A pretreatment method for repair welding of austenitic stainless steel cast nuclear pump shell

A technology for austenitic stainless steel and nuclear pumps, which is applied in the field of defect repair of nuclear pump casting shells, can solve problems such as multi-impurity elements, stress direction and uneven distribution, achieve uniform welding stress distribution, avoid secondary defects, Easy-to-shape effect of weld seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The first step is to determine the defect: first, use the naked eye to inspect a large area macroscopically, check the obvious defect position and make a mark.

[0035] The second step, rough grinding of defects: Carry out preliminary grinding and removal treatment on the marked defects until the obvious defects are not visible to the naked eye; use corundum, alumina or diamond, and the grinding process should be ground and cut layer by layer to ensure the removal of defects clean.

[0036] The third step, non-destructive testing: use the penetrant testing (PT) method to conduct non-destructive testing on the surface without macroscopic defects, mark the detected defects, and polish the defects according to the method in the previous step.

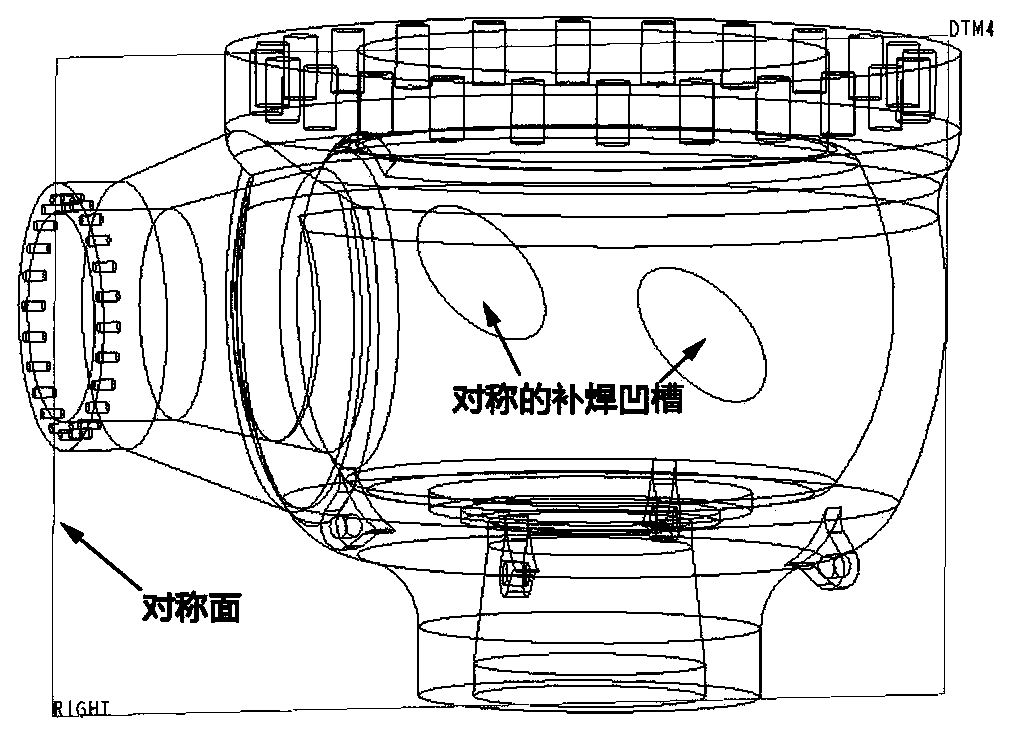

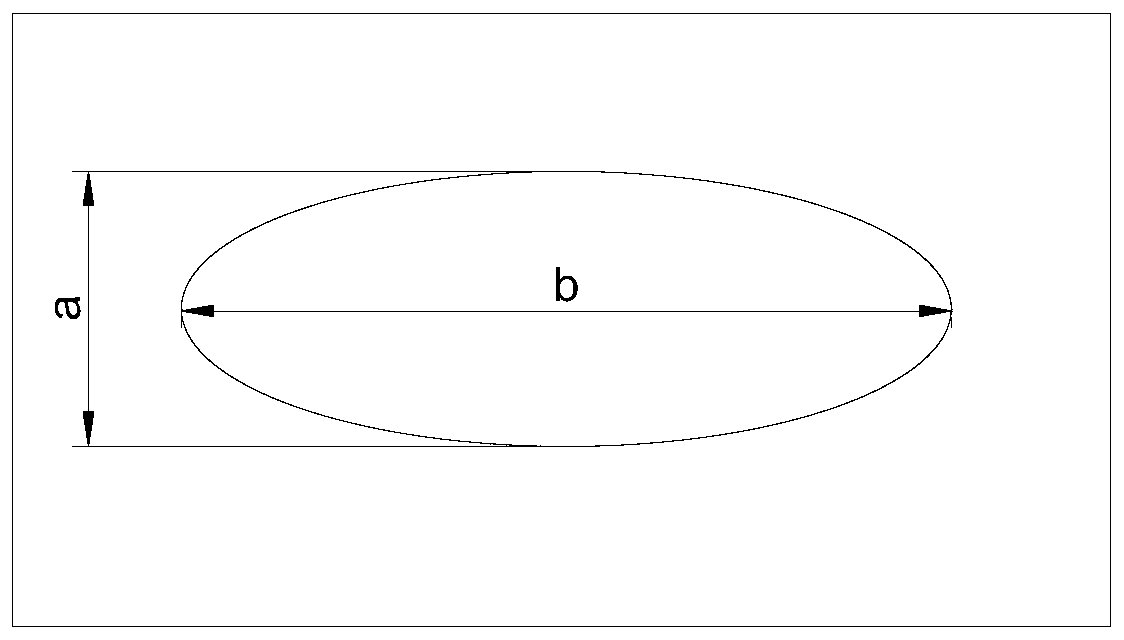

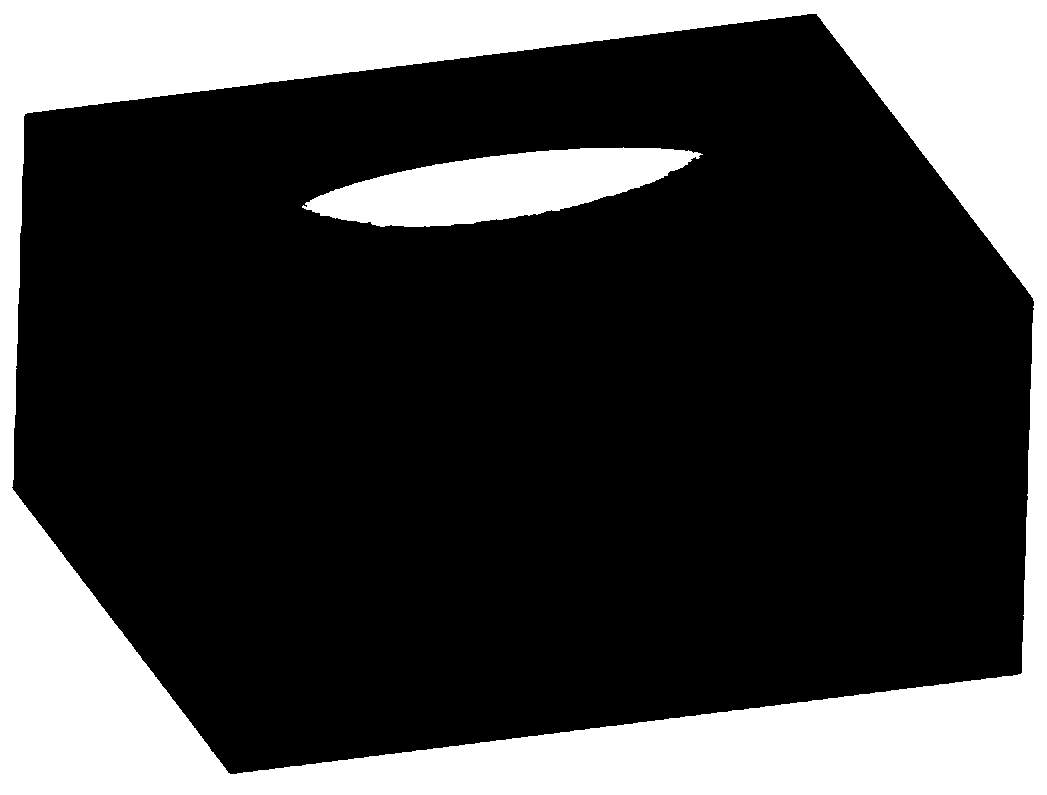

[0037] The fourth step, symmetrical grinding: use symmetrical grinding for the larger defects that appear, regardless of whether its symmetrical surface has defects or not, it must be ground into a symmetrical weld groove.

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com