Steel beam, concrete ring beam and concrete floor structure integrated construction method

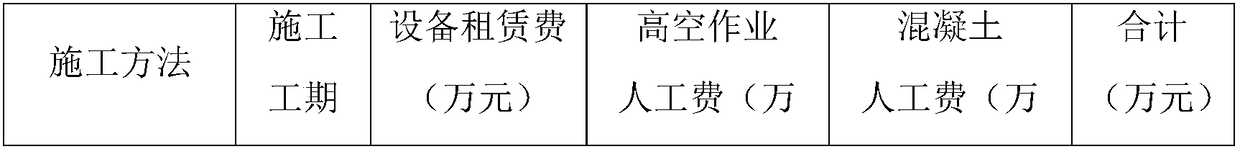

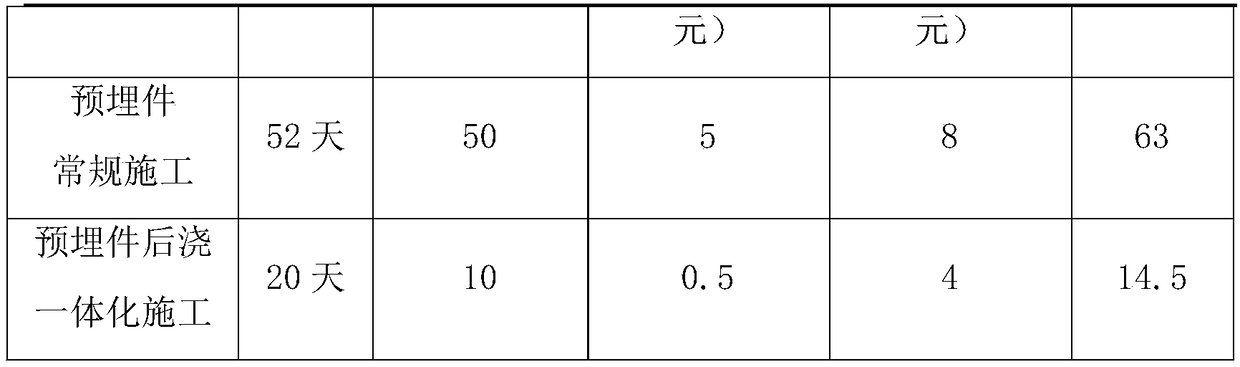

A technology of concrete and steel beams, which is applied in the direction of building construction, construction, and building materials processing, etc., which can solve the problems of high hoisting accuracy requirements, many high-altitude operations, and complicated procedures, so as to avoid unsafe factors and reduce turnover materials The consumption and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The integrated construction method of steel beam, concrete ring beam, and concrete floor structure provided in this embodiment includes the following steps:

[0069] (1) Bolting of embedded parts

[0070] The embedded parts are bolted into the ground before hoisting. The high-precision bolting method ensures the overall construction quality of the later steel beams. The specific operations are as follows:

[0071] 1 Bolting and tightening: do initial and final tightening when bolting. In order to reduce the difference between the pretension of the high-strength bolts that are tightened first and tightened later, the tightening must be divided into two steps: initial tightening and final tightening. For large nodes with a large number of bolts, a re-tightening process and re-tightening torque are required. It is still equal to the initial tightening torque to ensure that the bolts reach the design value.

[0072] 2 Tightening inspection: The torque wrench used for tightening th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com