Automatic deburring equipment for skylights

A burr and equipment technology, which is applied in the direction of metal processing equipment, grinding/polishing equipment, grinding feed movement, etc., can solve the problems of heavy human injury, high work intensity of workers, and low efficiency, so as to improve the grinding efficiency and realize Product quality, effect of reducing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

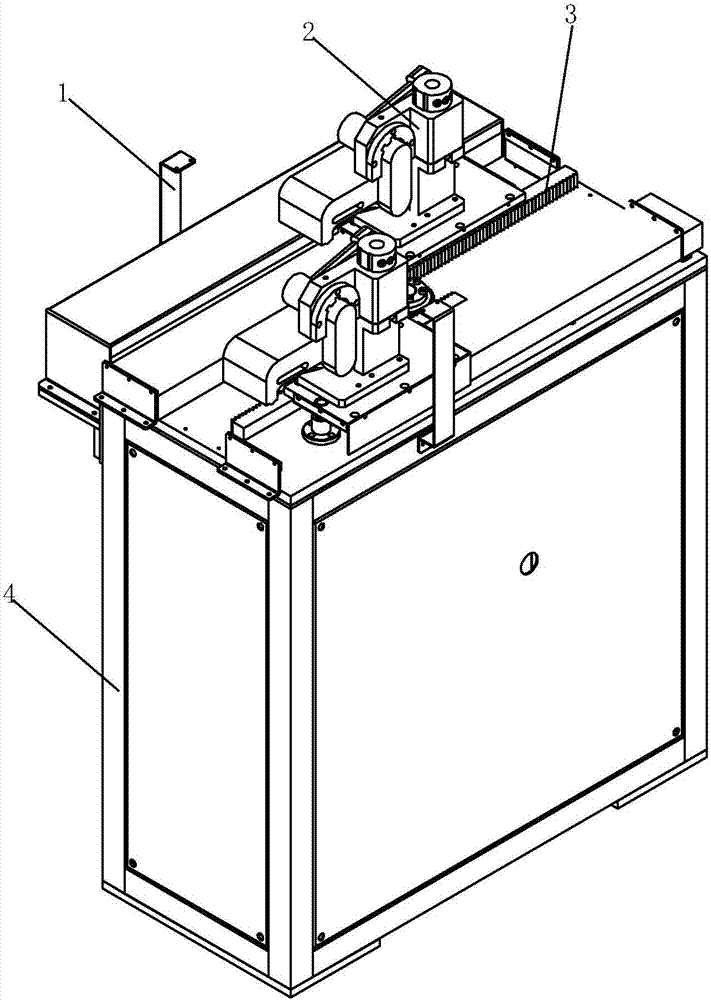

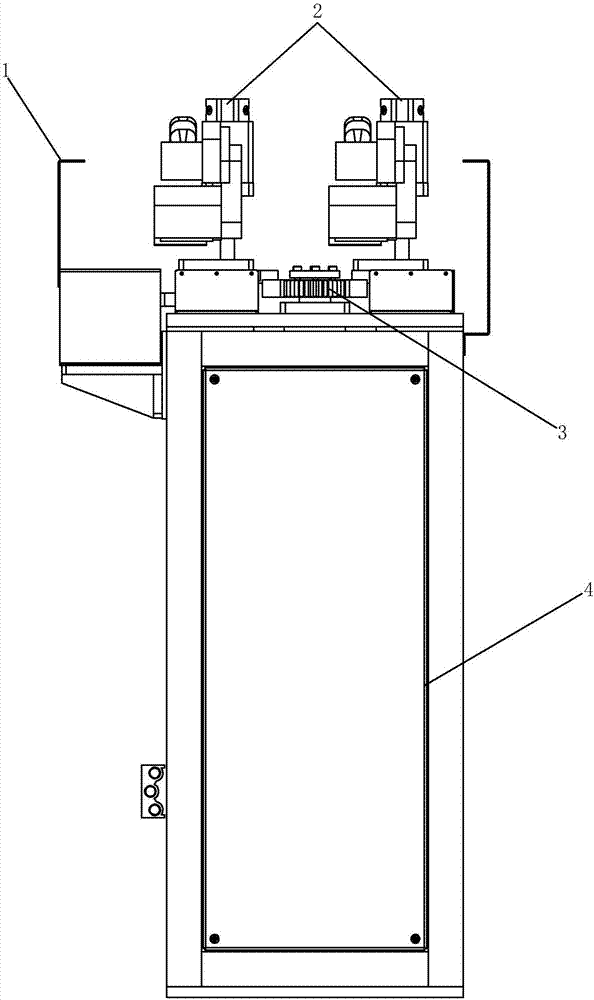

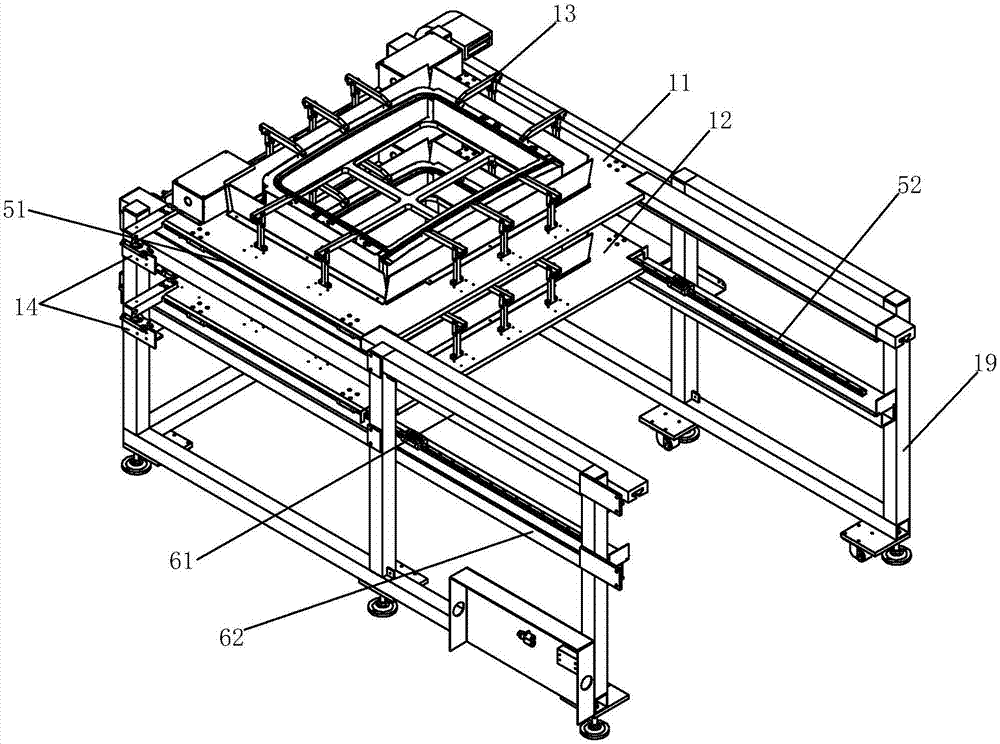

[0010] Such as figure 1 , 2 , an automatic skylight deburring equipment, including a grinding manipulator, a grinding tool exchange table, a double-layer feeding platform, the grinding tool exchange table includes an exchange table support 4, and two grinding machines 2 are arranged on the exchange table support 4, and the grinding machine 2 The gear mechanism 3 is arranged on the support 4 of the exchange table, and one side of the grinding machine 2 is provided with an opposite light eye 1. The double-layer feeding platform includes a tooling bracket 19, and the tooling bracket 19 is provided with upper and lower slide rails. 51 is provided with upper-level tooling 11, and lower-level tooling 12 is arranged on the sliding rail 52. The upper-level tooling 11 is driven by the upper propelling cylinder 61, the lower-level tooling 12 is driven by the lower propelling cylinder 62, and the tooling positioning cylinder 14 is fixed on the tooling bracket 19. The positioning cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com