A soft instrument panel cavitation repair process method, its special filling body and device

A technology for instrument panels and fillers, which is applied in the field of soft instrument panel cavitation repair technology, its special fillers and devices, which can solve the problems of effective repair of cavitation, scrapping defective products, increasing production costs, etc., and achieve repair effects Good, avoid secondary defects, save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

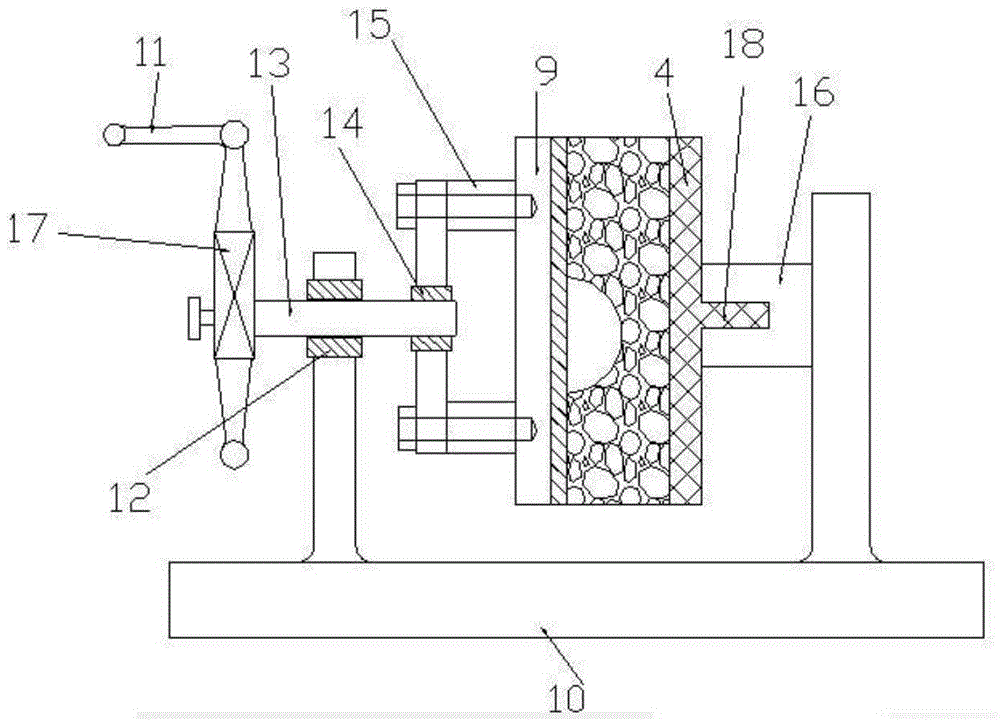

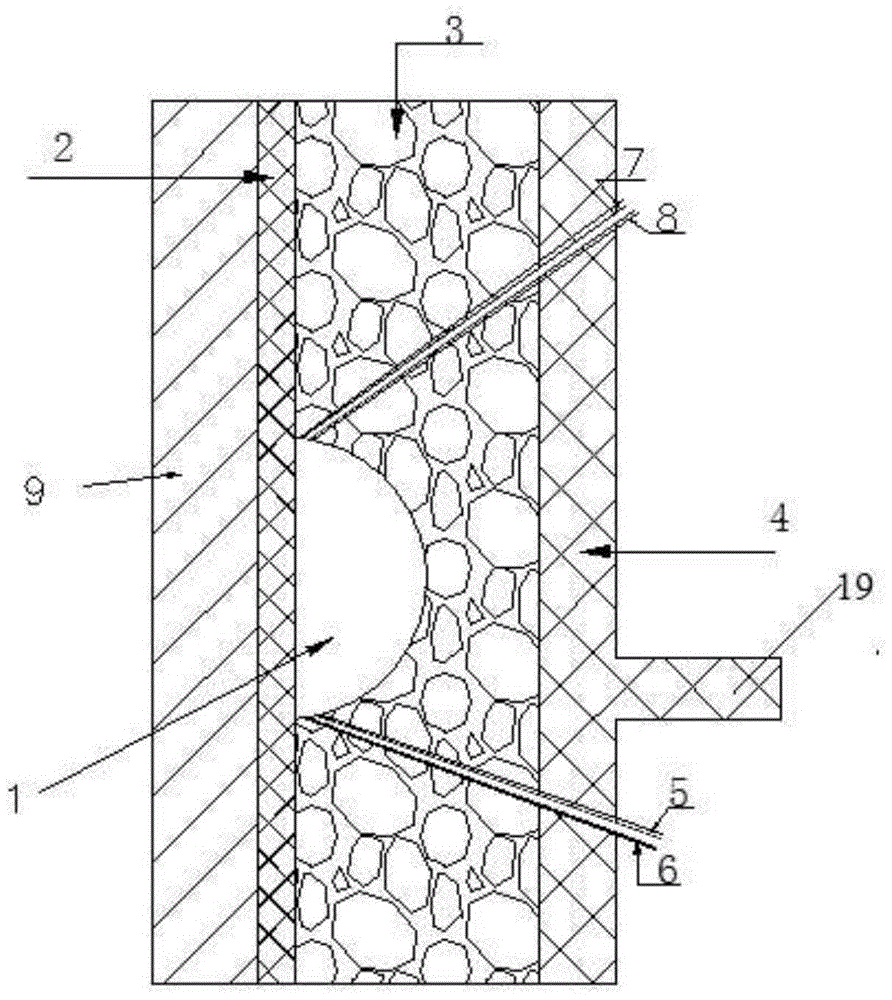

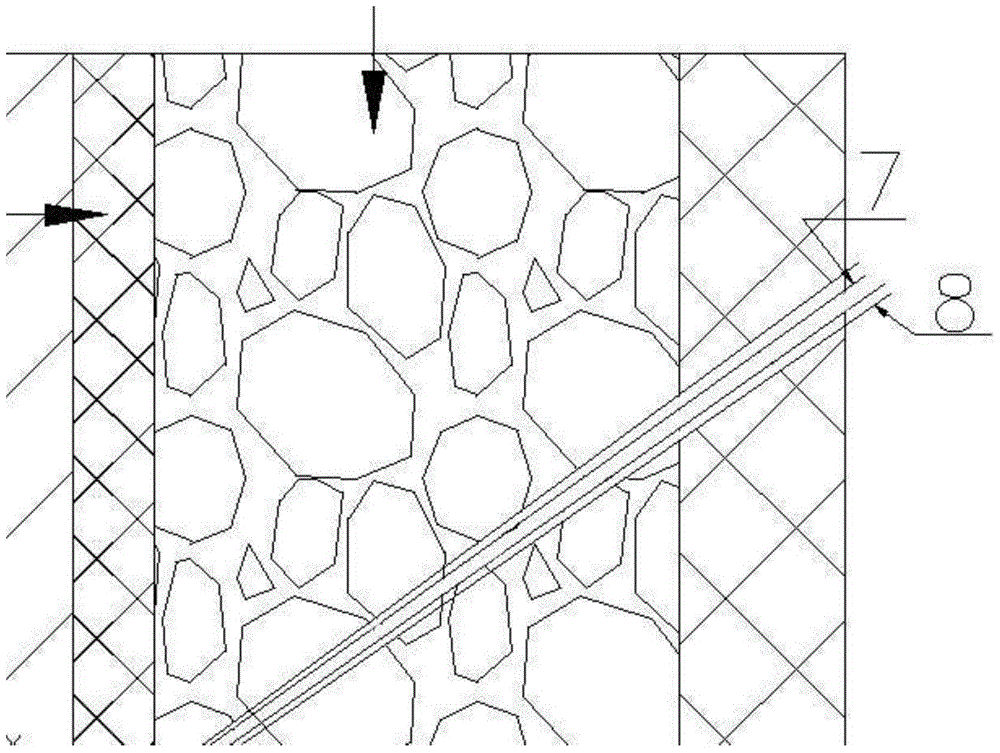

[0047] Such as Figure 1-4 As shown, there are defective air pockets 1 in the foam layer 3 of the instrument panel. On the back side of the epidermis, determine the highest point and the lowest point along the direction of the skeleton 4 on the section with the largest area on the air cavity 1 perpendicular to the surface of the epidermis 2, and respectively center the highest point and the lowest point by 10mm 2 Within the range of the area, a circular channel with a diameter of 3-5mm is respectively opened as the exhaust groove 8 and the pouring runner 5, and the acute angle between the exhaust groove 8 and the pouring runner 5 and the horizontal direction is at 0 °-30° between. Adopt a commercially available polyethylene pipe with a wall thickness of 0.3-0.5mm and an outer diameter slightly smaller than the diameter of the vent groove 8 and the pouring runner 5, and cut it into a short pipe consistent with the length of the vent groove 8 and the pouring runner 5 As exhaus...

Embodiment 2

[0052] When the air pocket 1 is close to the edge of the instrument panel, the exhaust groove 8 and the pouring runner 5 can also be directly passed into the outside world from the foam layer 3, such as Figure 5 As shown, other repair steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com