An automatic steel ball sorting device

A sorting device and steel ball technology, applied in sorting and other directions, can solve problems such as secondary defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

[0017] Examples, see Figure 1 to Figure 3 Shown:

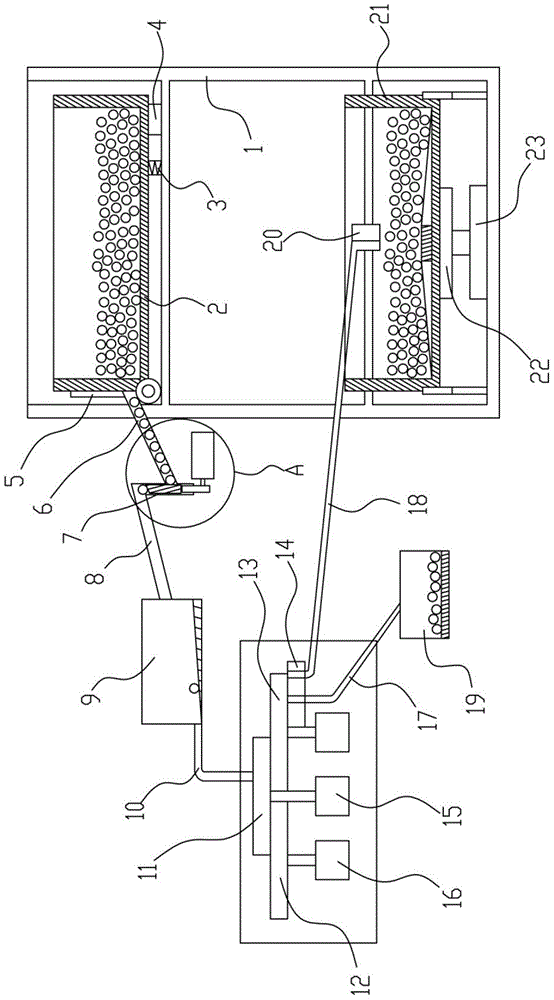

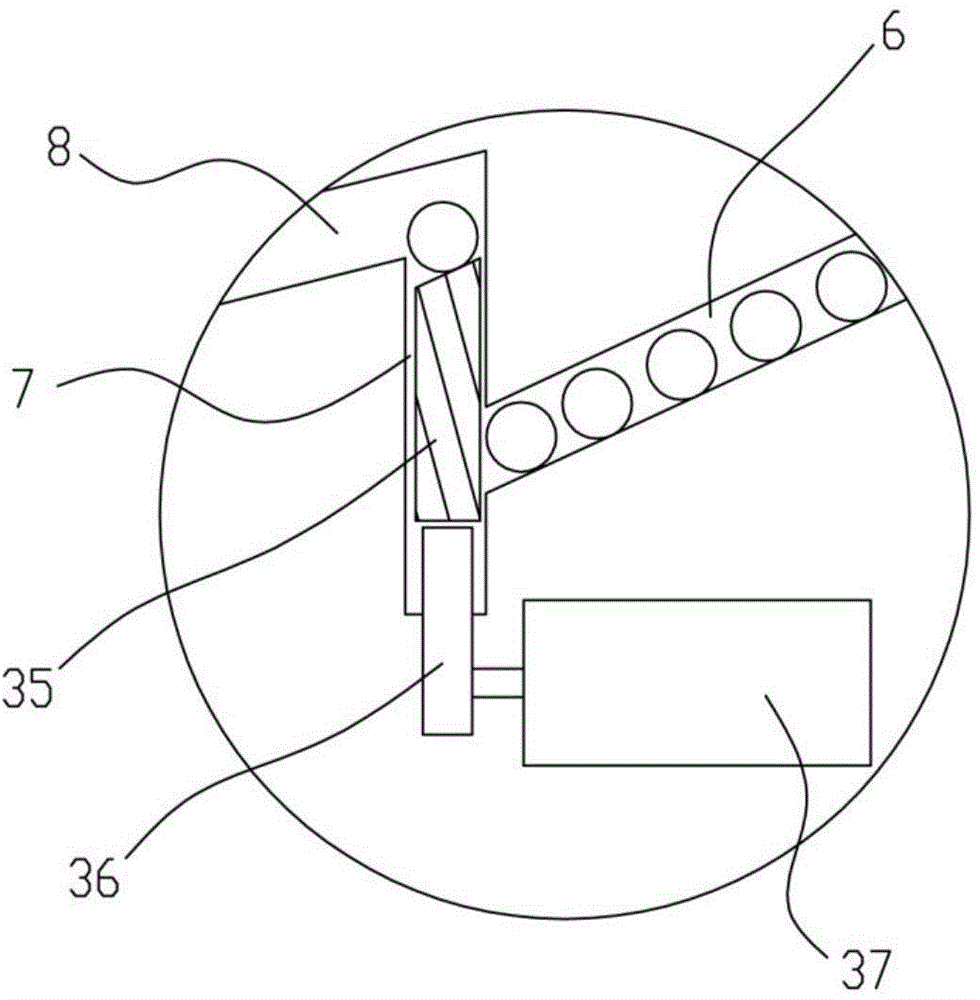

[0018] An automatic steel ball sorting device, comprising a frame 1, a feeding barrel 2, a discharging barrel 21, a waste ball bin 19, a quantitative ball supply device, a feeding box 9, a detection device and a control device.

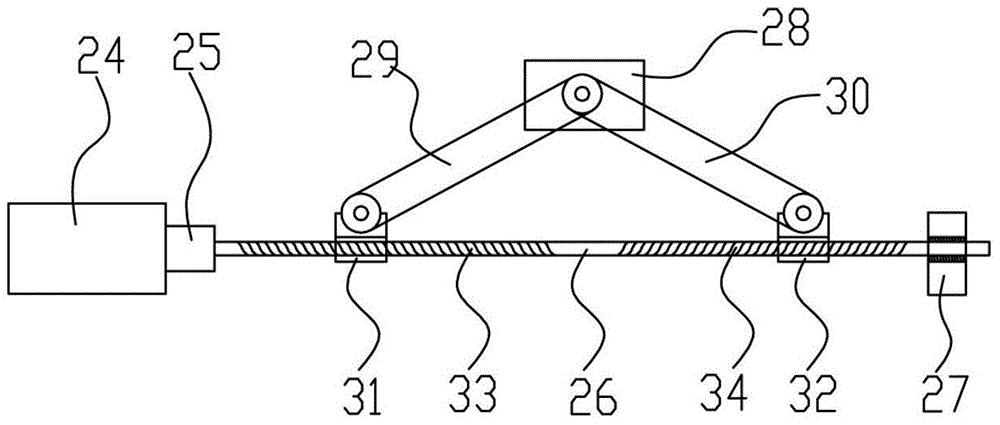

[0019]Feeding bucket 2 is located on the upper layer of the frame 1, the left side of the loading bucket 2 is hinged with the frame 1, and the right side of the loading bucket 2 is connected with the frame 1 through a unilateral lifting device 4. The unilateral lifting device 4 includes a first servo motor 24, a first connecting arm 29, and a second connecting arm 30 (it should be noted that "first and second" are sequential numbers of corresponding parts, and should not be understood as The limitation of its function or structure, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com