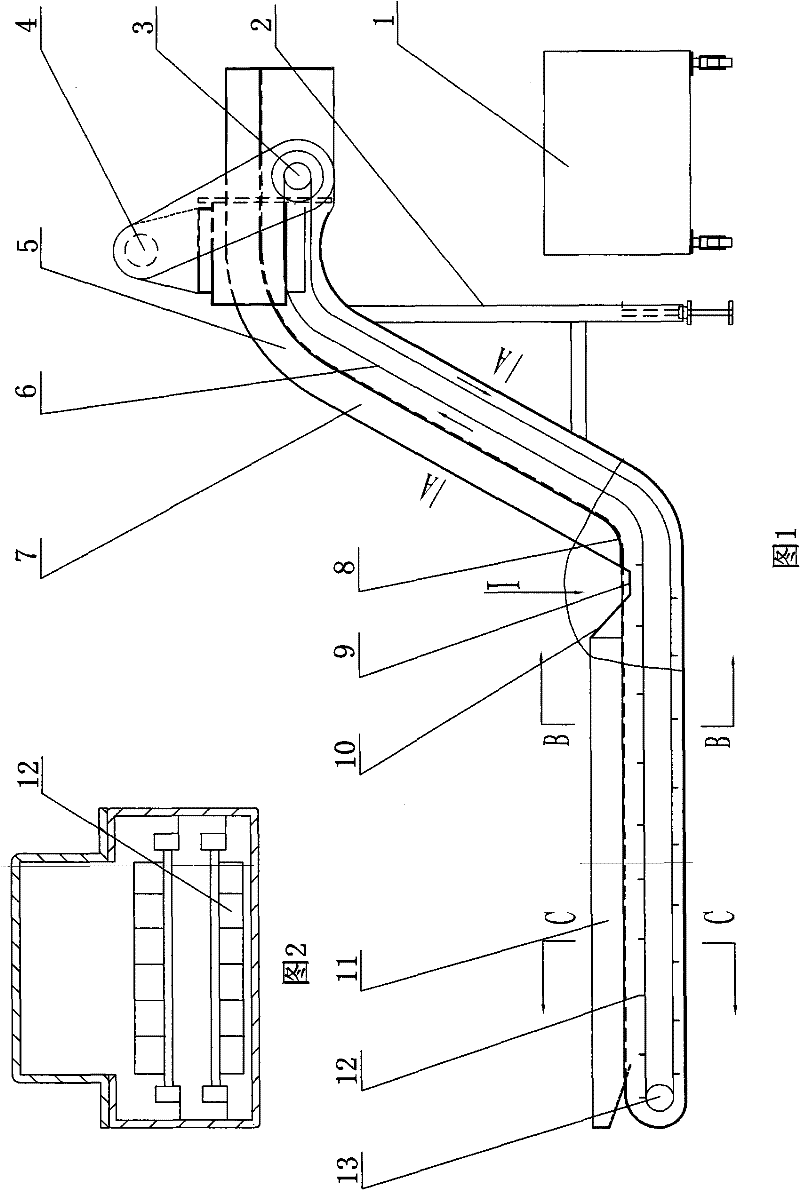

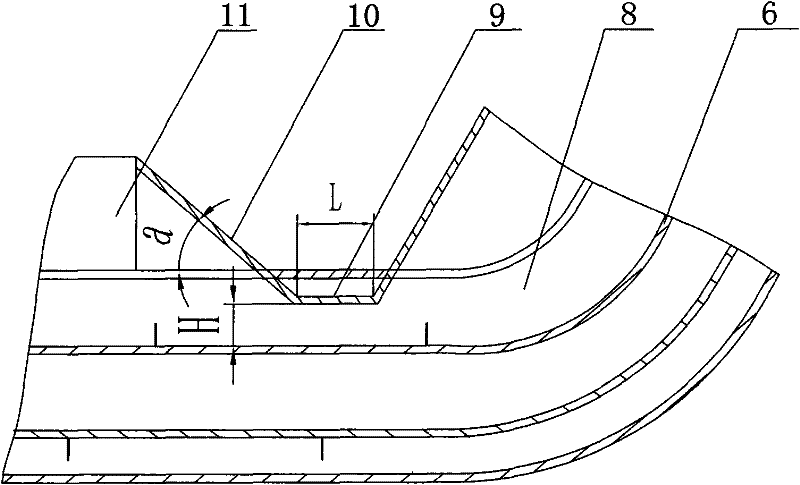

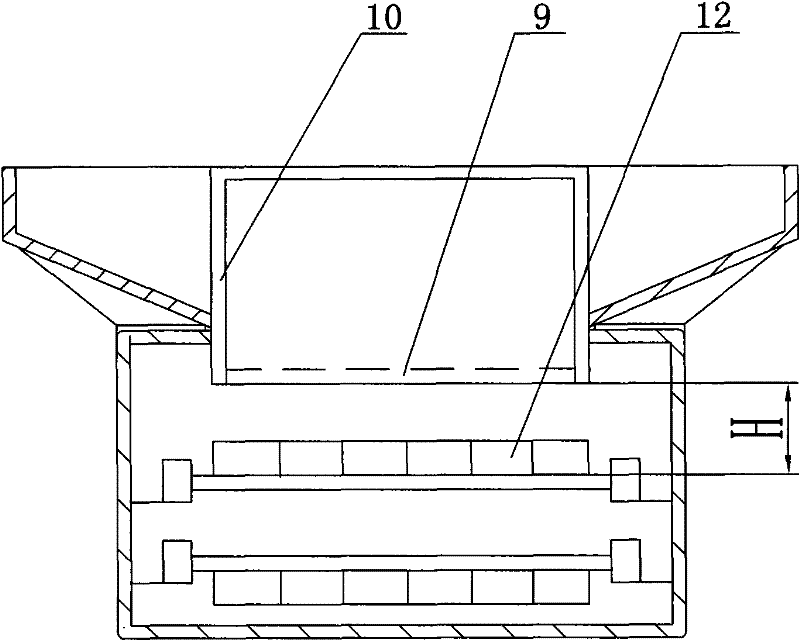

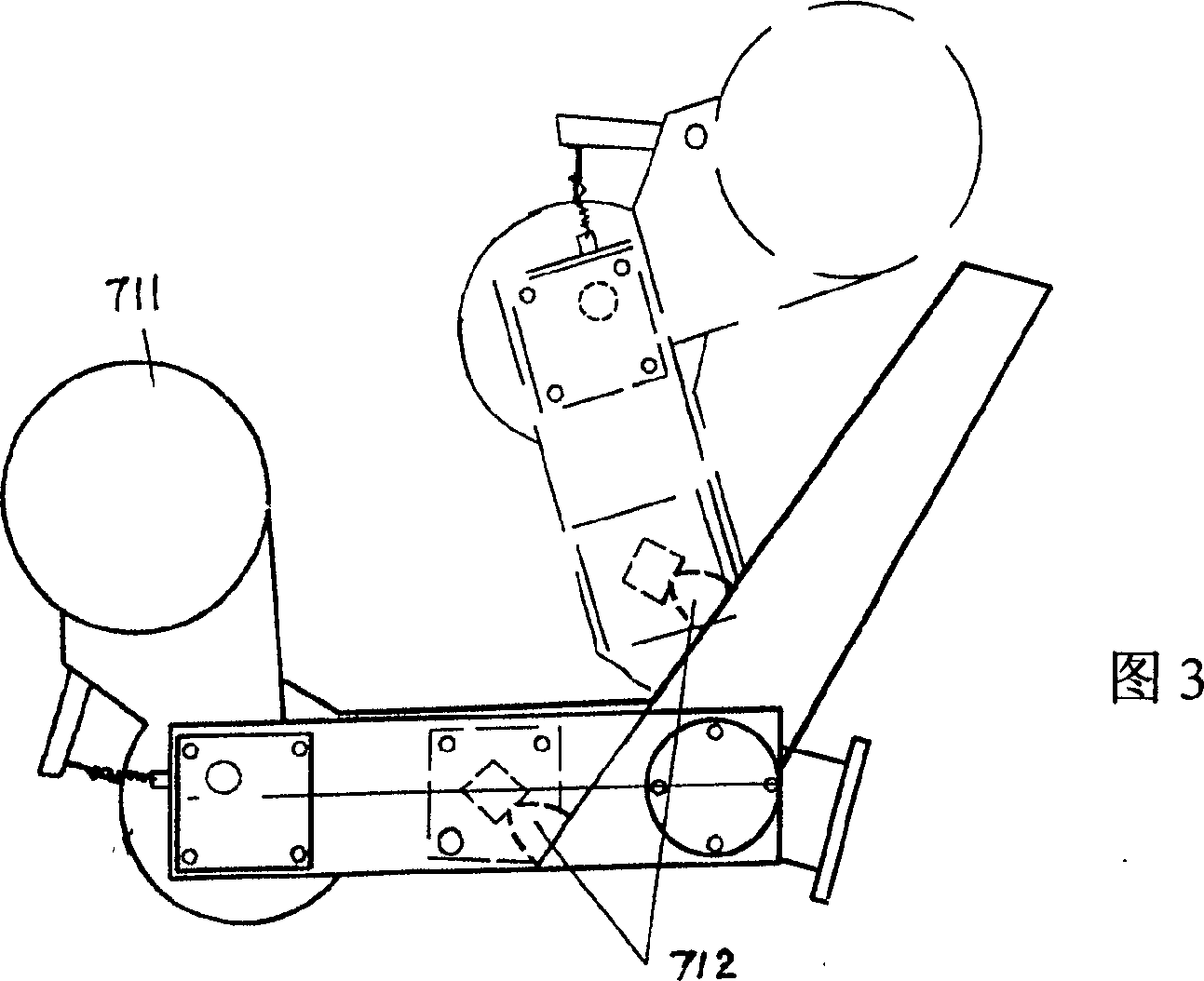

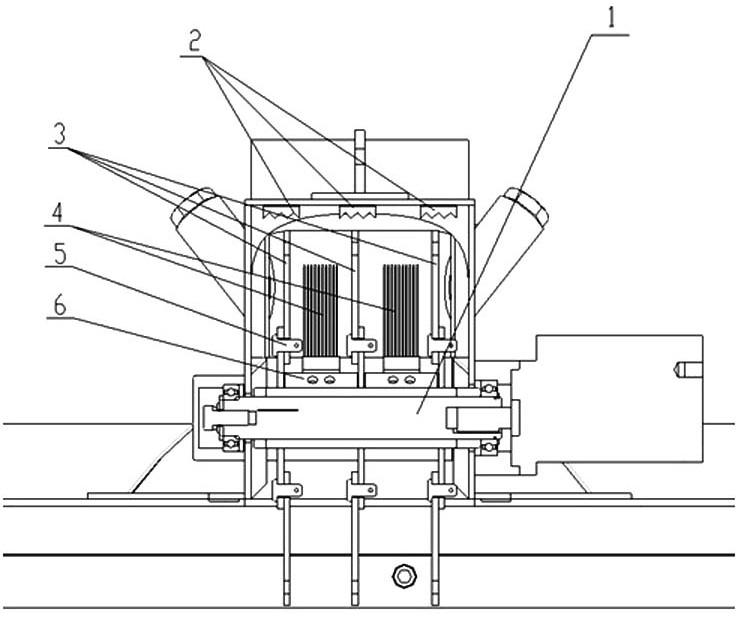

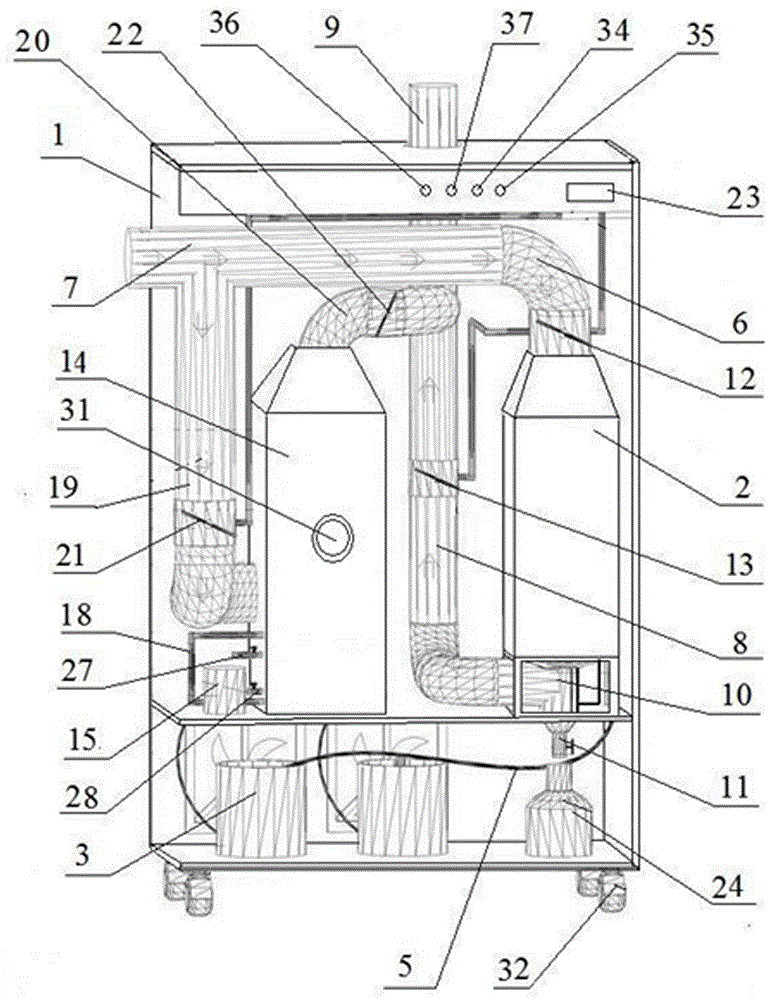

Compression automatic chip discharging machine for machine tool

InactiveCN102189439AEasy to cleanReduce the number of poursConveyorsLoading/unloadingNumerical controlProduction line

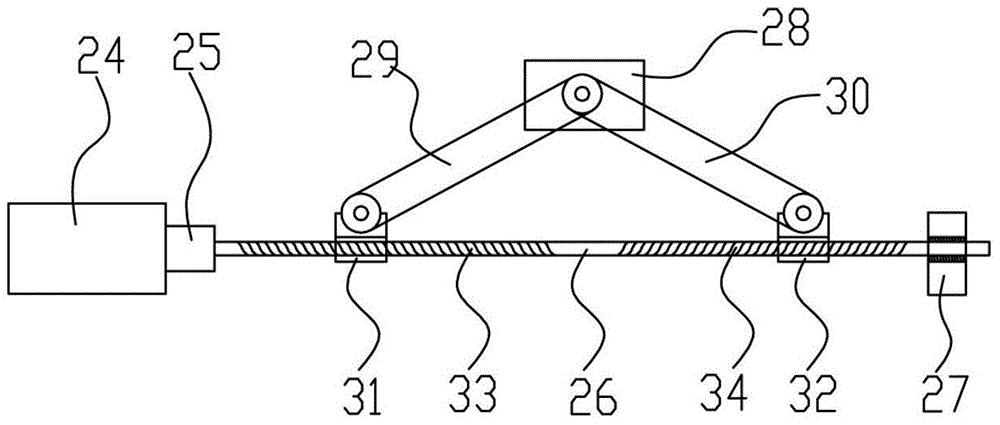

The invention discloses a compression automatic chip discharging machine for a machine tool. The compression automatic chip discharging machine is the special equipment matched with various numerical control machine tools, processing centers, specialized machine tools and production lines. The compression automatic chip discharging machine is used for collecting and continuously conveying various roll-shaped, round and stripped metal chips produced by a dry or wet processing center. The invention provides the compression automatic chip discharging machine for the machine tool and the compression automatic chip discharging machine contributes to cleaning the chips and improving production efficiency. The compression automatic chip discharging machine comprises a machine body; the machine body consists of a horizontal chute of which the top is provided with an opening and an inclined chute with a closed top; a chain plate conveying belt is arranged between a support shaft of the horizontal chute and a driving shaft of the inclined chute; the chain plate conveying belt is provided with a W-shaped chip pushing plate; an adjustable support leg is arranged below the inclined chute; the structural key points are that: the top of the intersection of the inclined chute and the horizontal chute is provided with a horizontal extrusion plate; an inclined chip guide plate is arranged at the inlet of the horizontal extrusion plate and the top of the horizontal chute; and an extrusion working cavity is formed between the bottom of the inclined chute and the chain plate conveying belt.

Owner:沈阳华邦通用机械技术开发有限公司

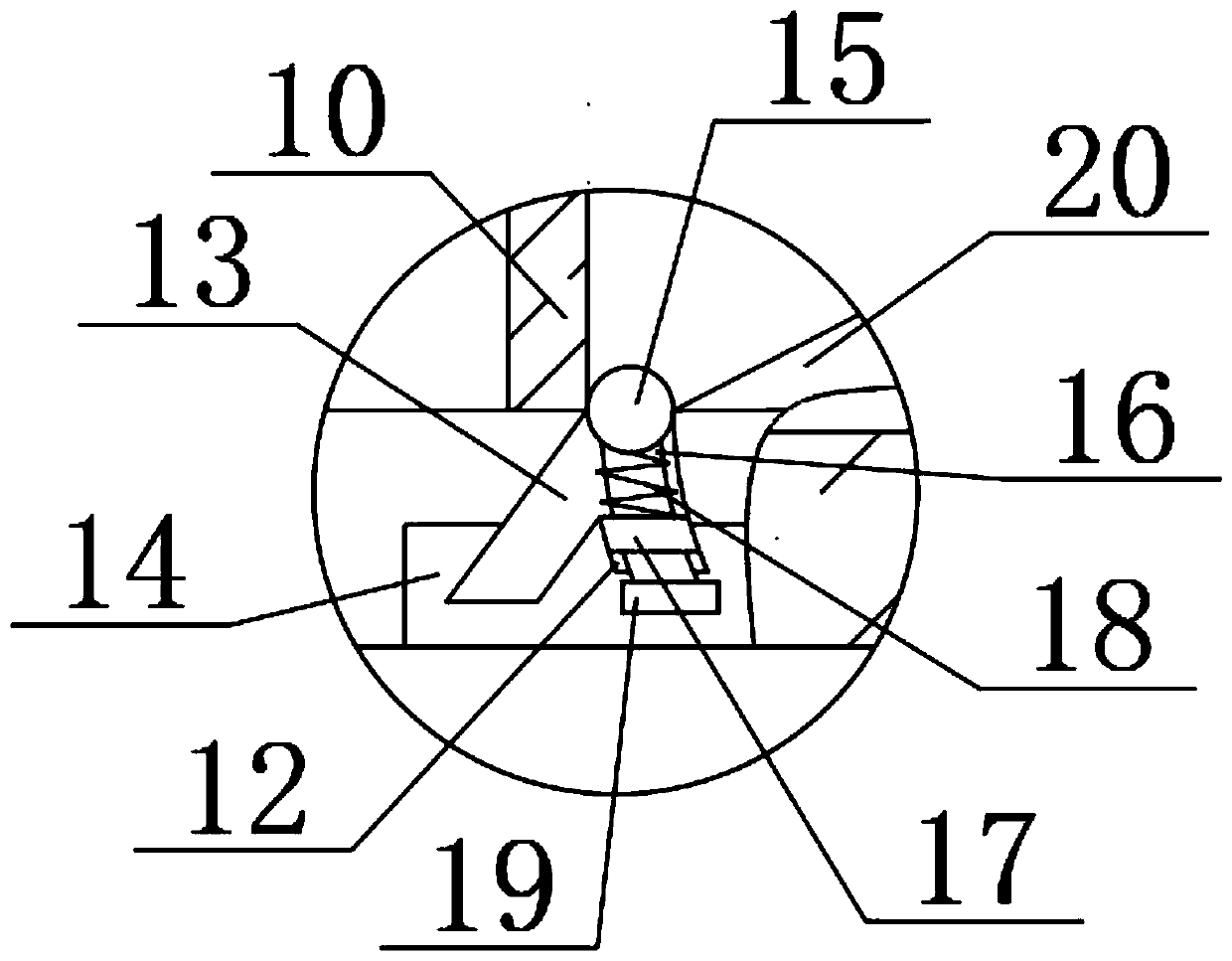

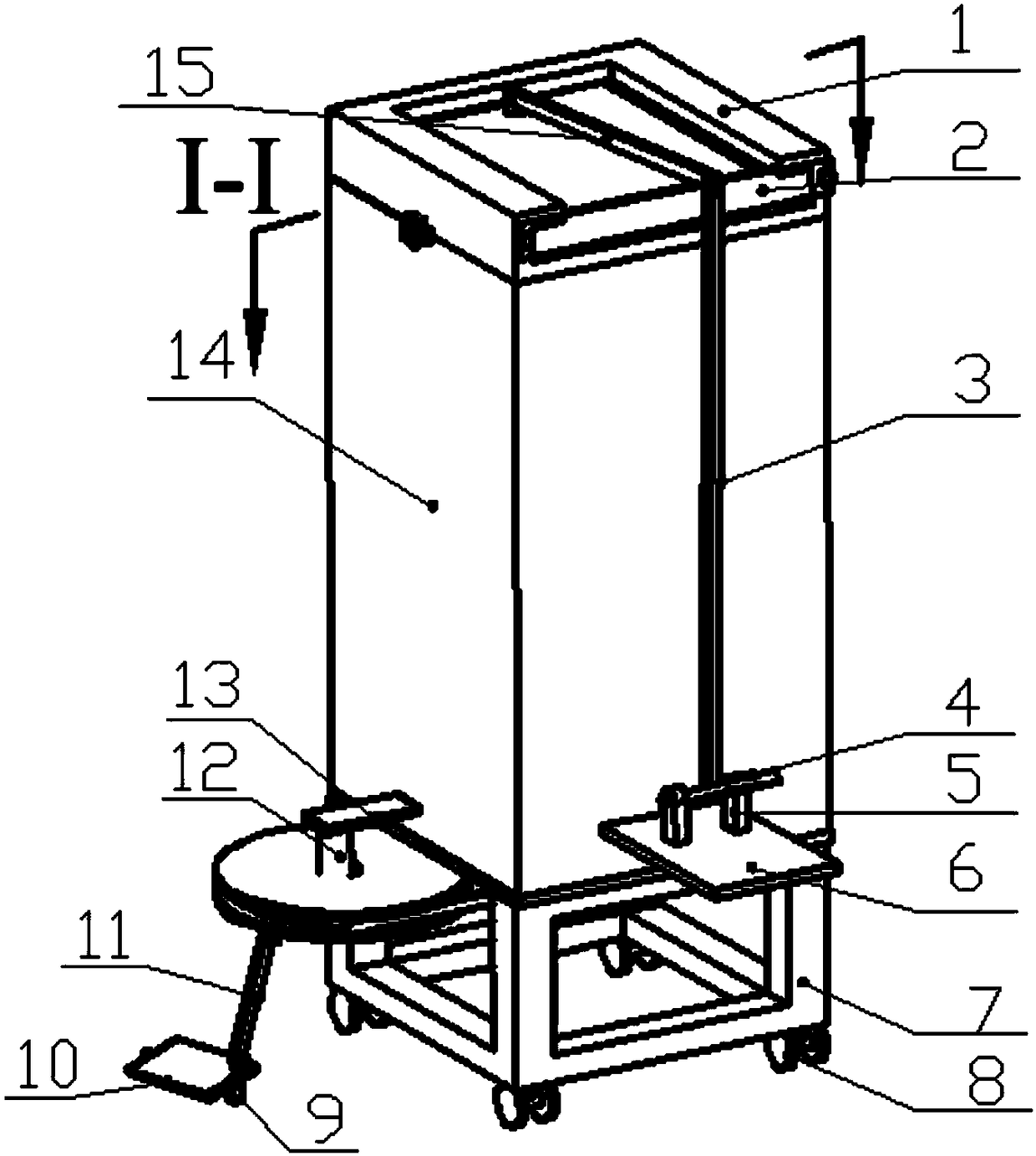

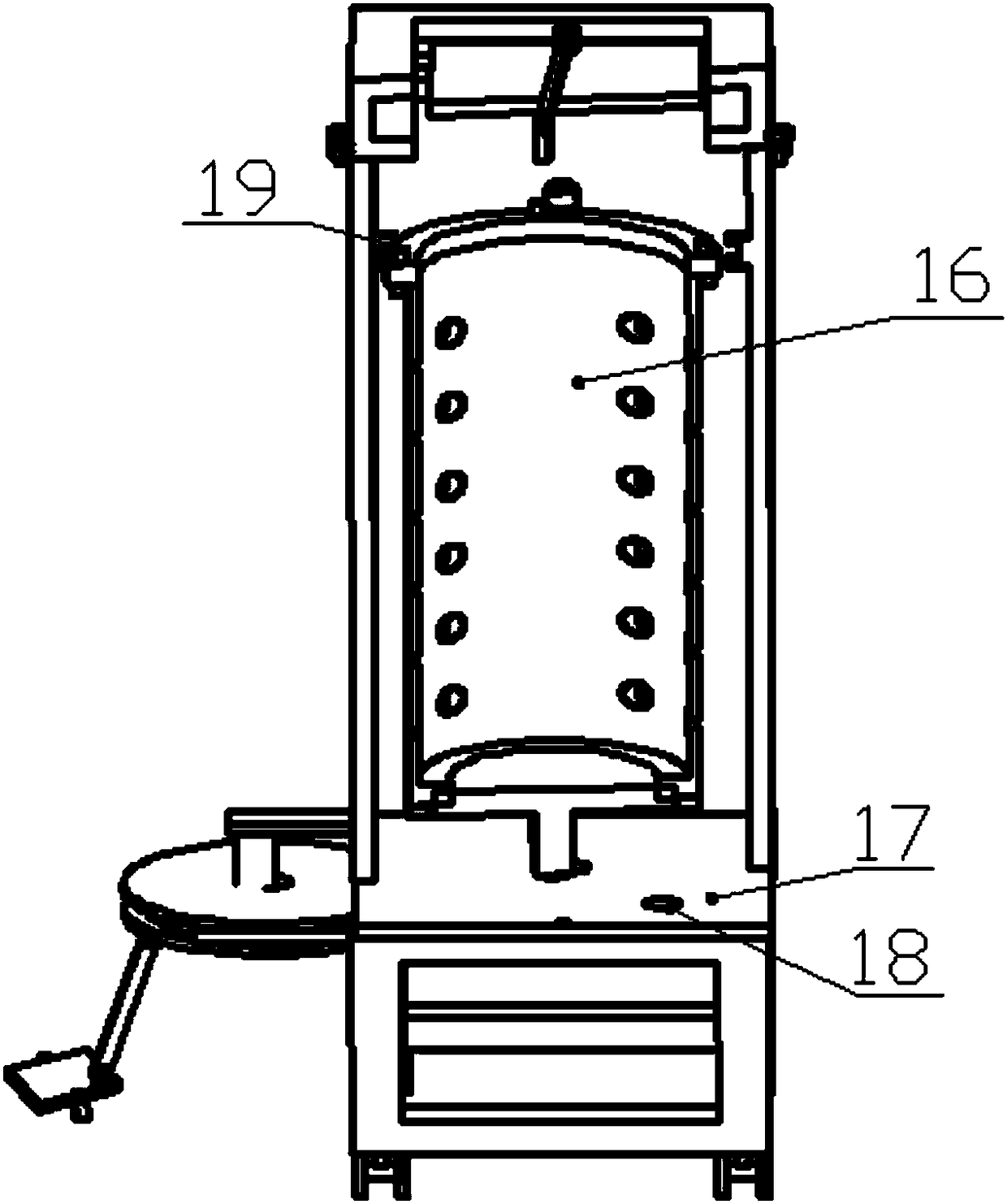

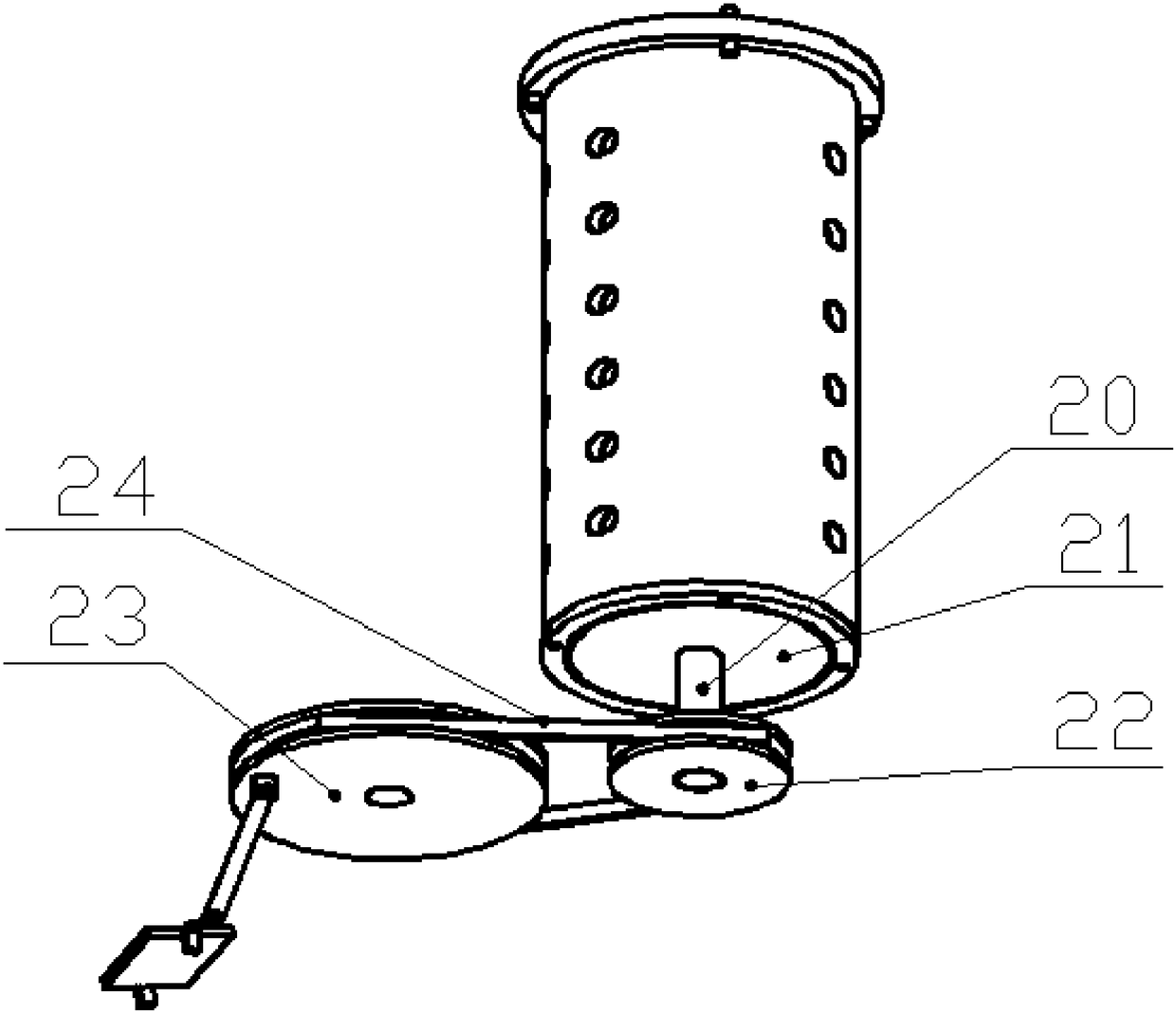

Centrifugal kitchen dustbin convenient to use

InactiveCN106275977AAvoid smallReduce the number of poursWaste collection and transferRefuse receptaclesSewageCentrifugal force

The invention discloses a centrifugal kitchen dustbin convenient to use and belongs to the field of living furniture. The centrifugal kitchen dustbin convenient to use is composed of a crank sliding block device and a crank rocker device. The centrifugal kitchen dustbin convenient to use is characterized in that the crank slide block device is composed of an extensible plate, a movable connecting rod, a swinging connecting rod and an upper foot treadle; the movable connecting rod is connected with the extensible plate and the swinging connecting rod through bolts correspondingly; the swinging connecting rod is fixedly mounted on the upper portion of the upper foot treadle; a centrifugal device is composed of a lower foot treadle, a centrifugal connecting rod, a large belt wheel, a belt, a small belt wheel and a rotary disc ; the centrifugal connecting rod is connected with the large belt wheel through a bolt; the large belt wheel is connected with the small belt wheel through the belt; a small belt wheel shaft is fixedly mounted on the lower side of the rotary disc; a bottom plate is fixedly mounted on a dolly frame through a screw; and four dolly wheels are mounted at the bottom of the dolly frame. The centrifugal kitchen dustbin convenient to use has the beneficial effects that kitchen waste can be treated in a separation mode, sewage drained in a separation mode can be discharged, and the waste can be conveniently and quickly packaged and cleared away.

Owner:宣城金博伟家居智能科技有限公司

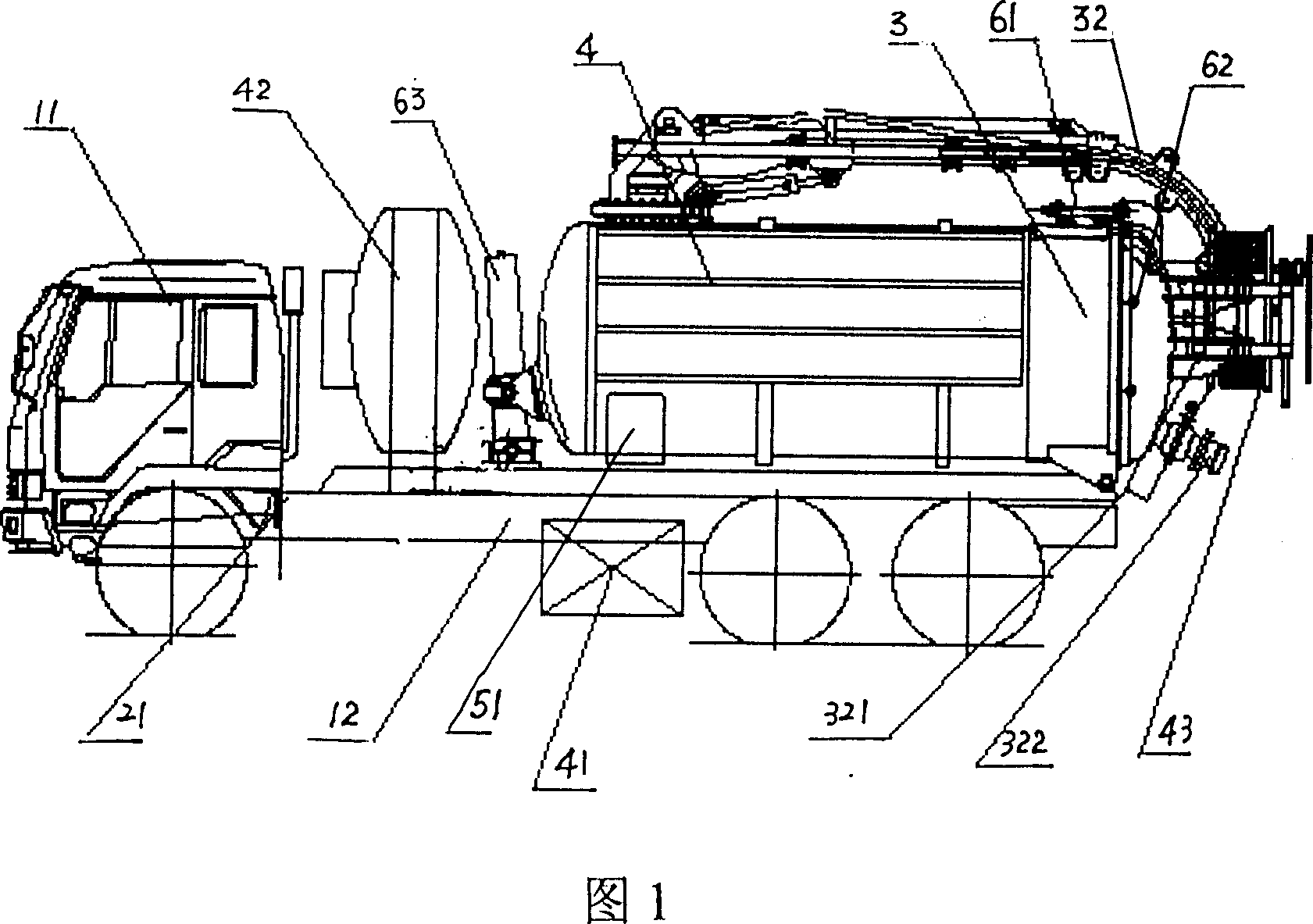

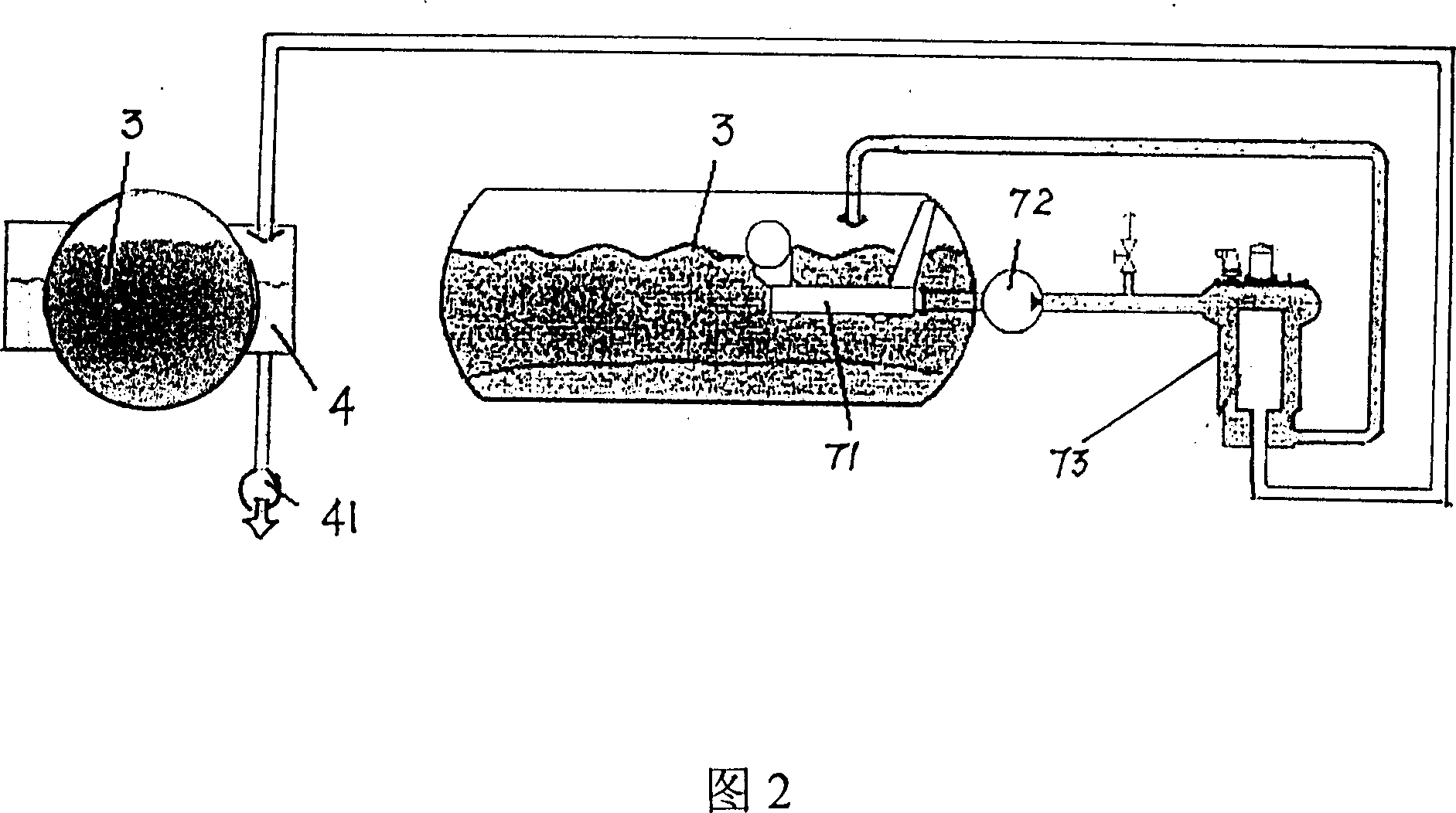

Sewage water cycling and reutilization type pipeline dredging soil pick-up vehicle

InactiveCN101077497AAchieve recyclingSave waterReversed direction vortexSewer cleaningSludgeWater quality

The present invention relates to one kind of pipeline dredging truck capable of utilizing the sewage. The pipeline dredging truck includes one truck body, one power set, one suction device, one flushing device, one sludge draining device and one electric control system, as well as one sewage reusing device, which includes one clear water tank, one sludge tank, one rotary filtering cylinder, one centrifugal pump, one cyclonic filter and one high pressure pump, and can complete three stage filtering of sewage for reuse. The present invention has saving in water resource, continuous operation and high operation efficiency.

Owner:JIANGSU STOKOTA SPECIAL PURPOSE VEHICLE

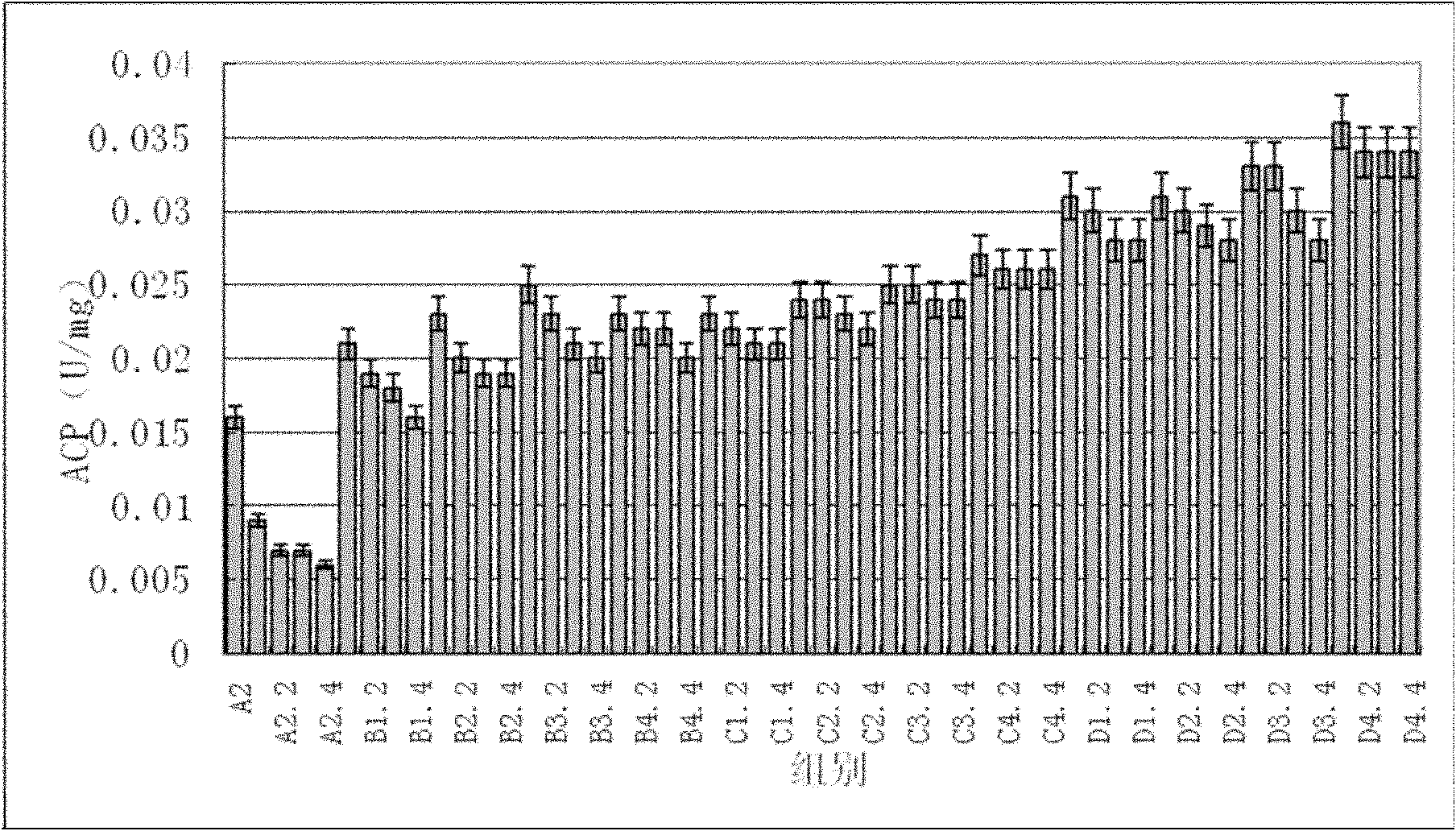

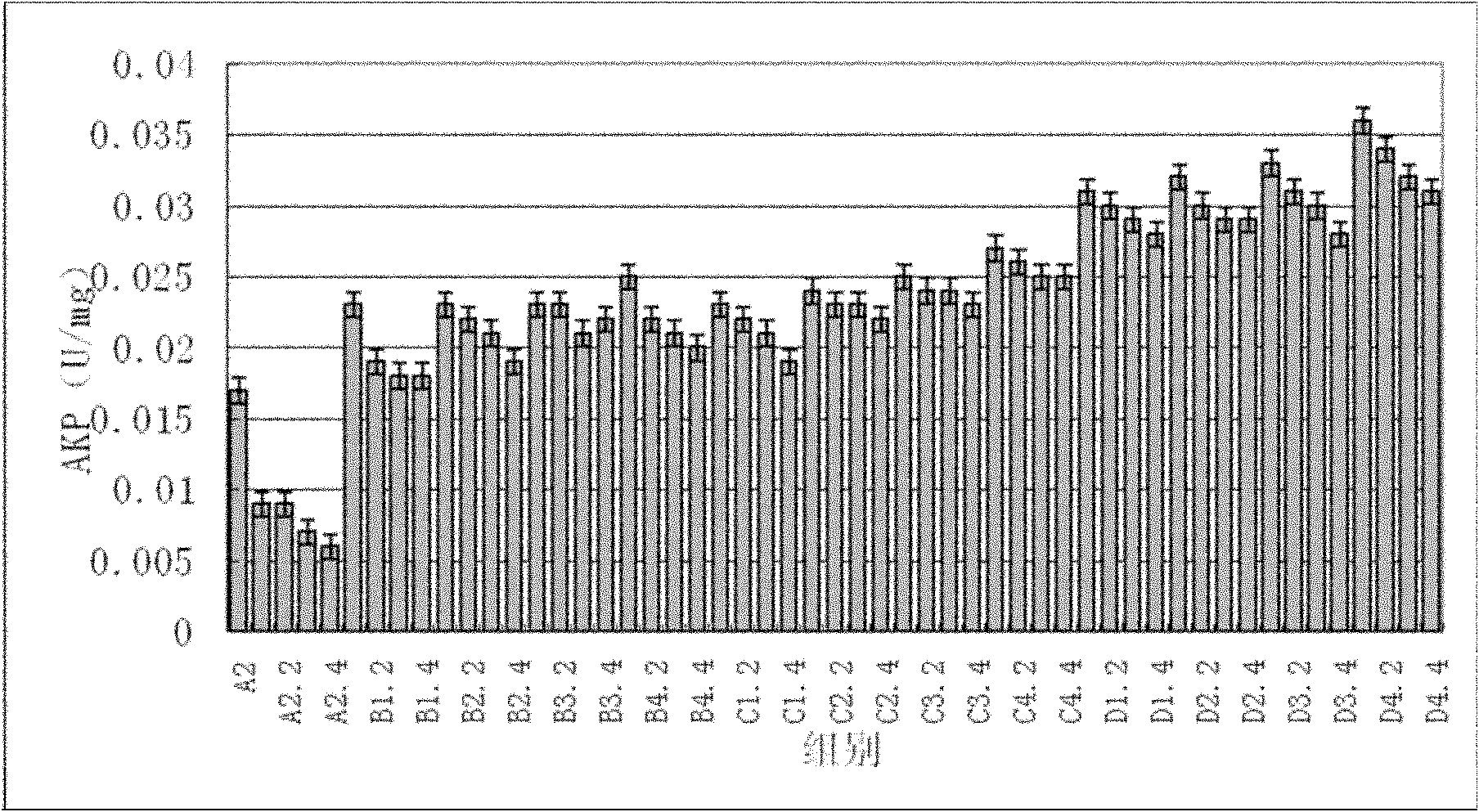

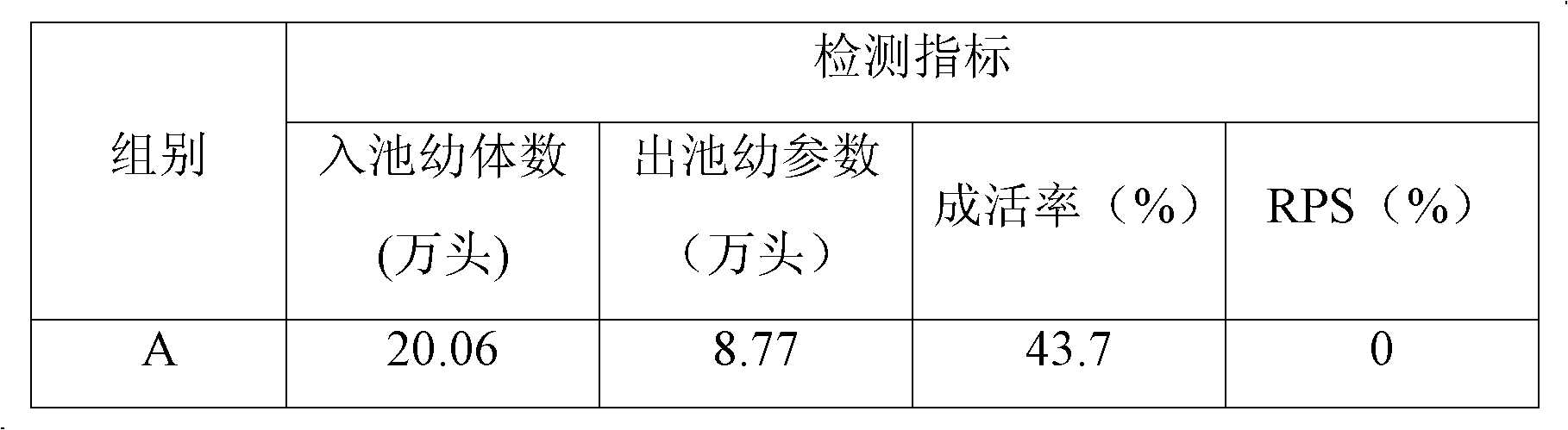

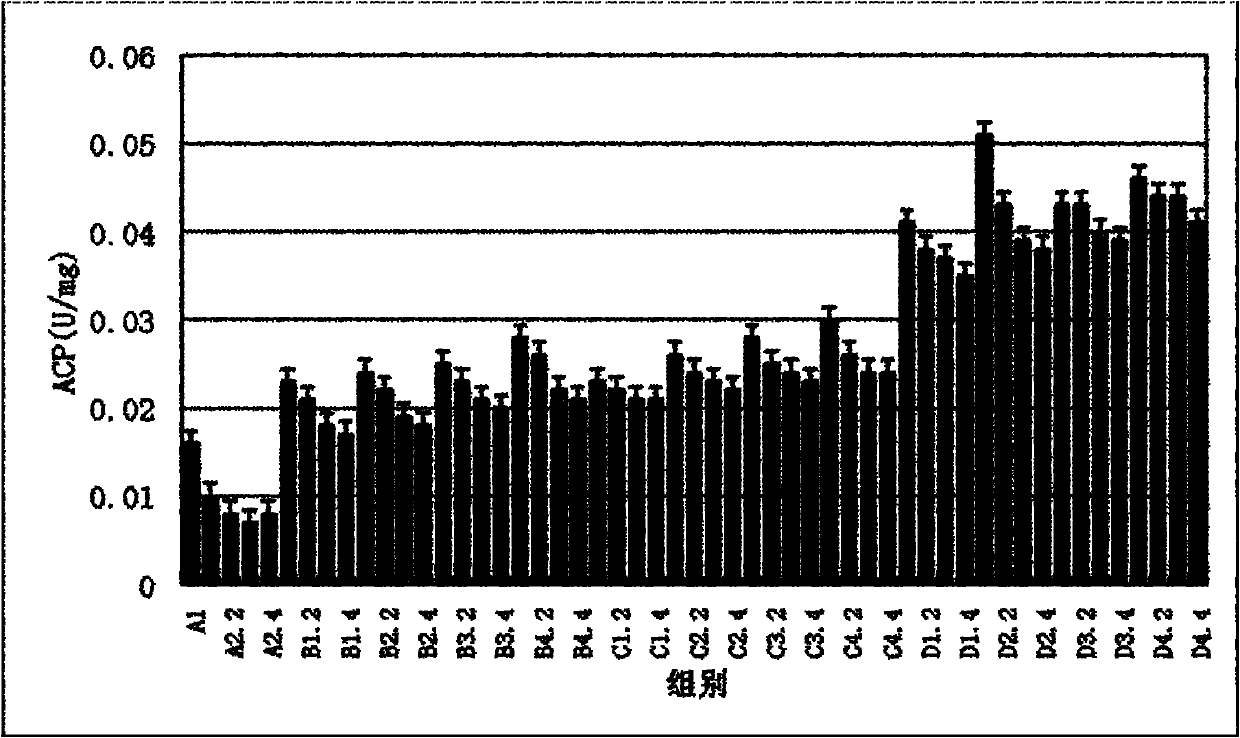

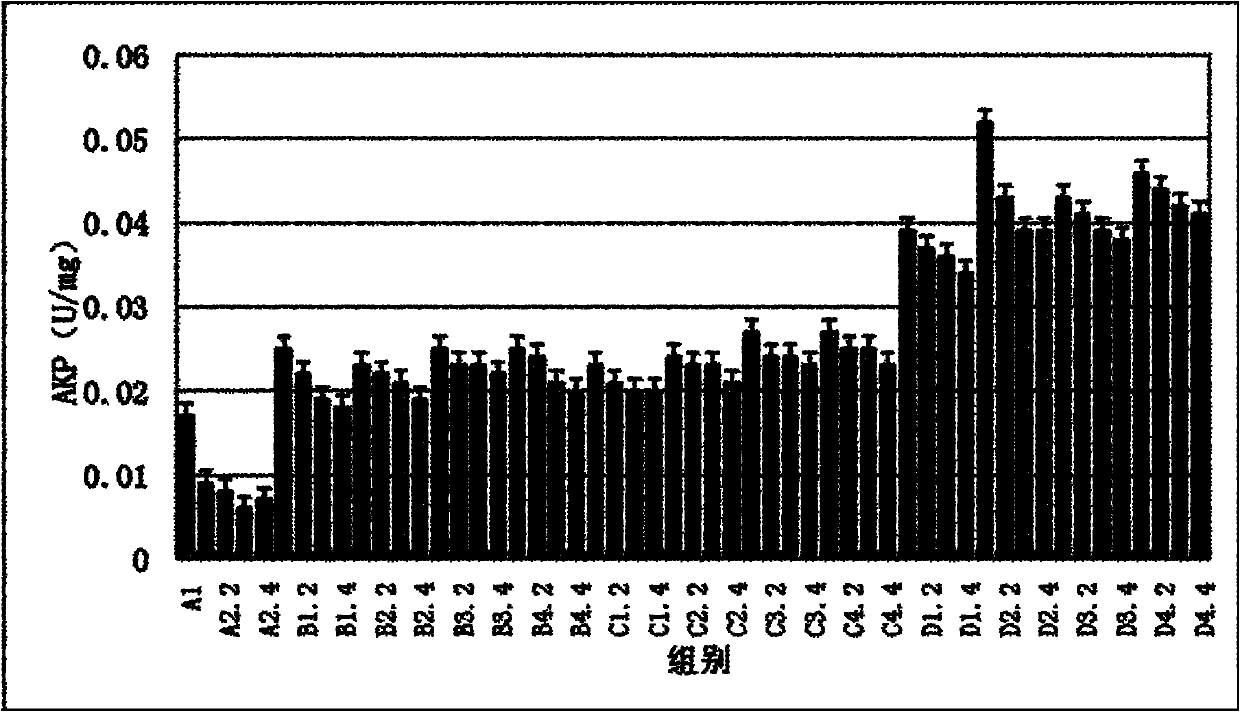

Application of bdellovibro swimmer bacterial liquid in culturing young sea cucumbers

InactiveCN102057883AImprove securityNo toxicityBacteriaClimate change adaptationWater savingWater quality

The invention discloses an application of bdellovibro swimmers in culturing young sea cucumbers, which is implemented by adding bdellovibro swimmer bacterial liquid to a water body and / or feeds. The implementation process specifically comprises the steps of preparing facilities and water quality conditions for culturing young sea cucumbers, catching parental sea cucumbers, rearing the parental sea cucumbers, hatching spawns and culturing larvae, and collecting and culturing young sea cucumbers. The key technology is as follows: adding the bdellovibro swimmer bacterial liquid with final concentration of 10-107pfu / mL to the water body and / or simultaneously soaking the feeds in the bdellovibro swimmer bacterial liquid with concentration of 10-107pfu / mL for 30 minutes. By applying the invention, the average survival rate of the cultured young sea cucumbers reaches more than 50%, and the water quality can be effectively improved. Experiment shows that the water can be kept unchanged in 20 days at most, thus saving the labor and cost and greatly improving the economic benefits. Besides, the survival rate of the cultured young sea cucumbers is high, the quality of the young sea cucumbers is good, and the invention is water-saving, energy-saving, environment-friendly and low-carbon.

Owner:SOUTH CHINA UNIV OF TECH

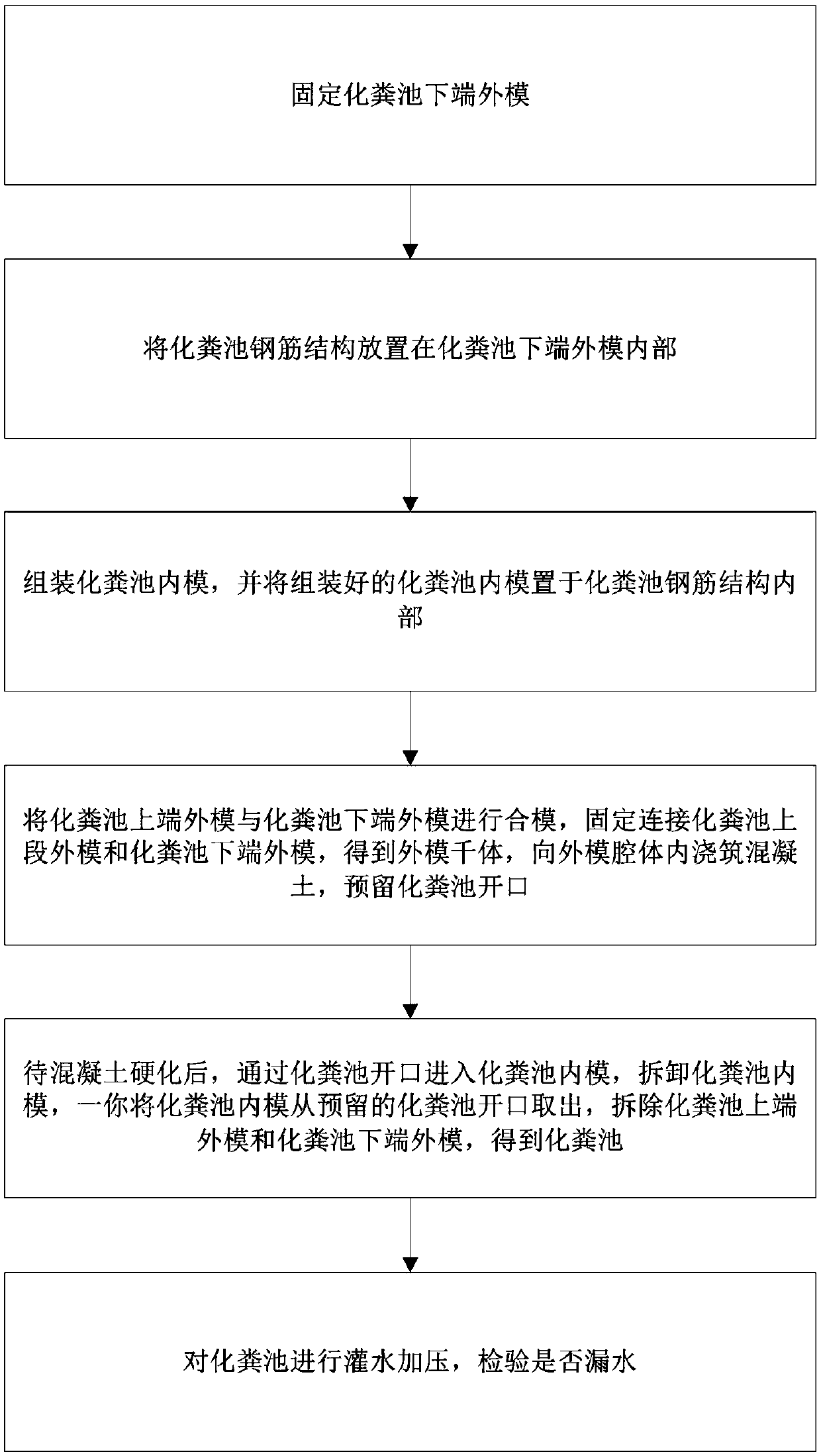

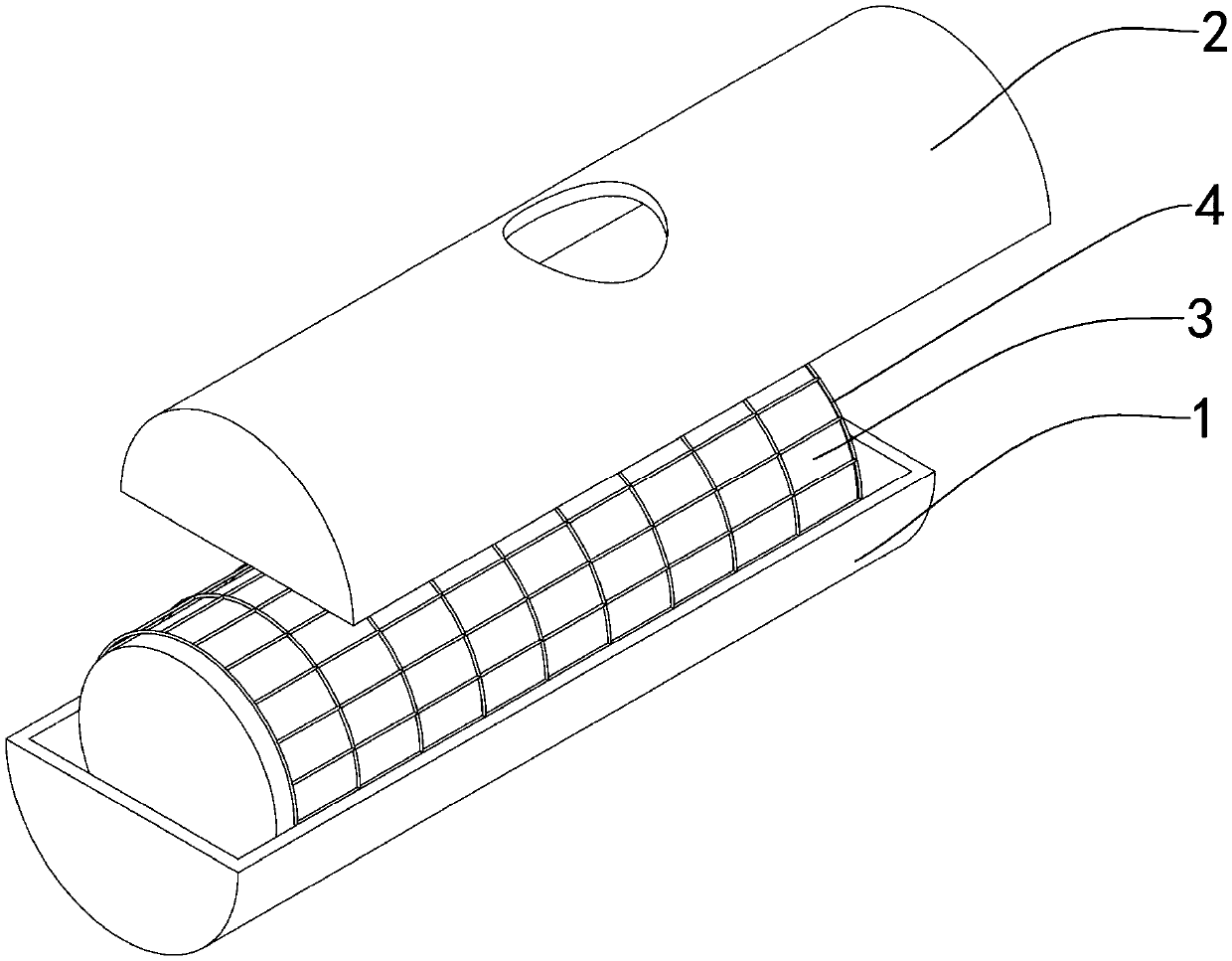

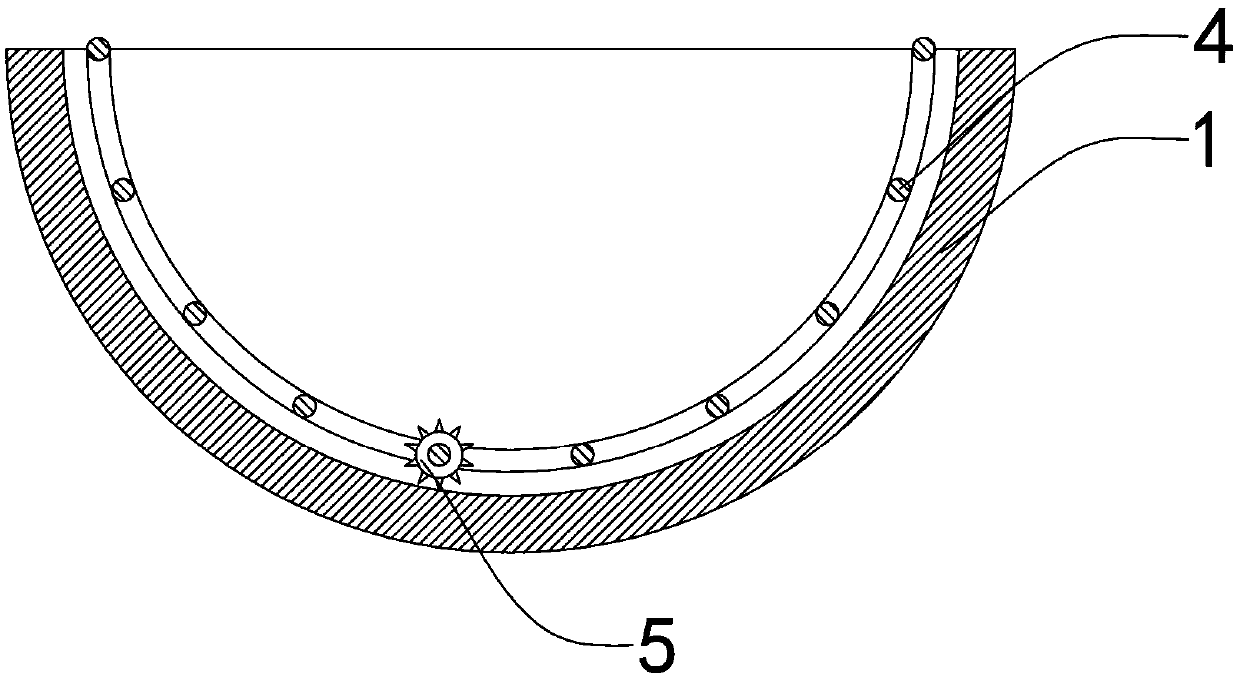

Integral molding method of septic tank

InactiveCN109534638AHigh degree of continuous internal structureHigh mechanical strengthBiological sludge treatmentWater leakageReinforced concrete

The invention provides an integral molding method of a septic tank. The septic tank comprises a septic tank lower end external mold, a septic tank upper end external mold, a septic tank internal moldand a septic tank reinforcing bar structure. The method comprises the specific molding steps of fixing the septic tank lower end external mold, placing the septic tank reinforcing bar structure insidethe septic tank lower end external mold, assembling the septic tank internal mold, placing the assembled septic tank internal mold inside the septic tank reinforcing bar structure, closing and fixedly connecting the septic tank upper end external mold and the septic tank lower end external mold so as to obtain an external mold cavity, pouring concrete into the external mold cavity, reserving a septic tank opening, disassembling the septic tank internal mold from the septic tank opening after the concrete is hardened, taking out the septic tank internal mold through the septic tank opening, and then, disassembling the septic tank upper end external mold and the septic tank lower end external mold, thereby obtaining the septic tank. The molding method provided by the invention is simple, the condition that reinforced concrete structured septic tanks suffer from slits and water leakage can be avoided, and the mechanical strength and use effect of the overall septic tank are improved.

Owner:漯河俊展环保科技有限公司

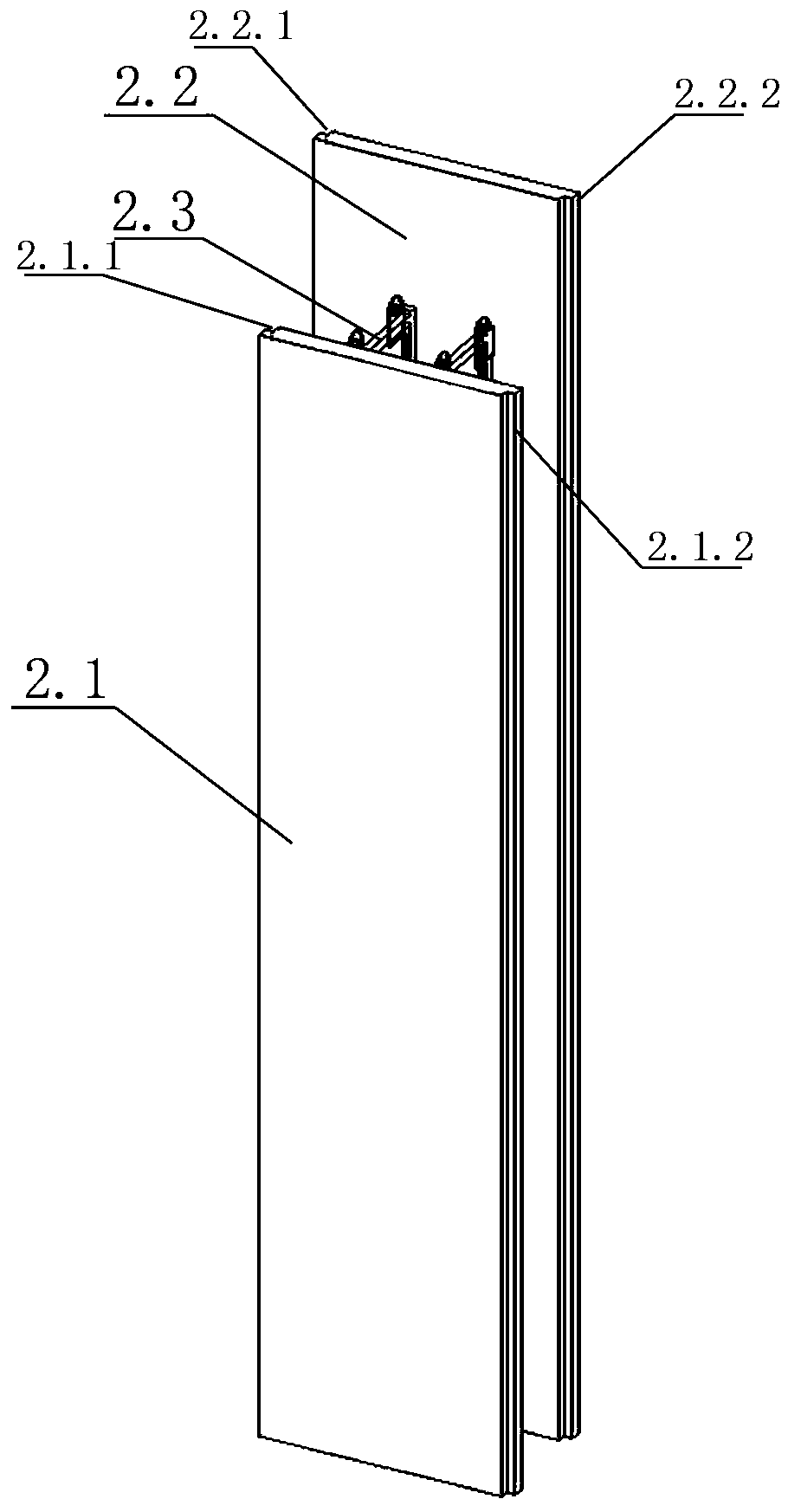

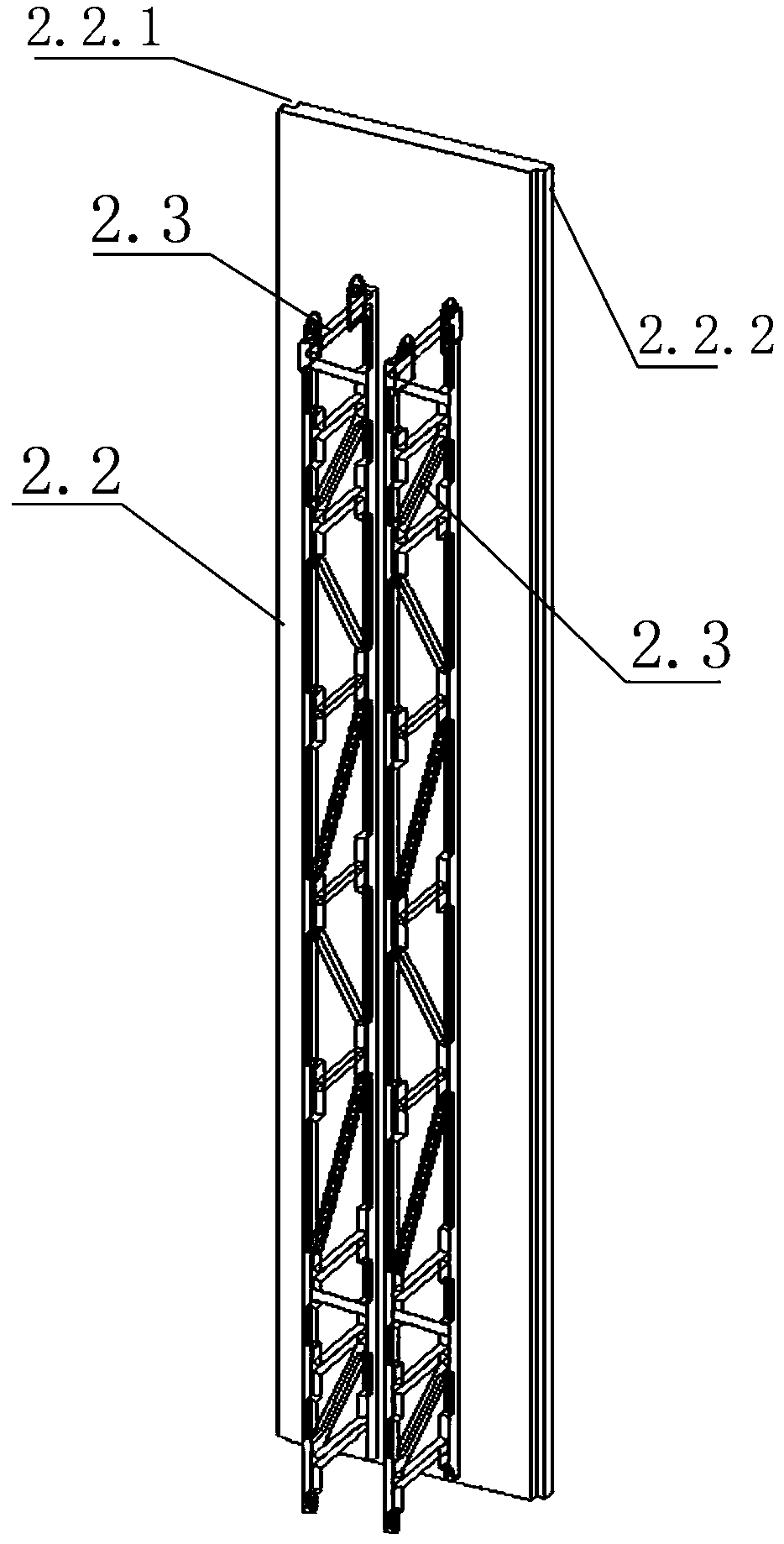

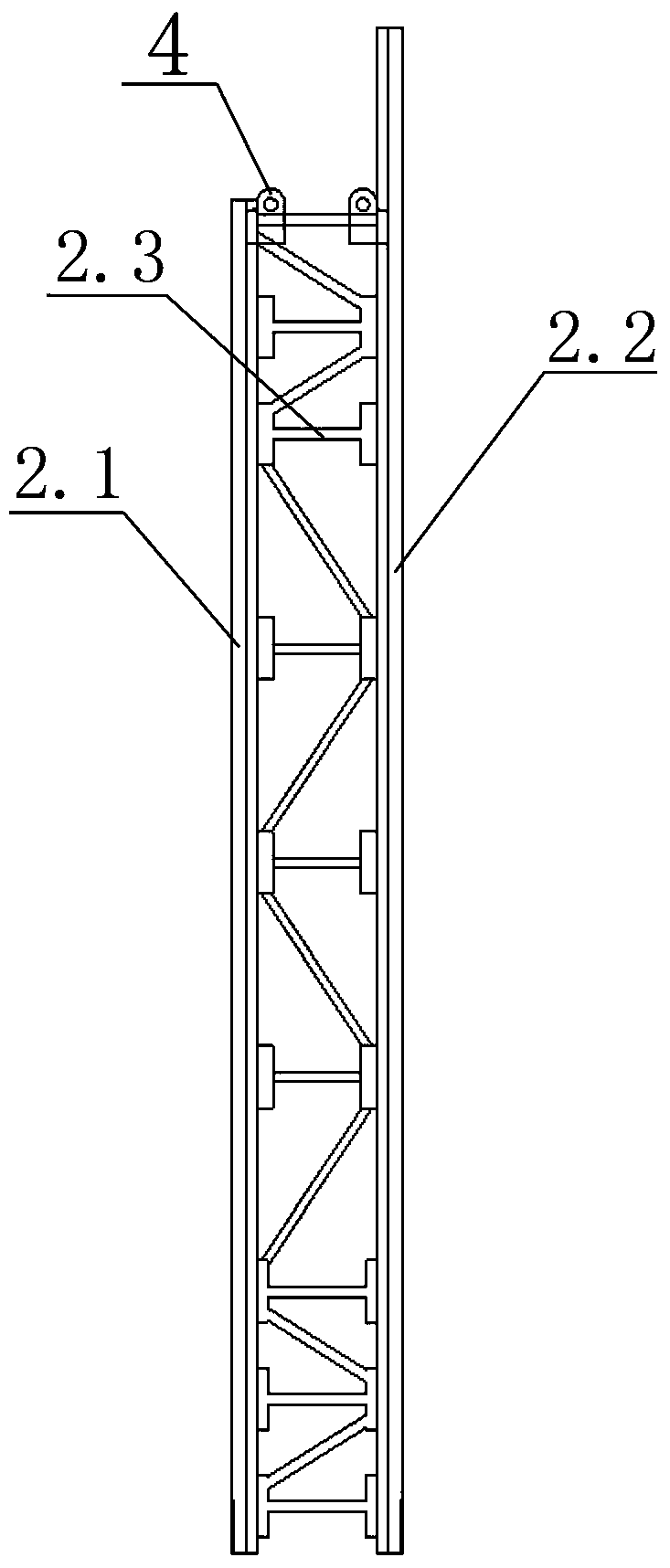

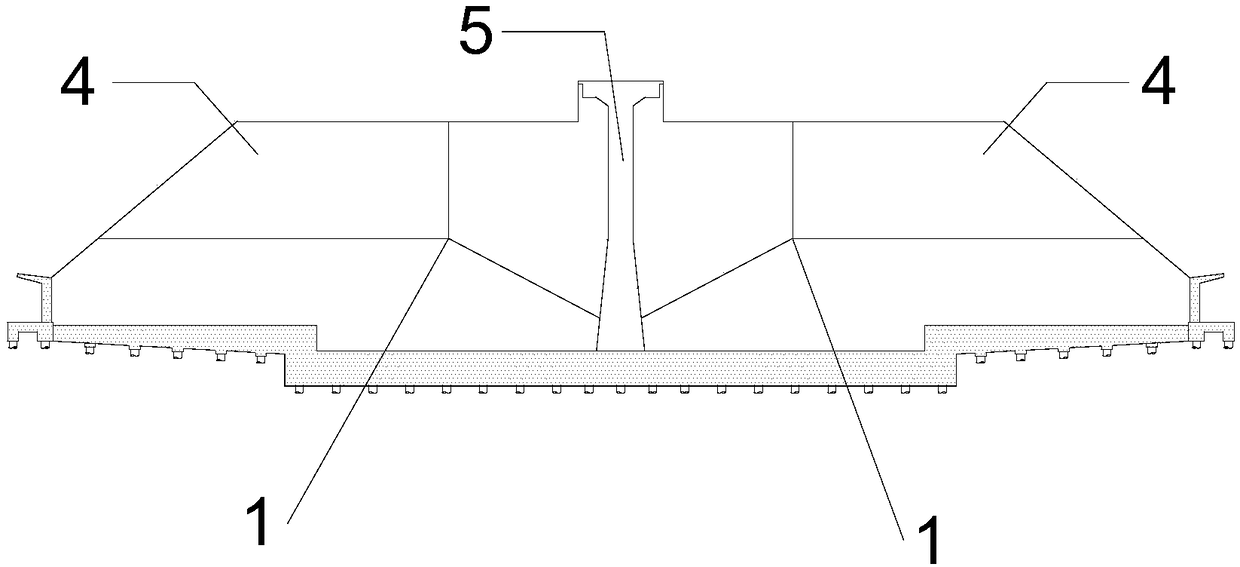

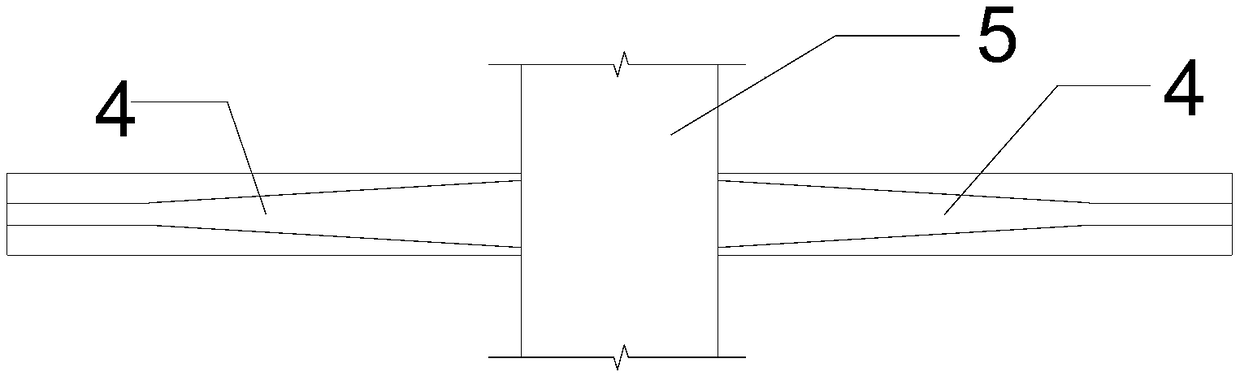

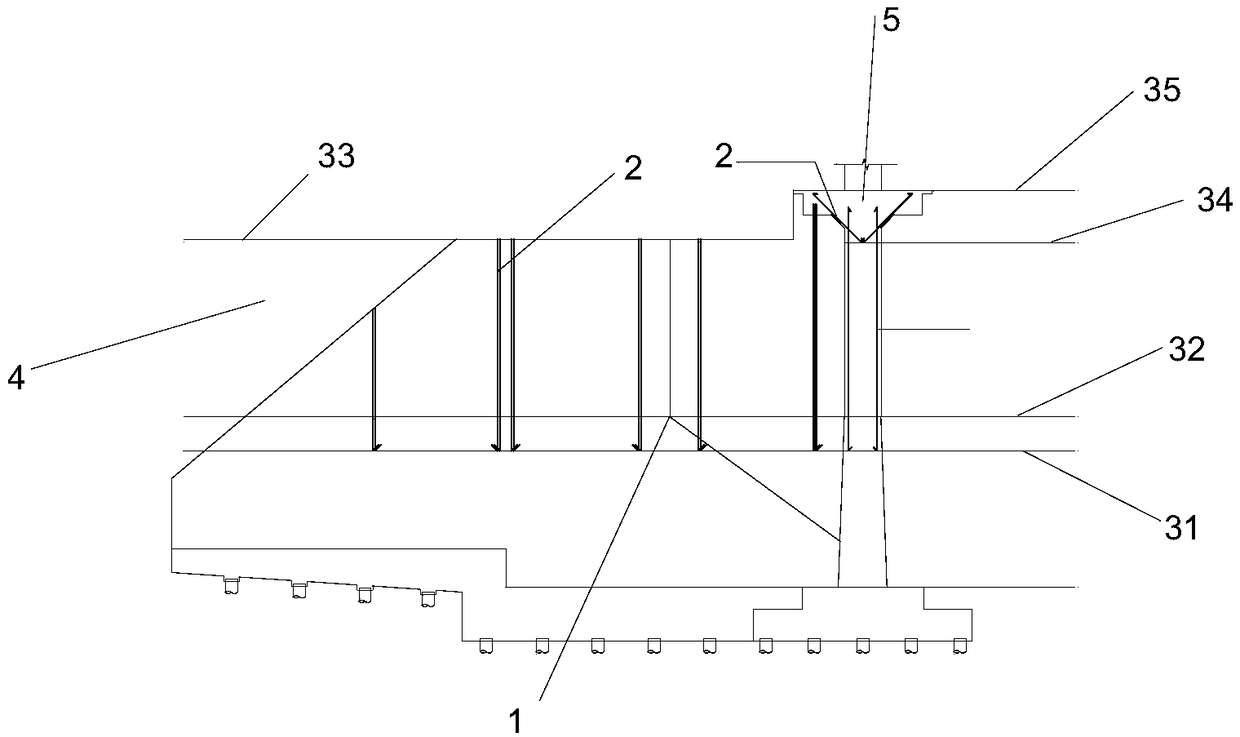

Profile steel truss double-skin wall structure and construction method thereof

The invention discloses a profile steel truss double-skin wall structure and a construction method thereof. The profile steel truss double-skin wall structure comprises a main body structure, a double-skin wall structure unit and a cast-in-place concrete layer, the double-skin wall structure unit is transversely connected in a spliced manner; the cast-in-place concrete layer is cast in the double-skin wall structure unit; the double-skin wall structure unit comprises a first precast concrete slab and a second precast concrete slab; a group of profile steel trusses are transversely arranged between the first precast concrete slab and the second precast concrete slab at an interval in parallel; each profile steel truss is arranged vertically in the length direction, a chord member on one side of each profile steel truss is cast in the first precast concrete slab, the chord member on the other side of each profile steel truss is cast in the second precast concrete slab. Scaffold and formwork support procedures in traditional cast-in-situ technology are simplified, labor force is saved, potential safety risks caused by high-formwork support are avoided, and the technical problems thatexisting steel bar truss double-skin walls have small thickness and height not exceeding 4 m and existing double-skin wall structures have low overall rigidity and concrete lateral pressure resistanceare solved.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

Environment-friendly classified dustbin realizing convenience in recycle

InactiveCN108263778ASimple structureReduce the number of poursRefuse receptaclesRight triangleLitter

The invention discloses an environment-friendly classified dustbin realizing convenience in recycle. The classified dustbin comprises a bin body and a cover plate, wherein the bin body is provided with a left chamber and a right chamber; the cover plate is hinged to the top end of the bin body; each chamber of the bin body is internally and vertically fixedly provided with a screw rod driven by amotor; each screw rod is matched and connected with a slider capable of sliding up and down along the corresponding screw rod; each slider is slidably connected with an oblique plate of which the section is in a right triangle shape; each slider comprises a positioning end matched with the side surface of the corresponding oblique plate, a limiting end matched with the bottom surface of the corresponding oblique plate, and a gear rack section connected with the corresponding oblique plate; one side, close to the corresponding slider, of each oblique plate is fixedly provided with two lugs; a first gear engaged with the corresponding gear rack section is rotationally connected between the corresponding lugs by virtue of a connecting shaft; the two ends of each connecting shaft are slidablyconnected to the two sides of the corresponding gear rack section; and each oblique plate is internally provided with a driving gear which is driven by a motor and is engaged with the corresponding first gear. The environment-friendly classified dustbin disclosed by the invention can be used for automatically compressing garbage so as to reduce the pouring times of a worker.

Owner:ZHEJIANG XIAYUAN INFORMATION TECH CO LTD

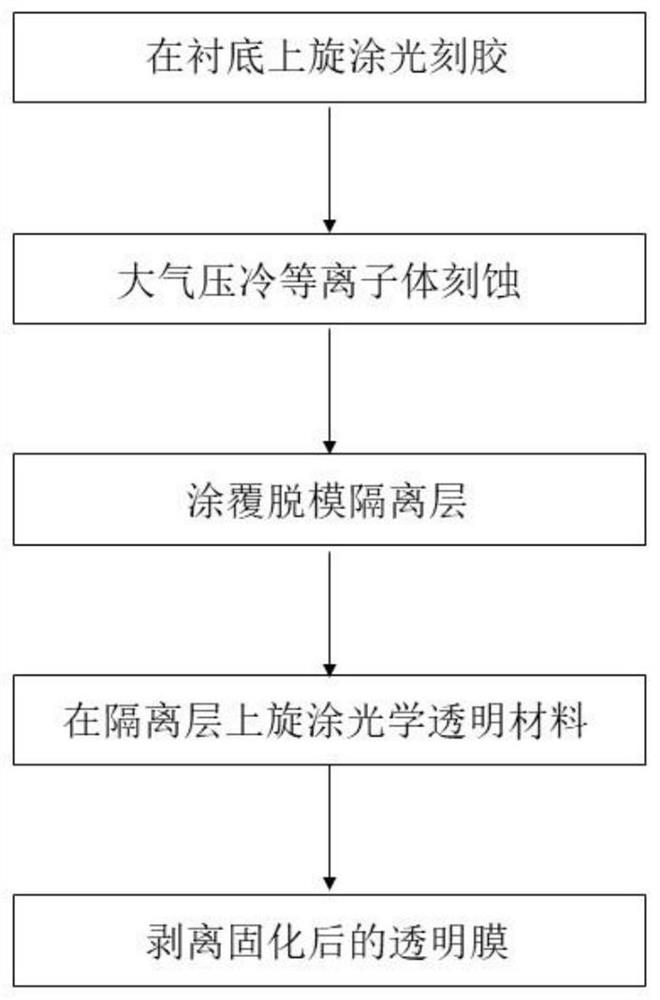

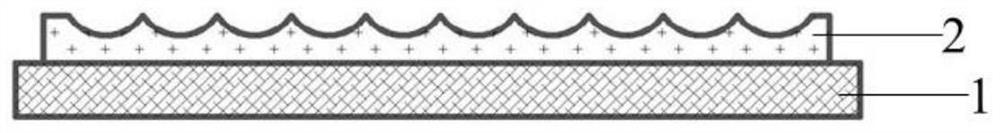

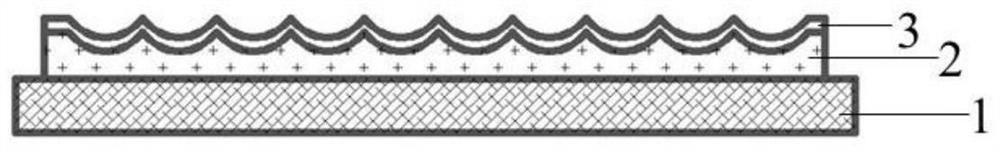

Artificial bionic compound eye preparation method based on atmospheric pressure cold plasma micromachining

The invention provides an artificial bionic compound eye preparation method based on atmospheric pressure cold plasma micromachining. The artificial bionic compound eye preparation method comprises the following steps of spin-coating a layer of photoresist on a substrate, etching the photoresist by adopting atmospheric pressure cold plasma jet, and obtaining a planar concave array structure on thephotoresist after etching, preparing a demolding isolation layer on the upper surface of the planar concave array structure obtained after etching, spin-coating a layer of optical transparent material on the isolation layer, and curing the optical transparent material to form a transparent film, and stripping the cured transparent film to obtain the compound eye lens with the planar convex arraystructure. According to the method, a mask plate is not needed, and the artificial bionic compound eye structure can be obtained through hot-pressing deformation after one-time mold reversing; compared with a traditional micro-lens machining process, the method has the advantages of simple process, low cost, high copying precision and the like.

Owner:SHANGHAI JIAO TONG UNIV

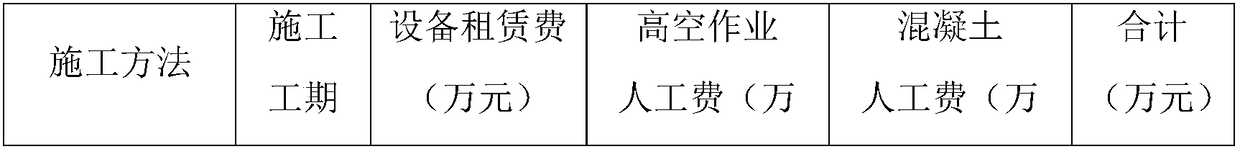

Steel beam, concrete ring beam and concrete floor structure integrated construction method

InactiveCN108756243AHigh positioning accuracyReduce the number of poursBuilding material handlingFloor slabSteel bar

The invention discloses a steel beam, concrete ring beam and concrete floor structure integrated construction method. The steel beam, concrete ring beam and concrete floor structure integrated construction method comprises the following steps that (1), built-in fittings are connected in a bolted mode; (2), a full-hall frame is erected; (3), a steel beam is hoisted and installed and fixed; (4), beam main steel bars and stirrups are arranged in advance and positions are reserved; (5), formwork erecting and steel bar binding are performed; and (6), concrete pouring and maintenance is performed. The built-in fittings (anchorage parts) and the steel beam are welded and connected in a bolted mode in a factory and then lifted to the designed elevation to be subjected to overall pouring with concrete ring beam slabs and columns though a deepening design of the steel structure, the positioning accuracy of the steel beam is improved, the number of concrete pouring is reduced, and the construction period is saved. According to the construction method, the built-in fittings and the steel beam are connected in the bolted mode on the ground in advance, the aloft work is reduced, and safety is improved. The integrated construction method specifies the steel bar binding sequence at the position of column and ring beam caused by the pre-installation of the steel beam, and can meet the quality requirements of steel bar binding.

Owner:QINGDAO BOHAI CONSTR GROUP +1

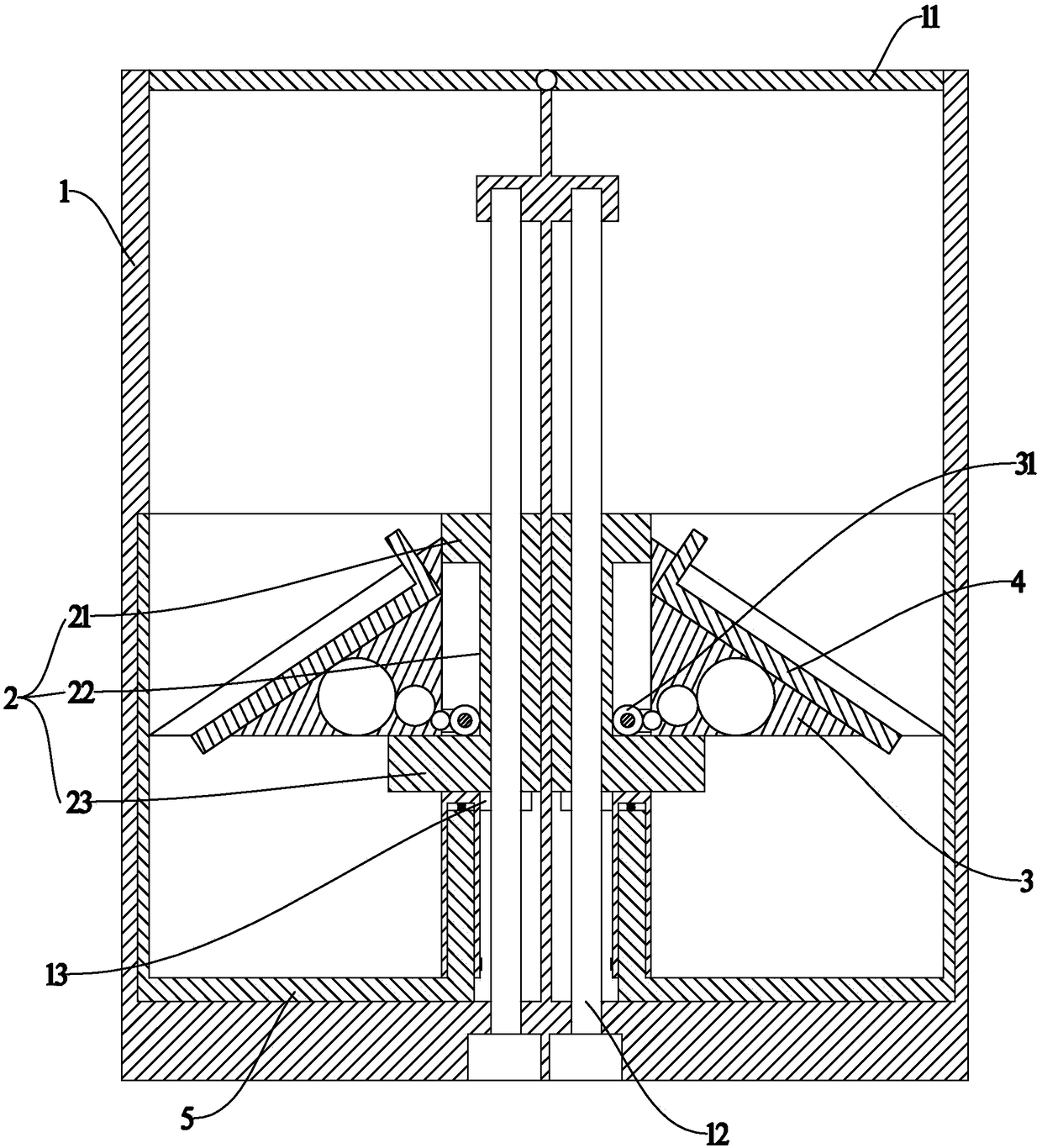

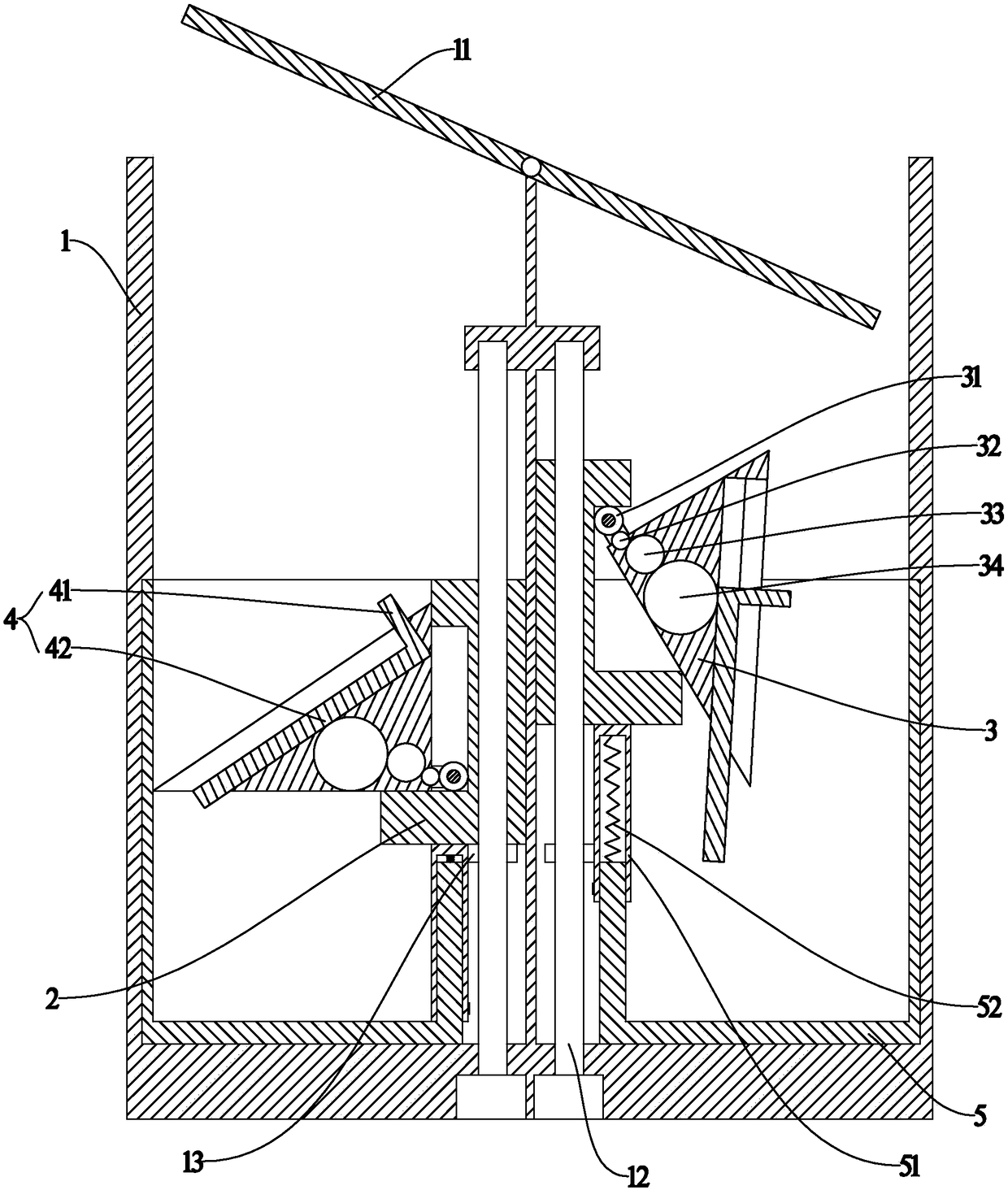

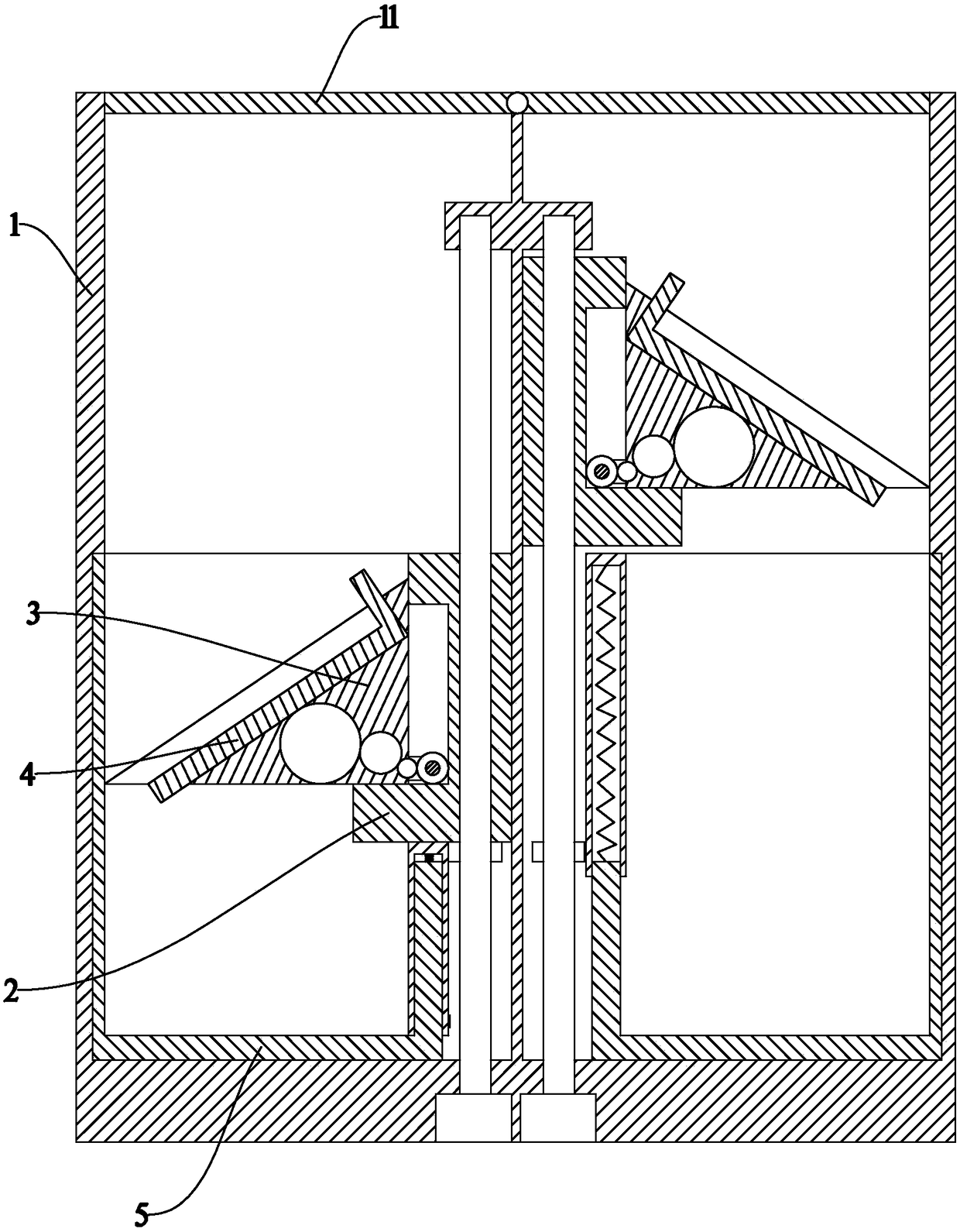

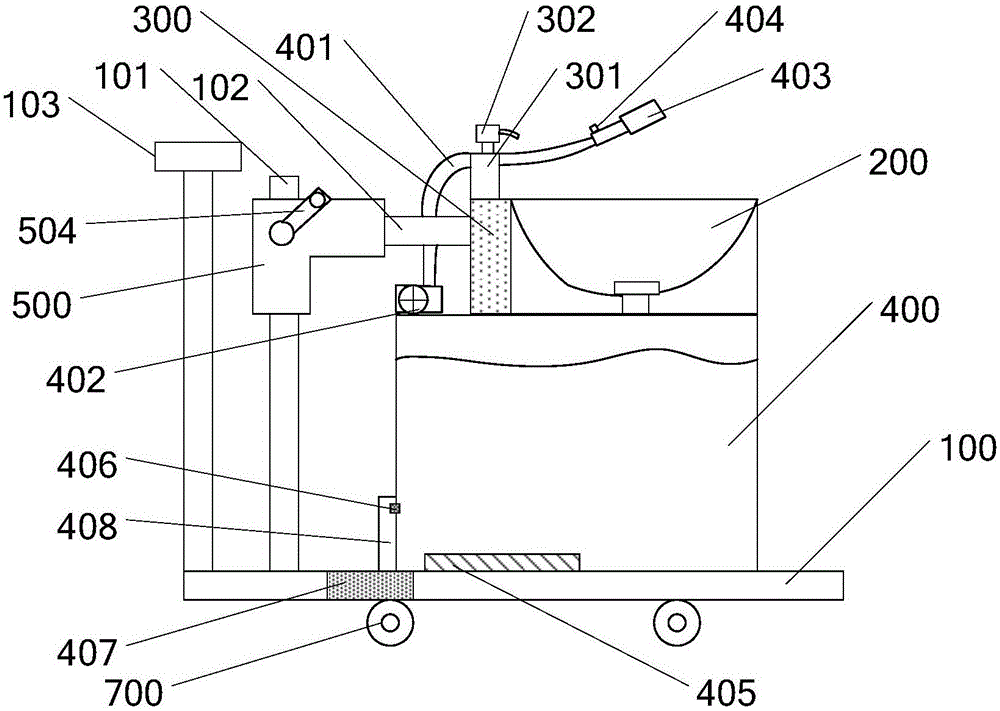

A powder vibrating screen for ore mining

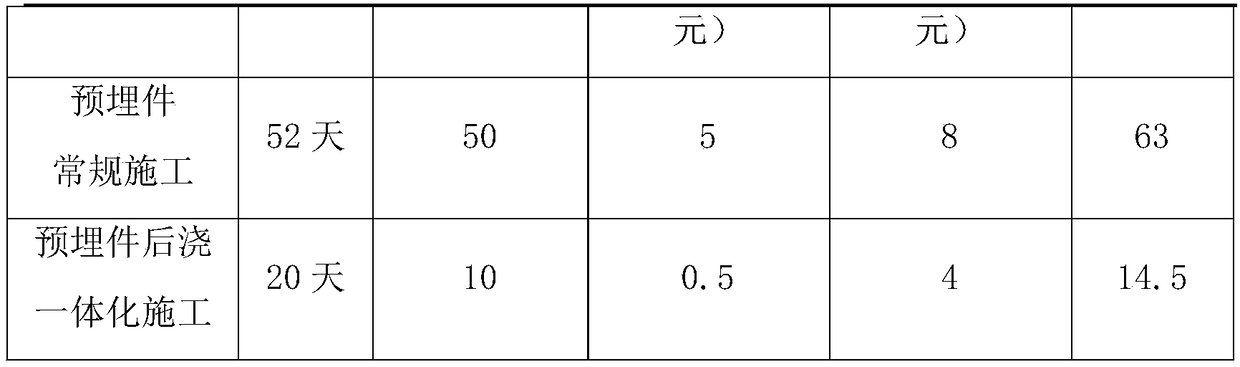

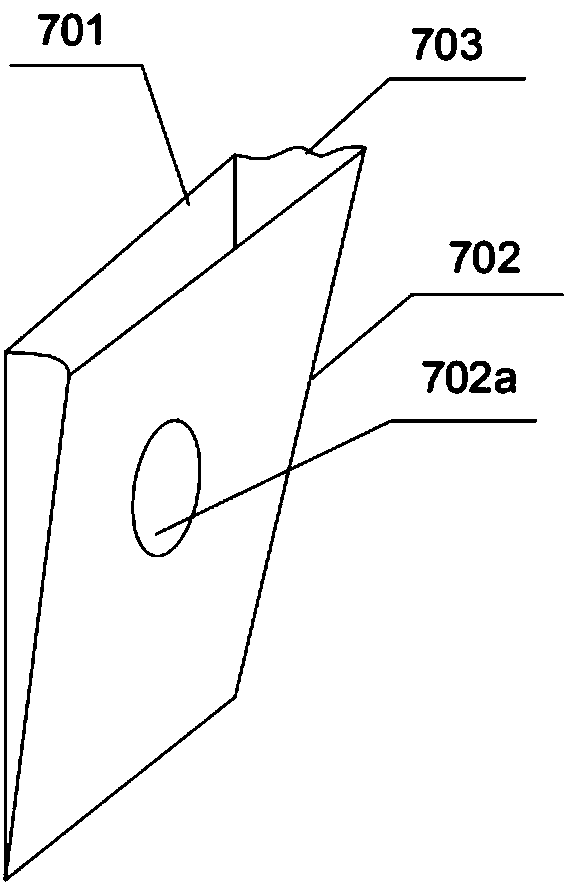

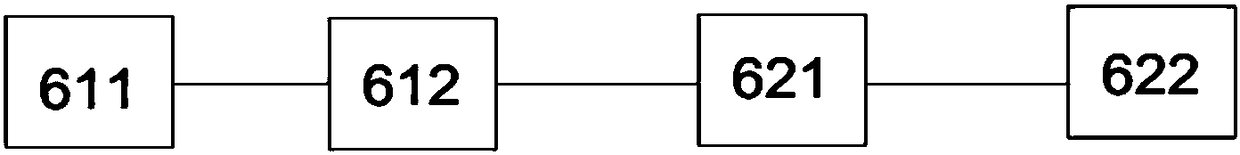

A powder vibrating screen for ore extraction, comprising a base (1), a cylinder device (2), a lower frame body (3), an upper frame body (4), a feeding device (5), a material pushing device (6), a mesh device (7), a screening device (8), and a pushing device (9); the base (1) being provided thereon with a first bracket (11), a second bracket (12), a third bracket (13), a first support pillar (14), and a second support pillar (15); the cylinder device (2) comprising a first cylinder (21), a first pushing rod (22), a fourth bracket (23), and a fifth bracket (24); the lower frame body (3) being provided thereon with a first support rod (30), a discharging frame (31), a first slant plate (32), a closing block (33), a second slant plate (34), a first filter plate (35), a first curved rod (36), a baffle (38), and a material receiving box (39); the upper frame body (4) being provided thereon with a second curved rod (41), a third cross rod (42), a first connection rod (43), and a first fixing frame (44); the feeding device (5) comprising a hopper (51), a material collection frame (52), and a second vertical rod (53); the material pushing device (6) comprising a first motor (61), a rotation shaft (62), a screw rod (63), a third vertical rod (64), a second fixing frame (65), and a third support pillar (66); and the mesh device (7) comprising a mesh (71), a first magnet (72), and a first vibrator (73). The frequency of toppling can be reduced, reducing the labor intensity of an operator.

Owner:TONGLING ZHONGDU MINING CONSTR

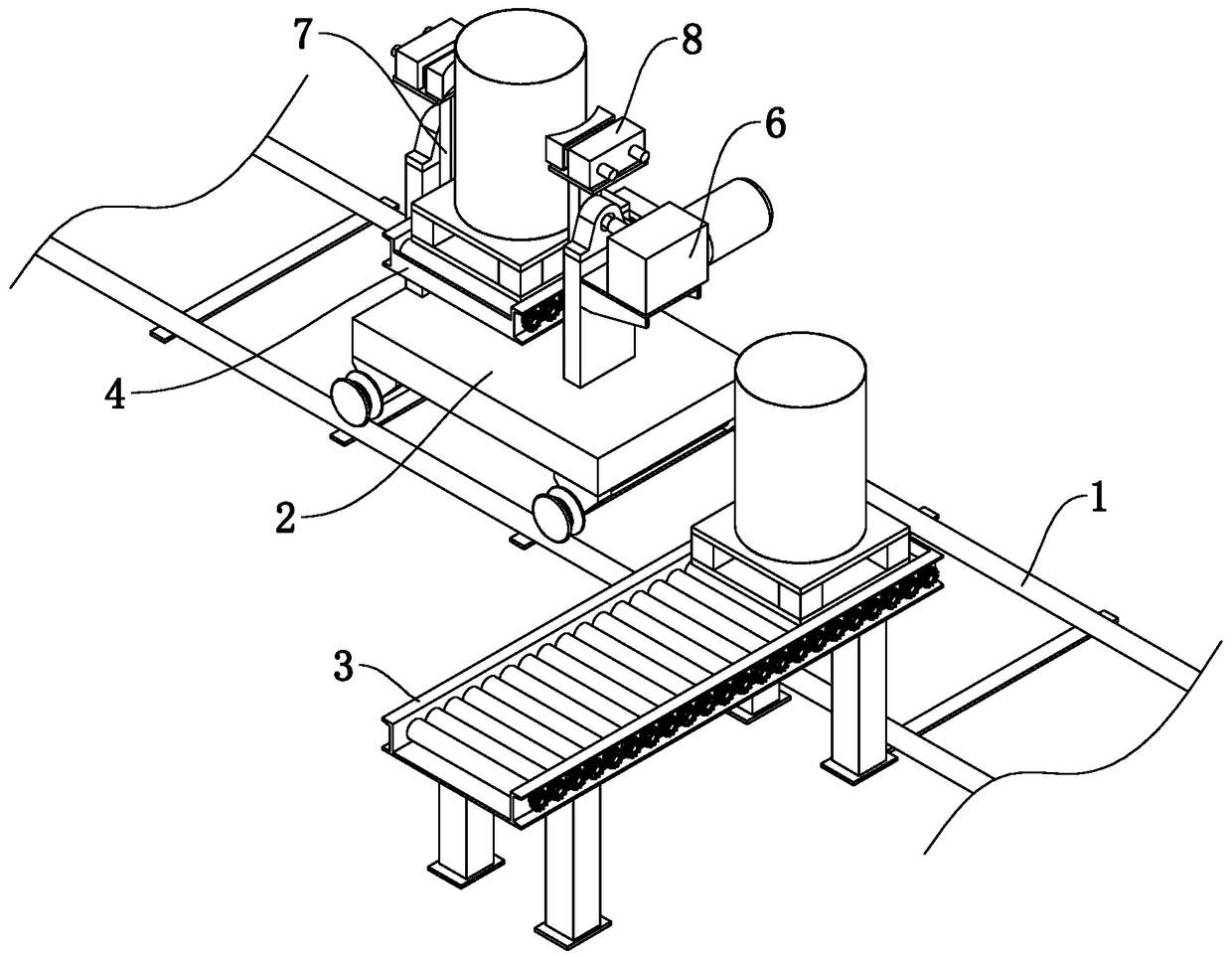

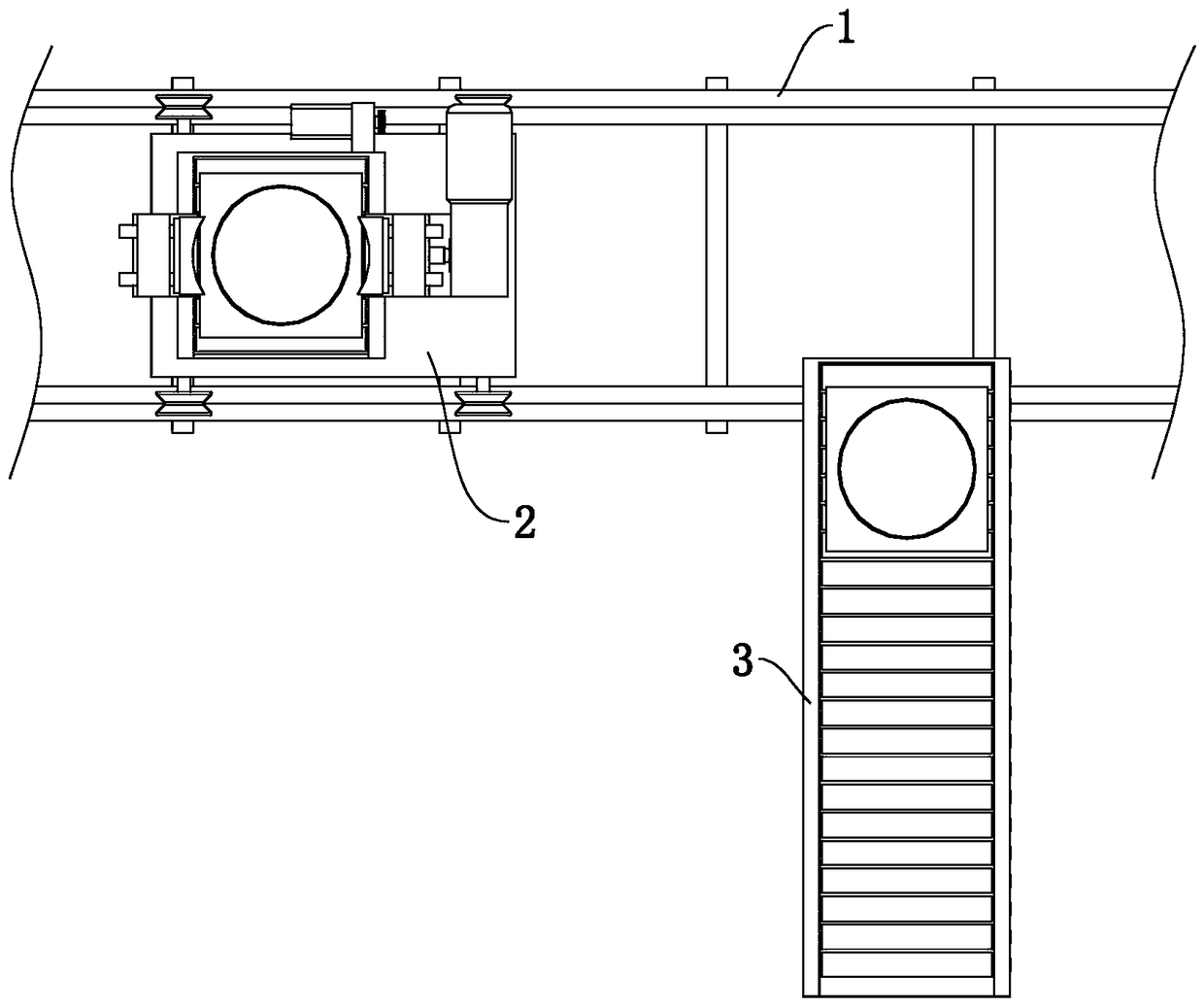

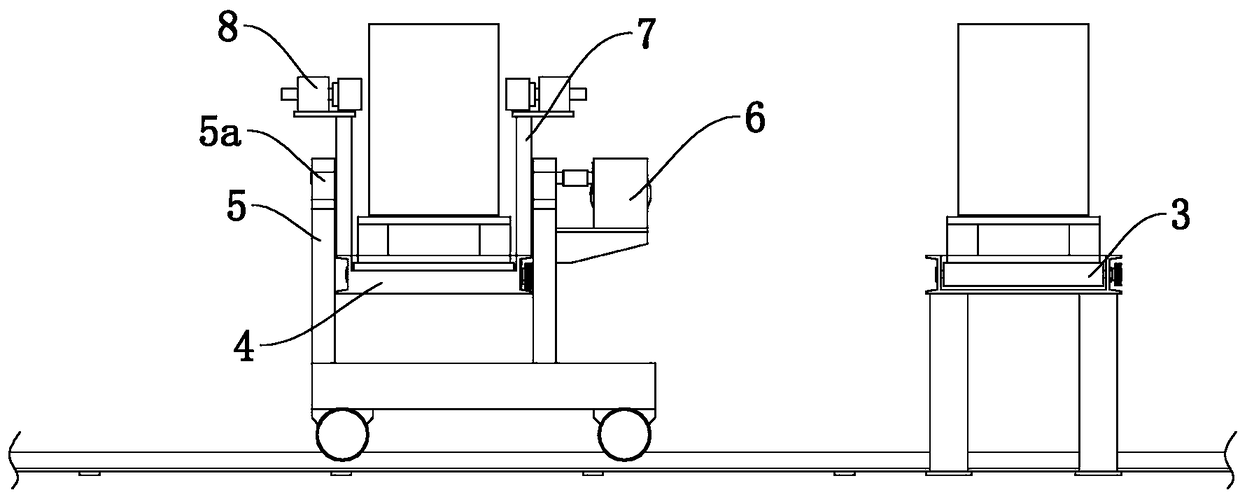

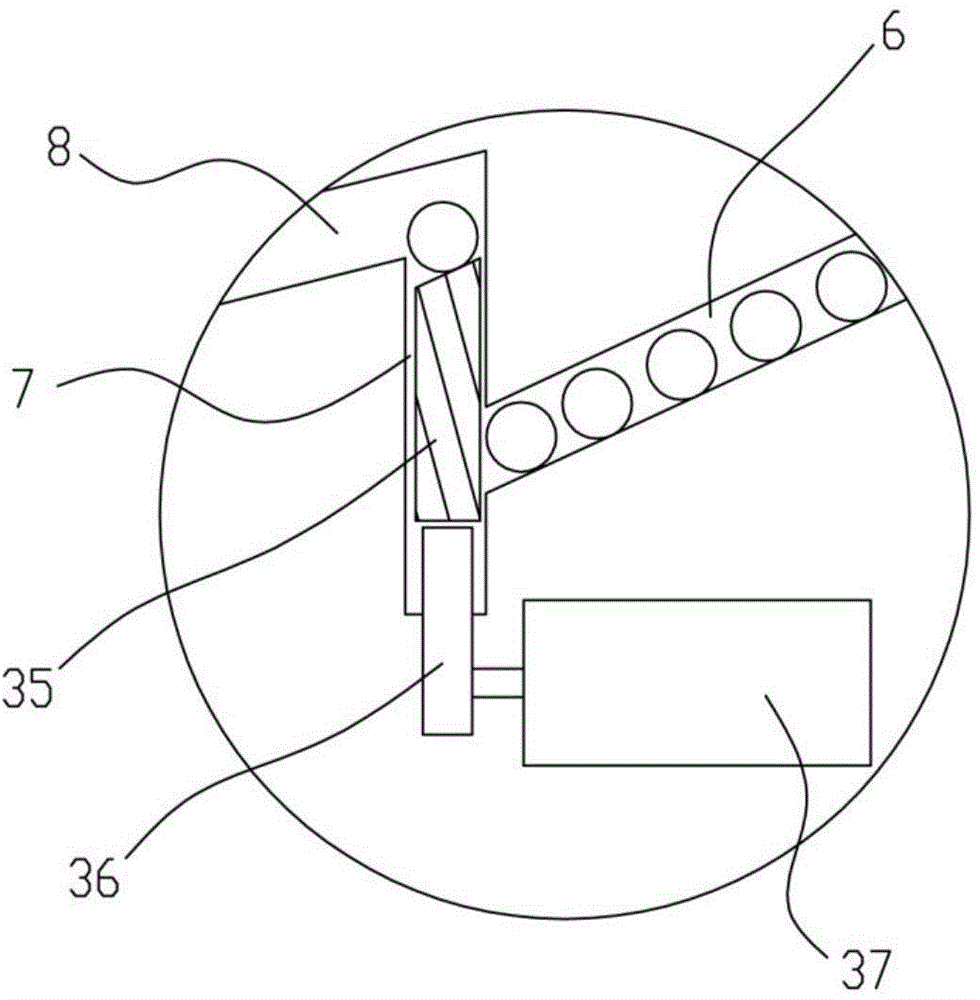

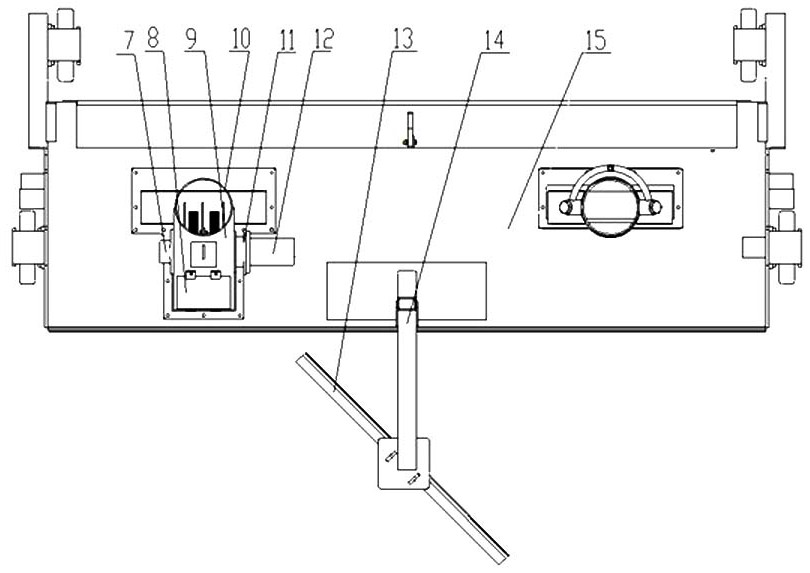

Single tipping type material bin replenishing system for new energy automobile magnetic steel raw material batching equipment

PendingCN109230600AReduce the number of poursAvoid mistakesConveyorsControl devices for conveyorsNew energyButt joint

The invention relates to the technical field of automatic batching equipment and in particular relates to a single tipping type material bin replenishing system for new energy automobile magnetic steel raw material batching equipment. A supplementary material turning device is mounted on an automatic material replenishing vehicle, an abut joint conveyor belt which can be connected with a materialsupply conveyor belt in an abutted manner is mounted on the supplementary material turning device, an output end of the material supply conveyor belt is provided with a material barrel blocking device, a tail end of the butt joint conveyor belt is also provided with a material barrel blocking device, a material barrel information identifying device is mounted on an output end of the material supply conveyor belt, and a material barrel blocking device is also mounted on a front end of an input end of the material supply conveyor belt. In the system disclosed in the invention, barreled raw materials are conveyed onto the butt joint conveyor belt of the automatic material replenishing vehicle via the material supply conveyor belt, material barrels filled with the raw materials can be overturned after being clamped tightly via the supplementary material turning device, a high automation degree can be achieved, raw material toppling times can be reduced in material replenishing processes, airborne dust can be effectively prevented from being generated in workshops, the output end of the material supply conveyor belt is provided with the material barrel information identifying device, and the raw materials can be effectively prevented from being mistaken.

Owner:NINGBO SONGKE MAGNETIC MATERIAL

Multifunctional garbage can for factory

InactiveCN108438661ASmall footprintAvoid distributingWaste collection and transferRefuse receptaclesElectric machineryCompression device

The invention discloses a multifunctional garbage can for factory. The garbage can comprises a first cylinder body and a second cylinder body, the second cylinder body is movably connected to the upper portion of the first cylinder body and communicates with the first cylinder body, and a rotatable cuboid is arranged on the upper portion of the second cylinder body; a solar panel assembly and a storage battery pack are arranged on the upper portion of the cuboid, and a compression device is arranged in the second cylinder body; and the compression device comprises a driving unit and a compression unit, and an opening is formed in one side, opposite to the compression device, of the second cylinder. According to the multifunctional garbage can for factory, a motor and a hydraulic pump arearranged to realize the compression of the garbage, the space of the multifunctional garbage can is fully utilized, the opening of the automatic opening and closing is formed during use, the situationthat peculiar smell cannot be given out is ensured, and the garbage can be conveniently delivered, so that the garbage can is widely applied to the technical field of garbage can for the factory.

Owner:XUZHOU COLLEGE OF INDAL TECH

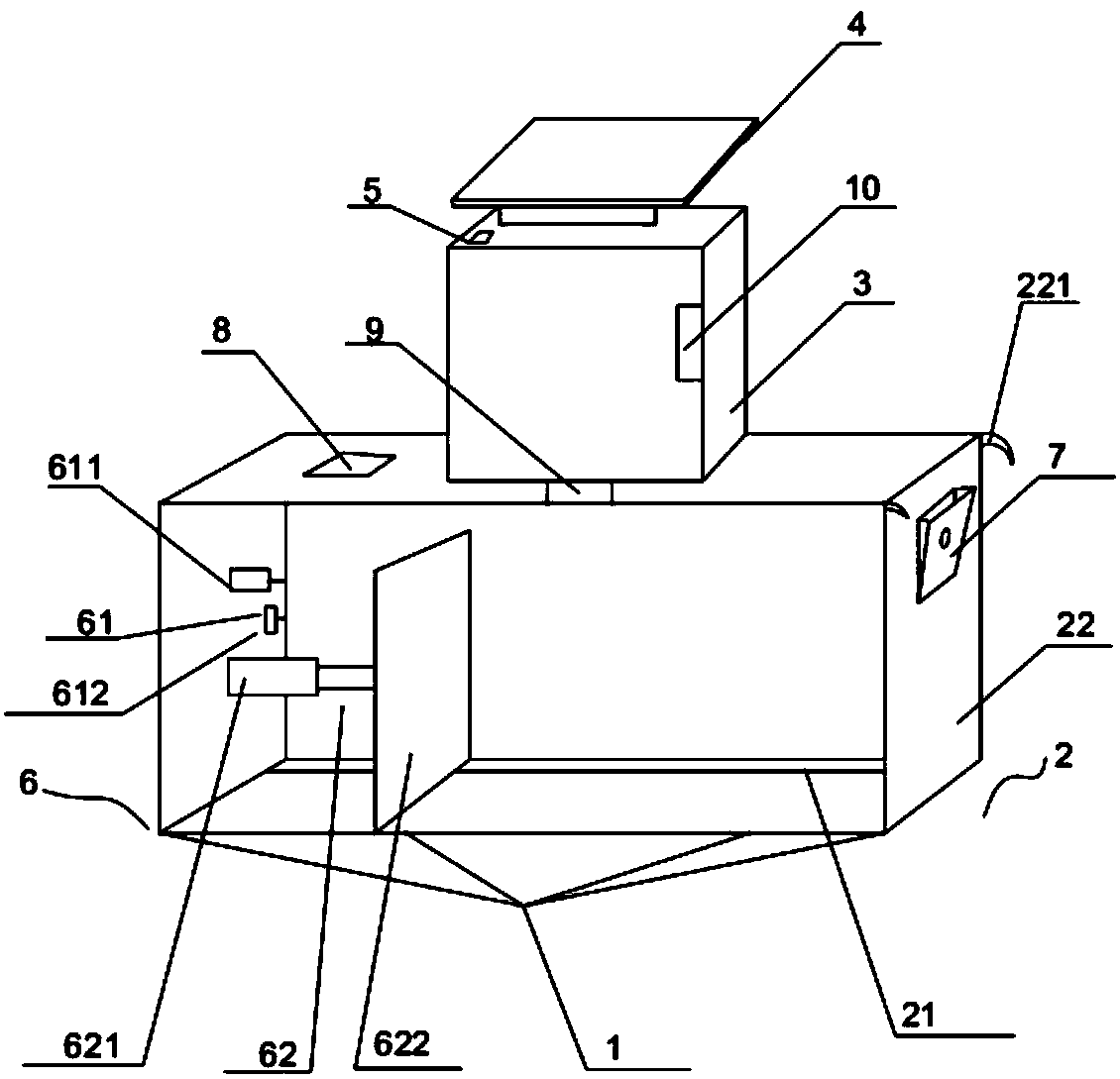

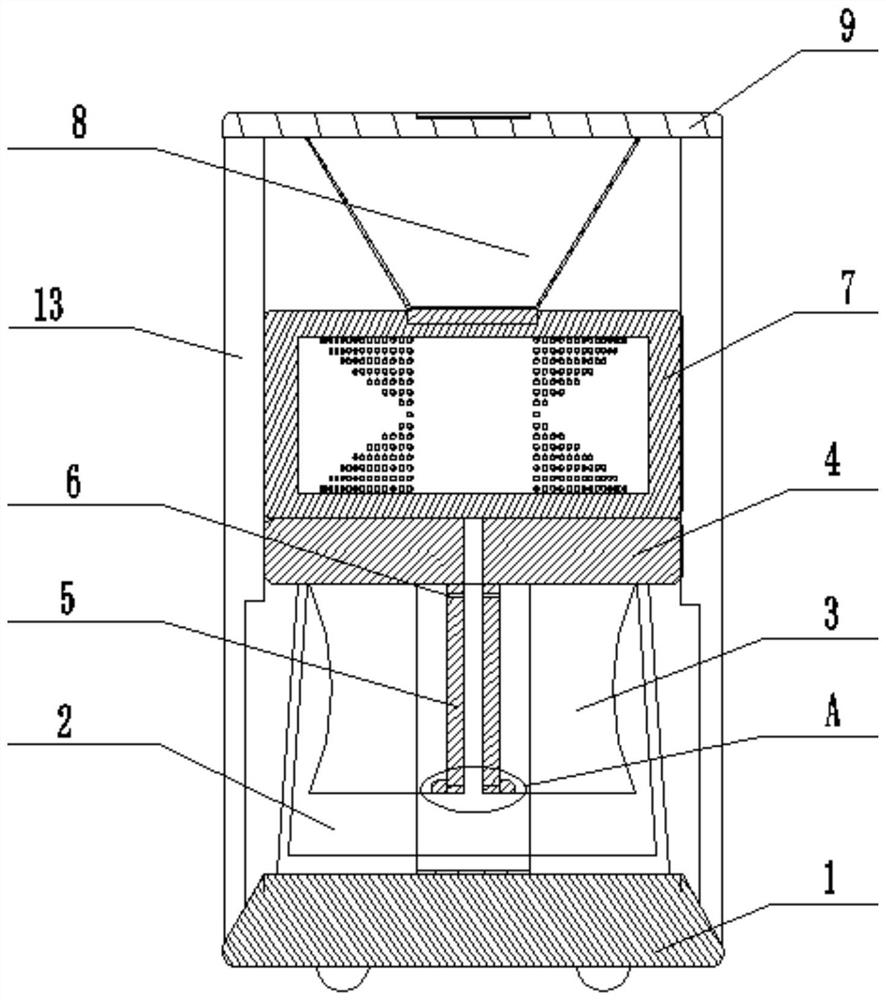

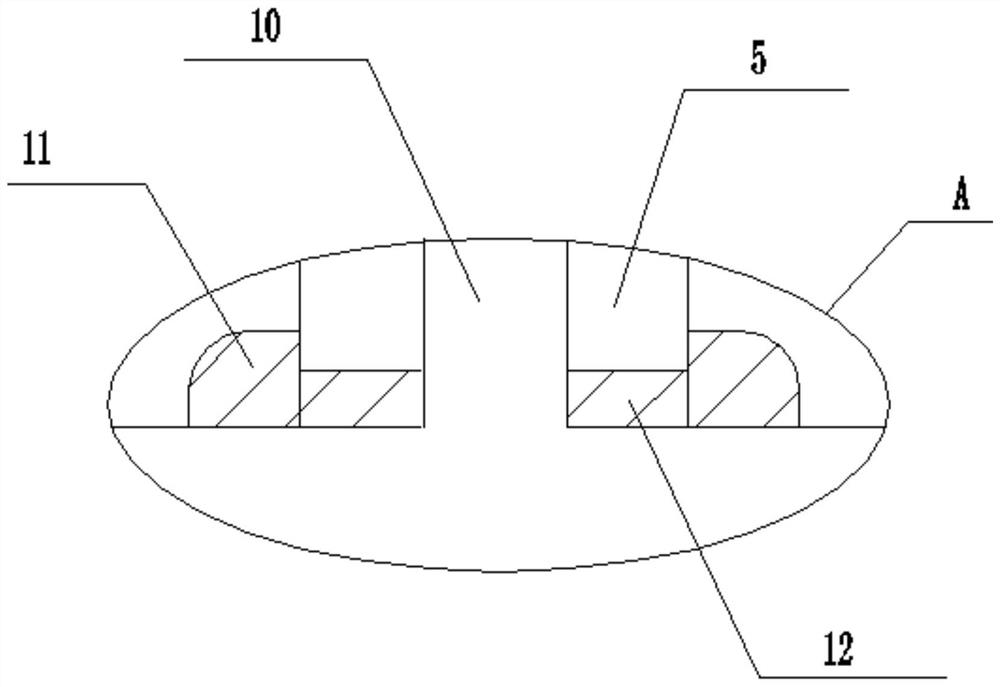

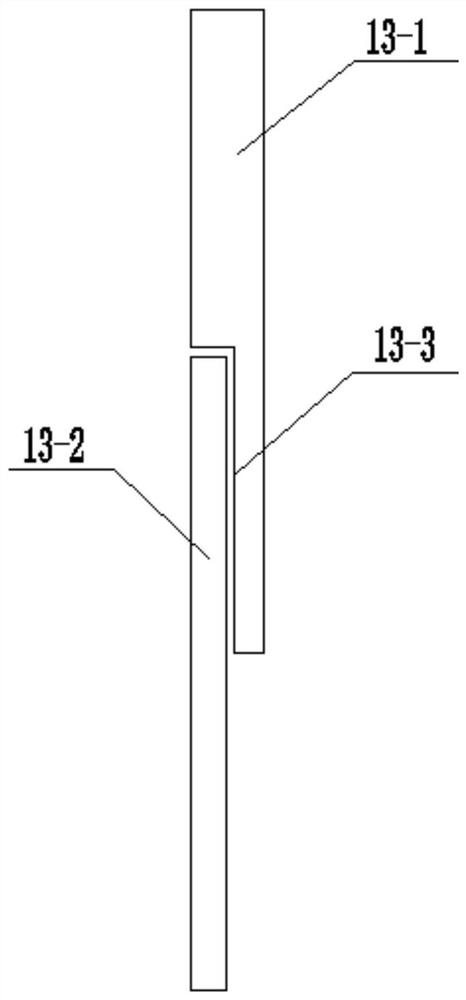

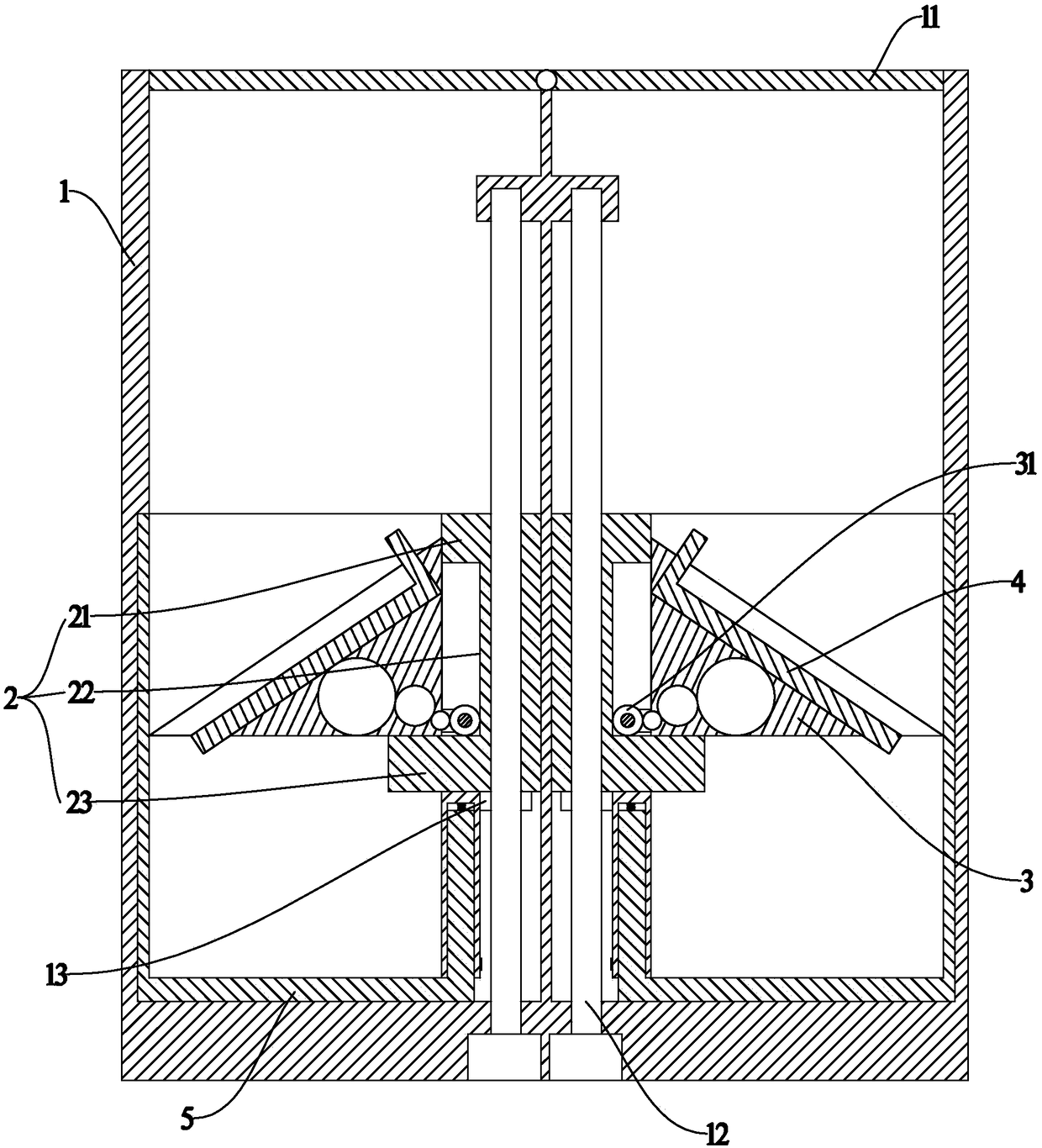

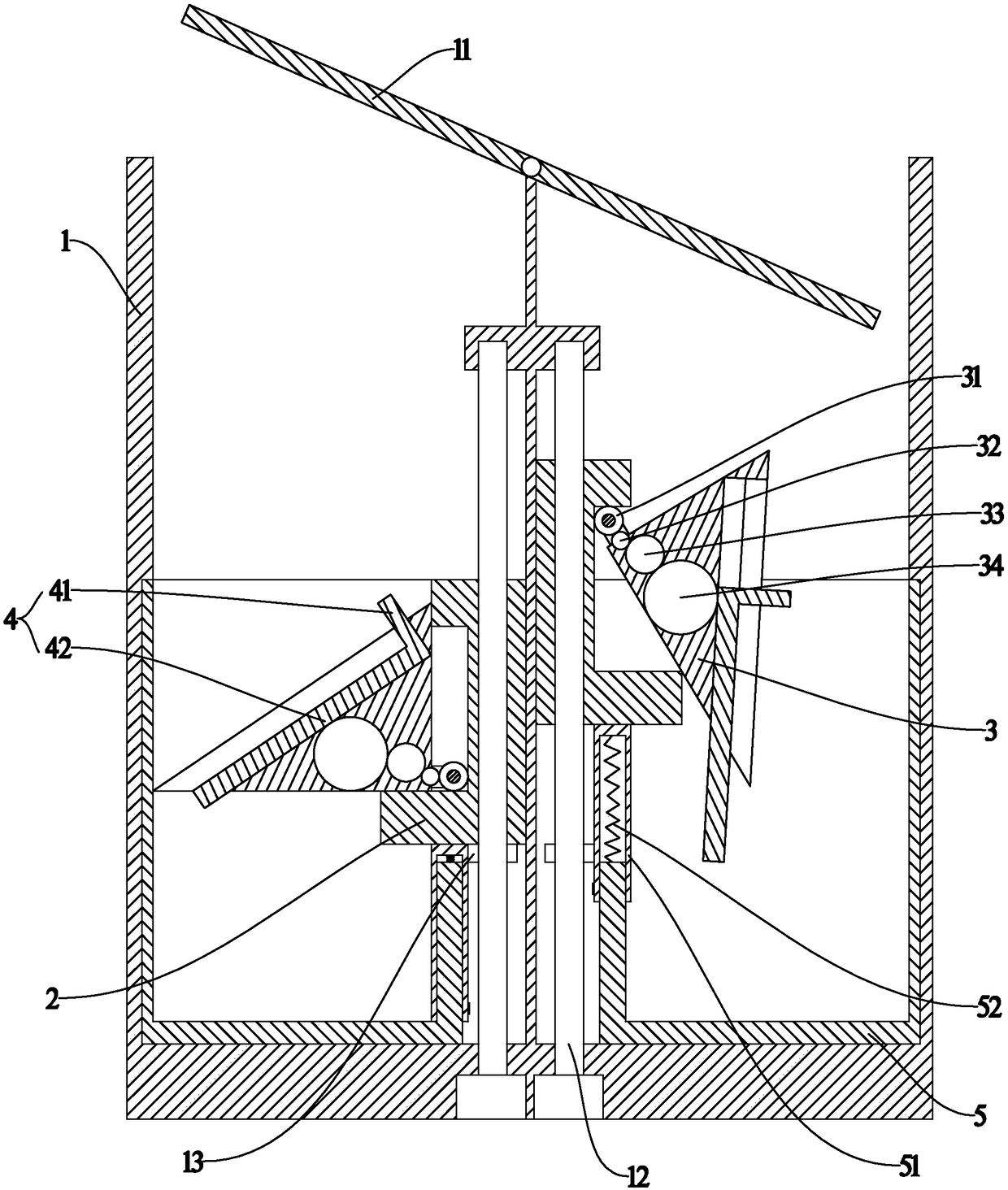

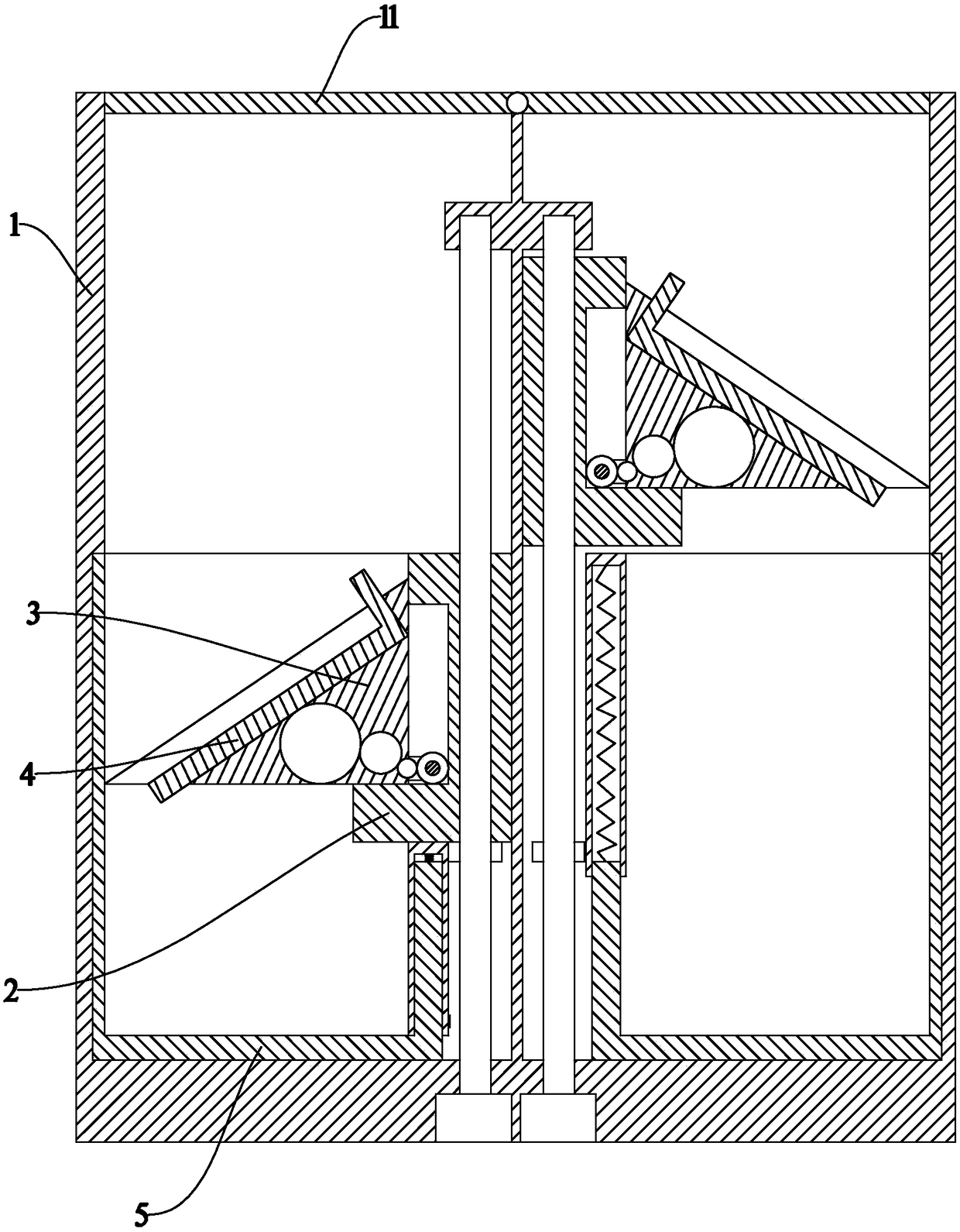

An automatic steel ball sorting device

The invention discloses an automatic steel ball sorting device, which comprises a frame, a loading bucket, a discharging bucket, a waste ball cabin, a quantitative ball supply device, a feeding box, a detection device and a control device, wherein the lower end of the loading bucket is provided with a gravity sensor; one side of the loading bucket is hinged to the frame; a single-side elevating device is arranged on the other side of the loading bucket; the loading bucket is connected with the quantitative ball supply device and the feeding box through a loading channel; the feeding box is connected with the detection device through a feeding channel; the detection device is connected with the waste ball cabin and the discharging bucket respectively through a discharging channel; a distance sensor is arranged above the discharging bucket; the lower end of the discharging bucket is provided with a horizontal elevating device. The automatic steel ball sorting device has the advantages of no need of manual attendance for a long time, lower processing cost, constant loading frequency, higher sorting efficiency and avoidance of secondary defects caused by falling of steel balls into the discharging bucket.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

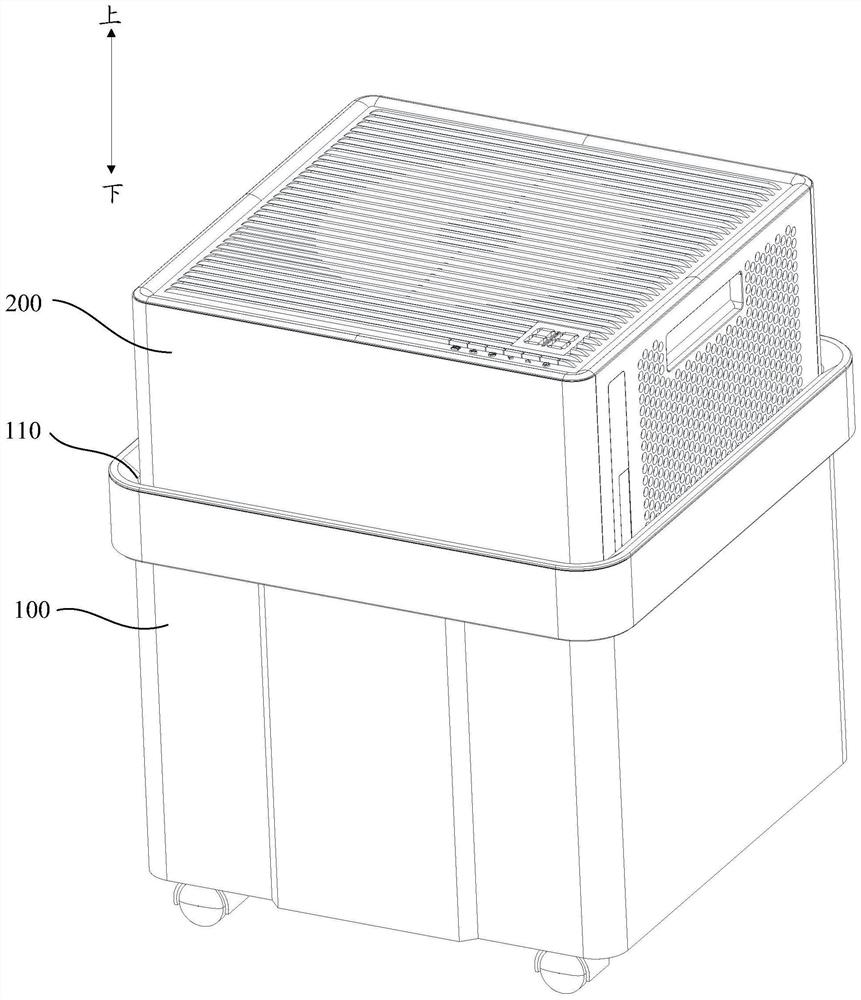

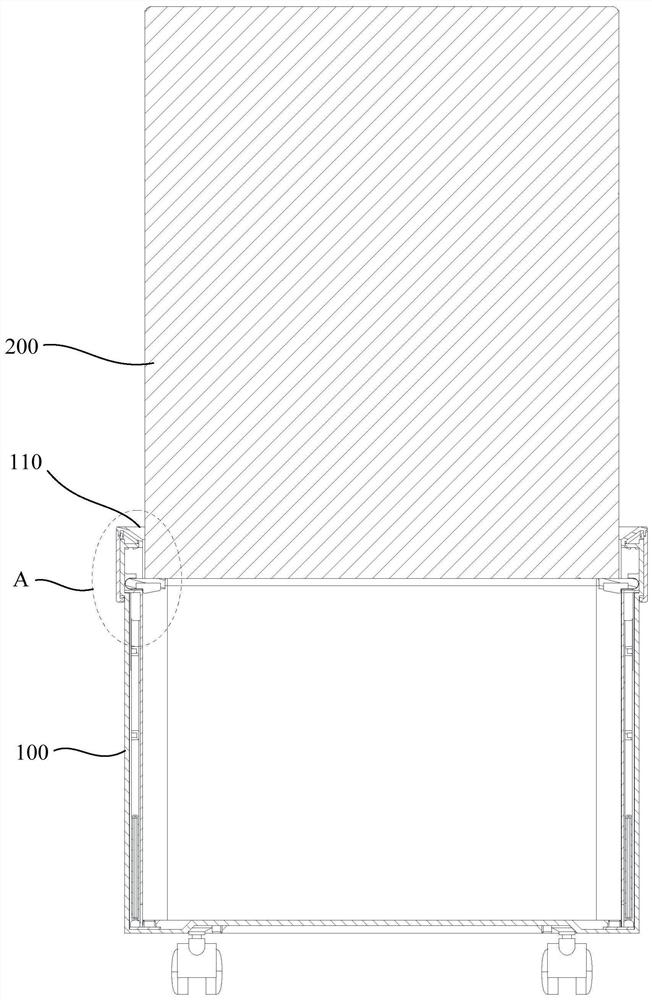

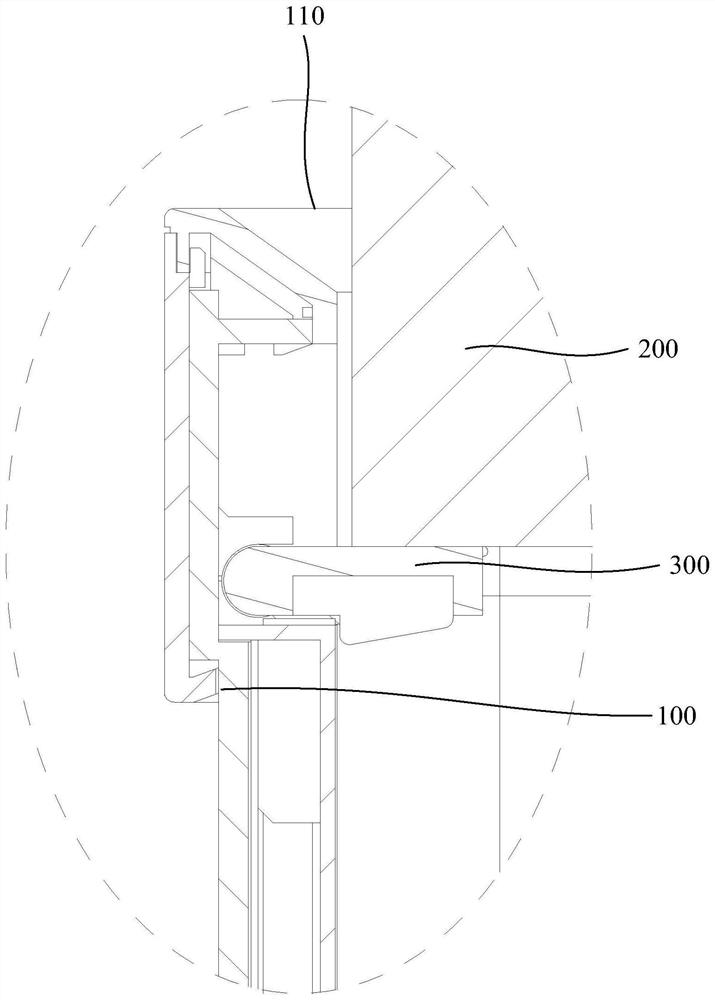

Variable-capacity dehumidifier

ActiveCN112594798ANo change in footprintIncrease water storageCondensate preventionLighting and heating apparatusWater tanksMechanical engineering

The invention belongs to the field of dehumidifiers, and particularly relates to a variable-capacity dehumidifier. The variable-capacity dehumidifier comprises a base, an outer water tank is fixedly mounted at the top of the base, an inner water tank is movably mounted in the outer water tank, the top of the inner water tank extends out of the outer water tank, a mounting seat is fixedly mounted at the top of the inner water tank, a dehumidifier body is fixedly mounted at the top of the mounting seat, and a 3D projection device is installed at the top of the dehumidifier body. By means of reasonable structural design, the two water tanks are stacked together, when the water storage capacity is increased, the inner water tank automatically rises, the two water tanks store water at the sametime, the water storage capacity is increased under the condition that the occupied space of the dehumidifier is not changed, and meanwhile, the dehumidifier is further provided with 3D projection, different visual images such as deserts, oceans and forests can be presented in the form of images when environmental humidity changes are recognized, a user can know whether the indoor humidity environment is suitable or not as soon as possible, and the purposes of humanization and intellectualization are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Environment-friendly classification rubbish bin capable of facilitating cleaning

InactiveCN108313560ASimple structureReduce the number of poursRefuse receptaclesRight triangleEngineering

Owner:ZHEJIANG XIAYUAN INFORMATION TECH CO LTD

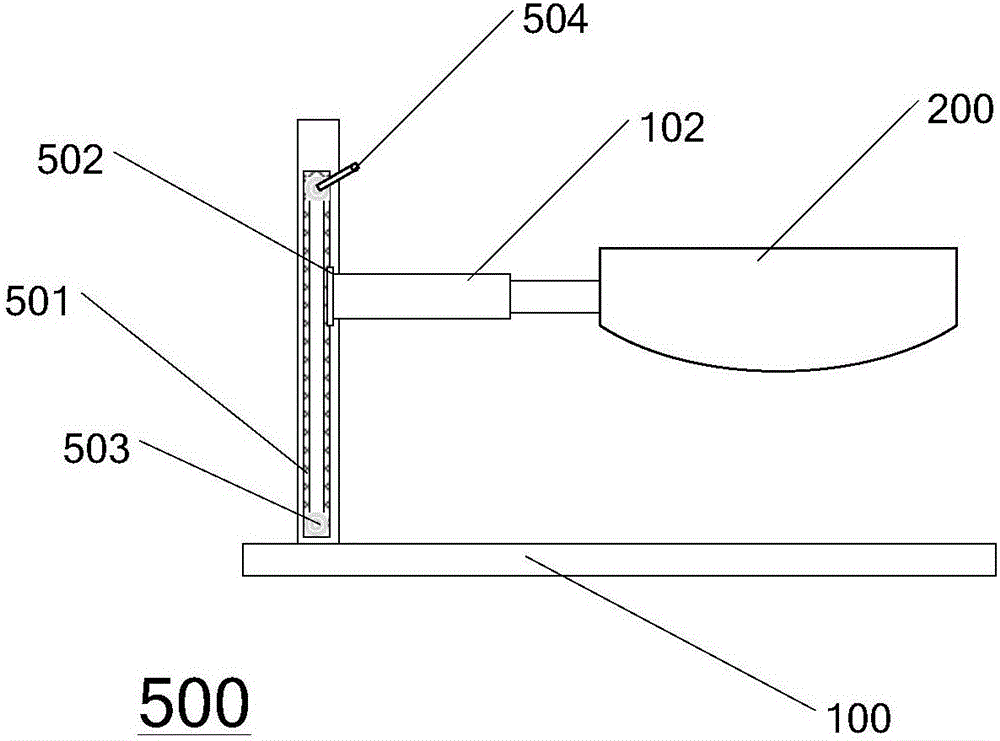

Medical patient nursing pot

InactiveCN106726274ASimple structureImprove the nursing experienceBedpansMedical transportDisinfectantEngineering

The invention discloses a medical patient nursing pot which comprises a base, a pot body, a sterilization device, a water supply device and a lifting device. A vertical beam and a horizontal stretchable beam are installed on the base, the pot body is installed at the free end of the horizontal stretchable beam, the pot body comprises a pot bottom and a side wall, the sterilization device comprises a disinfectant containing cavity which is provided with a disinfectant bottle, and a handlance is arranged on the disinfectant bottle; the handlance is located above the pot body; the water supply device comprises a water storage box and a water outlet pipe connected to the water storage box, a micro water suction pump is installed on the water outlet pipe, a water outlet faucet is installed at the tail end of the water outlet pipe, a switch for controlling the micro water suction pump is arranged on the water outlet faucet, the lifting device is arranged on the vertical beam, and the horizontal stretchable beam is controlled to ascend and descend. The medical patient nursing pot is simple in structure and capable of adjusting the height of the pot body according to different portions of a patient, running water washing is achieved, direct disinfection is achieved, and workloads of nurses are relieved.

Owner:SUZHOU SCI&TECH TOWN HOSPITAL

Method for determining reserved position of construction joint of reinforced concrete retaining wall

ActiveCN108612126AReduce temperature stress cracksAvoid cutsArtificial islandsUnderwater structuresTemperature stressReinforced concrete

The invention provides a method for determining the reserved position of a construction joint of a reinforced concrete retaining wall. The method comprises the following steps that the process of theposition of a horizontal construction joint is determined through the positions of horizontal intersecting lines, the specification of a template and the positions of inserting ribs, and the positionof a vertical construction joint is determined through the position of the horizontal construction joint. Compared with the prior art, the method for determining the reserved position of the construction joint of the reinforced concrete retaining wall has the beneficial effects that the position of the horizontal layered construction joint and the position of the vertical segmented construction joint are reasonably determined, so that the casting square amount of the horizontal construction joint and the vertical construction joint is smaller than or equal to 1000 cubic meters, and the temperature stress cracks of large-volume concrete are reduced; and the distance between the two construction joints is an integer multiple of the width or the length of the template, so that the template isprevented from being cut, the loss of steel bars and the template is reduced, and the cost is saved.

Owner:CHINA MCC20 GRP CORP

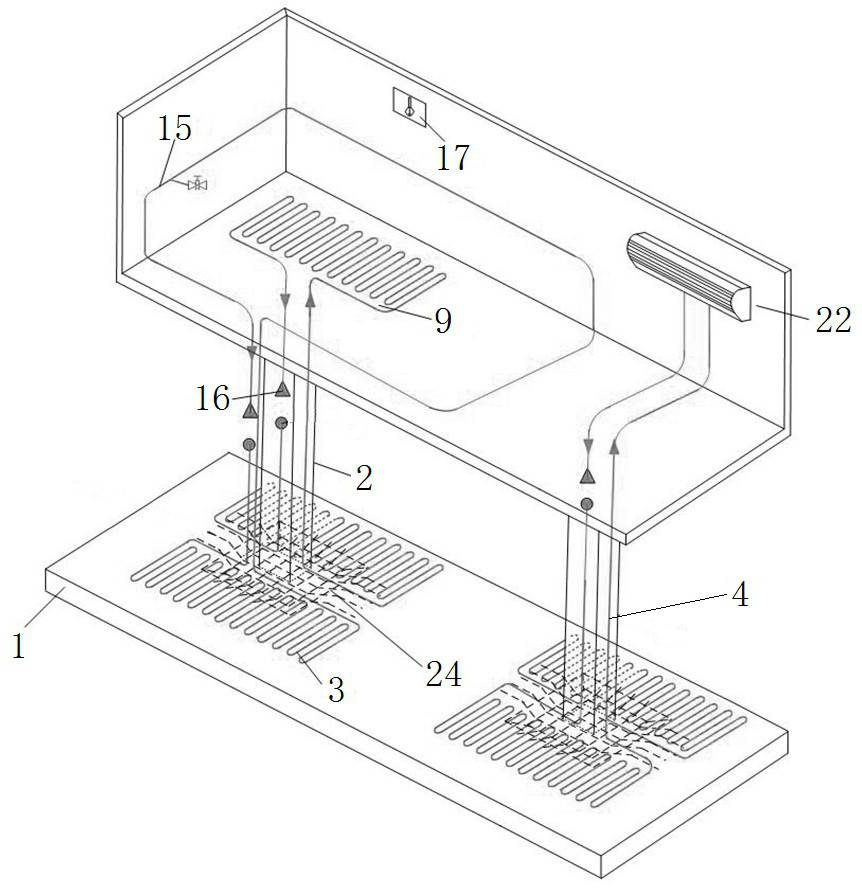

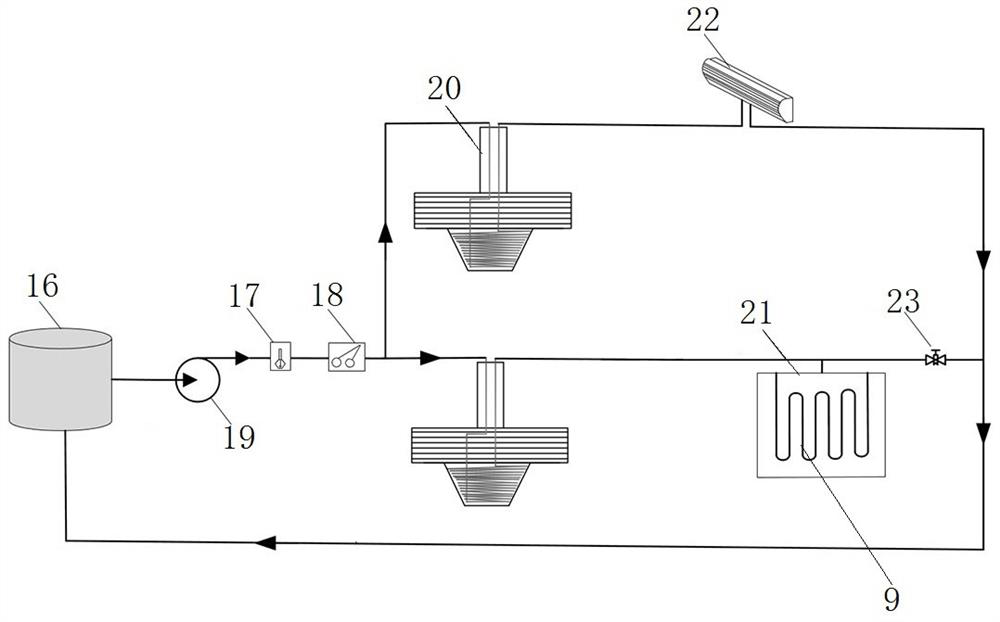

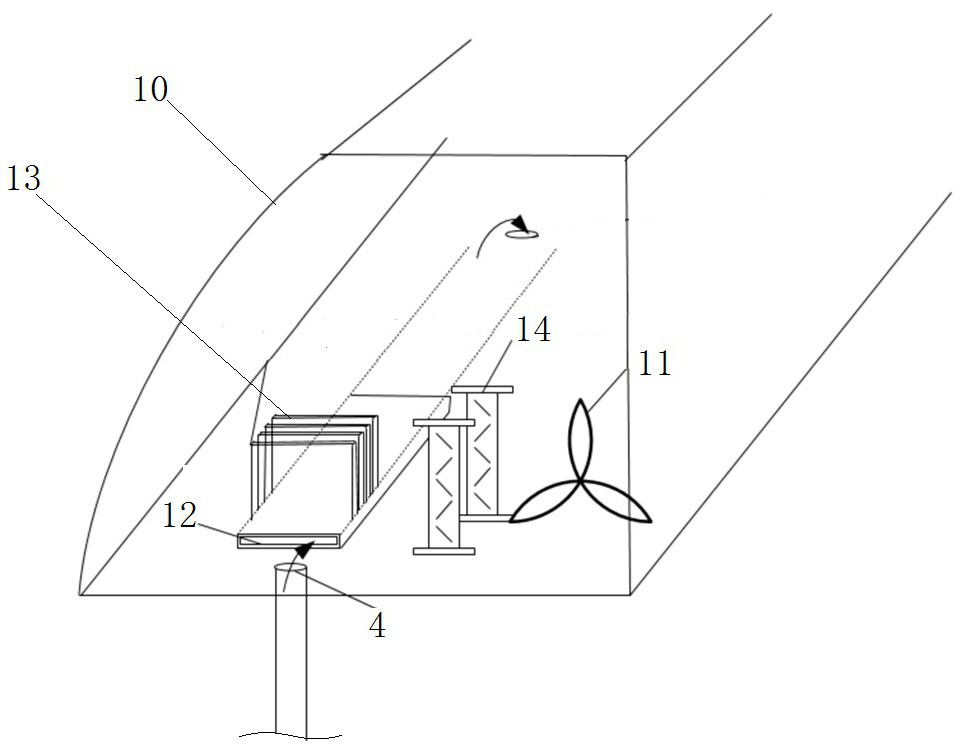

Indoor temperature control system utilizing geothermal energy

InactiveCN114576748ASimple structureEnergy savingMechanical apparatusLighting and heating apparatusDomestic water consumptionWater storage tank

The invention relates to an indoor temperature control system utilizing geothermal energy. The indoor temperature control system utilizing the geothermal energy comprises at least two stages of raft plate column pier type energy foundations, geothermal energy type floor heating devices connected with the corresponding stages of raft plate column pier type energy foundations to form floor heating circulation branches, and geothermal energy type water-cooling air conditioning devices connected with the corresponding stages of raft plate column pier type energy foundations to form water-cooling circulation branches. The system comprises a water storage tank, a self-priming pump, a domestic water pipeline and a control system, each stage of raft plate column pier type energy foundation is connected in parallel and comprises a raft plate foundation and an energy column pier which are integrally poured through concrete, and heat exchange pipes for heat exchange with heat energy in soil are pre-buried in the raft plate foundation and the energy column pier. The control system comprises an intelligent temperature controller used for monitoring the indoor temperature and a multi-way switch connected with the intelligent temperature controller, and the multi-way switch is connected with the corresponding circulation branch when the temperature monitored by the intelligent temperature controller is smaller than or larger than a set value. Terrestrial heat can be effectively utilized, and energy consumption is reduced.

Owner:THE FOURTH OF CHINA CONSTR SEVENTH ENG

Wet garbage disturbance crushing device

InactiveCN112252249AReduce volumeReduce the number of poursRoad cleaningGrain treatmentsAgricultural engineeringPower apparatus

The invention belongs to the technical field of sanitation vehicles, and particularly relates to a wet garbage disturbance crushing device which is characterized in that a suction nozzle is movably arranged on a sucker, a shell is integrated on the suction nozzle, and the interior of the shell is communicated with the interior of the suction nozzle; a main shaft is arranged in the shell, a knife rest assembly is arranged on the main shaft, a knife is installed on the knife rest assembly, and a brush is further arranged on the knife rest assembly. The spindle is in transmission connection witha power device. More wet leaves can be sucked up by the suction nozzle through the disturbance of the brush to the wet leaves, so that the ground is cleaned more cleanly. The size of the crushed wet garbage is reduced, the containing capacity of the garbage can is effectively improved, and the garbage dumping frequency is reduced.

Owner:XUZHOU XUGONG ENVIRONMENTAL TECH CO LTD

Floor secondary cabinet for electric power engineering

PendingCN111313277AEnsure balanceReduce the number of poursSubstation/switching arrangement casingsPower engineeringScrew thread

The invention relates to the technical field of electric power engineering, and in particular relates to a floor secondary cabinet for electric power engineering. The cabinet comprises a cabinet body,a rectangular frame and arc-shaped channels; a supporting bottom plate is mounted at the bottom of the cabinet body; supporting inclined rods are fixed to the two sides of the bottom of the supporting bottom plate through screws; the front surface of the cabinet body is movably connected with a closed cover plate through a hinge. According to the invention, a wedging groove, a balance block, a positioning nut and a wedging groove are arranged; the rectangular frame is adjacent to a concave-convex position; the wedging groove and a threaded groove body are connected and match each other; a stressed screw rod realizes rotary rotation until the balance block is taken out from the interior of the wedging groove; the bottom of the balance block just abuts against the uneven position of the ground; at the moment, under the condition that the position of the positioning nut is fixed, the arrangement of the positioning balance block can play an auxiliary supporting role in the arrangement ofthe whole cabinet body; the balance of the left end and the right end of the whole cabinet body after arrangement is guaranteed; and the toppling frequency of the cabinet body is reduced.

Owner:天津东方新能电气有限公司

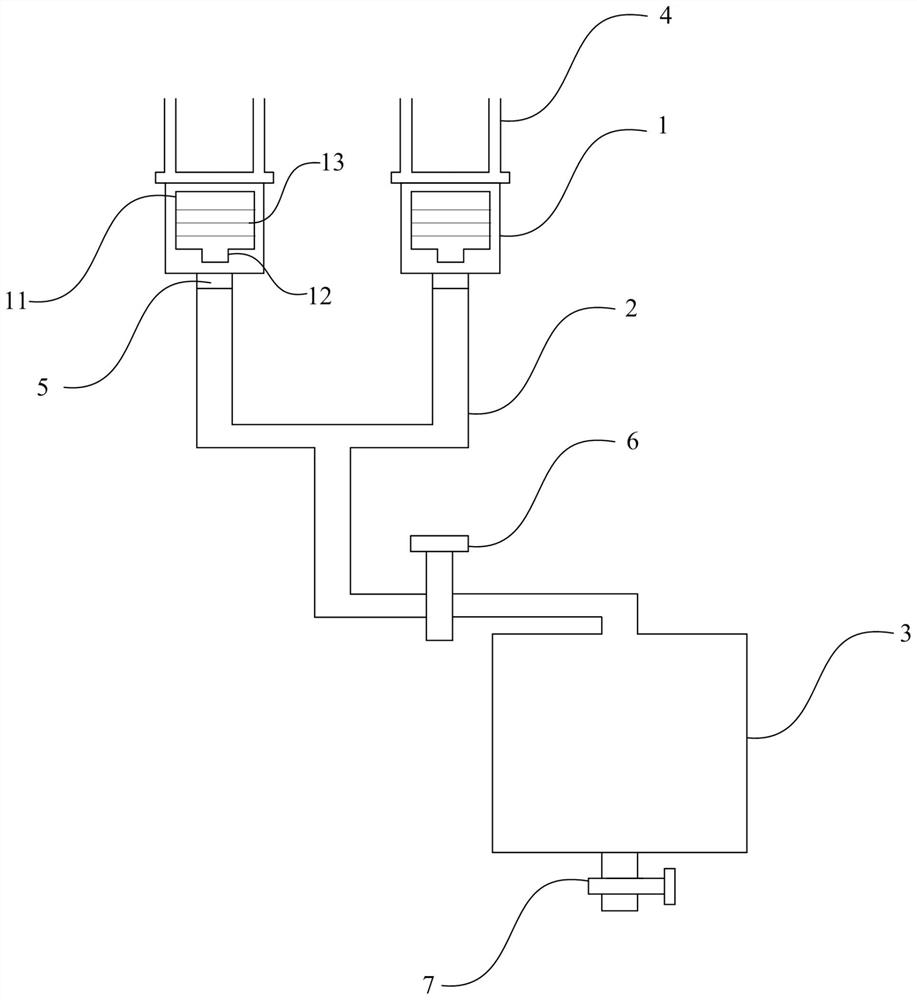

Dehumidifier

PendingCN113701261AIncrease volumeReduce the number of poursCondensate preventionLighting and heating apparatusMachineIndustrial engineering

The invention discloses a dehumidifier which comprises a machine body, a water tank, a supporting piece and a limiting piece, and the water tank is provided with an upward mounting opening; the supporting piece can movably enter and exit from the mounting opening and has a first state of entering the mounting opening and a second state of exiting from the mounting opening, in the first state, the supporting piece can support the lower end of the machine body, and in the second state, the machine body can be at least partially contained in the water tank through the mounting opening; the supporting piece is provided with a limiting part; and the limiting piece is movably arranged on the water tank and provided with a first position and a second position, the limiting piece can be matched with the limiting part of the supporting piece in the first state at the first position so as to limit the supporting piece in the first state, and the limiting piece and the limiting part are arranged at intervals at the second position. According to the technical scheme, the volume of the water tank can be increased to reduce the water pouring frequency of the water tank.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

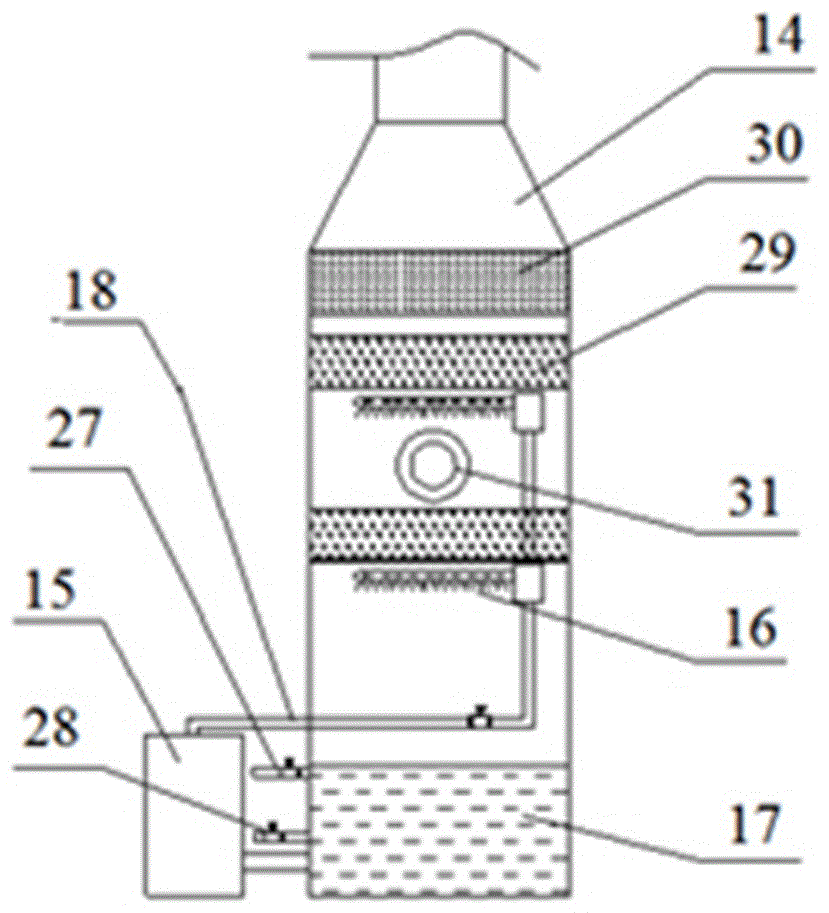

Condensate water collecting device of breathing machine

InactiveCN114344658AReduce the number of poursPlay the role of monitoring water storage bottlesRespiratorsWater storageWater flow

The invention discloses a breathing machine condensate water collecting device. The device comprises a water storage bottle; the water storage bottle is connected with a breathing machine pipeline; two inserting holes for breathing machine pipelines to be inserted are formed in a bottle cap of the water storage bottle, a water outlet is formed in the bottom of the water storage bottle, one end of the drainage tube is connected with the water outlet, and the other end of the drainage tube is connected with the drainage bag. The prompting cup is arranged in the water storage bottle, the lower surface of the prompting cup is located at the one-third height position in a bottle body of the water storage bottle, a through hole is formed in the lower surface of the prompting cup, and the prompting cup is communicated with the water storage bottle through the through hole. According to the breathing machine condensate water collecting device, the water outlets are formed in the bottoms of the two water storage bottles of the breathing machine pipeline and connected with the drainage pipeline, the tail end of the drainage pipeline is connected with the anti-backflow drainage bag, the dumping frequency can be reduced, and it is not needed to worry that condensate water flows back to the breathing machine pipeline when the anti-backflow drainage bag is applied; by arranging the prompt cup, the function of monitoring the water storage bottle can be achieved, and the function of safety protection is achieved.

Owner:YANTAI YUHUANGDING HOSPITAL

A kind of kitchen centrifugal convenient dustbin

InactiveCN106275977BAvoid smallReduce the number of poursWaste collection and transferRefuse receptaclesVehicle frameSewage

The invention discloses a centrifugal kitchen dustbin convenient to use and belongs to the field of living furniture. The centrifugal kitchen dustbin convenient to use is composed of a crank sliding block device and a crank rocker device. The centrifugal kitchen dustbin convenient to use is characterized in that the crank slide block device is composed of an extensible plate, a movable connecting rod, a swinging connecting rod and an upper foot treadle; the movable connecting rod is connected with the extensible plate and the swinging connecting rod through bolts correspondingly; the swinging connecting rod is fixedly mounted on the upper portion of the upper foot treadle; a centrifugal device is composed of a lower foot treadle, a centrifugal connecting rod, a large belt wheel, a belt, a small belt wheel and a rotary disc ; the centrifugal connecting rod is connected with the large belt wheel through a bolt; the large belt wheel is connected with the small belt wheel through the belt; a small belt wheel shaft is fixedly mounted on the lower side of the rotary disc; a bottom plate is fixedly mounted on a dolly frame through a screw; and four dolly wheels are mounted at the bottom of the dolly frame. The centrifugal kitchen dustbin convenient to use has the beneficial effects that kitchen waste can be treated in a separation mode, sewage drained in a separation mode can be discharged, and the waste can be conveniently and quickly packaged and cleared away.

Owner:宣城金博伟家居智能科技有限公司

Application of?mixed bdellovibrio swimmer and bdelloplast bacterial liquid in sea cucumber seedlings cultivation

The invention discloses the application of mixed formulations of bdellovibrio swimmer and bdelloplast in sea cucumber seedlings cultivation which is realized by adding mixed bdellovibrio swimmer and bdelloplast bacterial liquid into water and feeding stuffs. The application comprises specifically the following parts: seedlings cultivation facilities and water quality conditions, parent sea cucumber fishing, parent sea cucumber cultivation, spawning, hatching and seedling cultivation, seedling collection and sea cucumber fingerling cultivation. The key technique is that 10-10<7> pfu / ml mixed bdellovibrio formulations, by concentration, is added into water, and / or feeding stuffs is soaked in 10-10<7> pfu / ml mixed bdellovibrio formulations for about 30 minutes. By application of this invention, the average survival rate of sea cucumber seedlings can reach more than 50% and water quality can be effectively improved. Relevant experiments demonstrate that water can be kept for at most 20 days; thus, this invention can save cost, labour, water and energy, is low-carbon and environmentally-friendly, and greatly boost economical interests with high seedling survival rate and good seedling quality.

Owner:SOUTH CHINA UNIV OF TECH

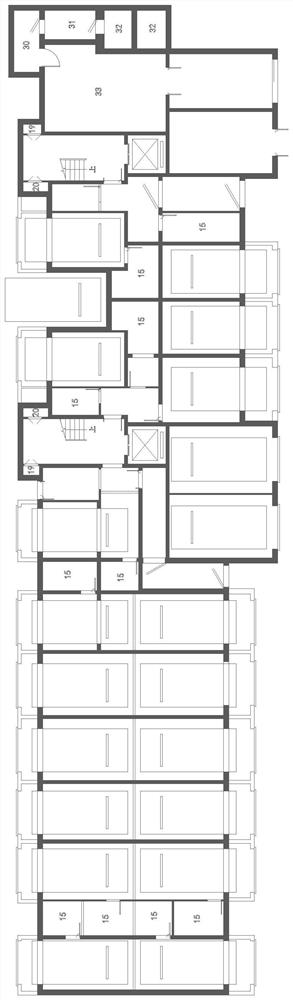

Novel multi-storey drop house building

PendingCN114837465AReduce the number of poursImprove construction efficiencySustainable buildingsDwelling buildingFloor slabArchitectural engineering

The invention provides a novel multi-storey falling house building, relates to the field of buildings, and provides a plurality of choices for owners through reasonable structural design, reduction of the number of poured floor slabs, improvement of construction efficiency, formation of multi-point lighting, multi-direction home entry and falling house type design and flat layer and spring layer combined design, house type product advantages are improved, shared places are reduced, and the house yield is improved. And favorable conditions are created for the building facade image.

Owner:北京元启建筑设计有限公司

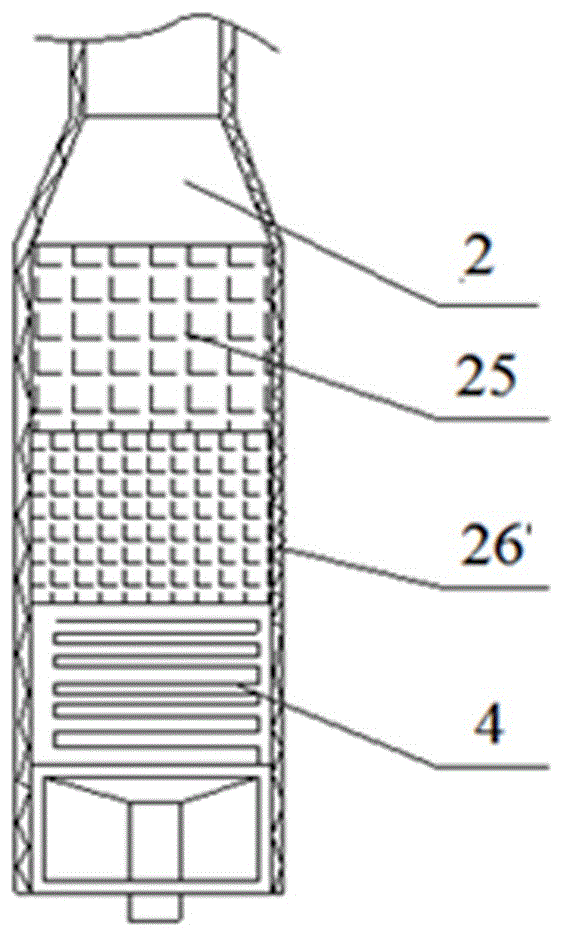

Laboratory exhaust gas purification treatment equipment

InactiveCN104624042BImprove purification effectEfficient purificationDispersed particle separationEngineeringAtmospheric pollution

The invention relates to laboratory waste gas purification treatment equipment which comprises a shell, a condensing treatment tank, a compressor, a condenser, an evaporator, a water treatment tank, a water pump and a spray device, wherein the shell is provided with a gas inlet and a gas outlet; the condensing treatment tank is provided with the gas inlet and the gas outlet; the evaporator is positioned in the condensing treatment tank; the water treatment tank is provided with the gas inlet and the gas outlet; and the spray device is positioned in the water treatment tank. The laboratory waste gas purification treatment equipment disclosed by the invention is provided with double treatment channels aiming at different characteristics of organic and inorganic waste gases, has the characteristics of easiness and convenience for operation, low operation cost, less energy consumption, small size and convenience for maintenance and can be used for effectively purifying the toxic harmful gases, namely an organic gas, an inorganic gas and the like which are discharged from a laboratory, and reducing the atmospheric pollution.

Owner:SHIJIAZHUANG HUAYU XINRUI TECH

A variable capacity dehumidifier

ActiveCN112594798BNo change in footprintIncrease water storageCondensate preventionLighting and heating apparatusWater storageMoisture capacity

The invention belongs to the field of dehumidifiers, in particular to a variable-capacity dehumidifier, comprising a base, an outer water tank is fixedly installed on the top of the base, an inner water tank is movably installed in the outer water tank, and the top of the inner water tank extends to the outside Outside the water tank, a mounting seat is fixedly installed on the top of the inner water tank, a dehumidifier body is fixedly installed on the top of the mounting seat, and a 3D projection device is installed on the top of the dehumidifier body. The two water tanks are superimposed together. When the water storage capacity increases, the inner water tank automatically rises, and the two water tanks store water at the same time, increasing the water storage capacity without changing the space occupied by the dehumidifier. When it recognizes the change of environmental humidity, it will present different intuitive images such as desert, ocean, forest, etc. in the form of images, so that users can know whether the indoor humidity environment is suitable at a glance, and realize the goal of humanization and intelligence.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com